Self-adjusting energy-saving device for oil-burning gas-fired boiler

A gas-fired boiler and energy-saving device technology, applied in the direction of reducing greenhouse gases, climate sustainability, and mitigation of combustion technology, can solve the problems of high boiler production costs, reduce maintenance rates and repairs, avoid low-temperature condensation corrosion, and increase water temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

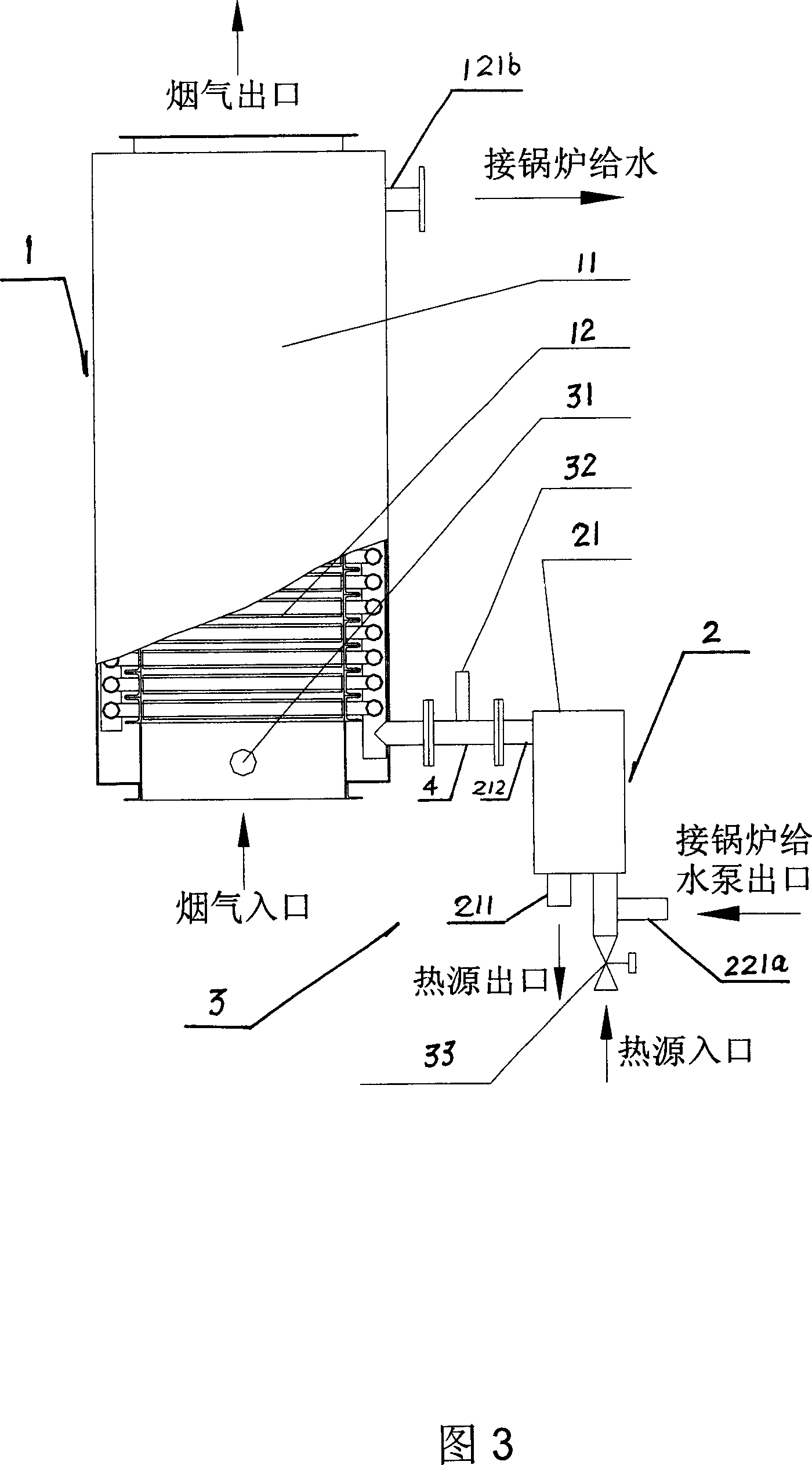

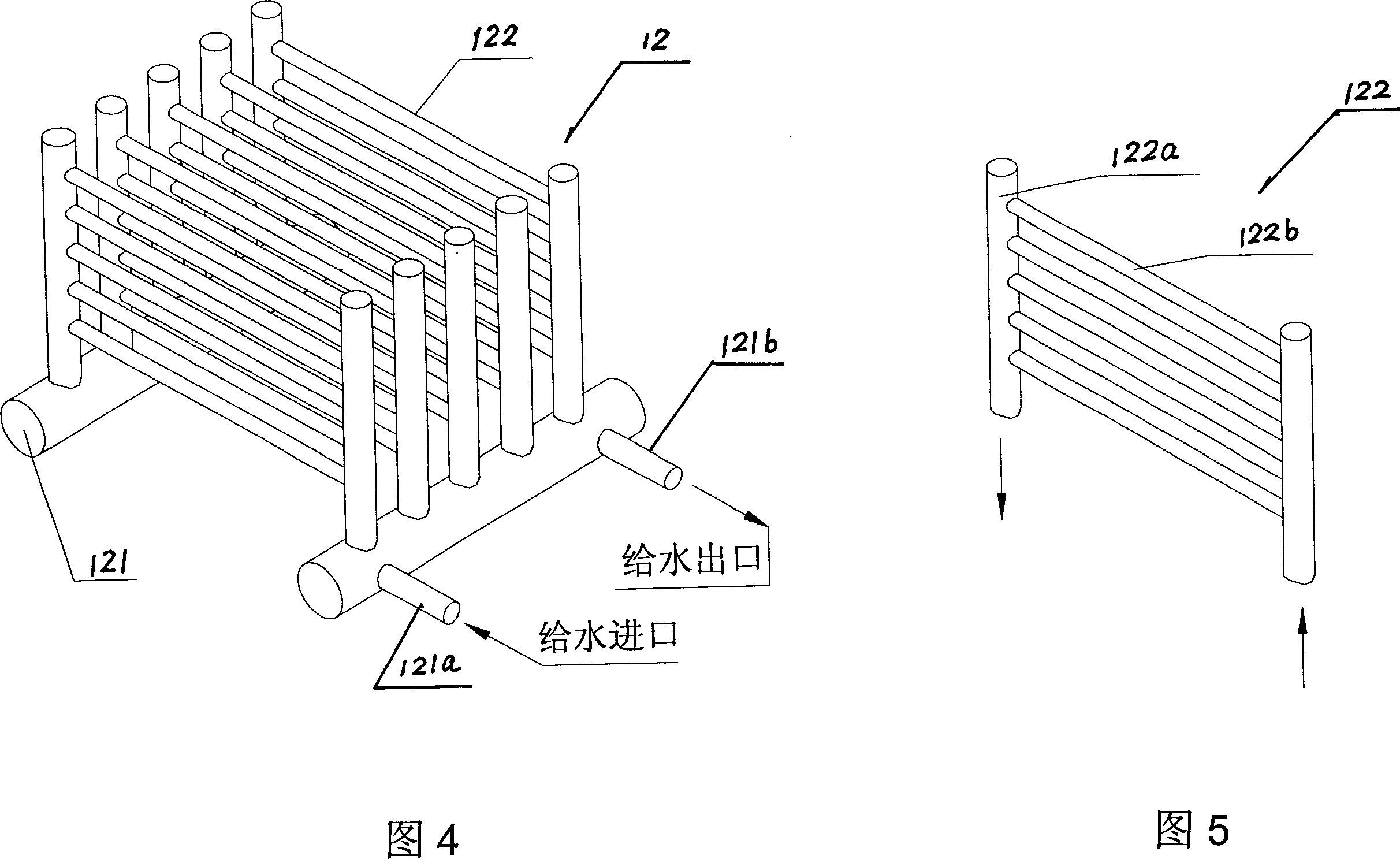

[0039] Please refer to Figure 3, the self-regulating energy-saving device of the oil-fired gas boiler is composed of a heat exchanger 1, a mixer 2 and a temperature measurement control component 3; It consists of a shell 11 and a heat exchanger body 12 arranged in the shell 11; the mixer 2 is located outside the flue gas inlet of the heat exchanger, and the mixer 2 is connected to the heat exchanger 2 through a water pipe 4; the temperature measurement control component 3 It consists of a thermal resistor 31 on the flue gas side, a thermal resistor 32 on the water supply side, and a temperature control valve 33; In the shell 11 of the flue gas inlet part of the heater 1, the thermal resistor 32 on the water supply side (in this embodiment, the thermal resistor 32 adopts a thermal resistor with a type of Pt100) is arranged in the phase between the heat exchanger 1 and the mixer 2. On the connected water pipe 4 , a temperature control regulating valve 33 (the temperature control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com