Elliptically polarizing plate and method of producing the same

A technology of ellipsoidal polarization and polarizer, which is applied in the field of manufacture of the elliptical polarizer, can solve the problems of reduced output, reduced productivity, difficulty in high precision, etc., and achieves the effects of reduced thickness, good production efficiency and good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

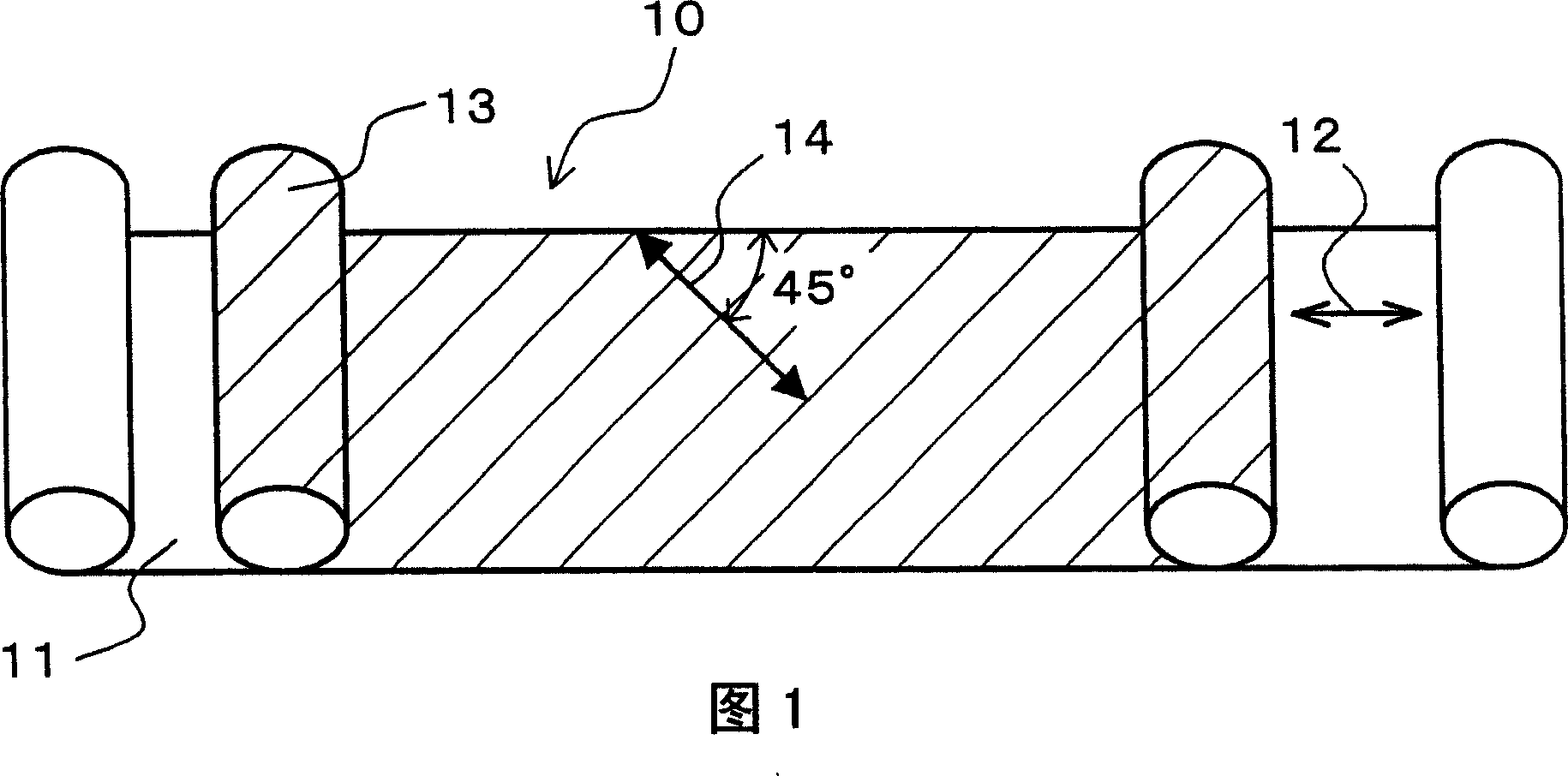

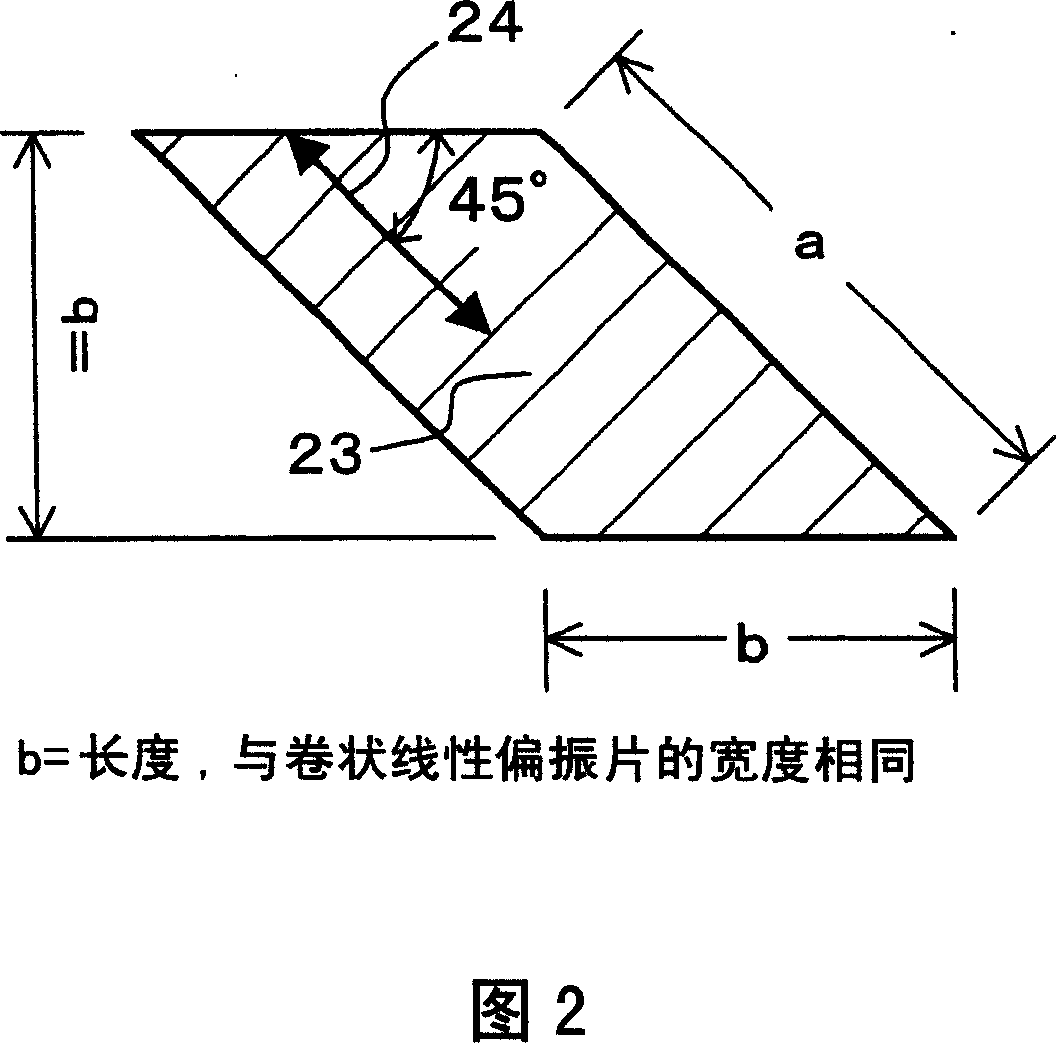

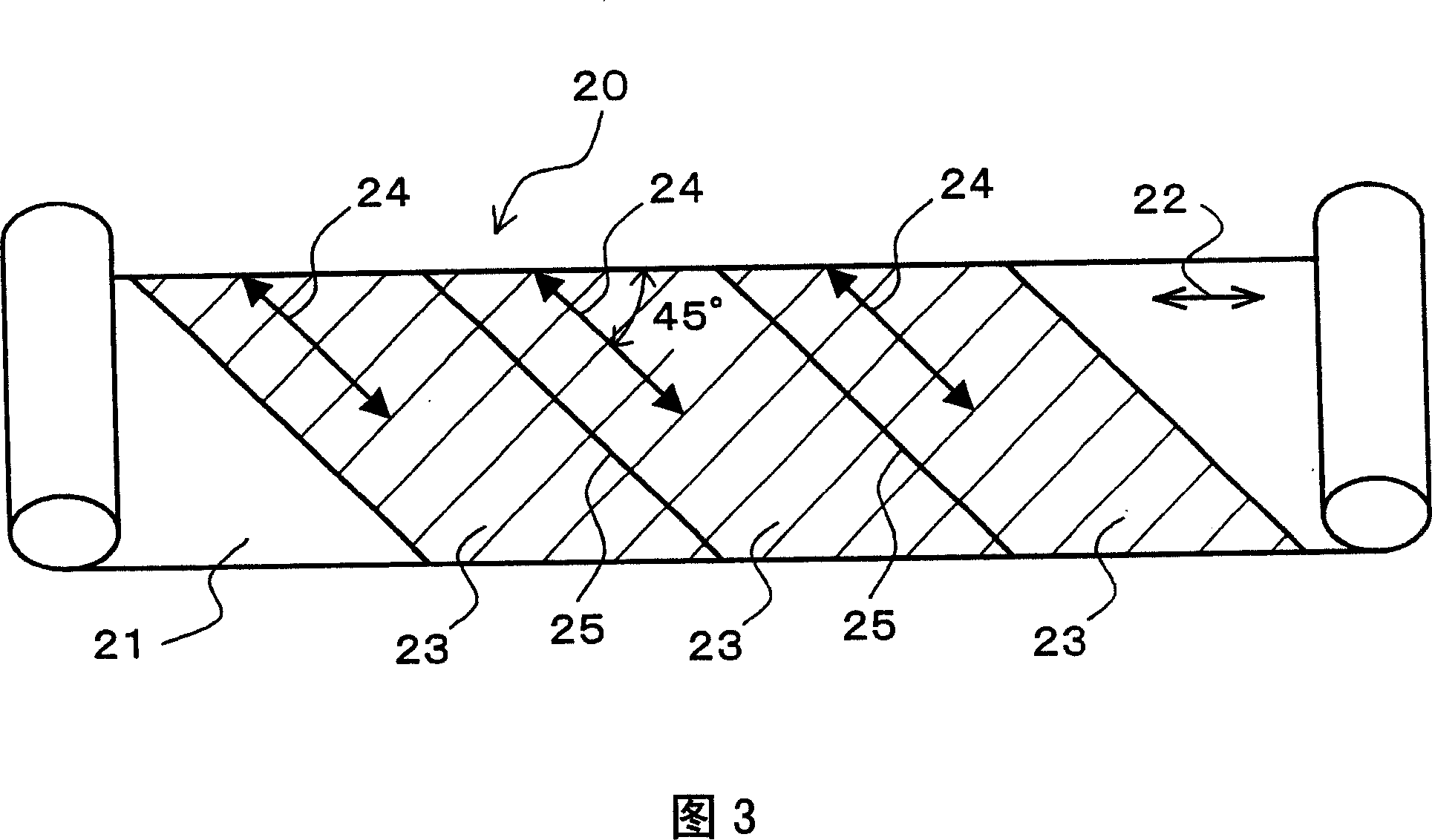

[0076] (a) Rolled 1 / 4 wave plate

[0077] A photo-alignment layer is used to directionally polymerize the liquid crystal compound along one side of a roll-shaped substrate that is obtained by saponifying a triacetyl cellulose film with a thickness of 80 μm ("Fujitac TF80UL", available from Fuji Photo Film Co. , Ltd.) and produced a roll-shaped quarter-wave plate having a slow axis in a direction inclined at an angle of 45°C in the film plane relative to the longitudinal direction of the roll-shaped transparent substrate .

[0078] (b) Rolled linear polarizing film

[0079] Using a dry method, a rolled polyvinyl alcohol film with a thickness of 75 μm, an average degree of polymerization of about 2,400 and a degree of saponification of 99.9 mol% or more is uniaxially stretched at a stretching magnification of 5 times, and then the strain is maintained while , Immerse in an aqueous solution of iodine / potassium iodide / water with a weight ratio of 0.05 / 5 / 100 at 28°C for 60 seconds. The...

Embodiment 2

[0085] When the rolled elliptically polarizing plate (width 100 mm × length 5 m, the longitudinal direction is parallel to the absorption axis of the linear polarizing plate) obtained in Example 1, the sheet-shaped elliptical polarizing plate (length 100 mm × width 50 mm) is cut so that the length direction is in the linear polarization In the direction of the absorption axis of the sheet, 100 elliptically polarizing sheets without joints can be cut out. In this embodiment, the extraction efficiency R calculated by the above formula (1) is 100%.

Embodiment 3

[0087] When the rolled elliptically polarizing plate (width 100 mm × length 5 m, the longitudinal direction is parallel to the absorption axis of the linear polarizing plate) obtained in Example 1, the sheet-shaped elliptical polarizing plate (length 50 mm × width 50 mm) is cut so that the length direction is in the linear polarization In the direction of the absorption axis of the sheet, 200 elliptically polarizing sheets without joints can be cut out. In this embodiment, the extraction efficiency R calculated by the above formula (1) is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com