Process for producing transmission cable

A manufacturing method and transmission cable technology, applied in cable/conductor manufacturing, printed circuit manufacturing, insulated cables, etc., to achieve the effects of eliminating noise, reducing manufacturing costs, and suppressing connection resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the transmission cable to which the present invention is applied and its manufacturing method will be described in detail with reference to the accompanying drawings.

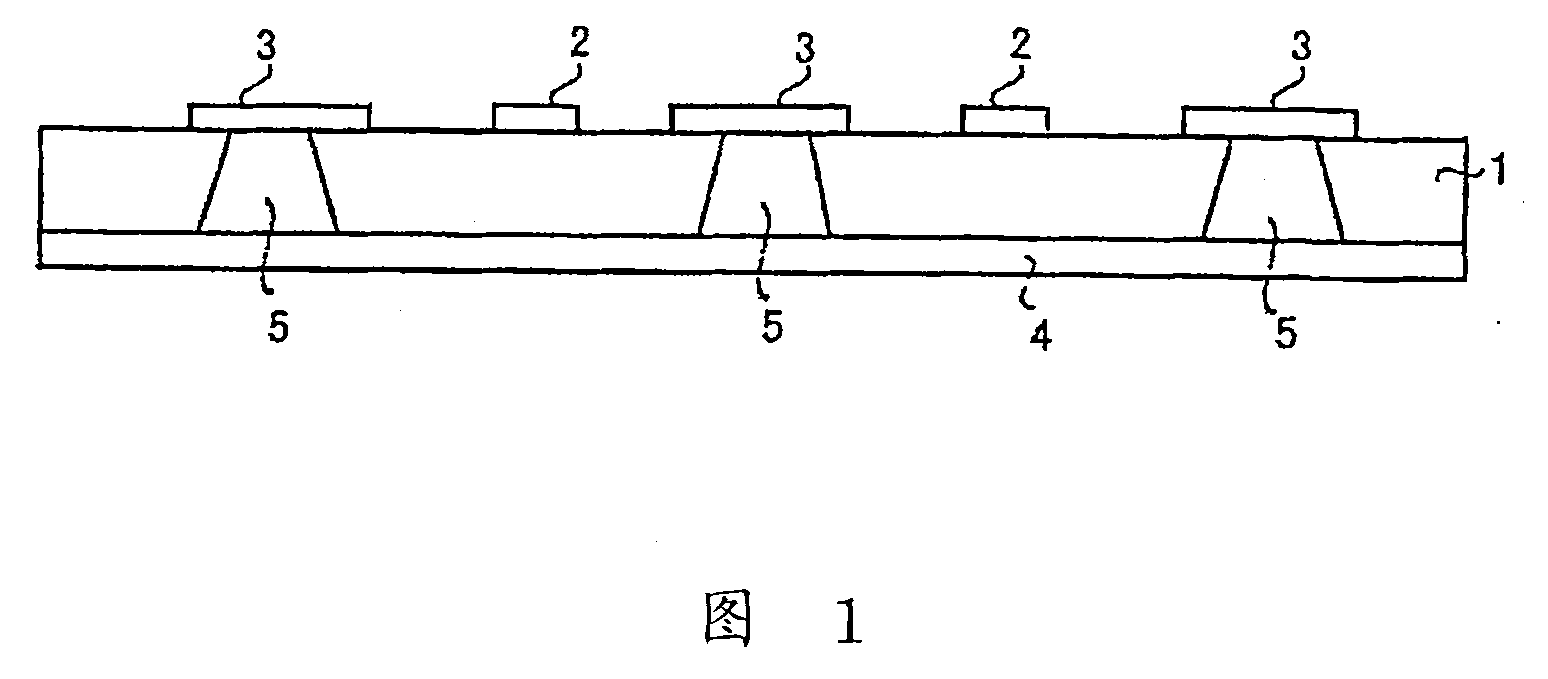

[0022] figure 1 It is a figure showing the structure of the transmission cable to which this invention is applied. In this transmission cable, a signal line 2 is formed on one surface, here, an upper surface, of an insulating layer 1 serving as a substrate, and a ground line 3 is formed thereon. The signal line 2 is used to transmit various signals such as transmission data, and constitutes the center of the transmission cable.

[0023] In this signal line 2, malfunctions due to the entry of noise become a problem, and, as shown in this example, when a plurality of (two) signal lines 2 are formed, the mutual interference between the signal lines 2 become a problem. Therefore, in the transmission cable of this embodiment, the ground wire 3 is provided between these signal wires 2 to elimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com