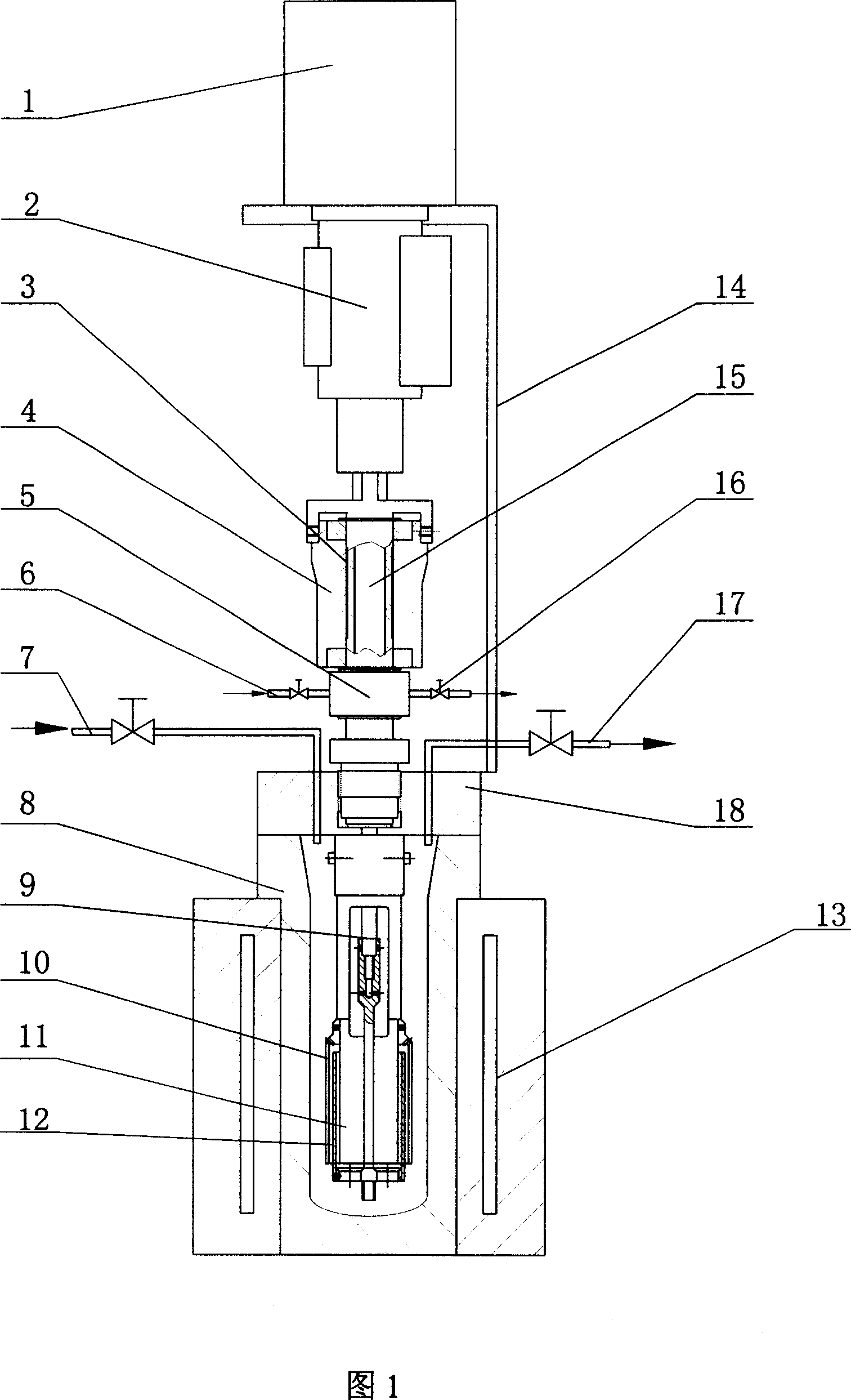

Method and device for detecting high temperature high pressure oil coal slurry rheological characteristic

A technology for measuring devices and rheological properties, applied in flow properties, measuring devices, instruments, etc., can solve problems such as inability to guarantee measurement accuracy and the impact of falling columns, and achieve prevention of coal powder deposition, wide viscosity measurement range, and frictional resistance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

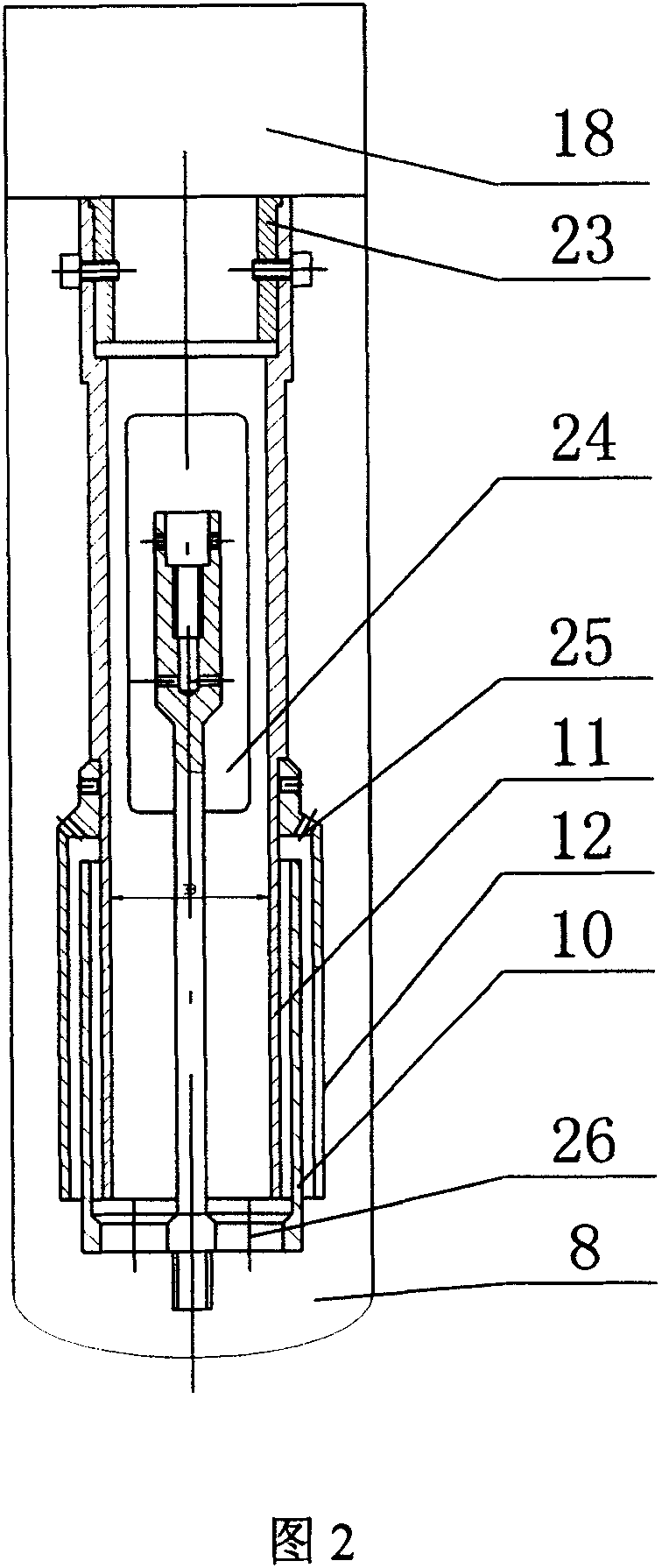

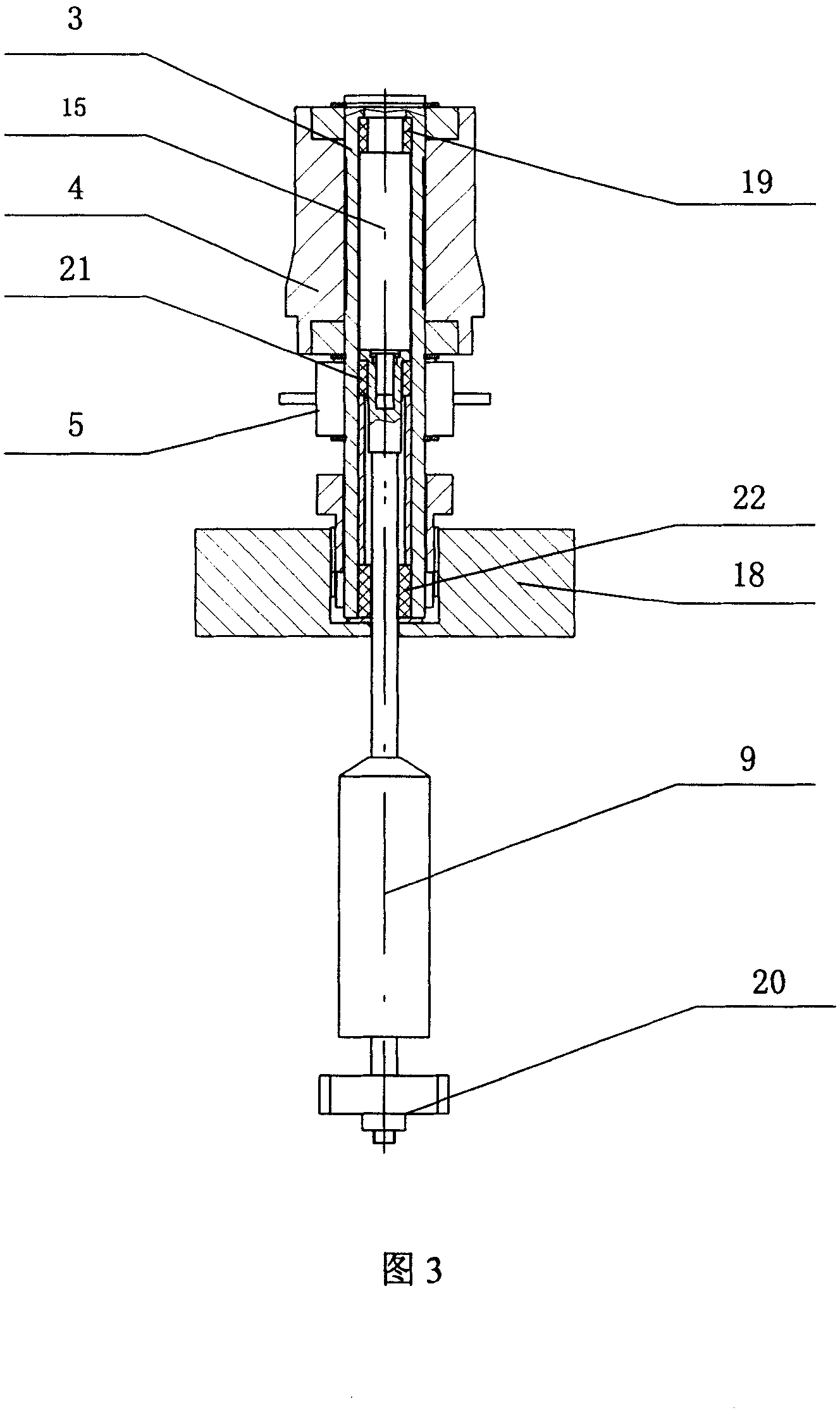

[0028] A method for measuring the rheological properties of high-temperature and high-pressure oil-coal slurry. The method includes the following steps:

[0029] First, coal powder (particle size <0.15mm), solvent (usually heavy oil produced by coal liquefaction), and catalyst (iron-based catalyst) are made into oil-coal at a ratio of 90g coal powder, 110g solvent and 2g catalyst Pour the slurry into the reaction kettle, press the flange cover tightly, adjust the concentricity and verticality of the torque measuring device;

[0030] Second, at room temperature, first purge with nitrogen, then purge with low-pressure hydrogen, and then slowly charge high-pressure hydrogen into the kettle to an operating pressure of 10.0~14.0MPa;

[0031] Third, start the micro-motor, start stirring at the set stirring speed, the speed of the stirrer is usually 50-800 rpm, and the torque measurement system is turned on at the same time to record the measured data;

[0032] Fourth, heat the reactor at th...

Embodiment 2

[0035] The ratio of the oil-coal slurry is 112.5g coal powder, 137.5g solvent, and 2.5g catalyst; the rest of the steps are the same as in Example 1.

Embodiment 3

[0037] The ratio of the oil-coal slurry is 135g coal powder, 165g solvent, and 3g catalyst; other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com