Coal powder boiler straight-flow burner igniting device

A pulverized coal boiler and ignition device technology, which is applied in the direction of combustion ignition, burner, burner for burning powder fuel, etc., can solve the problem of waste of ignition fuel oil, etc., achieve obvious fuel saving effect, simple structure, and wide industrial application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

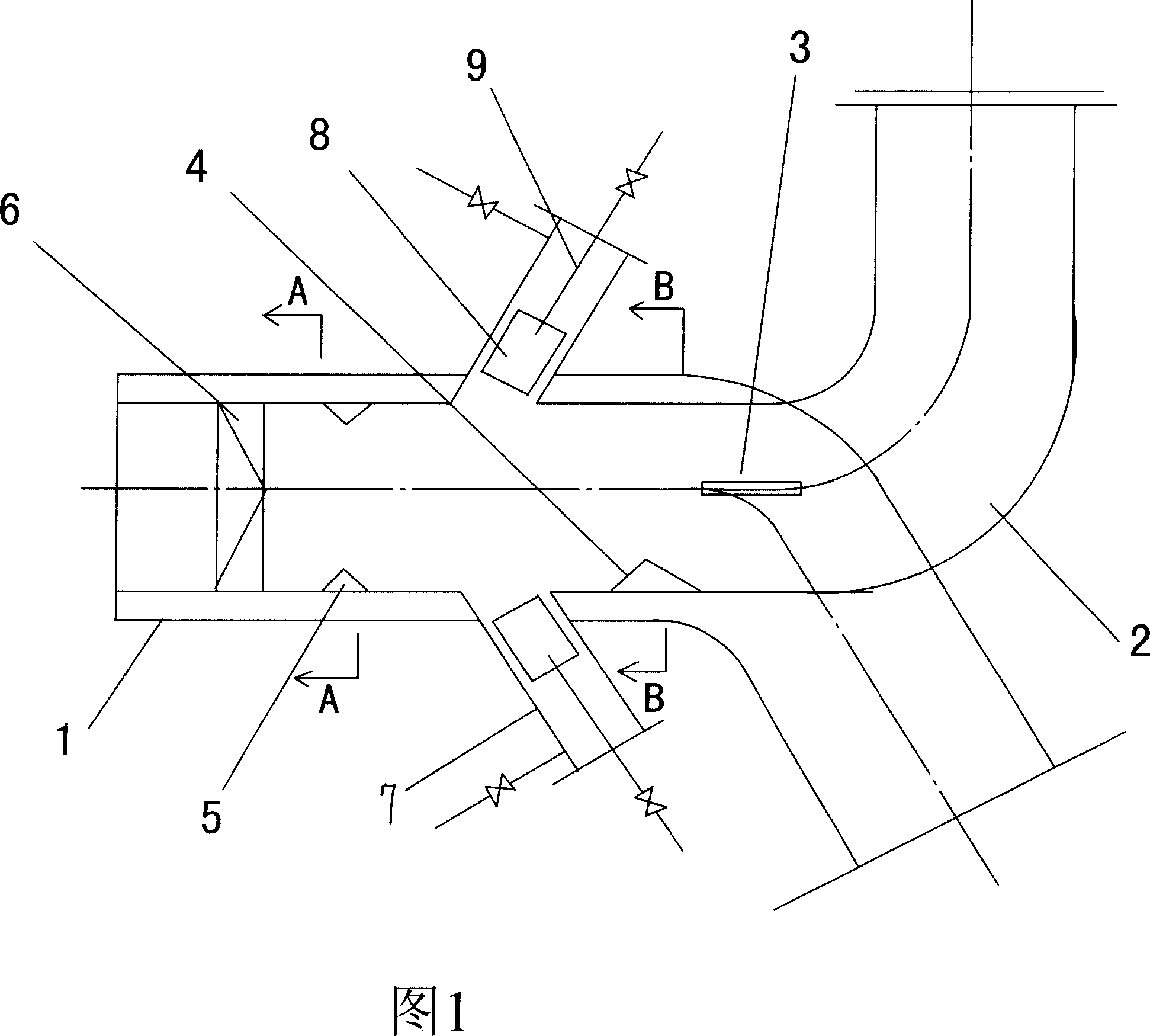

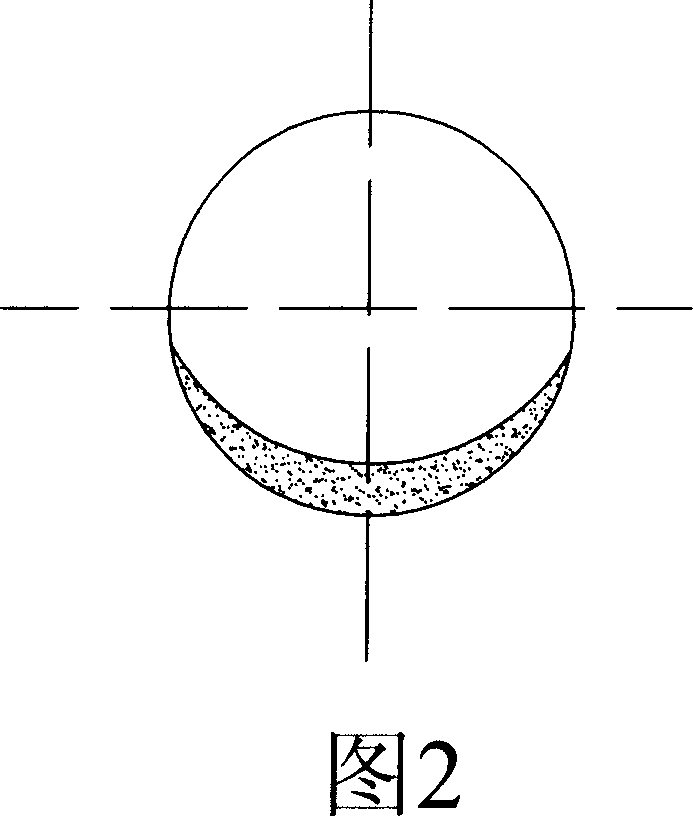

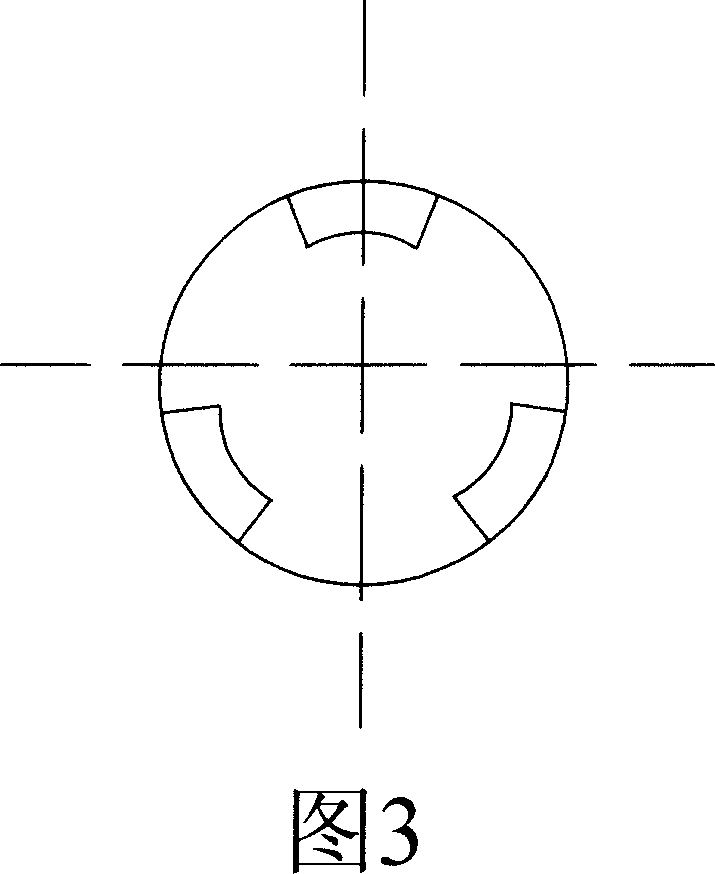

[0015] The ignition device of the direct current burner of the pulverized coal boiler includes the burner body 1 and the primary air pipe 2. The burner body 1 and the primary air pipe 2 are fixedly connected. Square opening. A separation partition 3 is welded in the primary air duct 2, and a crescent-shaped guide block 4 is welded on the front end of the separation partition 3 on the inner wall of the burner body 1, and three phases are welded on the inner wall of the front part of the burner body 1. The 120° stable combustion flap 5, the front part of the burner body 1 is fixed with a sky garden place 6, and the side wall of the burner body 1 is located between the guide block and the stable combustion flap 5. There are two mutually symmetrical and facing Rear inclined oil gun barrel 7, two oil gun barrels 7 are fixedly equipped with a combustion tube 8 respectively, and a small oil gun 9 is inserted in the combustion tube 8, and the small oil gun 9 inserts in the combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com