Sintered powder confection

A powder, sintering technology, used in confectionery, food preparation, food science, etc., can solve problems such as brittleness, product hardness, dryness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

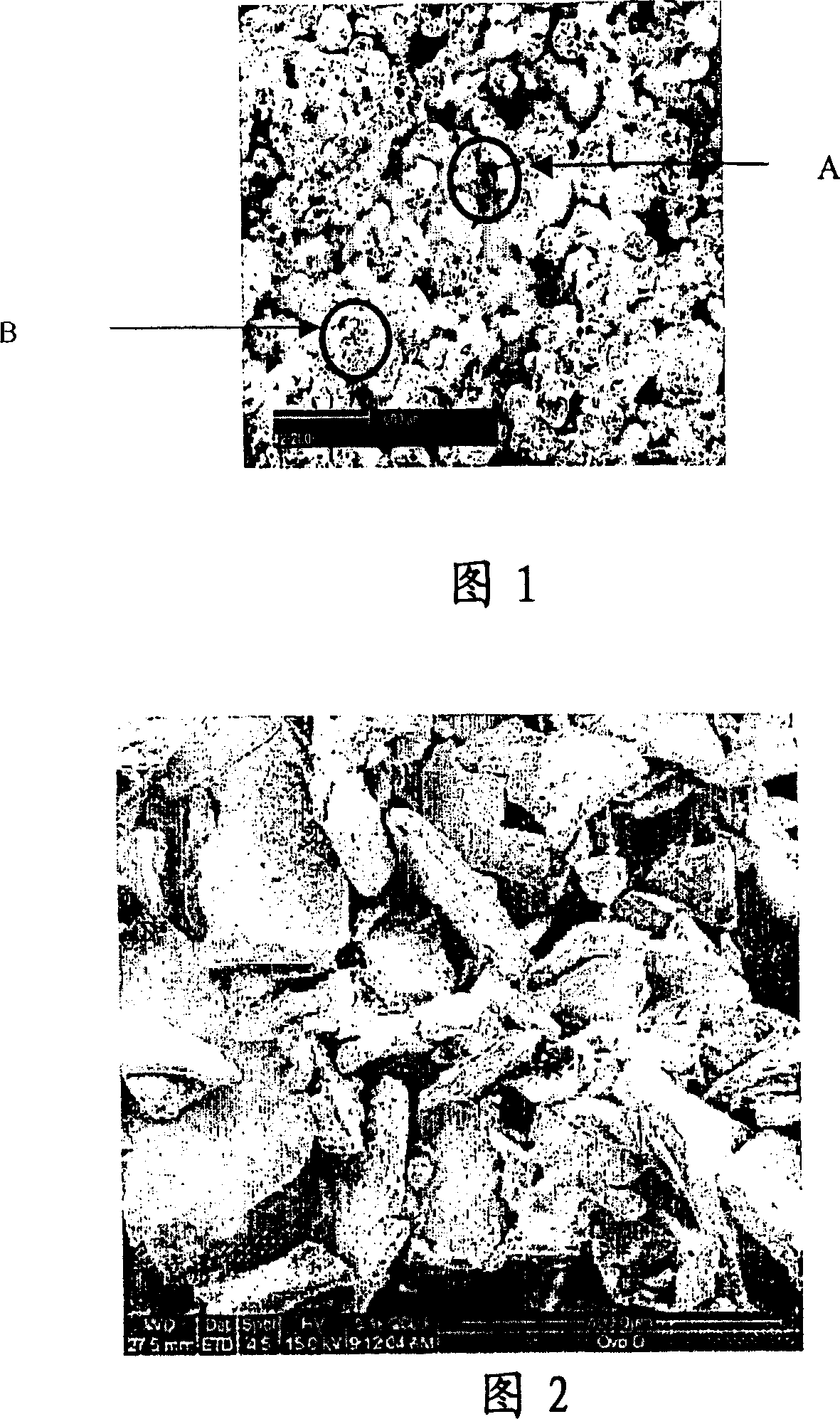

[0053] The sweetened milk mixture foam was spray dried using a nitrogen sparge, resulting in a low density and highly porous (30-70% closed porosity) spray dried sweet milk powder. The initial formulation of the sweetened milk mix was 70% whole milk powder, 15% sucrose and 15% maltodextrin (dry basis). Conventional molds are then loosely filled with this powder. The mold was covered and heated in a convection oven to raise the temperature of the powder above its glass transition temperature (Tg). No compaction is performed prior to heating. The oven temperature was set at 280°F (about 137°C) and the dessert was placed in the oven for about 10 minutes. Cool the confection and remove it from the mold.

[0054] The crumb or confectionery center is then coated with traditional chocolate or a variety of compound coatings.

[0055] The final product is lightweight and quickly dissolves in the mouth, and is non-stick. It provides high levels of milk solids (75%) and has a fresh ...

Embodiment 2

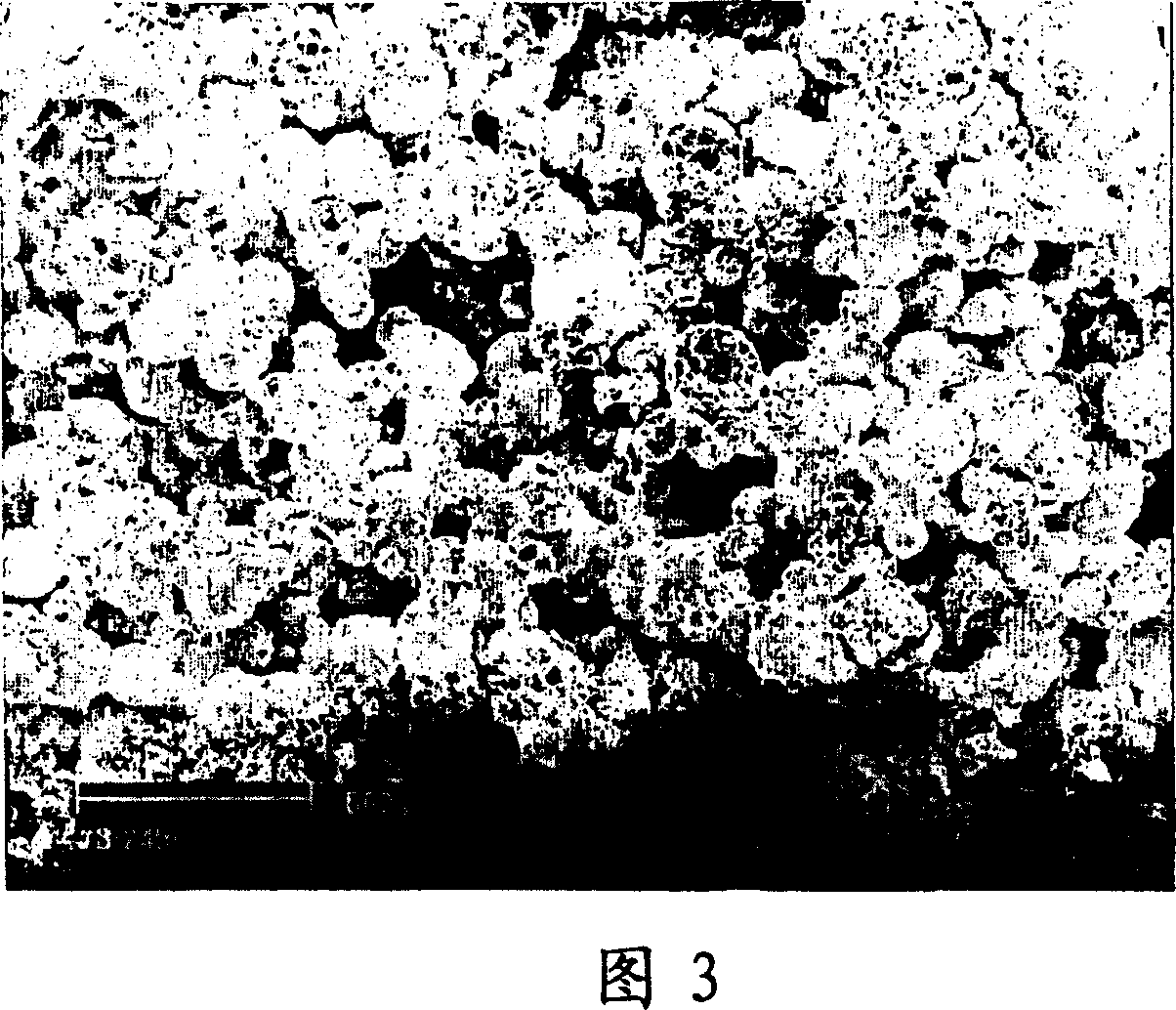

[0057] The dairy-based mixture is dried to produce a low density and highly porous (30-70% closed porosity) powder. The initial formulation of the dairy-based blend was 70% whole milk powder, 0-15% sucrose, and 15-30% low DE corn syrup solids (dry basis). This powder is then loose-filled in conventional molds to produce preformed flakes or preformed individual pieces. The powder is then heated above the glass transition temperature of the powder in a covered mold or by exposing the powder to moist air (12-21% RH (relative humidity)) to sinter the product. No compaction is performed prior to heating. The oven temperature was set at 240°F (about 115.5°C) and the dessert was placed in the oven for about 8 minutes. The confectionary product is then cooled to achieve a solid state. This product is characterized by a density of 0.1-0.6 g / ml, a closed porosity of 15-70%, an open porosity of 10-45%, and a total porosity of 15-90%.

[0058] This crumble or dessert center is then co...

Embodiment 3

[0061] Two or more powders / granules with different physical properties can be used to form unique products. Powders / granules may be amorphous or crystalline (one must be at least partially in the glassy state and one must have a minimum closed porosity such that when the two materials are mixed the mixture has a closed porosity of at least 15%) . Examples of powders include, but are not limited to: milk powder, fruit powder, Nesquik, Milo, flavoring and coloring. The products produced by the following applications are characterized by a density of 0.1-0.6 g / ml, a closed porosity of 15-70%, an open porosity of 10-45%, and a total porosity of 15-90%. This application can be used in the following ways:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com