Manufacturing method of catalysis-isolation integral mini-size membrane reactor

A manufacturing method and reactor technology, which are applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problem of uneven defects in molecular sieve membranes, restricting the development of molecular sieve membranes, and difficulty in molecular sieve membranes. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 1.50gNaOH and 0.650gNaAlO 2 Mix well with 16.7g deionized water, then age for 1 hour to get aluminum source solution; weigh 2.18gNaOH and 2.43gNaOH 2 SiO 3 9H 2 O was thoroughly mixed with 16.7 g of deionized water, and aged for 1 hour to obtain a silicon source solution. Then mix and stir the silicon source solution and the aluminum source solution for 10 to 60 minutes to obtain a uniform and transparent sol, and the final formula is 2SiO 2 :Al 2 o 3 : 15Na 2 O: 500H 2 Synthetic Mother Liquor 1 of O.

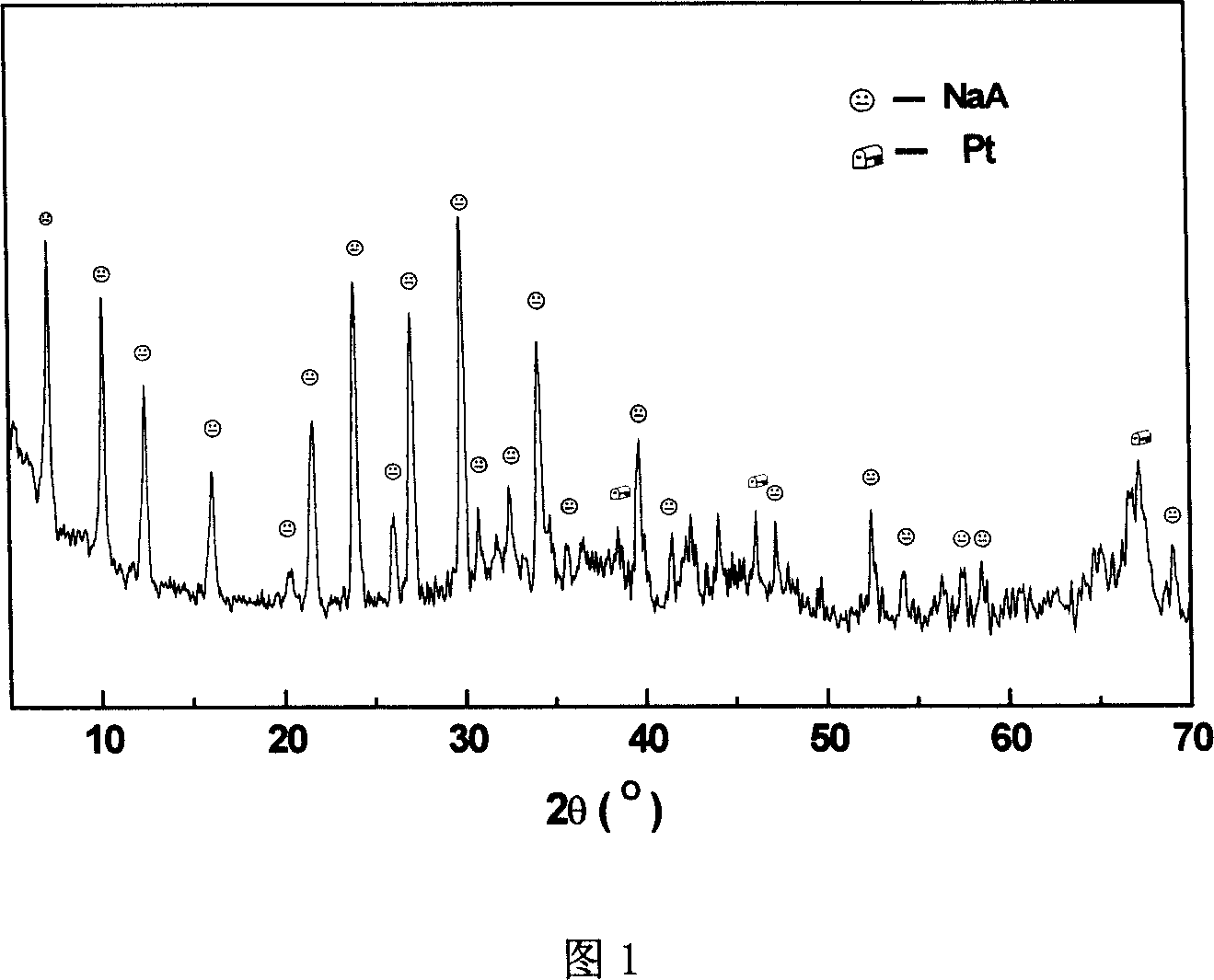

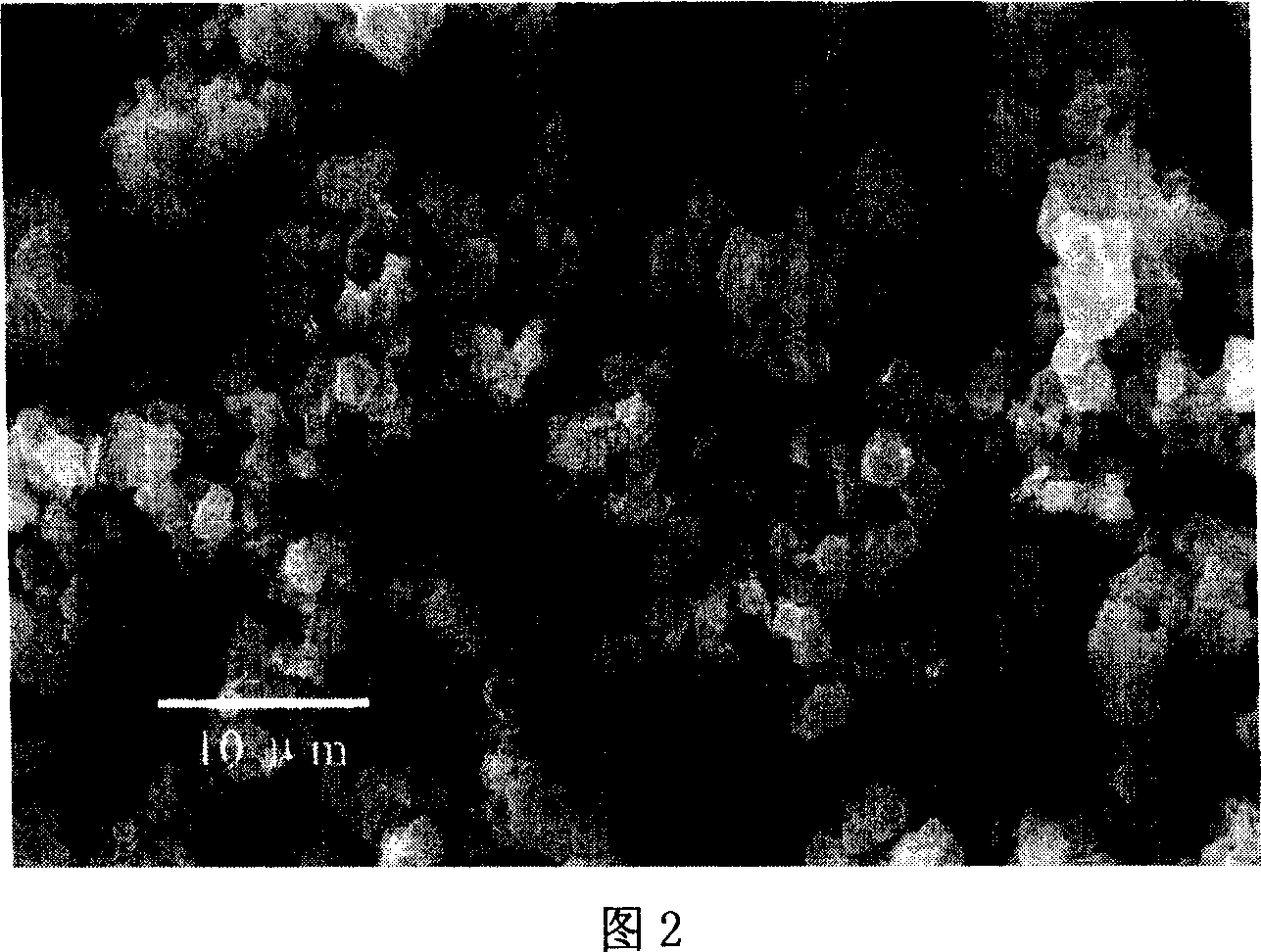

[0026] 0.5% Pt / Al prepared by impregnation method 2 o 3 Put 4.02g of the granular catalyst into the synthesis mother liquor 1, age for 1 hour, put it into a microwave oven, adjust the microwave output power to 725W, and make the temperature rise rapidly to 90°C, then adjust the output power to 200W, and microwave the reaction at 90°C After cooling for 10 minutes, filter with suction, wash until neutral, and dry at 80°C for 10 hours to prepare a microwave ...

Embodiment 2

[0028] Weigh 1.50gNaOH and 0.650gNaAlO 2 Mix well with 16.6g deionized water, then age for 1 hour to get aluminum source solution; take 2.17gNaOH and 2.43gNaOH 2 SiO 3 9H 2 O was thoroughly mixed with 16.7 g of deionized water, and aged for 1 hour to obtain a silicon source solution. Then mix and stir the silicon source solution and the aluminum source solution for 10 to 60 minutes to obtain a uniform and transparent sol, and the final formula is 2SiO 2 :Al 2 o 3 : 15Na 2 O: 500H 2 Synthetic Mother Liquor of O2.

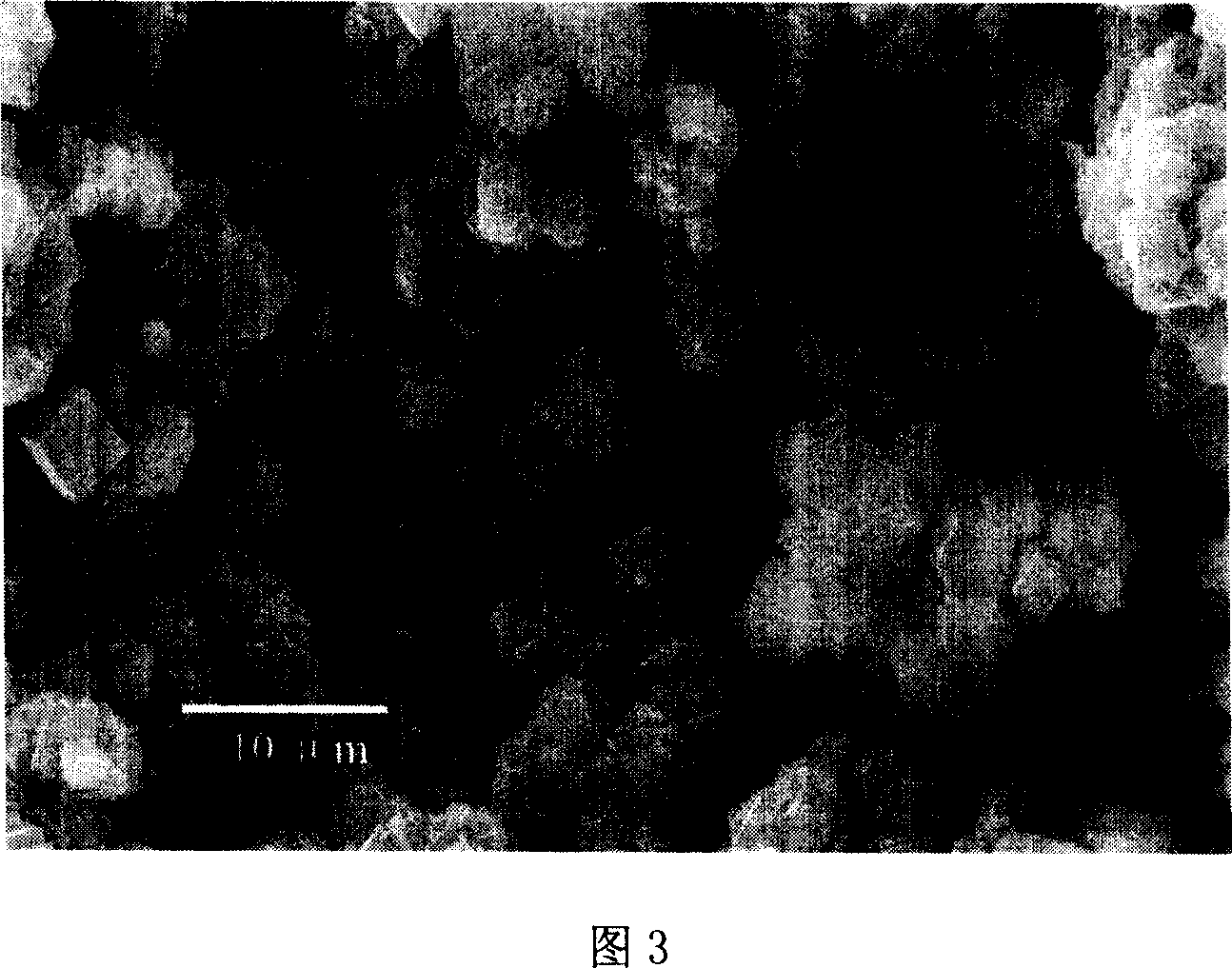

[0029] Take by weighing the primary synthesis sample NaA / Pt / Al obtained in embodiment 1 2 o 3 Put 2.05g into the obtained synthetic mother liquor 2, put it into a microwave oven after aging for 1 hour, adjust the microwave output power to 725W, and make the temperature rise rapidly to 90°C, then adjust the output power to 200W, keep the temperature at 90°C, and microwave Heating and reacting for 10 minutes, cooling, suction filtration, washing to neutralit...

Embodiment 3

[0031] Weigh 1.50gNaOH and 0.652gNaAlO 2 Mix well with 16.8g deionized water, then age for 1 hour to get aluminum source solution; take 2.17gNaOH and 2.44gNaOH 2 SiO 3 9H 2O was thoroughly mixed with 16.6 g of deionized water, and aged for 1 hour to obtain a silicon source solution. Then mix and stir the silicon source solution and the aluminum source solution for 10 to 60 minutes to obtain a uniform and transparent sol, and the final formula is 2SiO 2 : Al 2 o 3 : 15Na 2 O: 500H 2 Synthetic Mother Liquor of O 3.

[0032] 0.5% Pt / Al prepared by impregnation method 2 o 3 Put 4.00g of the granular catalyst into the synthetic mother liquor 3, put it into a microwave oven after aging for 1 hour, adjust the microwave output power to 725W, and make the temperature rise rapidly to 90°C, then adjust the output power to 200W, and keep the temperature at 90°C. Microwave heating reaction for 20 minutes, after cooling, suction filtration, washing to neutrality, and drying at 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com