Optimizing method for preventing and controlling scrab in cold band-steel continuous milling machine

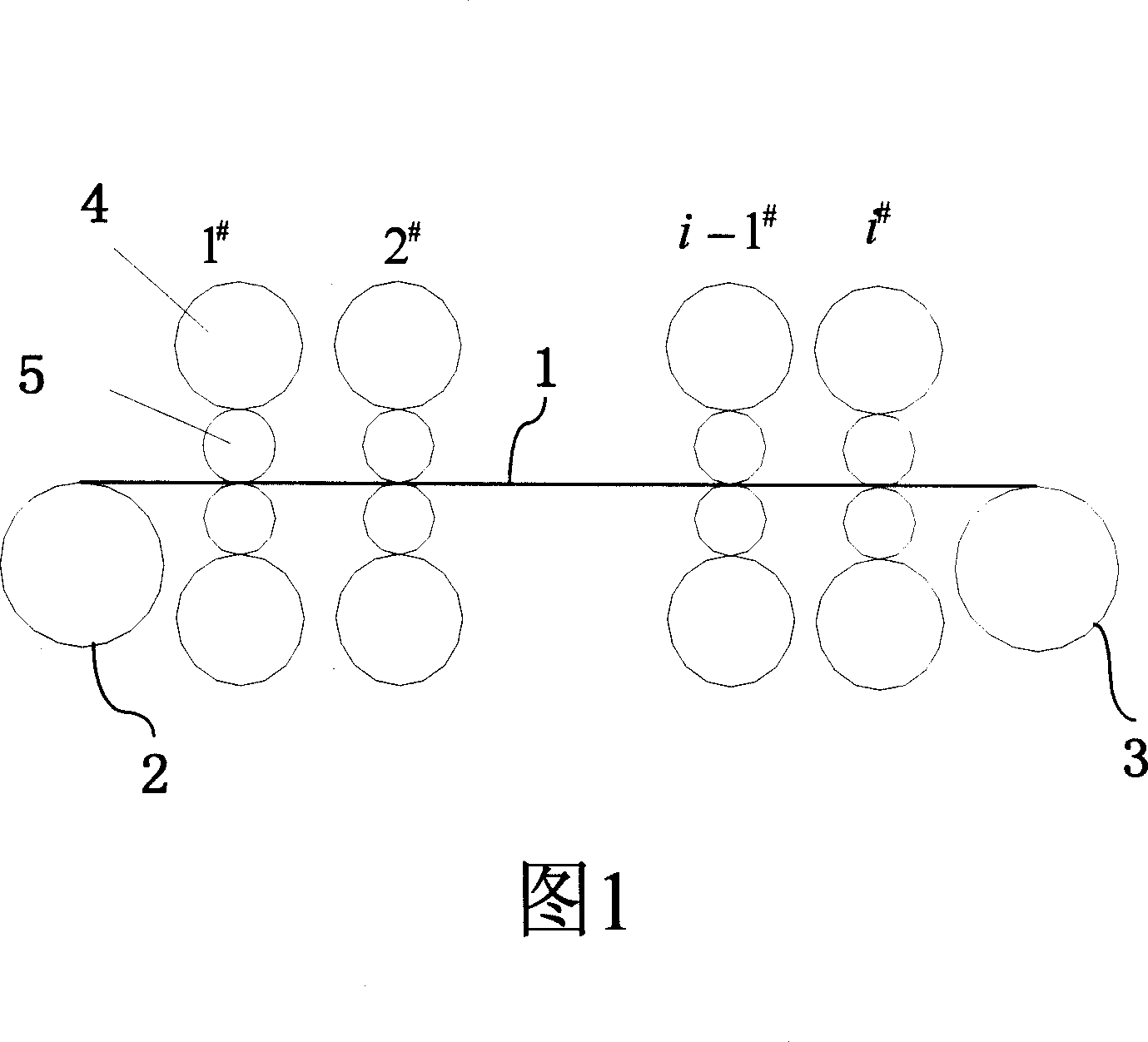

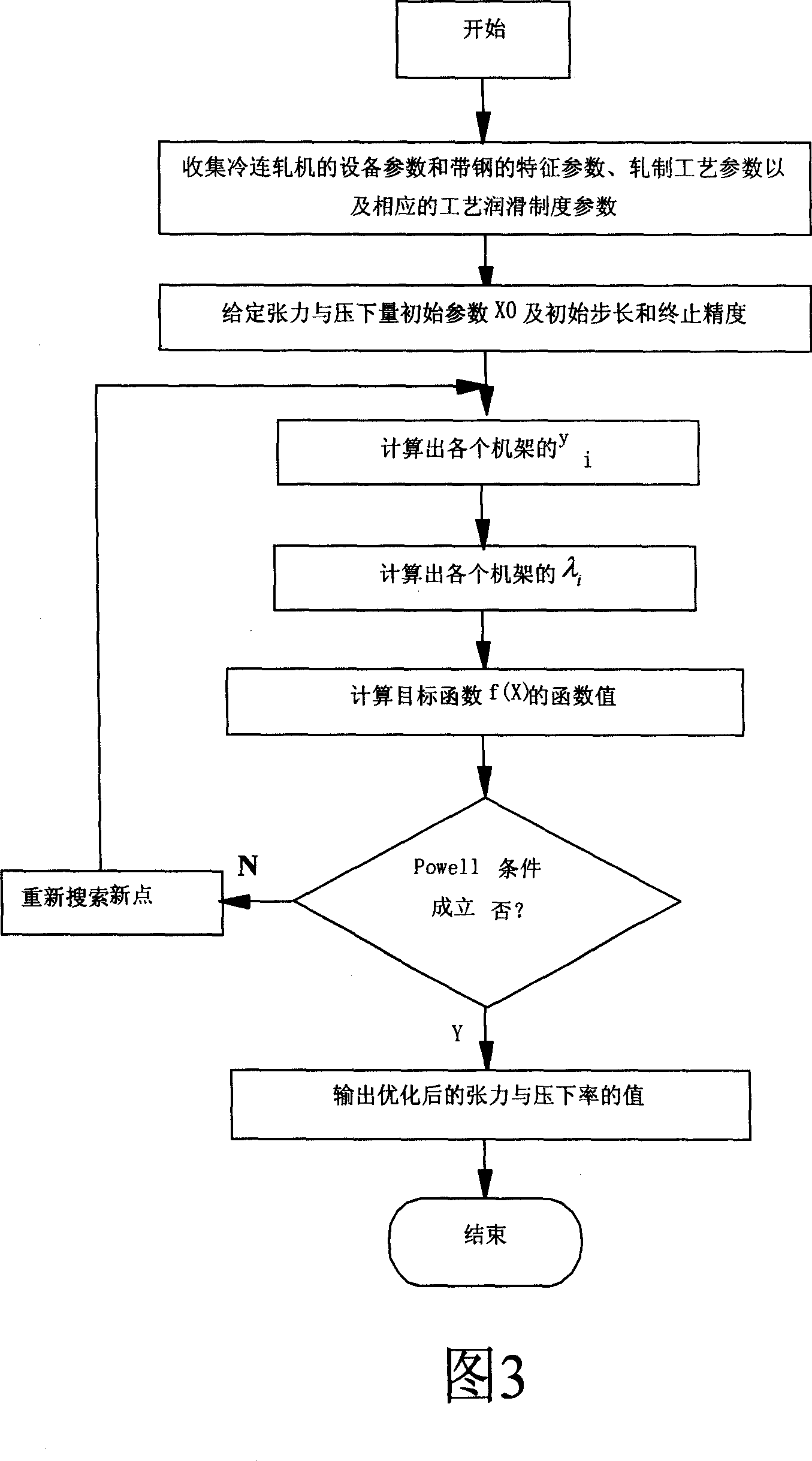

An optimization method and technology for a tandem cold rolling mill, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of not considering scratch prevention and prevention, limiting rolling mill output, judging scrap, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

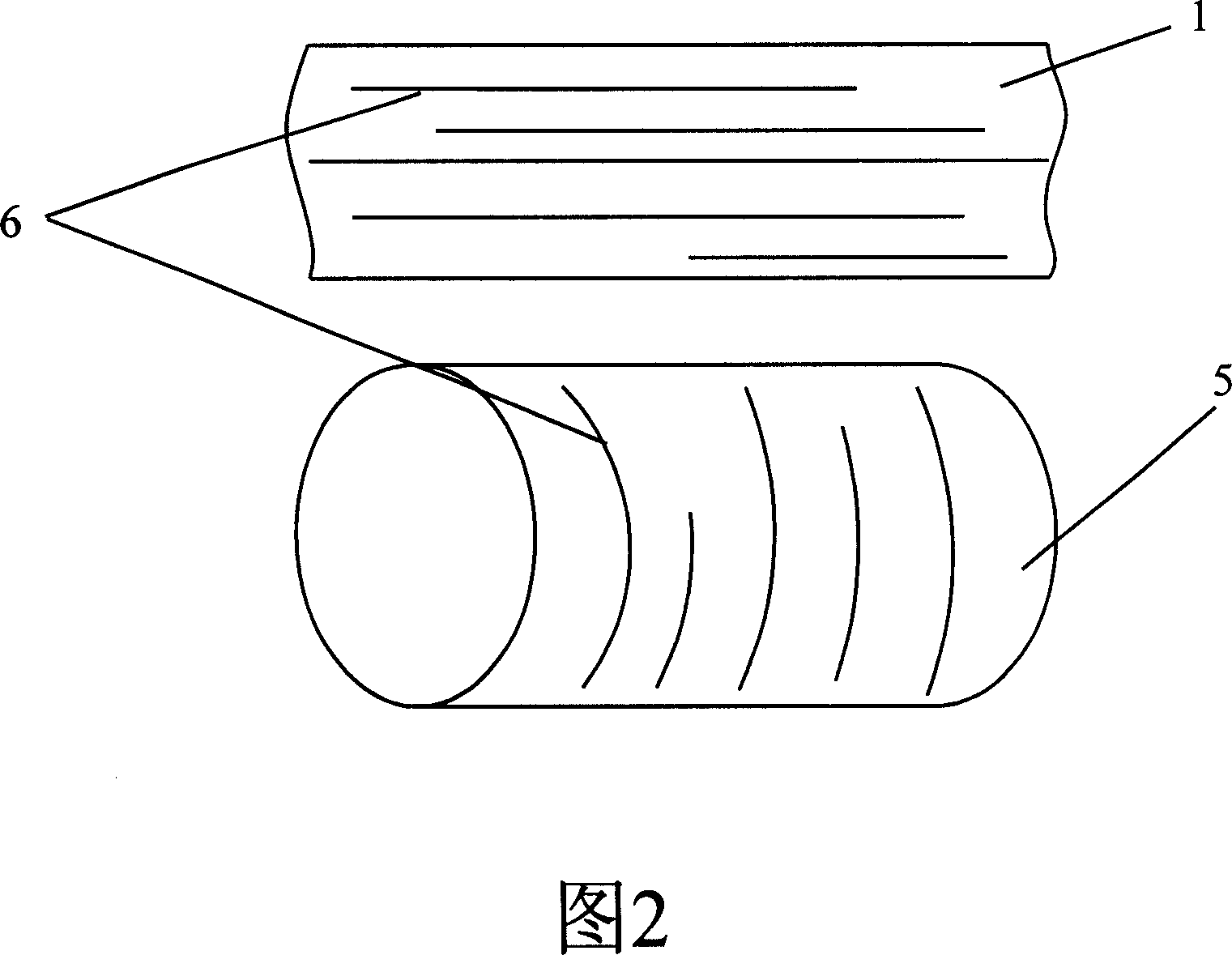

Method used

Image

Examples

Embodiment

[0090] (1) Collect the required equipment and strip raw data

[0091] Cold tandem mill equipment parameters: work roll diameter D w1 =550 / 500mm; D w2 =533.4(~535) / 470mm; D w3 =533.4(~535) / 470mm; D w4 =533.4(~535) / 470mm; D w5 =533.4(~535) / 470mm

[0092] Working roll original roughness: Ra 1 =0.60μm; Ra 2 =0.58μm; Ra 3 =0.56μm; Ra 4 =0.43μm; Ra 5 =0.38μm

[0093]Rolling kilometers of working rolls: L w1 =80Km; L w2 =80Km; L w3 =80Km;L w4 =80Km;L w5 =80Km

[0094] Product variety specification range: strip width 1000mm, entrance thickness 1.8mm, exit thickness 0.195mm, steel type is MRT3

[0095] (2) Selection of rolling process parameters

[0096] The exit rolling speed of the last stand of the cold tandem mill is set at 1600m / min

[0097] (3) The room temperature viscosity of the lubricant at one atmospheric pressure is 80, the viscosity pressure coefficient of the lubricant is 50, and the viscosity temperature coefficient of the lubricant is 0.2

[0098] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com