Organic bistable element and its manufacturing method

A manufacturing method and bistable technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems affecting component life, multi-stable layer damage, limited application level, etc., to improve life, Effect of increasing write/erase times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

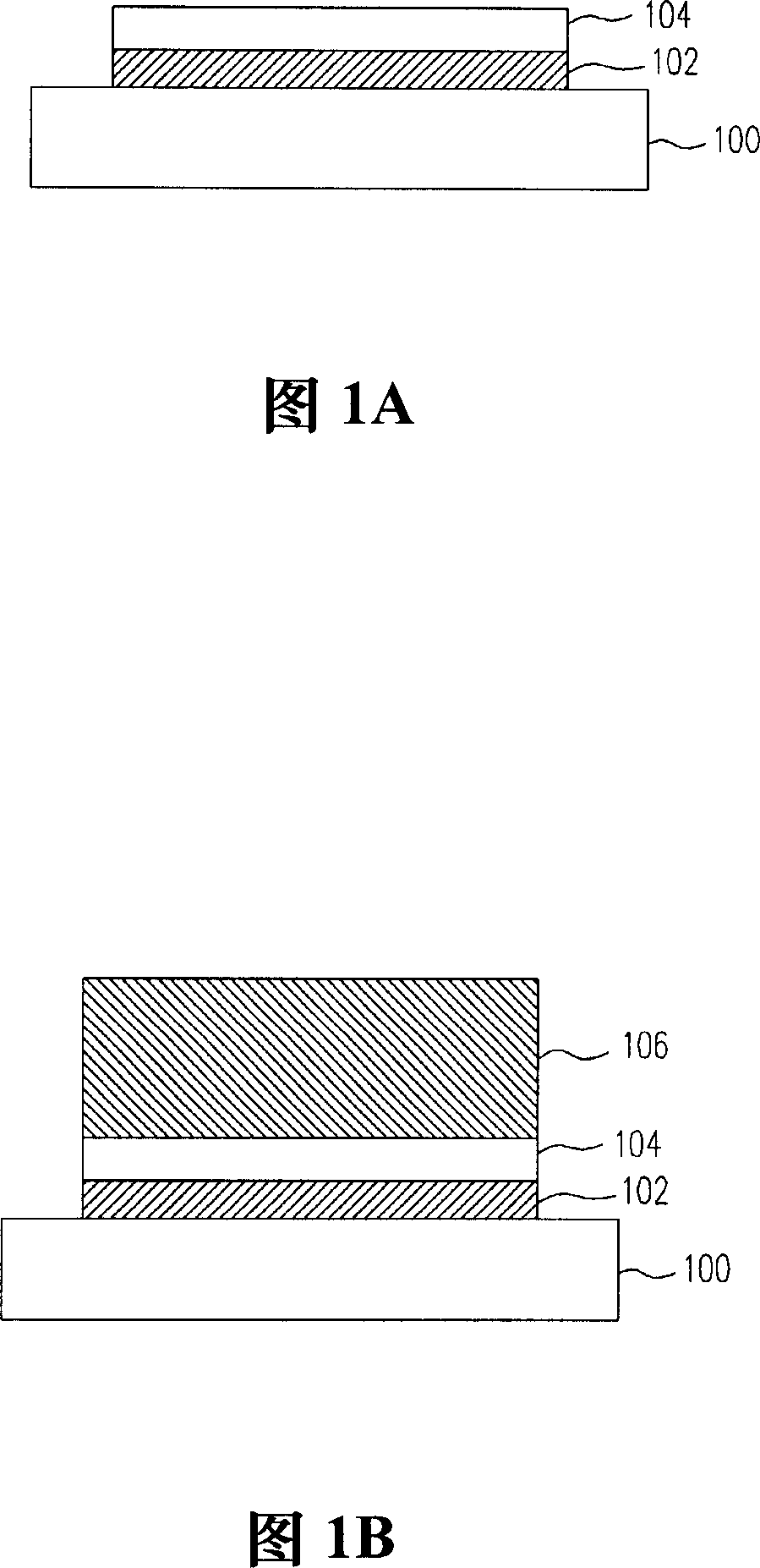

[0050] 1A to 1C are cross-sectional views of a method for manufacturing an organic bistable device according to a preferred embodiment of the present invention.

[0051] Referring to FIG. 1A , a substrate 100 is provided. A first metal layer 102 is formed on the substrate 100 . The material of the first metal layer 102 is copper, gold, silver, aluminum, cobalt or nickel, and the thickness of the first metal layer 102 is about 700 angstroms. Afterwards, a buffer layer 104 is formed on the first metal layer 102 . Wherein the buffer layer 104 is formed by, for example, a material with a high dielectric constant, and the material with a high dielectric constant is preferably Al 2 o X , LiF, MgO, V 2 o 5 or TiO 2 . Also, the thickness of the buffer layer 104 is about 40 angstroms.

[0052]Next, please refer to FIG. 1B , an organic mixed layer 106 is formed on the buffer layer 104 . Wherein, the method for forming the organic mixed layer 106 includes performing a jet printi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com