A method to fabricate high resistance value polysilicon resistance in high voltage IC

A high-voltage integrated circuit, polysilicon resistor technology, applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of increasing production costs, affecting efficiency, wasting time, etc., to achieve stable resistance, reduce costs, and in-plane Good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

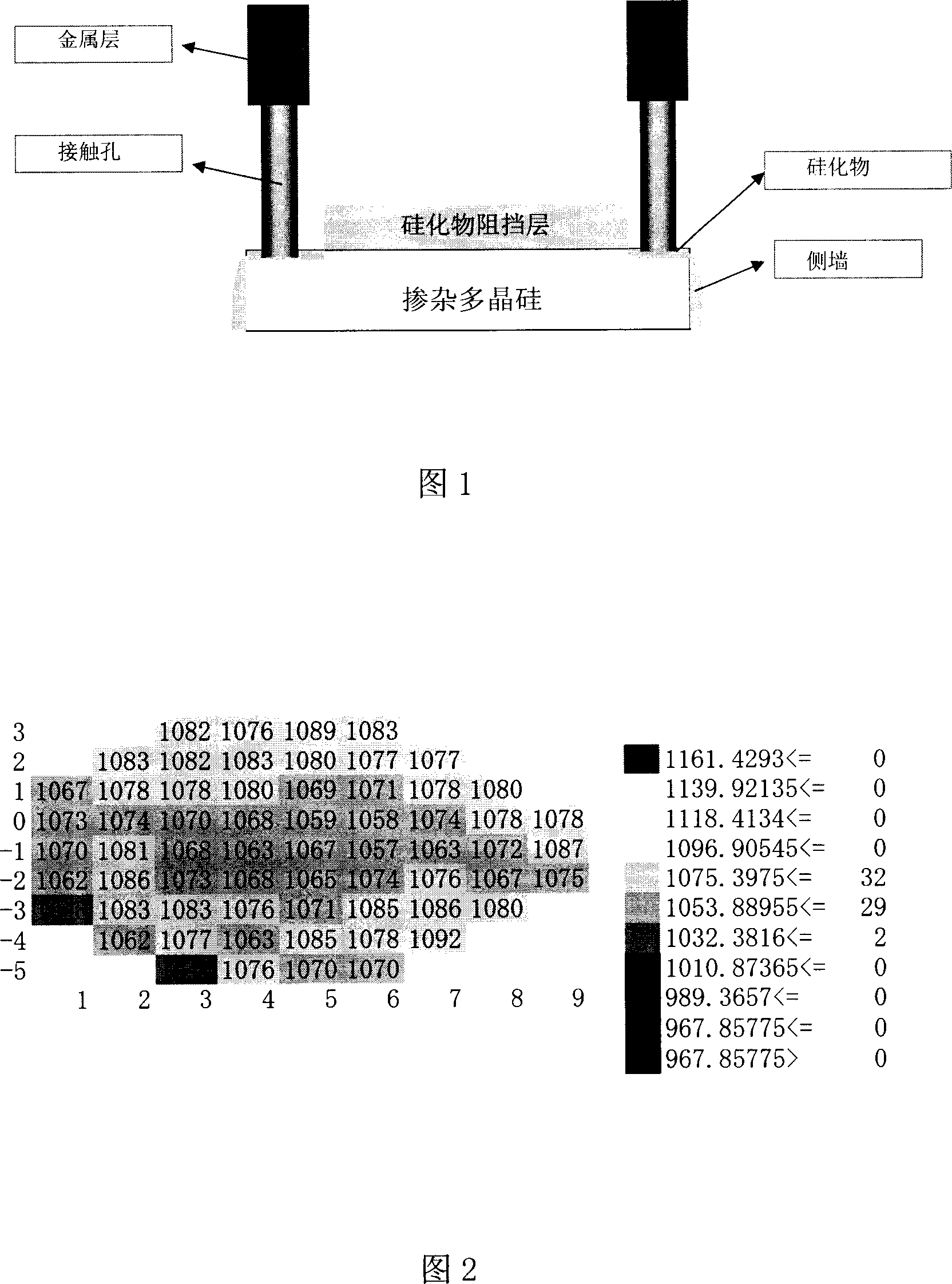

[0017] The main technical points of the method for manufacturing high-resistance polysilicon resistors in high-voltage integrated circuits of the present invention are: the deposition process of in-situ arsenic-doped polysilicon, the doping concentration and deposition process parameters affect the resistance value of the resistor itself; The subsequent thermal process mainly affects the distribution of impurities in polysilicon.

[0018] The doped polysilicon (DOPOS) is deposited by low pressure plasma enhanced chemical vapor deposition (LPCVD).

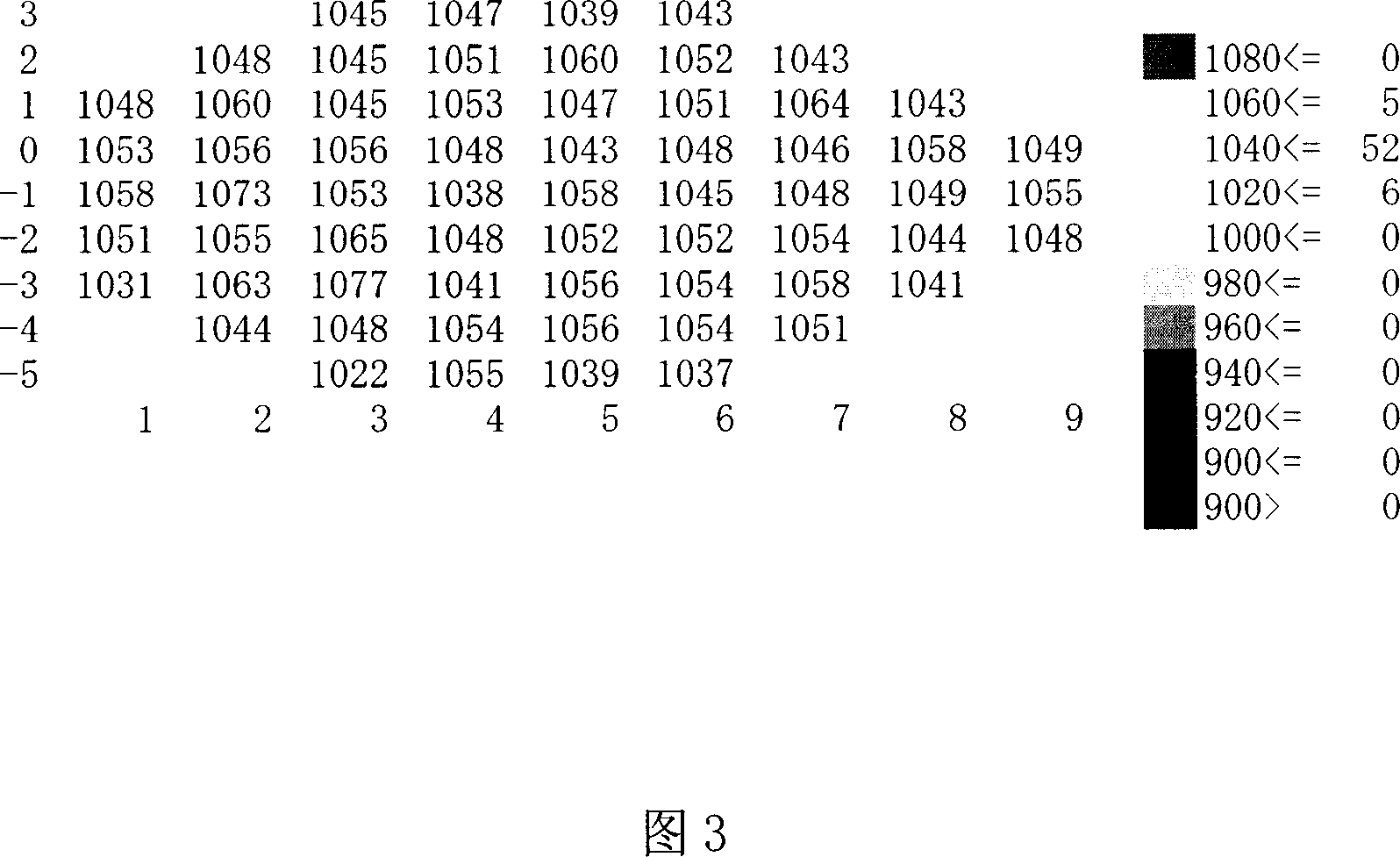

[0019] The specific process parameters are as follows: S i h 4 (Silane) flow rate 1600cm 3 / min, pH 3 (phosphine) flow rate 12.8cm 3 / min, time 34.5 minutes, furnace temperature 530°C, pressure 0.0997Kpa.

[0020] The follow-up thermal process after the DOPOS deposition affects the distribution of impurities in the polysilicon as mentioned above, and then affects the resistance value. In the present invention, the subsequent hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com