Bergmeal particle loaded nano TiO2 preparation method

A technology of diatomite and microparticles, applied in chemical instruments and methods, catalyst activation/preparation, light water/sewage treatment, etc., can solve the problems of preparation method and loading mechanism discussion, achieve strong loading binding force and simple preparation process , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

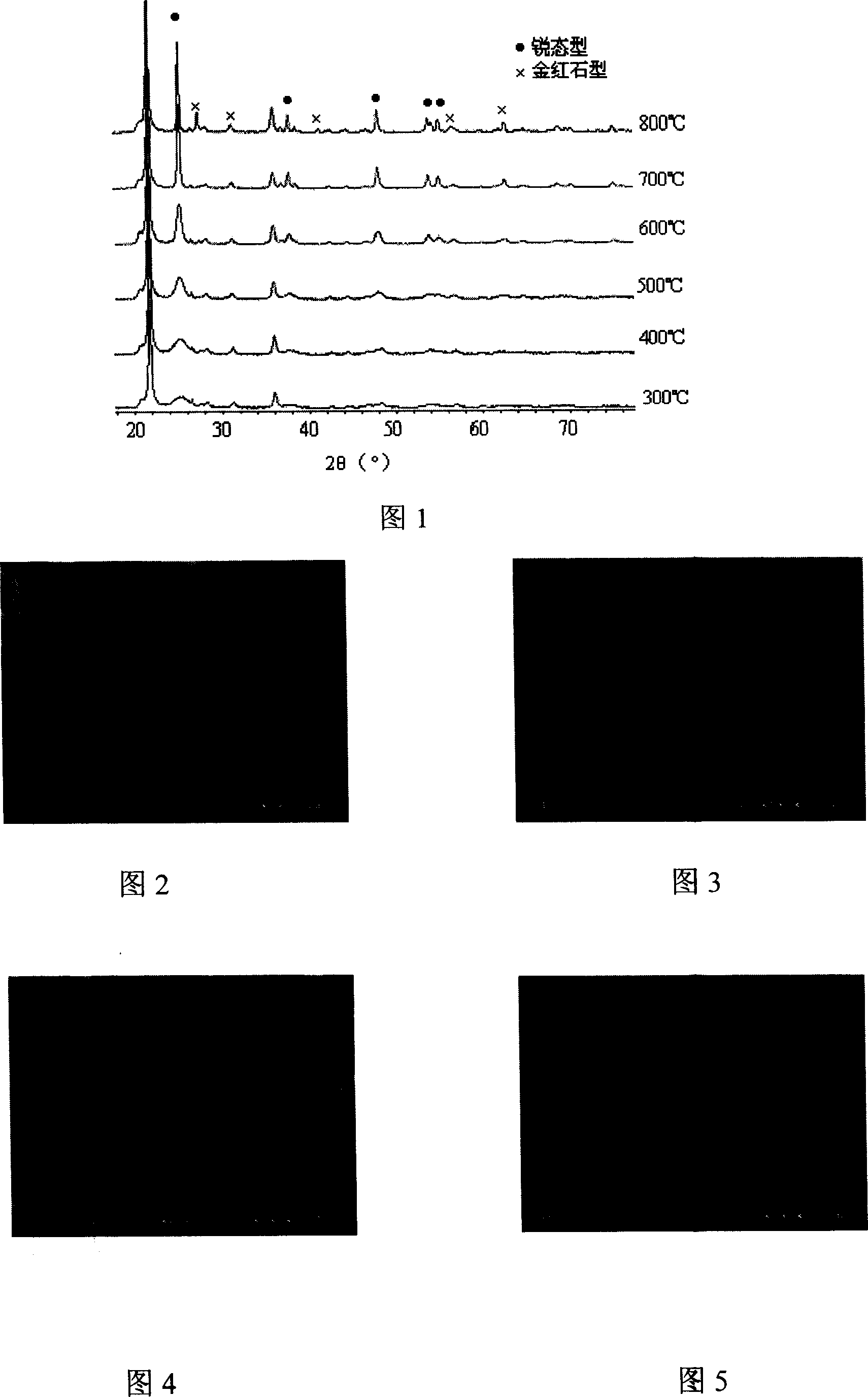

example 1

[0016] Take 3g of urea and add water to 50ml, add 0.16g of diatomite particles, stir, and prepare 6 parts of such a suspension; take 4ml of 0.5mol / L titanyl sulfate solution and add water to 50ml, and prepare 6 parts of the solution. Corresponding to mixing respectively, the numbers of the mixtures are 1, 2, 3, 4, 5, and 6 respectively. Use concentrated sulfuric acid with a mass concentration of 98% to adjust the pH values of the above six mixed solutions to 0.5, 1, 1.5, 2, 2.5, and 3 respectively, and stir and react in a water bath at 75°C for 2 hours, filter respectively, and store at 120°C After drying for 1 hour and roasting at 500°C for 2 hours, 6 kinds of diatomite-loaded nano-titanium dioxide products were prepared respectively. The conclusion obtained by SEM scanning analysis is that when the pH value is 1.5, the prepared diatomite-loaded nano-titanium dioxide The particle size of titanium dioxide in the product is the smallest, its loading rate is the largest, and t...

example 2

[0018] Separately prepare TiOSO 4 Solutions with a concentration of 0.005mol / L, 0.01mol / L, 0.02mol / L, 0.04mol / L, 0.08mol / L, and 0.1mol / L; take 3g of urea and dissolve it in 50ml of deionized water to prepare such a solution6 Parts, diatomaceous earth content of 0.04g, 0.08g, 0.32g, 0.48g, 0.64g, 0.8g corresponding to the urea solution. Mix the above 6 parts of TiOSO separately 4 Solution and urea-diatomaceous earth suspension, the mixture numbers are 1, 2, 3, 4, 5, 6 respectively. Stir and react in a water bath at 75°C for 2 hours at pH 1.5, filter, dry at 120°C for 1 hour, and roast at 500°C for 2 hours to prepare 6 products. TiSO was calculated and analyzed by SEM scanning. 4 When the concentration is 0.01mol / L, the prepared product has a uniform particle size, a large loading rate, and no agglomeration.

example 3

[0020] Take 2ml of 0.5mol / L TiOSO 4 Add water to the solution to 50ml, and prepare 6 parts of the solution; take 3g of urea and add water to 50ml, make 6 parts of such a solution, weigh and TiO 2 Diatomaceous earth with a mass ratio of 1:4, 1:2, 1:1, 2:1, 3:1, 4:1 was added to the above 6 parts of urea solution respectively. Mix the above 6 parts of TiOSO separately 4 Solution and urea-diatomaceous earth suspension, the mixture numbers are 1, 2, 3, 4, 5, 6 respectively. Adjust the pH value to 1.5, stir and react in a water bath at 75°C for 2 hours, filter, dry at 120°C for 1 hour, and roast at 500°C for 2 hours to prepare 6 products. TiO 2 When the mass ratio is 2:1, the product obtained has small particle size, high loading rate, tight combination and no agglomeration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com