Automatic offal untie method and device

A tobacco stem and automatic technology, which is applied in the field of tobacco product processing equipment, can solve the problems of uncoordinated highly automated cigarette production process, harsh production environment, and high labor intensity, so as to improve automation procedures, reduce production costs, and reduce labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

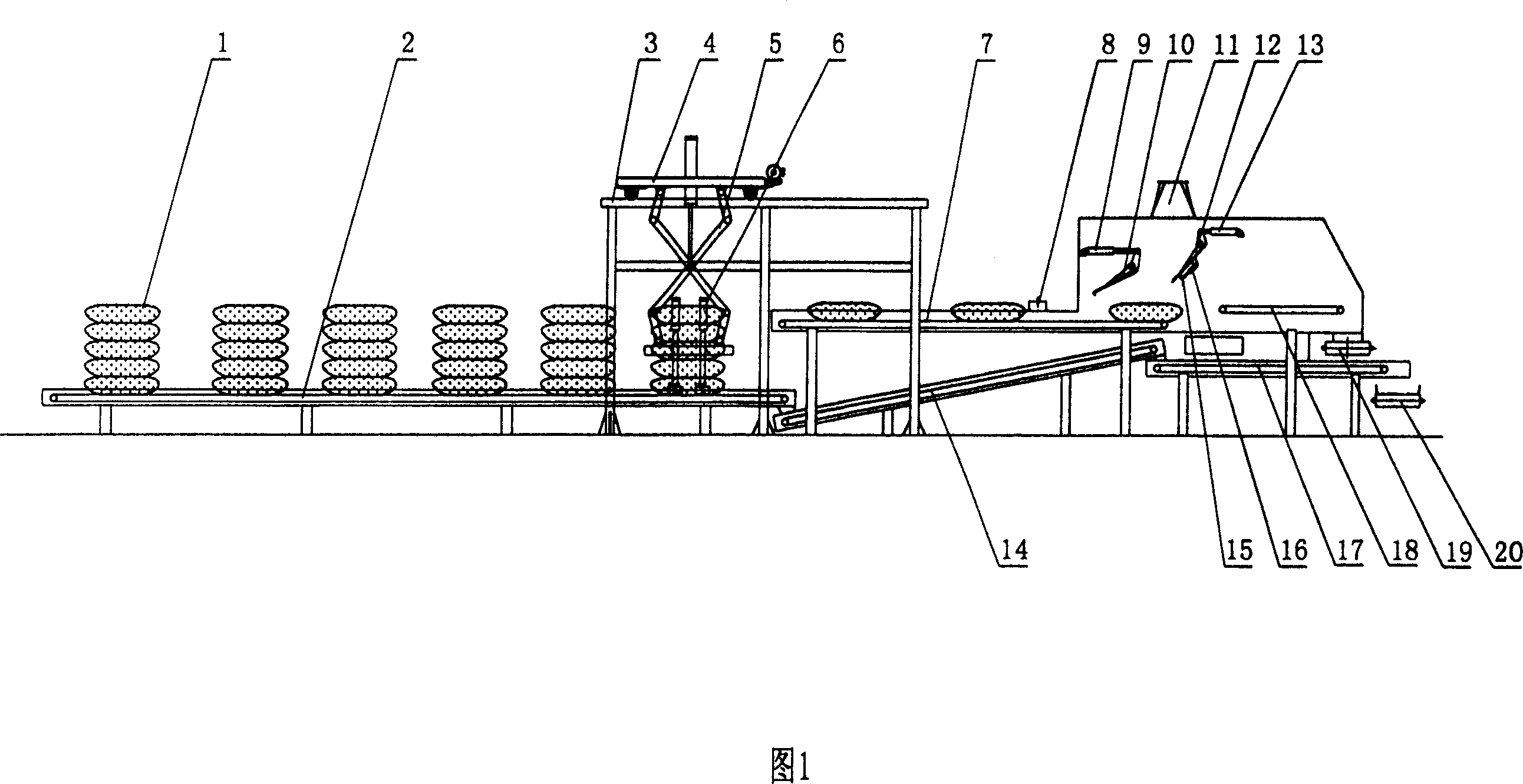

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Accompanying drawing 1 is an embodiment of the present invention, and its structure comprises:

[0031] The first stage sack conveyor belt 2, the end of the sack conveyor belt is located in the working area of the bag lifting mechanism;

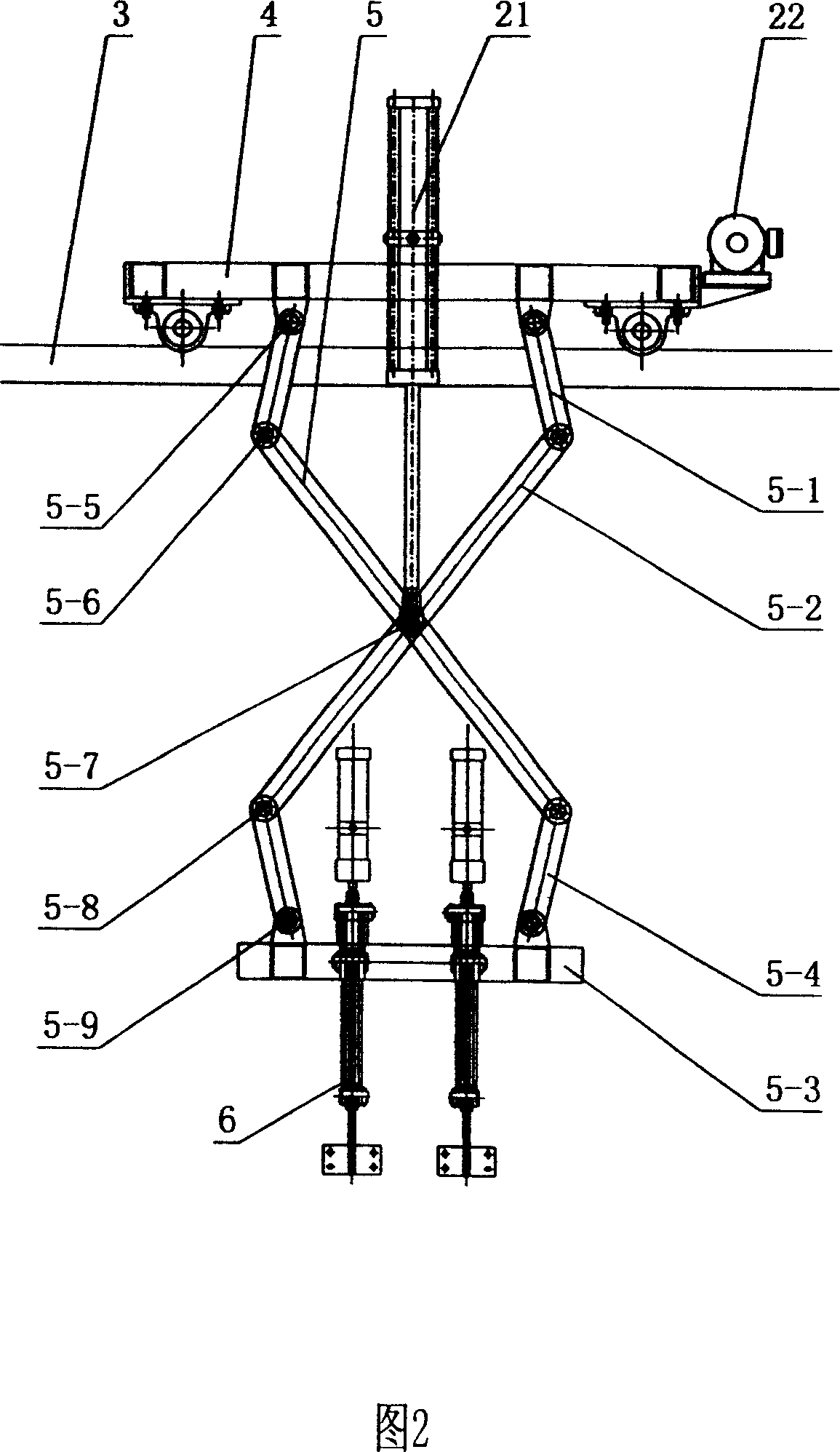

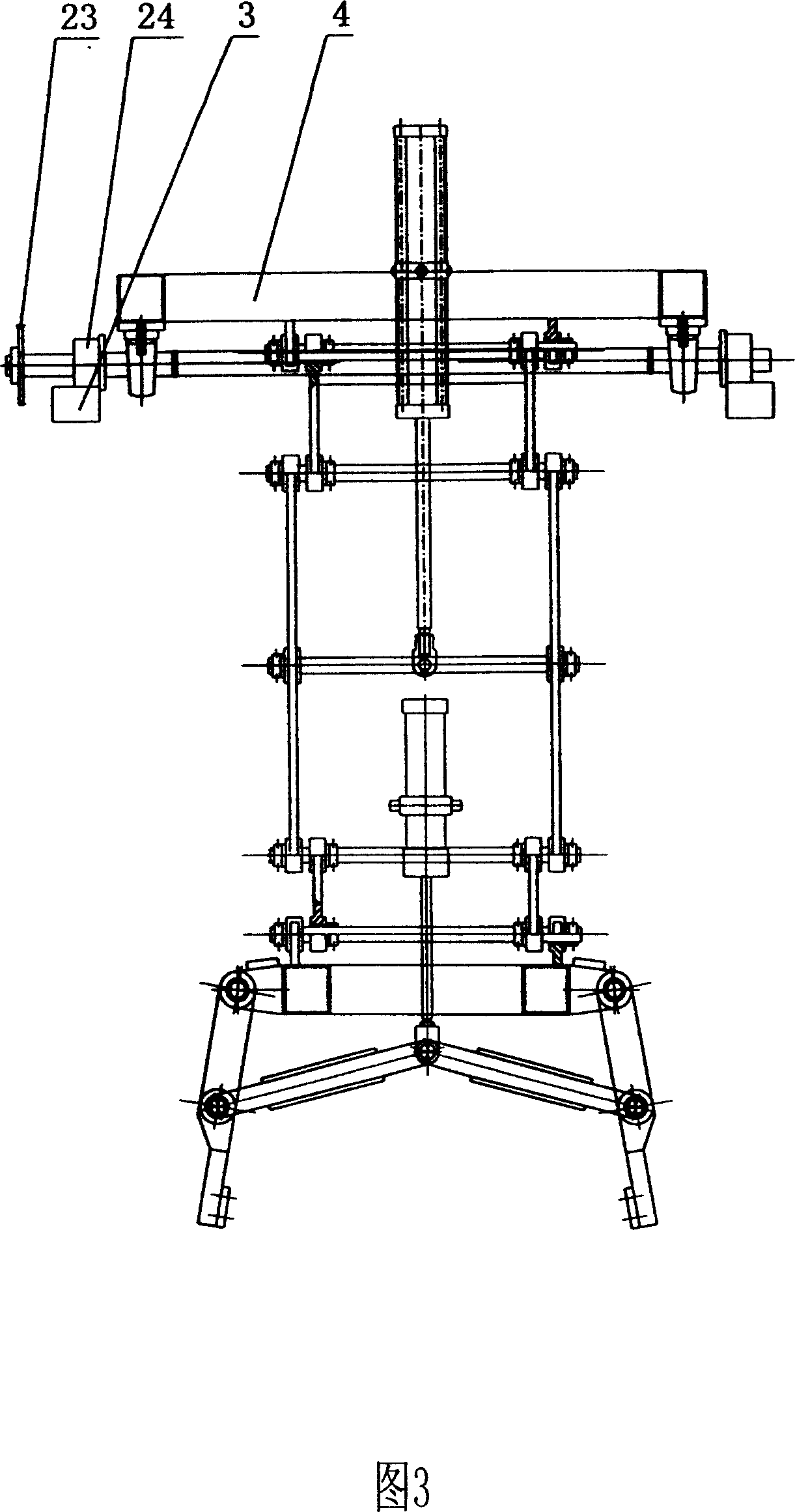

[0032] The clamping lifting mechanism includes a clamping mechanism 6 and a lifting mechanism 5. Clamping mechanism 6 is movably fixed (by rotating shaft 6-1) on the left and right clamping arm beams 5-3 by the ends of two pairs of clamping arms 6-2, and every pair of clamping arms 6-2 middle part passes through rotating shaft 6-3 respectively and One end of the two tension arms 6-1 is movably connected, and the other end of the two tension arms 6-1 is movably connected with the piston end of the cylinder 25 provided above the rotating shaft 6-5 to form the clamping mechanism 6; Lifting beam 5-2 and its fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com