Semi-coaxial cavity resonator, filter using the same, and communication apparatus using the same

A coaxial cavity and resonator technology, applied in resonators, waveguide devices, circuits, etc., can solve the problems of increased manufacturing costs, weight, and temperature waveform confusion, and achieve the effect of increased length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] first embodiment

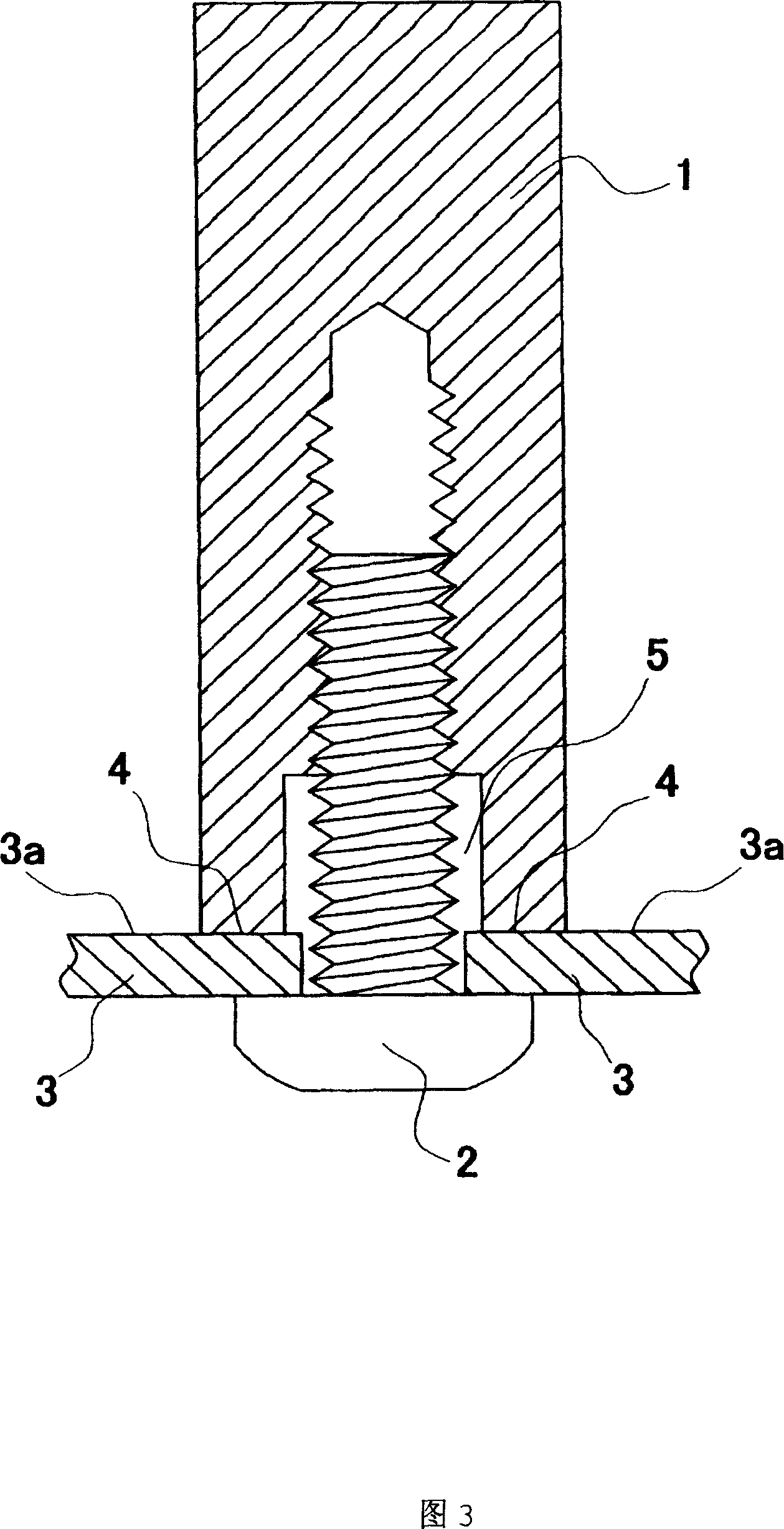

[0072] Fig. 3 has shown the cross-section of the internal conductor fixed part according to the first embodiment of the present invention, is a semi-coaxial cavity resonator in the filter shown in Fig. 4 and is cut along the partial cross-sectional view of A-A;

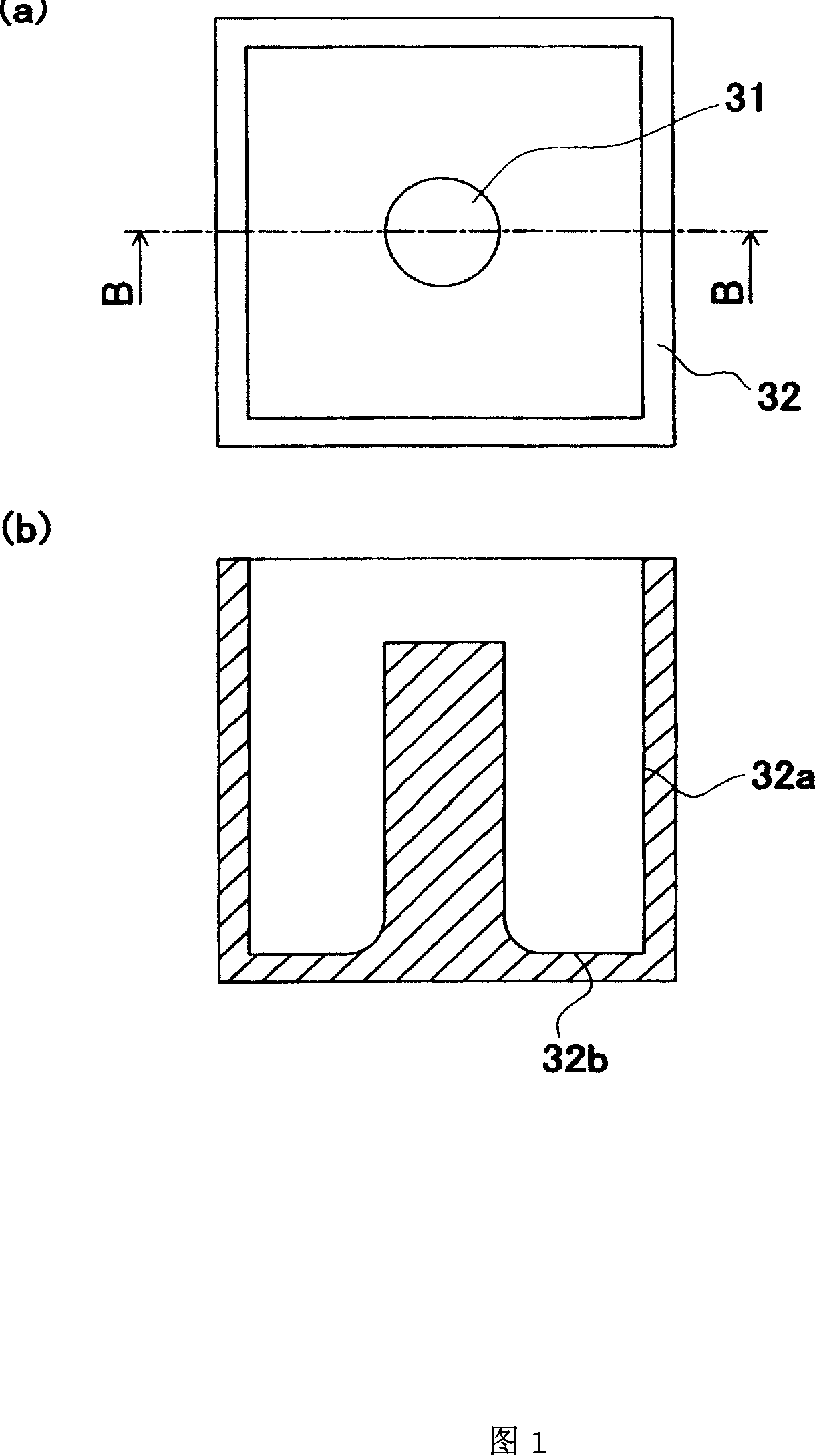

[0073] First, Fig. 4 will be described. FIG. 4(a) is a plan view of a bandpass filter using both a semi-coaxial cavity resonator and a dielectric resonator, showing the internal structure of the filter after part of the upper conductor plate 21 is removed. FIG. 4( b ) is a side view of FIG. 4( a ), showing the internal structure of the filter after part of the outer conductor 3 is removed.

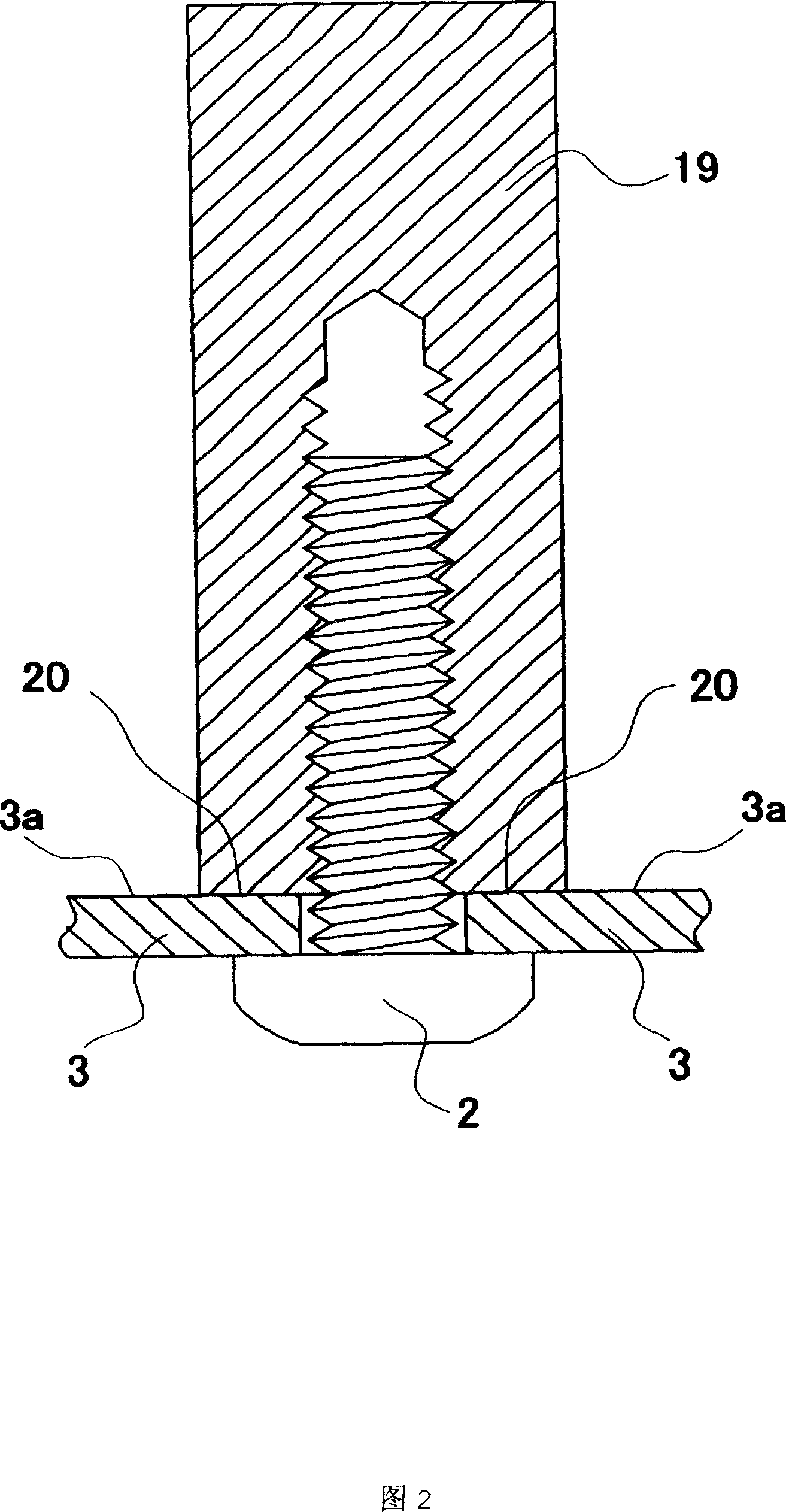

[0074] The outer conductor 3 is a cavity structure with cavities with openings on one side, and each cavity is separated by a partition plate. The inner conductor 1 is fixed on the bottom surface 3 a of the outer conductor 3 by means of bolts 2 . This will be described in detail in Figure 3. But the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com