Method for modifying polylactic acid using superbranched polymer

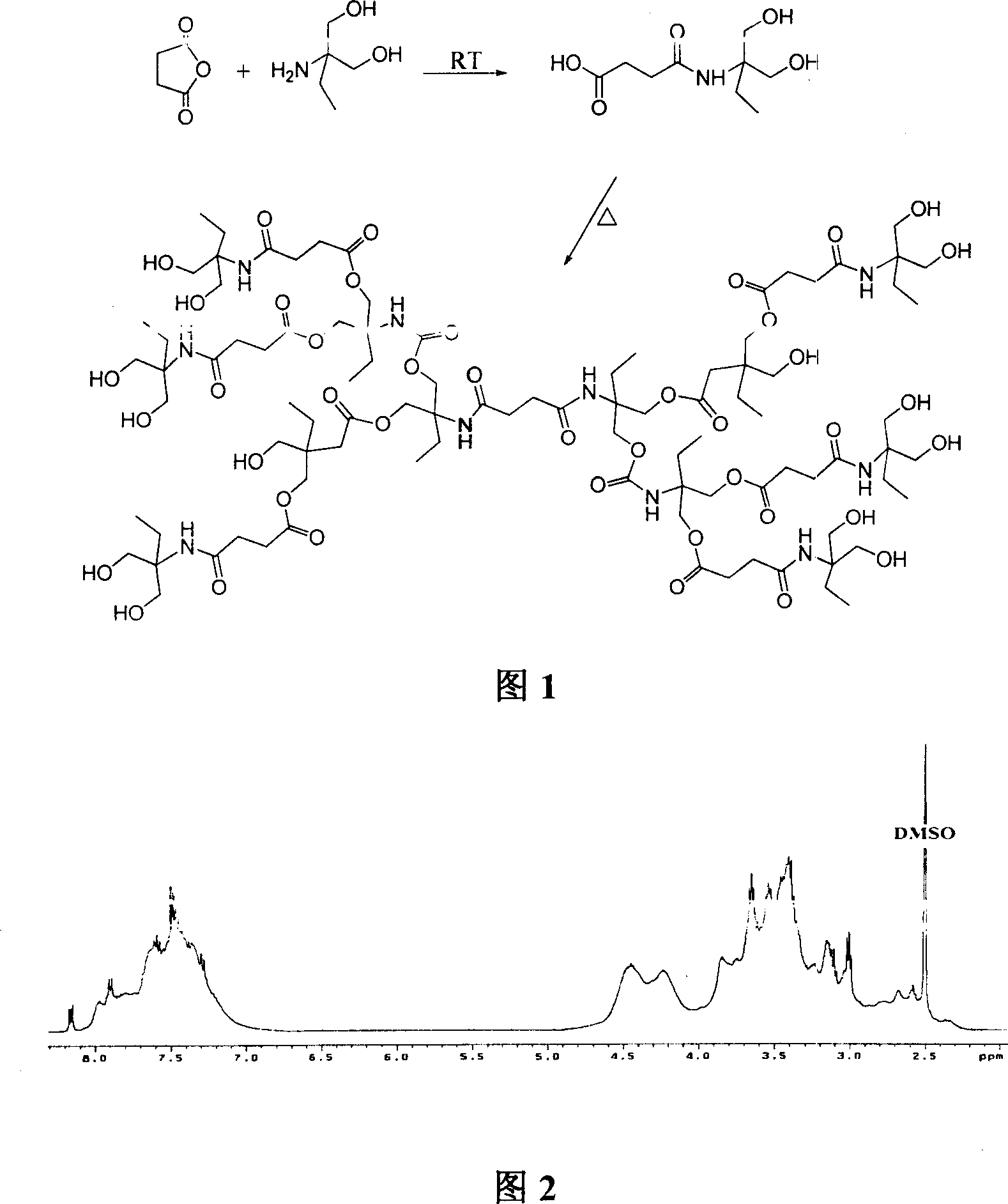

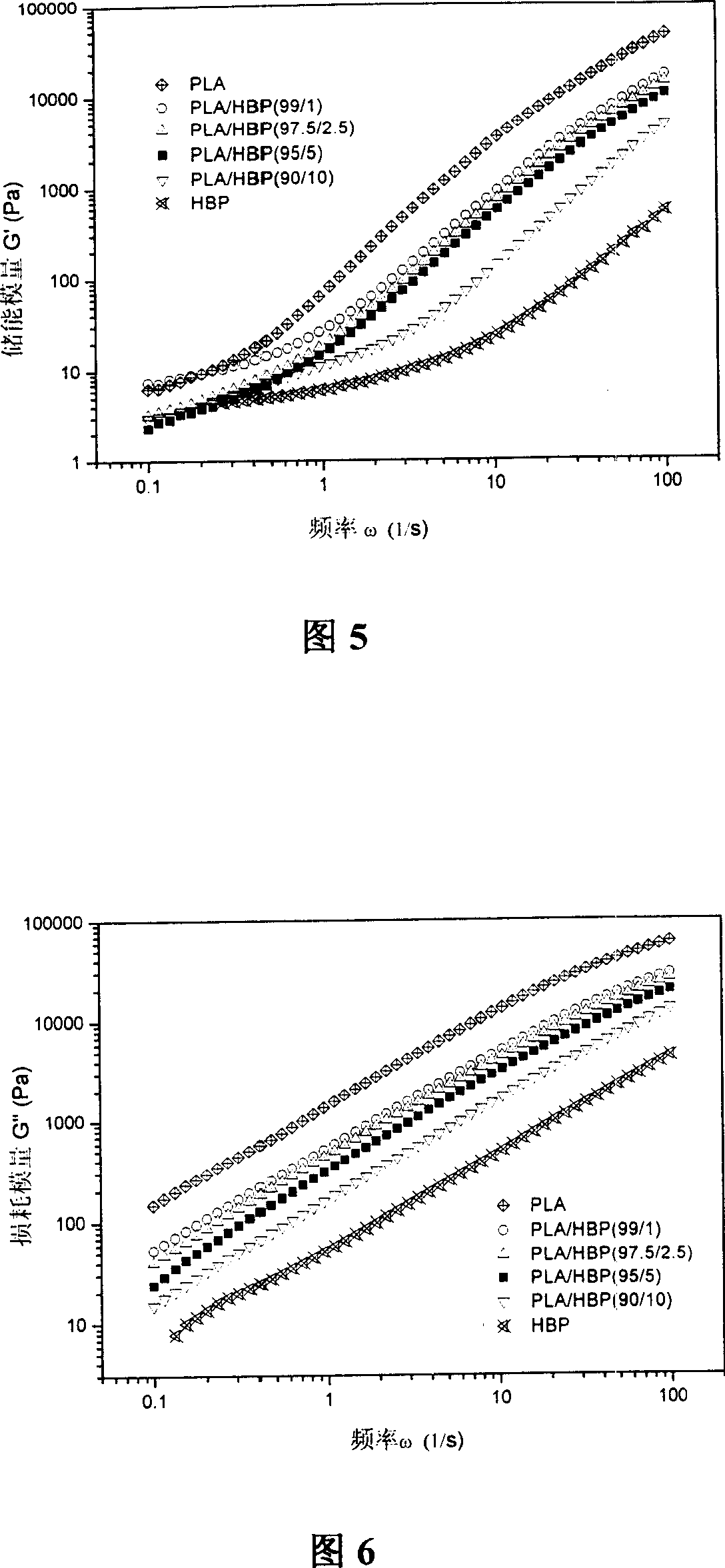

A technology of hyperbranched polymer and polylactic acid, which is applied in the field of improving polylactic acid with hyperbranched polyester amide, can solve the problems that have not been seen before, and achieve the effects of reducing brittleness, reducing viscosity, improving mechanical properties and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

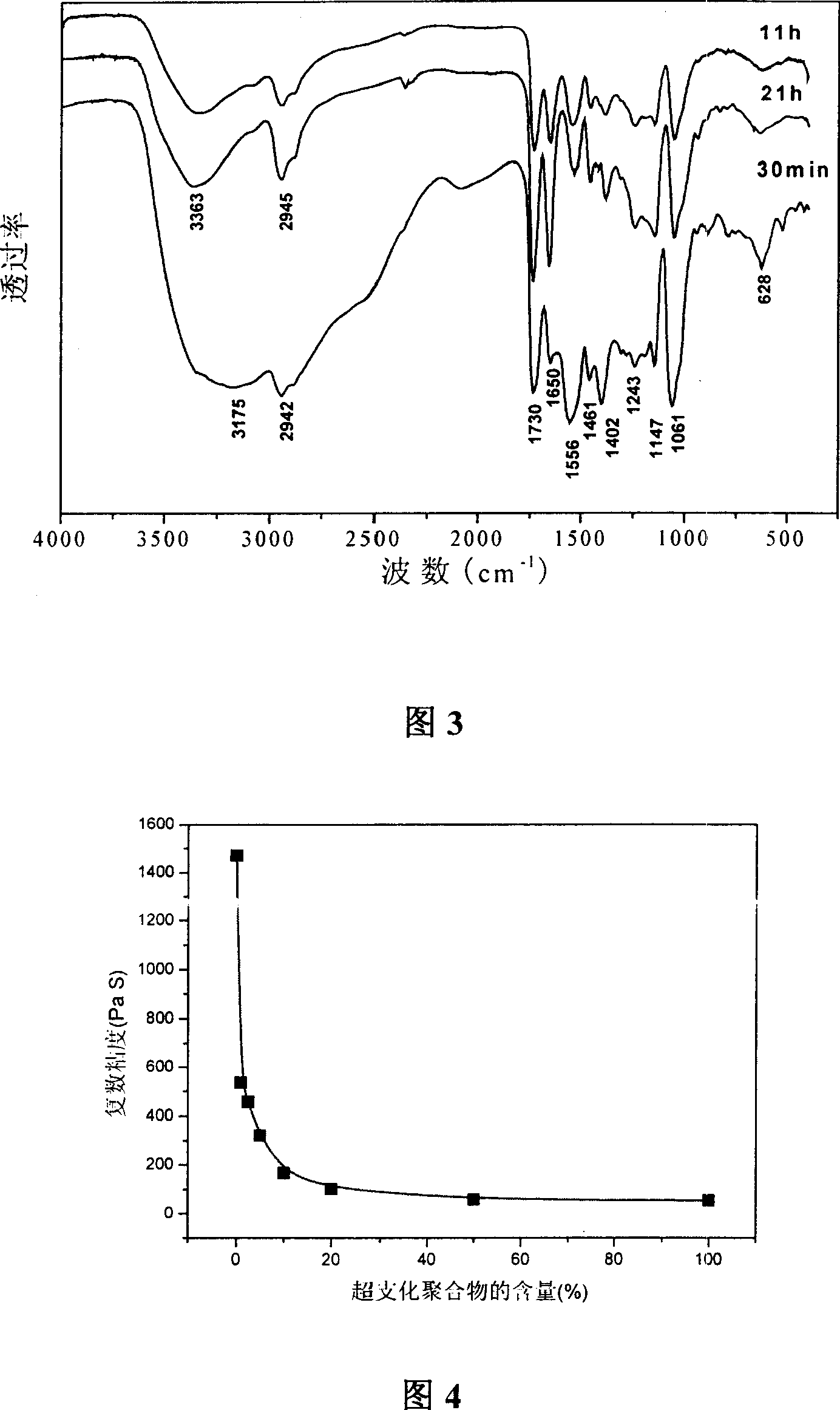

[0030] Under a nitrogen atmosphere, add 6.190g of GA (0.054mol) and 6.460g of AEPO (0.054mol) to a 100ml reaction tube with two vents, put them in an oil bath preheated to 80°C, and mechanically stir vigorously to react After 2 hours, the temperature was raised to 120°C, and the stirring was continued for 45 hours. The viscosity of the system suddenly increased and it was difficult to stir. The temperature was lowered to about 80°C, and the vacuum was pumped for 2 hours. 10.69 g (85%) of hyperbranched poly(glutaric anhydride-dimethylolaminopropane) were obtained as a pale yellow transparent solid. The relative weight average molecular weight is 106.0 Kg / mol, the relative molecular weight distribution is 3.30, and the relative molecular weight distribution has a broad peak. pass 13 C~NMR spectrum analysis calculates that its branching degree is 0.42, DSC test does not exist melting and crystallization, the glass transition temperature is 7.2 ℃, and the temperature of thermal d...

Embodiment 2

[0032] Under a nitrogen atmosphere, add 5.590g of SA (0.056mol) and 6.66g of AEPO (0.056mol) to a 100ml reaction tube with two vents, put them in an oil bath preheated to 80°C, and mechanically stir vigorously to react After 2 hours, the temperature was raised to 130°C, and the stirring was continued for 45 hours. The viscosity of the system suddenly increased and it was difficult to stir. The temperature was lowered to about 80°C, and vacuum was applied for 2 hours. 10.77 g (88%) of hyperbranched poly(succinic anhydride-dimethylolaminopropane) were obtained as a pale yellow transparent solid. The relative weight average molecular weight is 70.3Kg / mol, the relative molecular weight distribution is 2.36, and the relative molecular weight distribution has a broad peak. pass 13 C~NMR spectrogram analysis calculates that its branching degree is 0.55, and there is no melting and crystallization in the sample by DSC test, the glass transition temperature is 34.1°C, and the temperat...

Embodiment 3

[0034]Under a nitrogen atmosphere, add 8.290g of DGA (0.071mol) and 8.510g of AEPO (0.071mol) to a 100ml reaction tube with two vents, put them in an oil bath preheated to 80°C, and mechanically stir vigorously to react After 2 hours, the temperature was raised to 110°C, and the stirring was continued for 18 hours. The viscosity of the system suddenly increased and it was difficult to stir. The temperature was lowered to about 80°C, and the vacuum was pumped for 3 hours. 15.18 g (90%) of hyperbranched poly(diethylene glycol anhydride-dimethylolaminopropane) was obtained as an orange-yellow transparent solid. The relative weight average molecular weight is 39.4Kg / mol, the relative molecular weight distribution is 2.60, and the relative molecular weight distribution has a broad peak. pass 13 C~NMR spectrogram analysis calculates that its branching degree is 0.47, and there is no melting and crystallization in the sample by DSC test, the glass transition temperature is 38.4°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com