Harness routing structure for vehicle

A wiring structure, high-voltage technology, applied to vehicle components, electrical components, electric power devices, etc., can solve the problems of high-voltage wiring durability and shortened service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

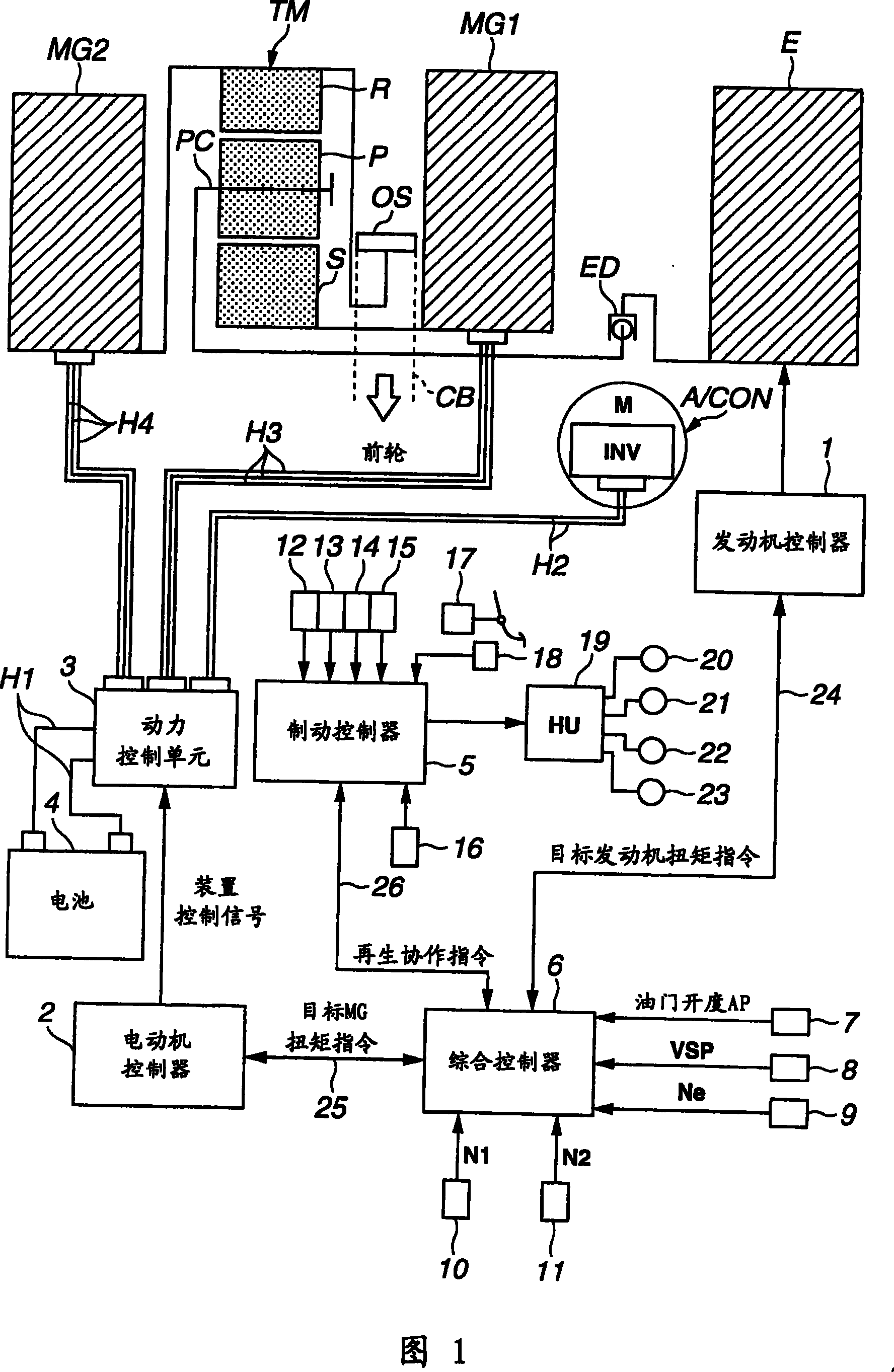

[0061] The structural configuration of the wiring wiring structure of the first embodiment is now explained.

[0062] 【System structure of composite vehicle】

[0063] figure 1 is a schematic block diagram showing a drive system of a compound vehicle (as one example of a vehicle) employing the wiring wiring structure of the first embodiment. like figure 1 As shown, the drive system of the compound vehicle in the first embodiment includes an engine E, a first motor / generator MG1, a second motor / generator MG2, an output sprocket (output sprocket) OS, a power (torque) distribution mechanism TM and Electric compressor unit (electric auxiliary unit) A / CON.

[0064] The engine E is a gasoline engine or a diesel engine. The valve opening degree and the like of the throttle valve of the engine E are adjusted in accordance with control commands from the engine controller 1 as described below.

[0065] Each of the first motor / generator MG1 and the second motor / generator MG2 is a syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com