Computerized method of remote monitoring temperature of aluminium electrobath casing

An aluminum electrolytic cell and remote monitoring technology, which is applied in the field of monitoring the temperature of the aluminum electrolytic cell shell, can solve problems such as error-prone and failure to detect hidden dangers in time, and achieve the effect of ensuring normal operation, avoiding further deterioration of the cell condition or even stopping the cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

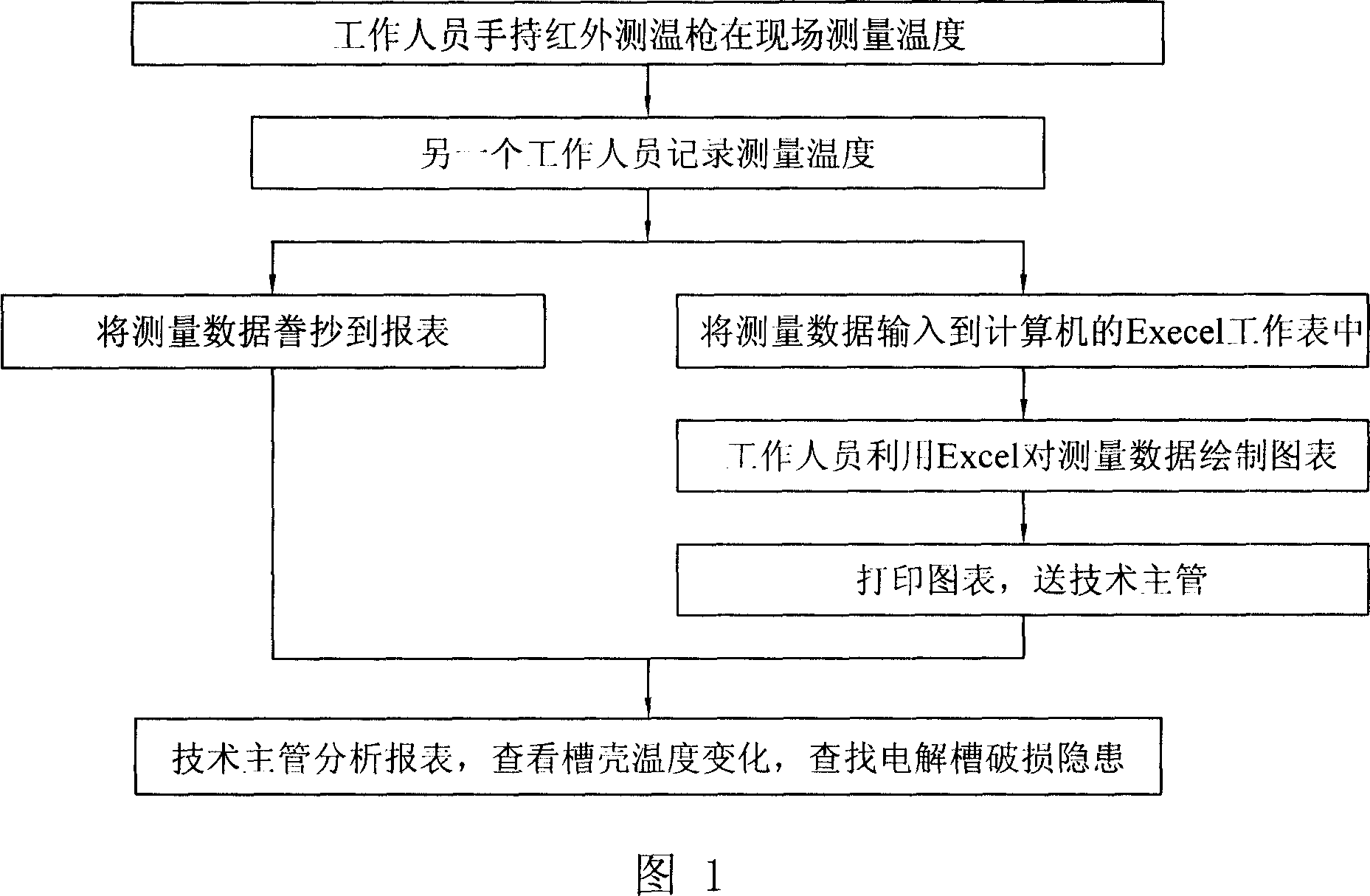

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

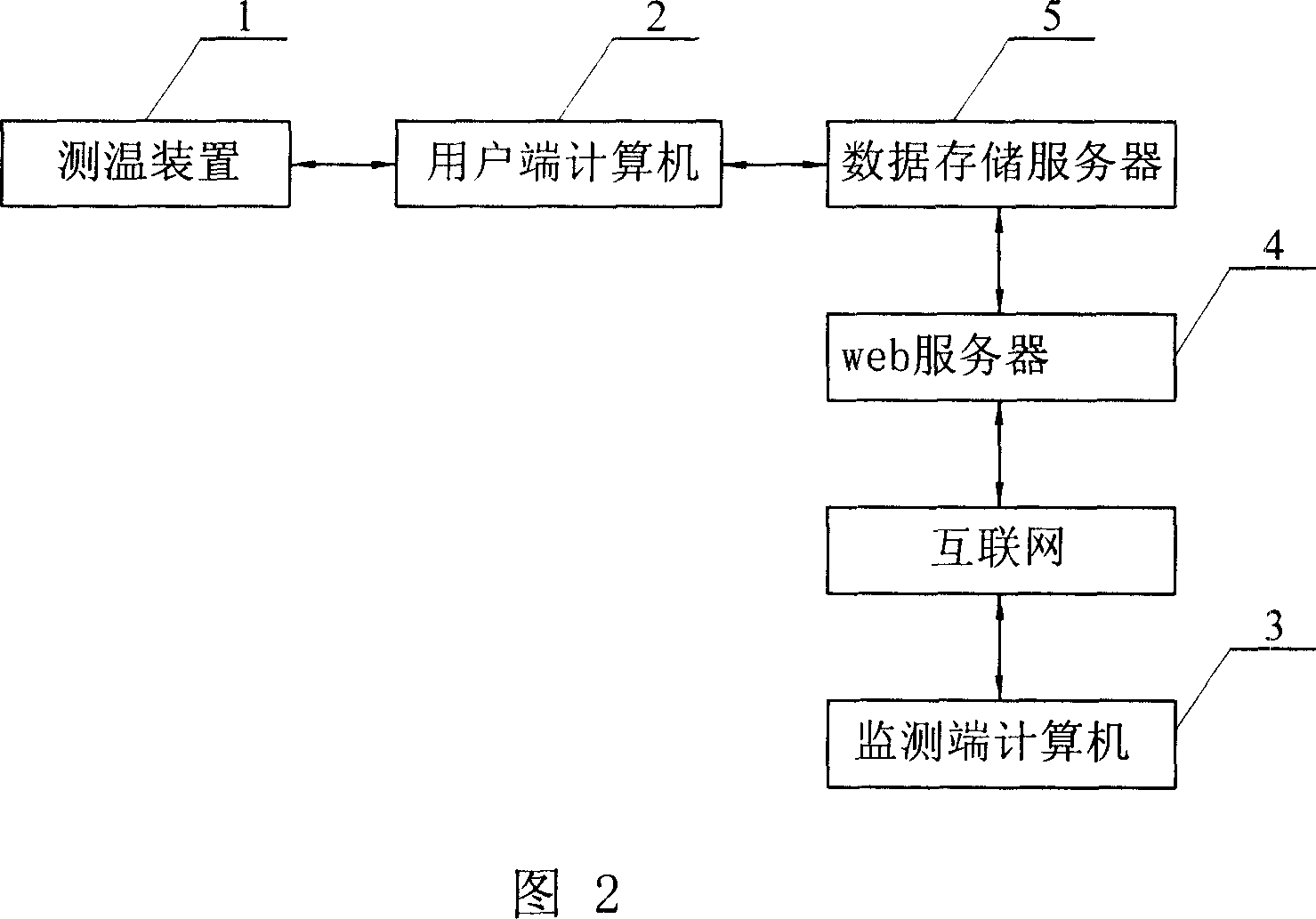

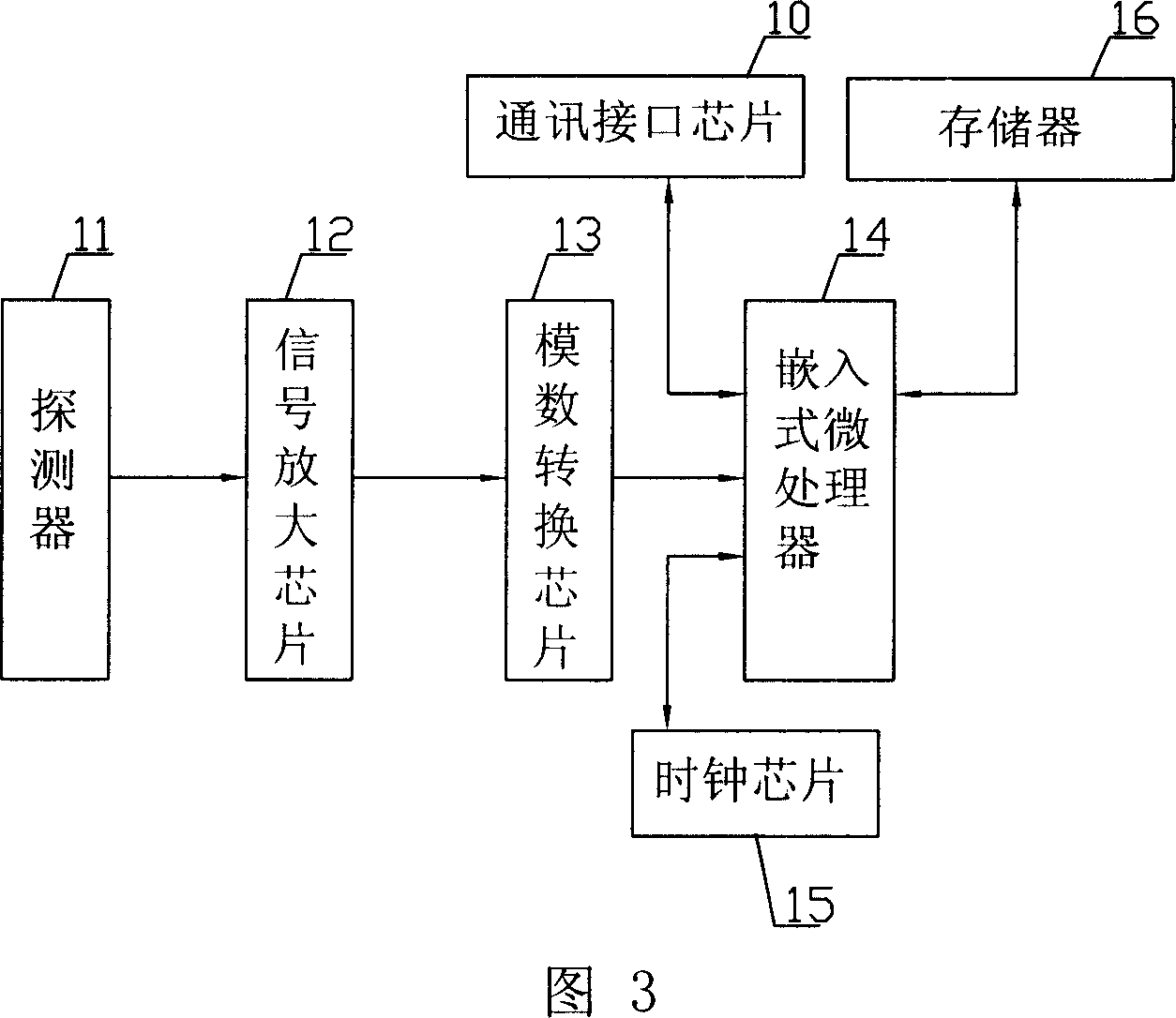

[0022] Specific embodiment 1: As shown in Figure 2, a method of using a computer to remotely monitor the temperature of the aluminum electrolytic cell shell in this specific embodiment is to use a temperature measuring device 1, a user end computer 2, and a monitoring end computer connected to the network 3, web server 4 and the data storage server 5 that is arranged between client computer 2 and web server 4 realize; As shown in Figure 3, described temperature measuring device 1 is provided with the detector 11 that object temperature is measured , signal amplification chip 12, analog-to-digital conversion chip 13, embedded microprocessor 14, clock chip 15, memory 16 and the communication interface chip 10 that is connected with client computer 2, the output terminal of detector 11 connects the input of signal amplification chip 12 end, the output end of the signal amplification chip 12 is connected to the input end of the analog-to-digital conversion chip 13, and the output e...

specific Embodiment approach 2

[0055] Specific embodiment two: as shown in Figure 7, the data monitoring in the monitoring method described in this embodiment includes the temperature monitoring of the measuring surface, which is carried out in the following steps:

[0056] 1. Use the temperature measuring device 1 to measure the temperature of the preset measuring points on each side of the electrolytic tank, and then save the temperature data together with the measuring time (accurate to minutes), the number of the measuring point and the information of the measuring tank number in the memory of the temperature measuring device 1 16 in;

[0057] 2. The client computer 2 reads the data in the temperature measuring gun and saves it in the database;

[0058] 3. The monitoring end users access and analyze the database data through the browser, the specific steps are:

[0059] 3-1. Monitor the user to open the browser, enter the website name in the address bar or enter the operating parameters on the page;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com