Process of producing whole wheat flour

A technology of whole wheat flour and production process, applied in the application, grain processing, agriculture and other directions, can solve problems such as affecting the quality of flour and nutrient absorption, and achieve the effects of easy absorption, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

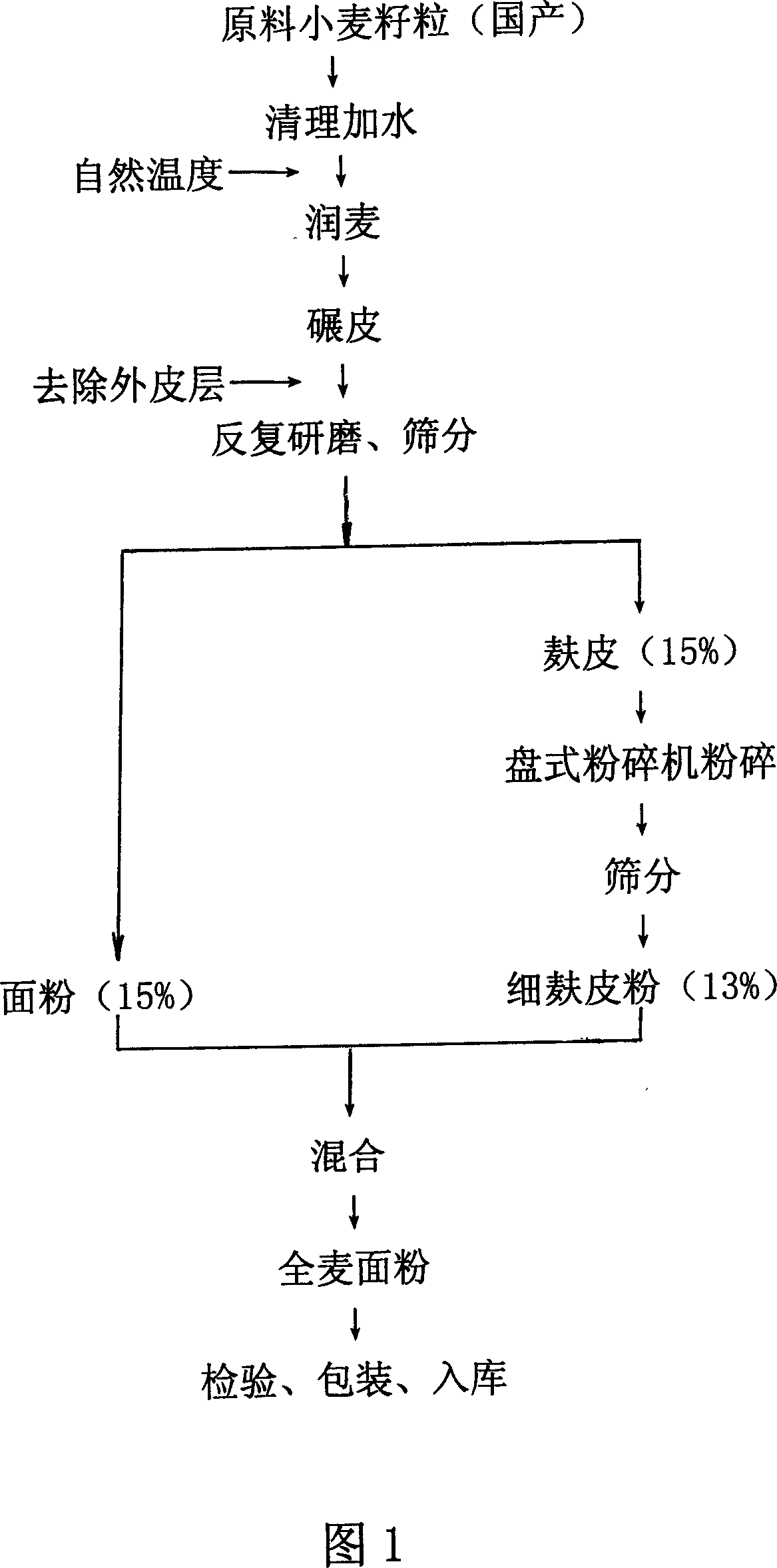

[0007] In order to further understand the characteristics and functions of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with reference to the accompanying drawings, please refer to FIG. 1 .

[0008] As shown in Figure 1: After the raw wheat grains are cleaned, water is added to remove impurities, microorganisms and residual pesticides on the surface of the wheat grains and in the ventral groove. The machine grinds the outer skin layer, which generally accounts for 7-8% of the total amount of wheat grains, and then the wheat grains with the outer skin removed are ground and sieved by milling equipment, so that the fineness achieved is all through CB30 No more than 10% of the remaining on the CB36 sieve, after the 78% of the sifted flour and the bran composed of the inner cortex and aleurone layer accounting for 15% of the total amount are separated, 78% of the flour enters the storage bin. The cortex has a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com