Multiple stage continuous adverse current type centrifugal leaching device suitable for powdery material

A powdery material, counter-current technology, applied in the direction of solid solvent extraction, etc., can solve the problems of long process, poor efficiency, large amount of attached solvent, etc., to achieve the effect of convenient production, improved efficiency, and reduced work site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

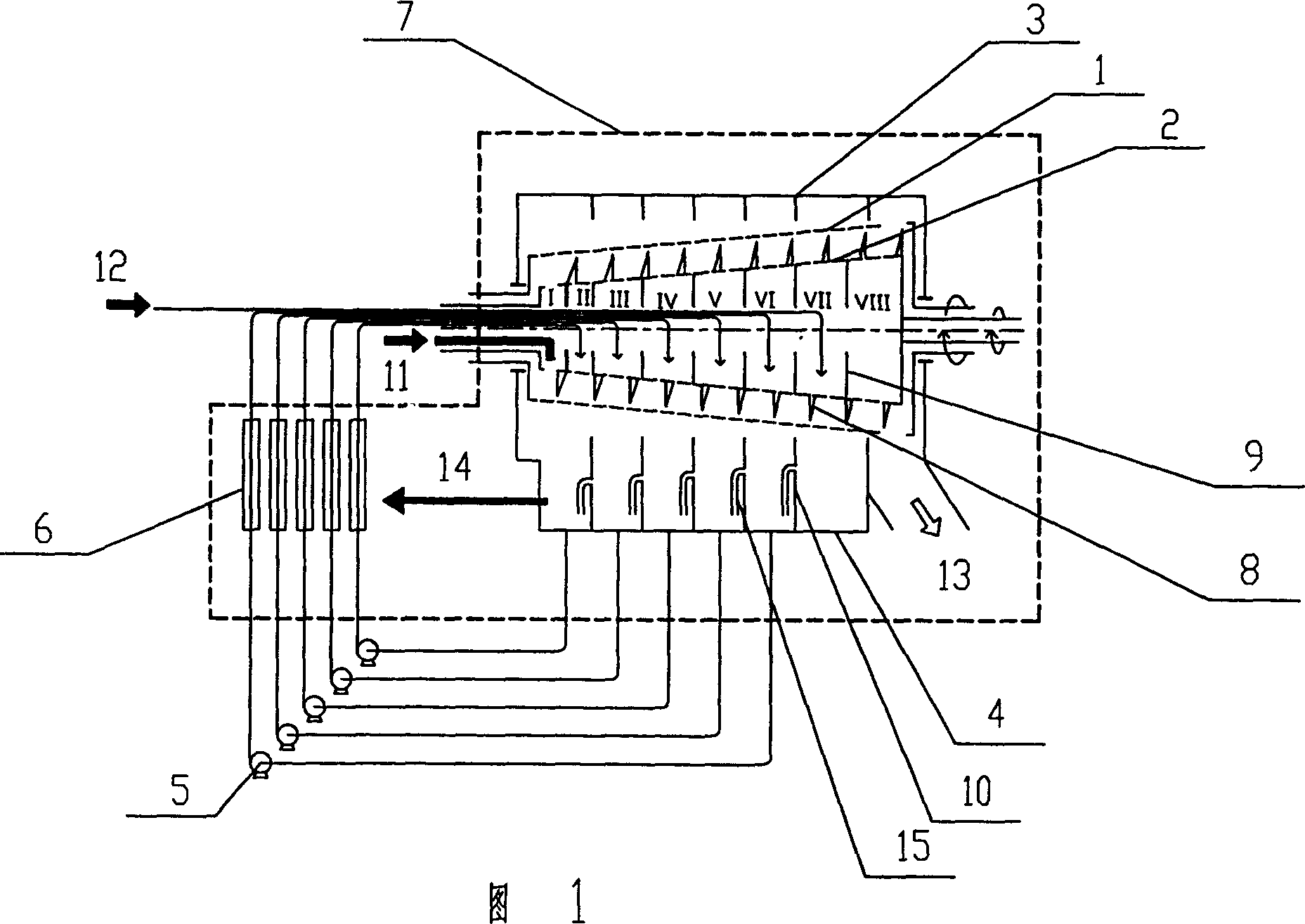

[0012] The present invention will be further described now in conjunction with accompanying drawing

[0013] A multi-stage continuous countercurrent centrifugal leaching device suitable for powdery materials, including product liquid extraction and residue solvent recovery, its structure is: two hollow cones with different diameters with the same taper, evenly distributed on the cone surface Small holes, coaxial and non-contacting; the outer surface of the small-diameter hollow cone has spirally extending blades 8, which vertically surround the end face of the small end of the cone to the end face of the large end, and the inner surface is composed of different outer diameters with a hole in the center The seven plane circular plates 9 of the vertical central axis of the vertical central axis are separated in parallel to form a spiral slagging device 2; the inner wall of the hollow cone with a large diameter is covered with a filter screen to form a drum 1; the hollow shaft at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com