Temperature difference generator welding method

A technology of thermoelectric generator and welding method, which is applied in the direction of welding equipment, circuits, semiconductor devices, etc. It can solve the problems affecting the thermoelectric conversion efficiency, life of the generator, large single contact resistance, poor joint strength, etc., and achieve high reliability , Low welding contact resistance, good welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

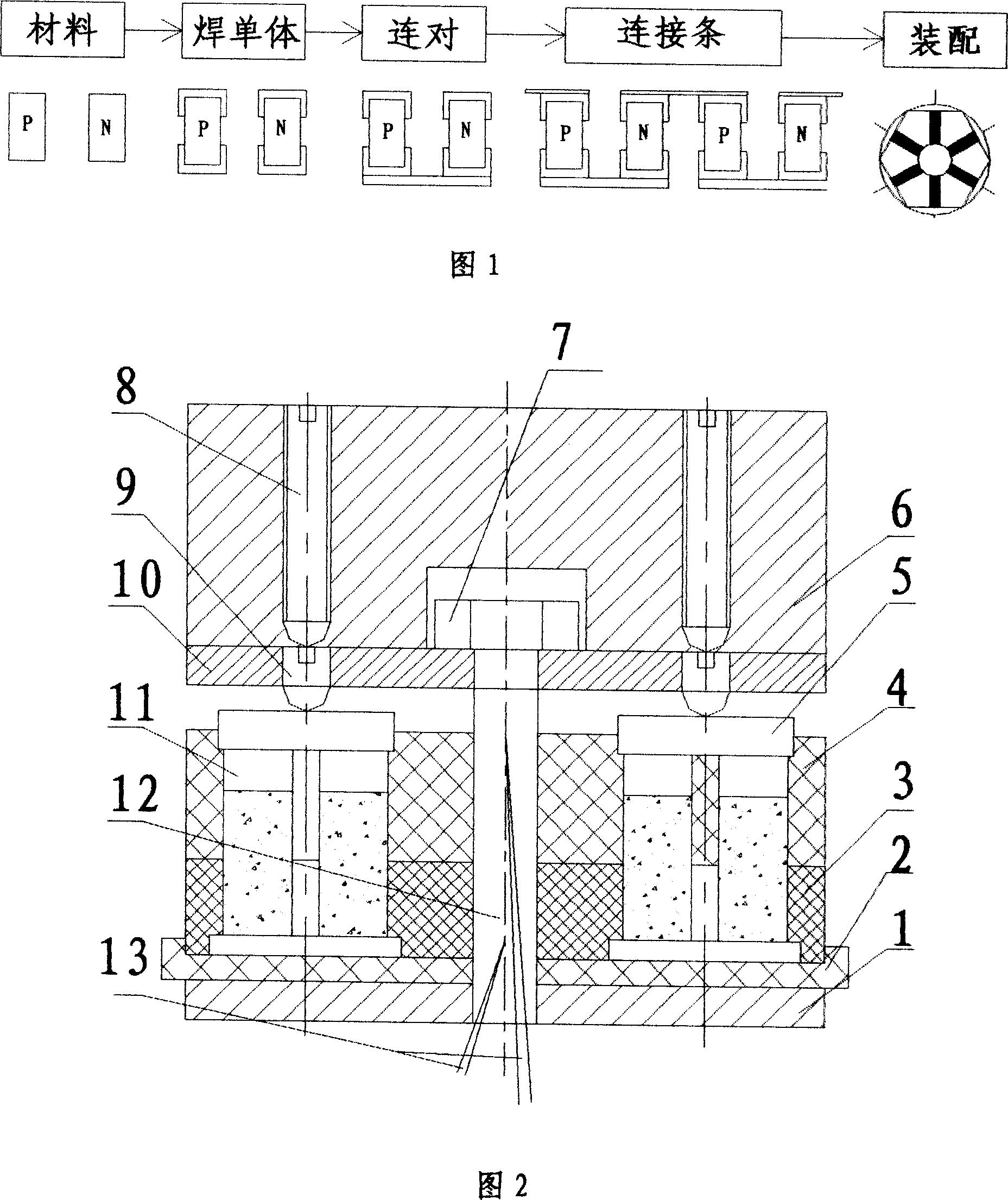

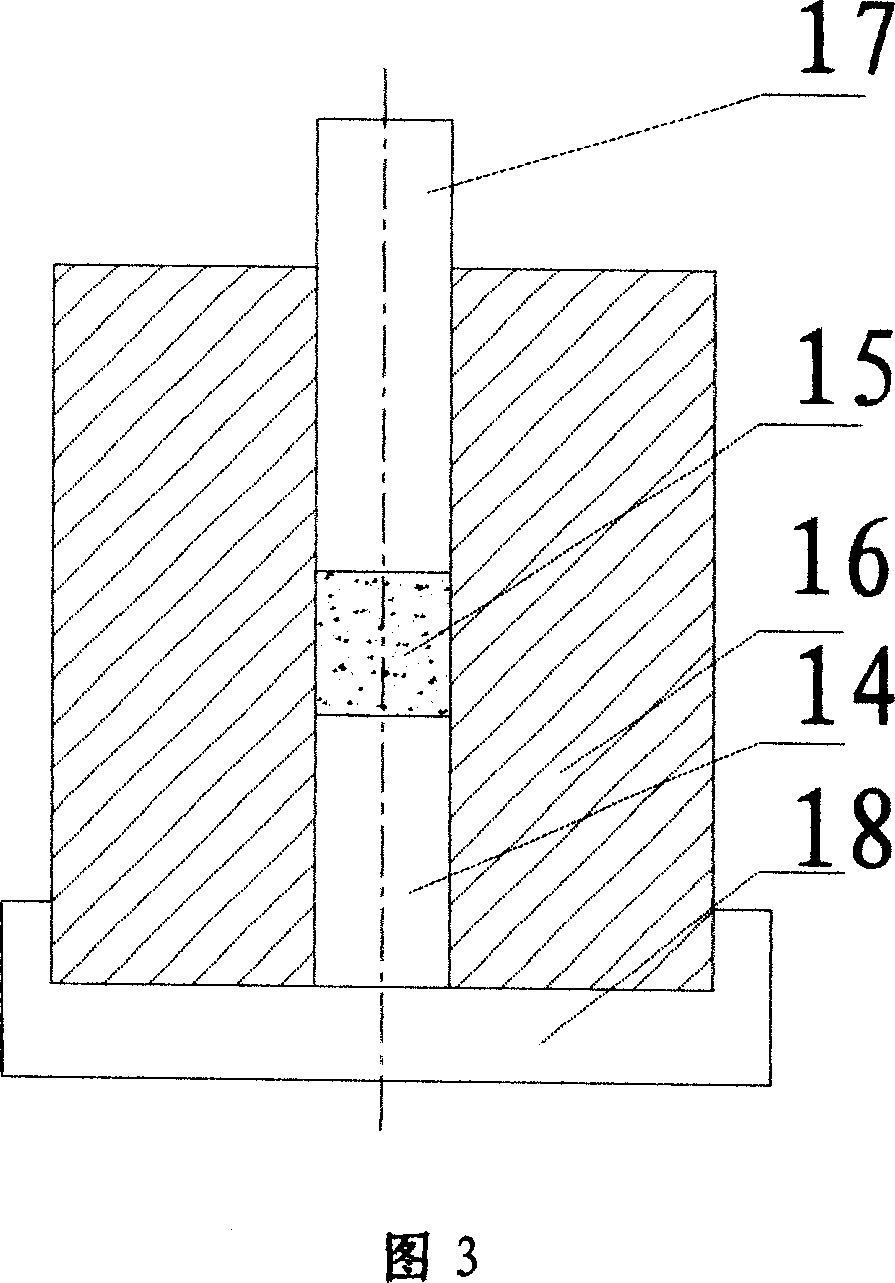

[0013] Embodiment 1: Referring to accompanying drawings 1-3, as shown in Figure 1, the welding method flow chart is to first press out the material as shown in Figure 3: that is, first put the mold lower pressure head 14 into the mold 16, and the mold 16 is placed on the mold bottom support 18, then pour the weighed solder powder 15 into the mold 16, vibrate slightly, then install the mold upper pressure head 17, turn clockwise for 2 to 3 circles, put it on the hydraulic press, and apply pressure. Hold the pressure for 1 minute, demoulding and forming; the method of welding the single body is to put the pressed N-type material into the lower electrode on the thermoelectric generator welding device described in Figure 2, and then put the central tube 12 and the positioning plate 10 and The briquette 6 is put into the furnace for one welding, and then taken out after welding; the connecting method is: put the diversion copper sheet into the lower mold cavity 3, cover the tray 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com