Inclined jetting column plate

A technology of trays and inclined angles, which is applied in distillation separation, chemical/physical/physicochemical processes, dispersed particle separation, etc., can solve the problems of plate towers that are difficult to take advantage of, low processing capacity, and low mass transfer efficiency, and achieve improved Space utilization, speed up the flow rate, and the effect of increasing the mass transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

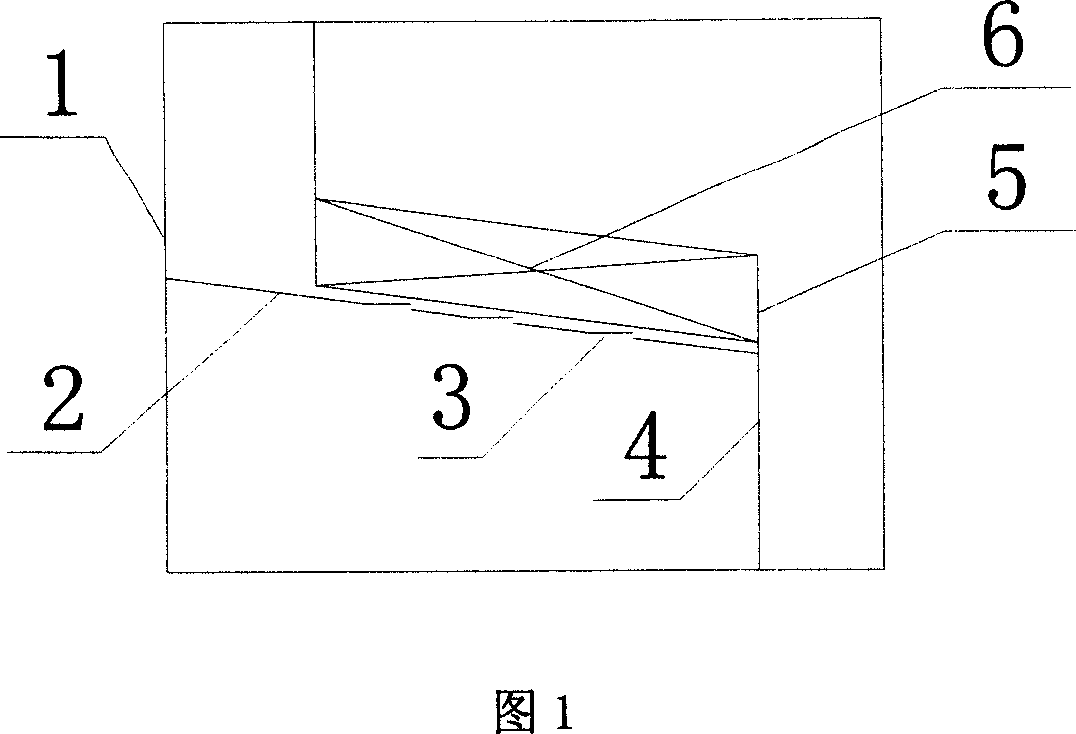

[0029] As shown in Figure 1, the present invention consists of a tower wall 1, a bottom plate 2, a downcomer 4 and a structured packing 6. The bottom plate 2 and the tower cross section are installed obliquely in the tower at a certain angle, and the inclination is obtained by the size of the liquid flow intensity on the plate. The angle is 4 degrees. There are louver-like long oblique holes 3 on the tray, and the opening direction points to the downcomer 4 of this floor. The angle of the oblique holes is equivalent to that of the tray 2, which is 4 degrees. The opening ratio of tray 2 is calculated according to the gas and liquid phase loads of the whole column. The appropriate opening ratio should make the plate hole kinetic energy factor relatively large, generally 10-12ms -1 (kg / m 3 ) 0.5 Within the range, the gas-liquid two phases on the tray form a spray operation state. The downcomer 5 of this example is an arcuate downcomer installed inside the tower wall 1 . The ...

Embodiment 2

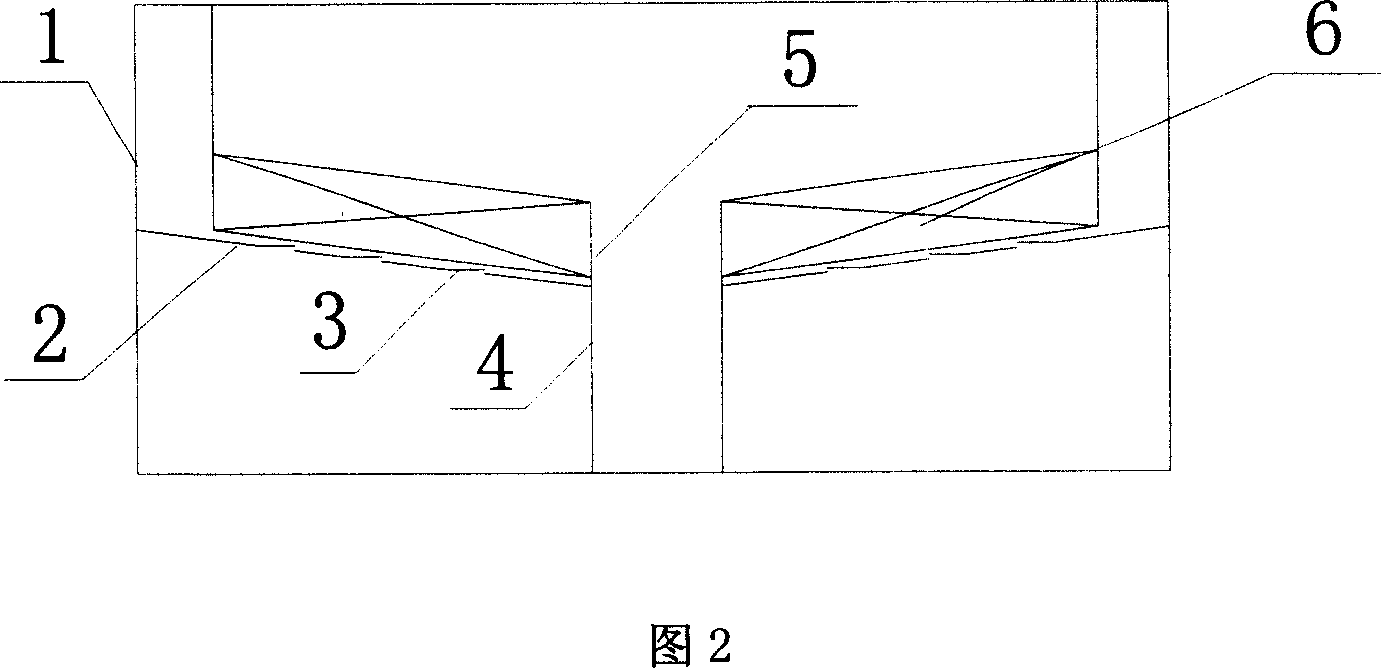

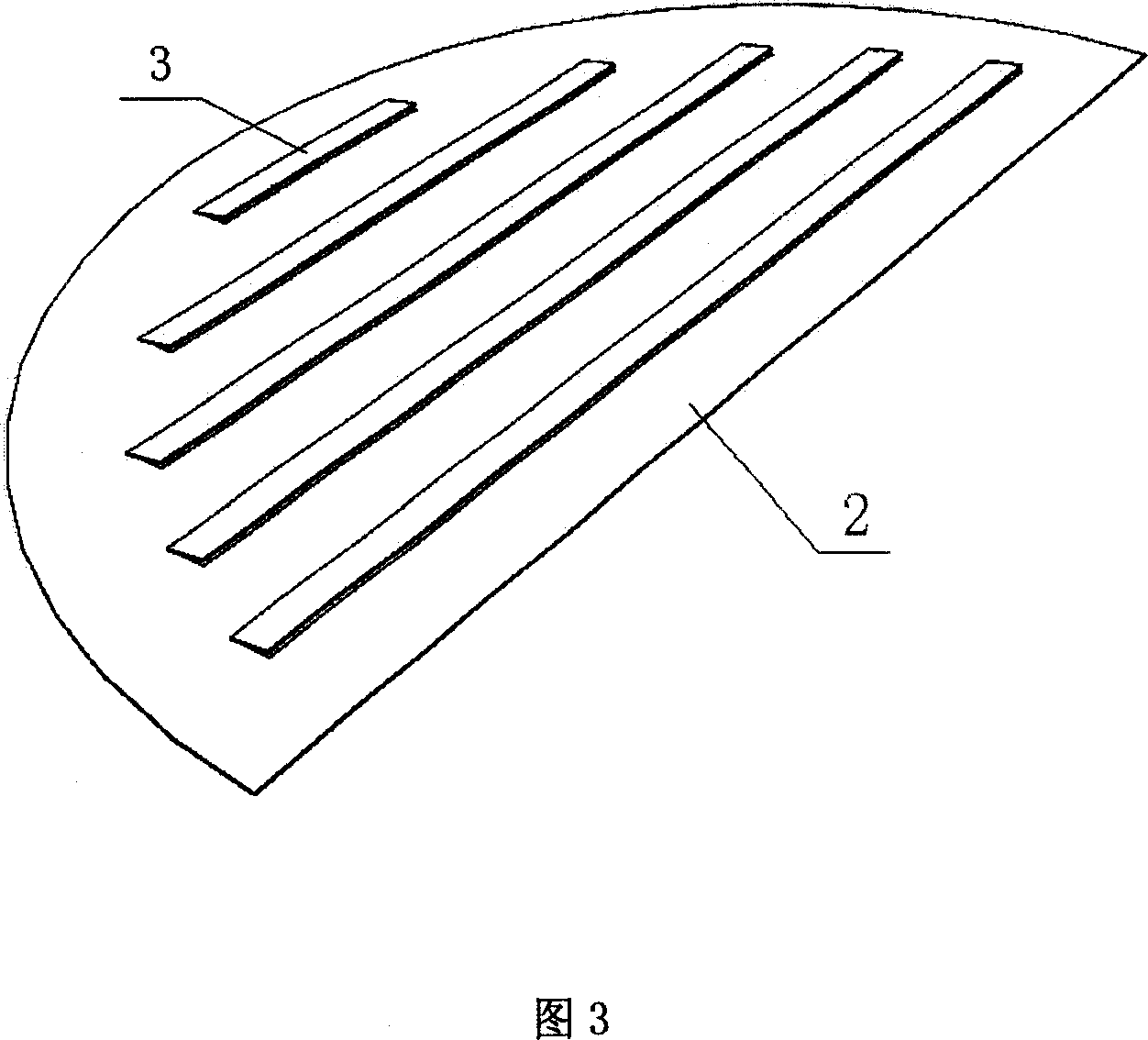

[0031] Figure 2-5 is a schematic diagram of the structure of the double overflow jet inclined tray. The double overflow jet inclined tray has a symmetrical structure, which is the same as the single overflow jet inclined tray. It is also composed of tower wall 1, bottom plate 2 and downcomer 4 And structured packing 6 composition. The tray 2 and the section of the tower are obliquely installed in the tower at a certain angle, and the installation angles on both sides are the same. Due to the double overflow, the overflow periphery on the tray increases, and the inclination angle of the tray is 2 degrees. Odd-numbered downcomers 5 are bow-shaped downcomers installed inside the tower wall 1; even-numbered downcomers 5 are rectangular downcomers installed in the center of the tower. The bottom plates on both sides of the downcomer 5 are provided with louver-like long oblique holes 3, and the direction of the opening points to the downcomer 4 on this floor. As shown in Figure 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com