Forced-air-cooled engine with cooling air guide cover

一种强制空冷、发动机的技术,应用在发动机元件、机器/发动机、发动机的冷却等方向,达到防止漏出的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

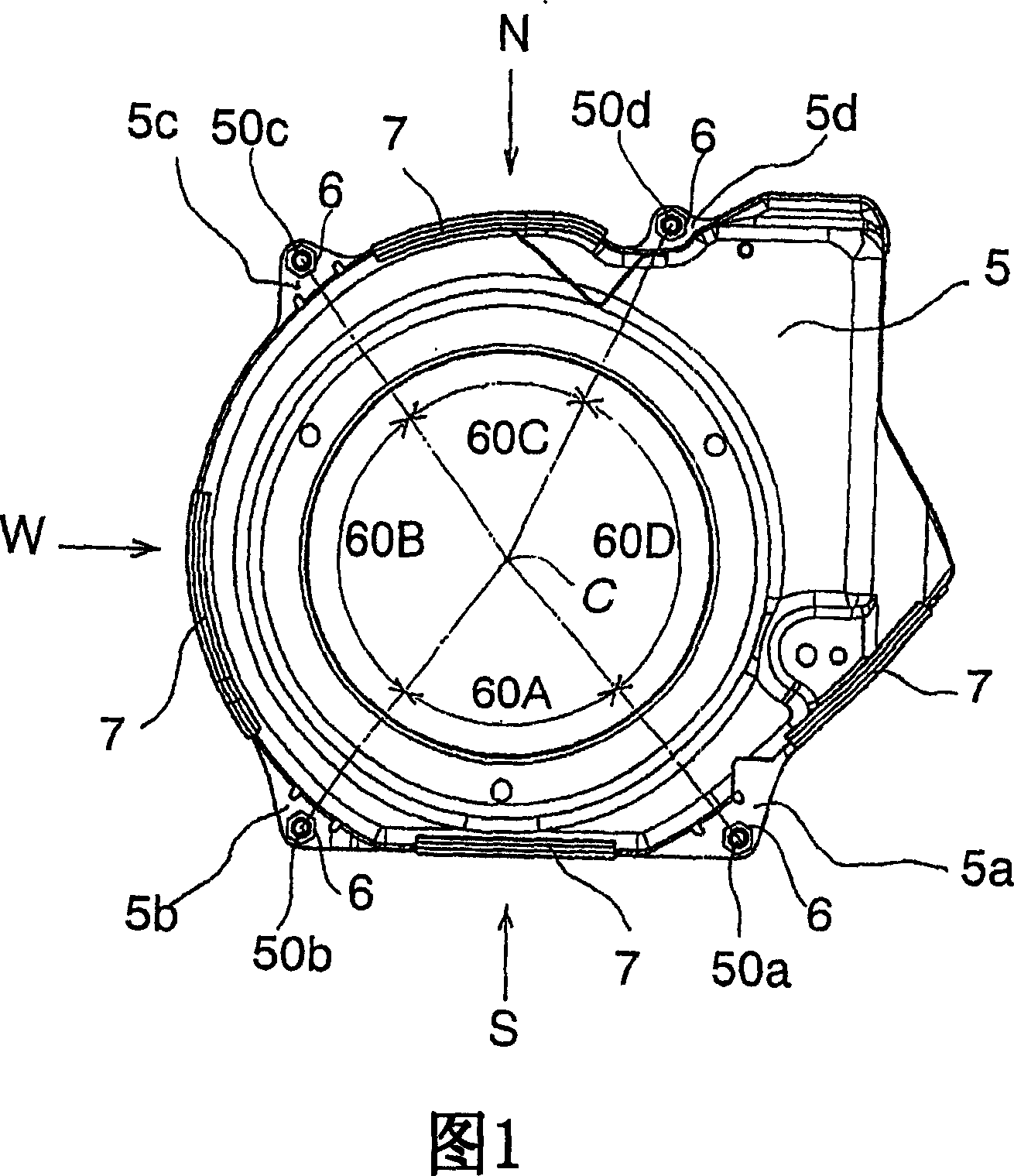

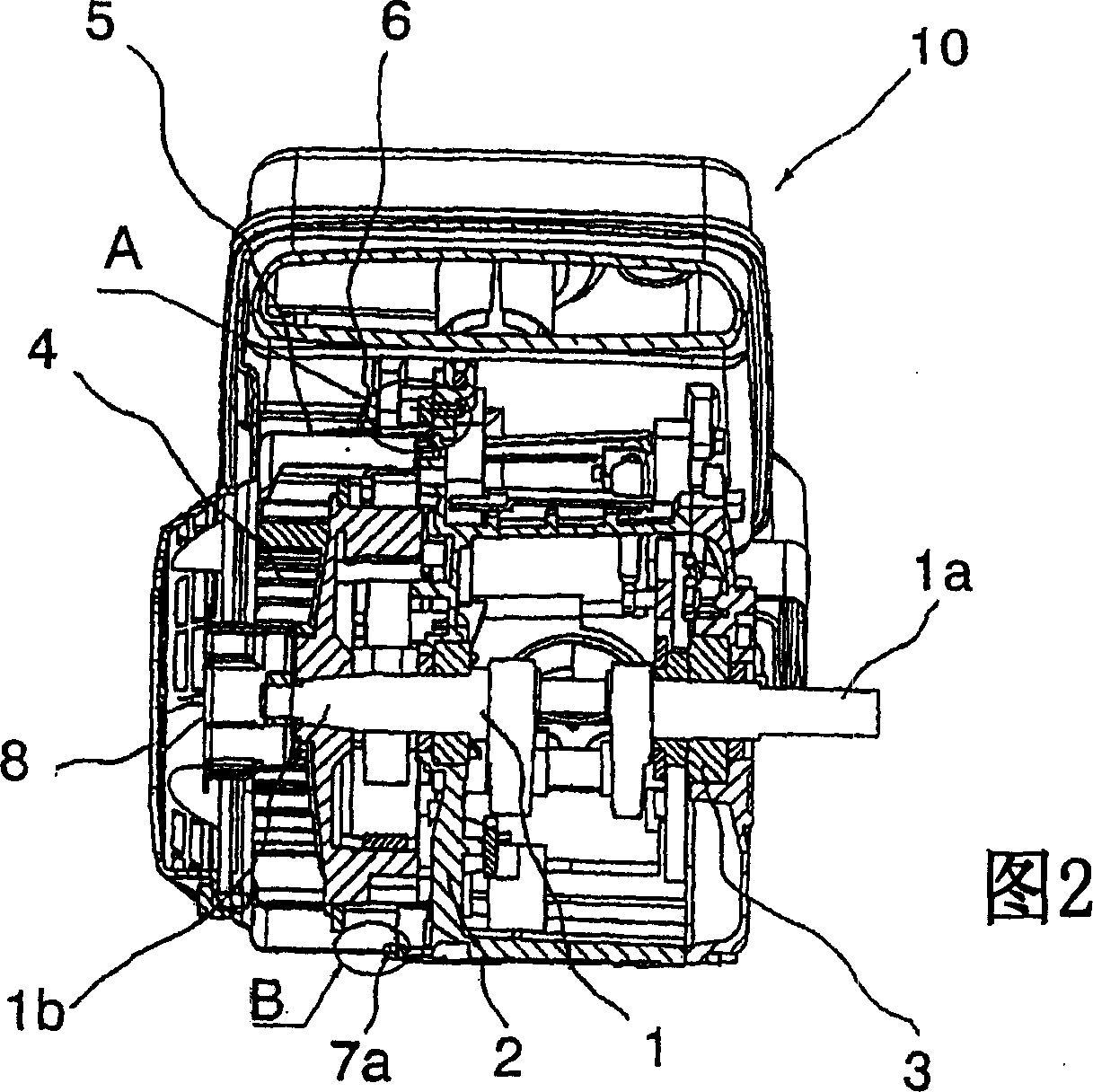

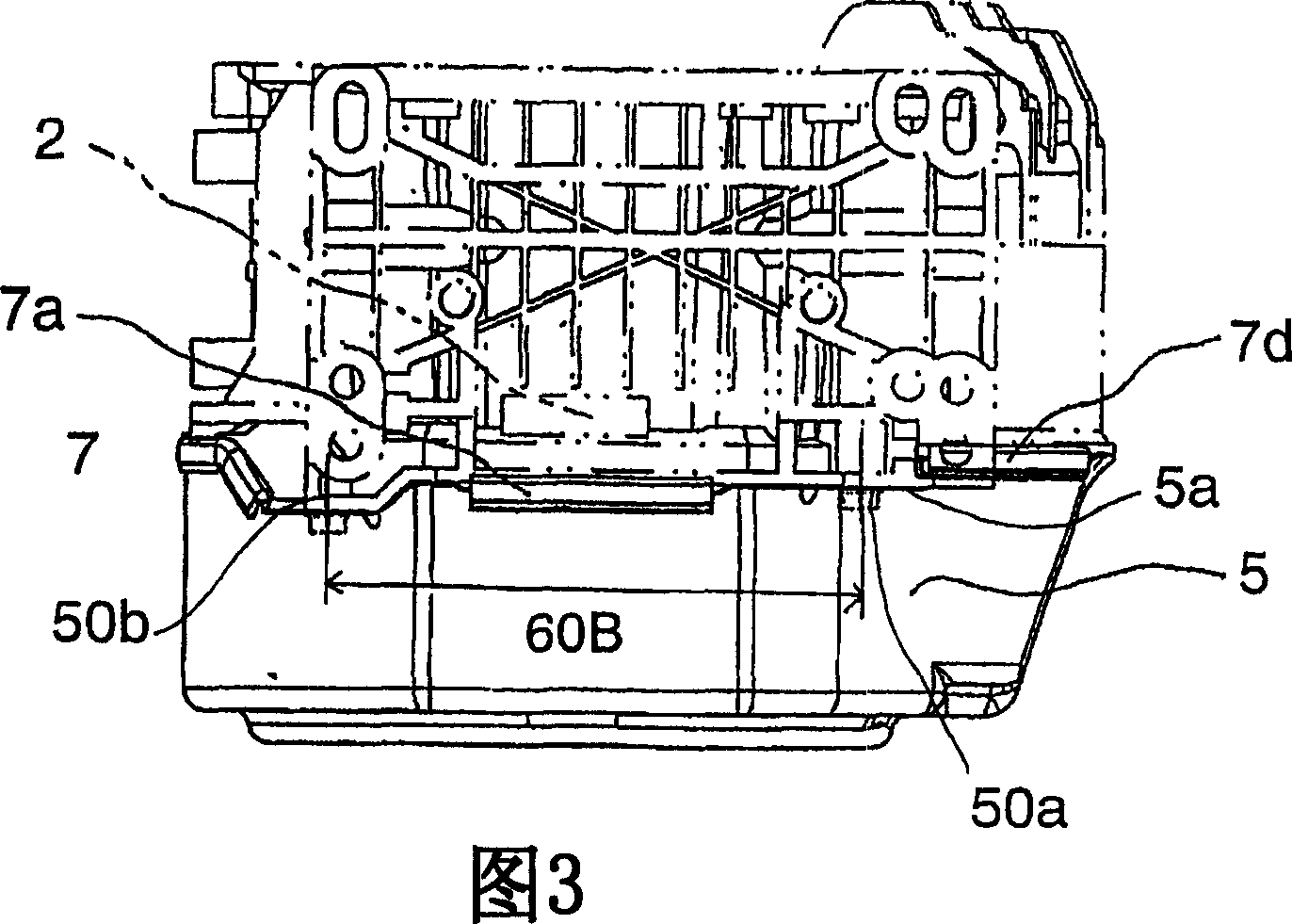

[0040] Embodiments of the present invention will be described with reference to the drawings. FIG. 1 is a front view of a cooling fan cover in a state where a soft vibration-proof member is embedded in a forced air-cooled engine, showing the inner surface of the fan cover viewed from the cylinder block side. Fig. 2 is a side sectional view of a forced air-cooled engine, including detailed parts and showing a cooling fan cover to which the present invention is applied in thick solid lines. Fig. 3 is a bottom view of the cooling fan cover of Fig. 1 seen from the S direction. FIG. 4 is also a side view of the cooling fan cover viewed from the N direction. FIG. 5 is also a side view of the cooling fan cover viewed from the W direction.

[0041] FIG. 6 is a vibration model showing a component of the cooling fan cover to facilitate understanding of the mode of resonance between the cooling fan cover and the engine to which the present invention is not applied. FIG. 7 shows a vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com