Probe card capable of replacing electron accessory rapidly

A technology for electronic parts and probe cards, applied in the field of probe cards, can solve problems such as time-consuming operation, electrical offset of probe cards, and unreliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

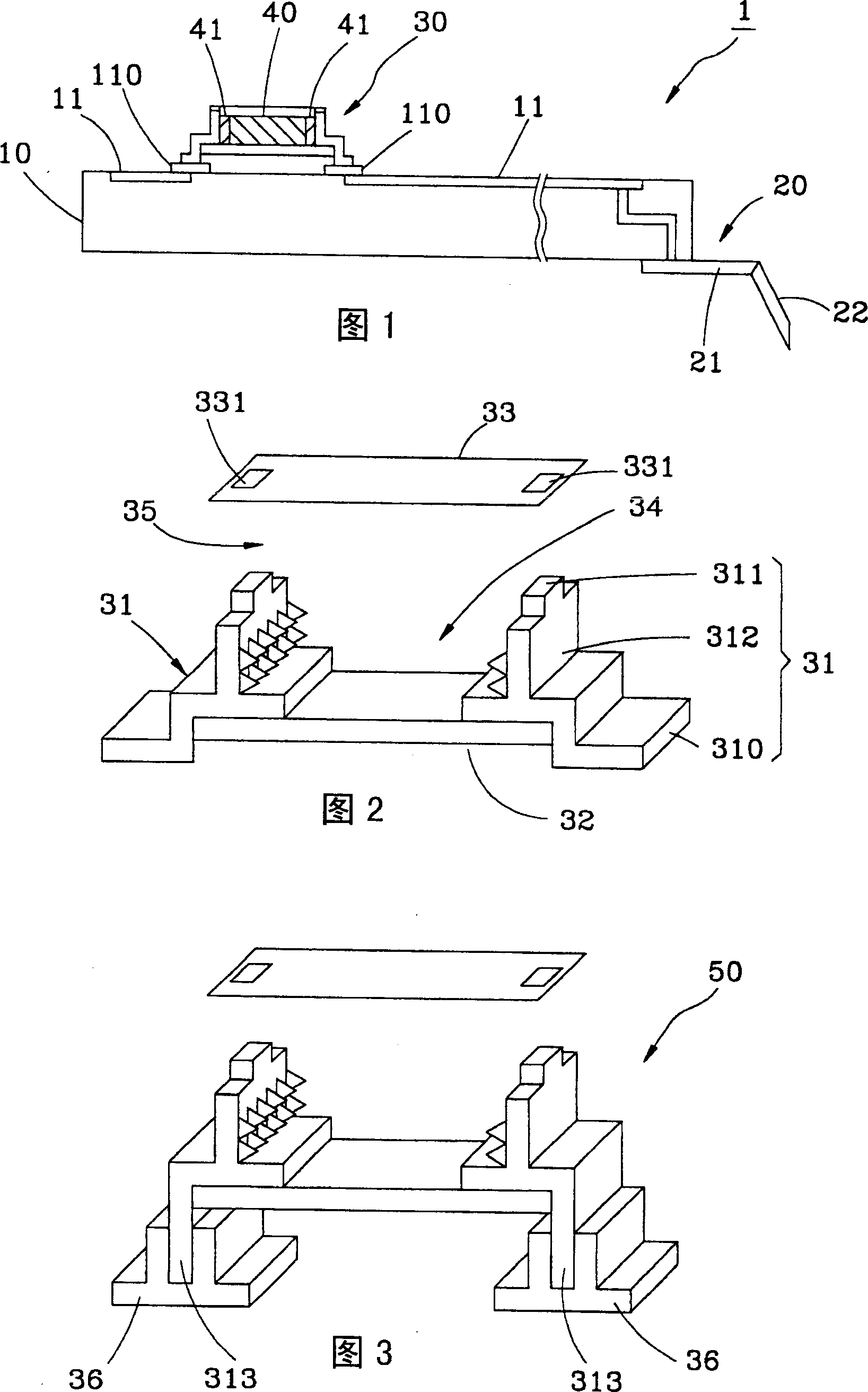

[0040] Please refer to the first preferred embodiment provided by the present invention shown in Fig. 1, which is a device schematic diagram of a probe card 1, which has a circuit board 10, a plurality of probes 20, a plurality of accommodating seats 30 and each of the accommodating Each electronic component 40 that is set in the seat 30, wherein:

[0041] The circuit board 10 is arranged with an electronic circuit 11 , and the layout of the electronic circuit 11 has a plurality of electrical nodes 110 for electrically connecting any passive components such as resistors, capacitors or inductors.

[0042] Each of the probes 20 includes a seat 21 and a needle 22, the electronic circuit 11 is electrically connected to the needle 22 through each seat 21, so that the probe card 1 can connect each of the needles 22 to the component to be tested (Fig. (not shown in the figure), and through the electronic circuit 11 and the measuring machine (not shown in the figure) are electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com