Welding method of titanium alloy framework and covering variable cross-section element

A welding method and titanium alloy technology, applied in the direction of welding medium, welding equipment, auxiliary welding equipment, etc., can solve the problems of large welding internal stress, asymmetric welding thermal expansion, uneven thickness of structure size, etc., and achieve simple and good maintenance and repair. Mechanical properties, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A method for welding titanium alloy skeleton and skin variable section member:

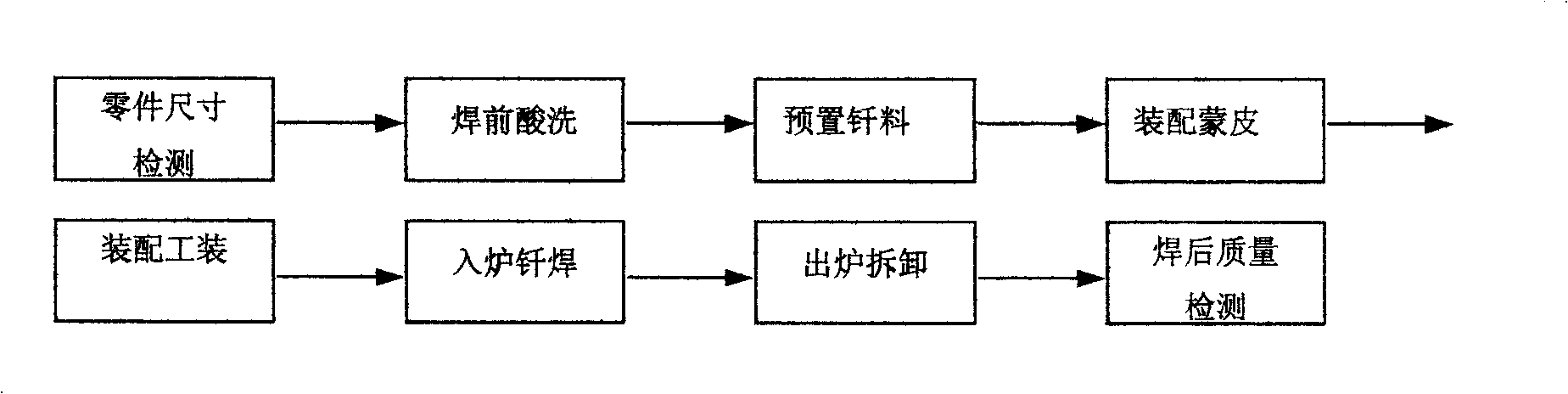

[0028] by figure 1 Shows the component vacuum brazing process. First, the inspected parts are cleaned by pickling, and the FTI high-strength foil solder is pre-installed on the frame to be welded, and then clamped by thermal expansion assembly tooling or profile pressurized thermal expansion assembly tooling Then enter the furnace for vacuum brazing, and pass suitable vacuum brazing parameters, such as high temperature brazing parameters: 870~950℃, heat preservation 2~60min; diffusion parameters: 700~850℃ heat preservation, 30~120min, make the solder at high temperature Melting occurs and heat preservation is performed at a temperature lower than the brazing temperature for solid diffusion. The diffusion further homogenizes the structure of the joint. After the product is welded, the tooling is disassembled to check the component size and welding quality.

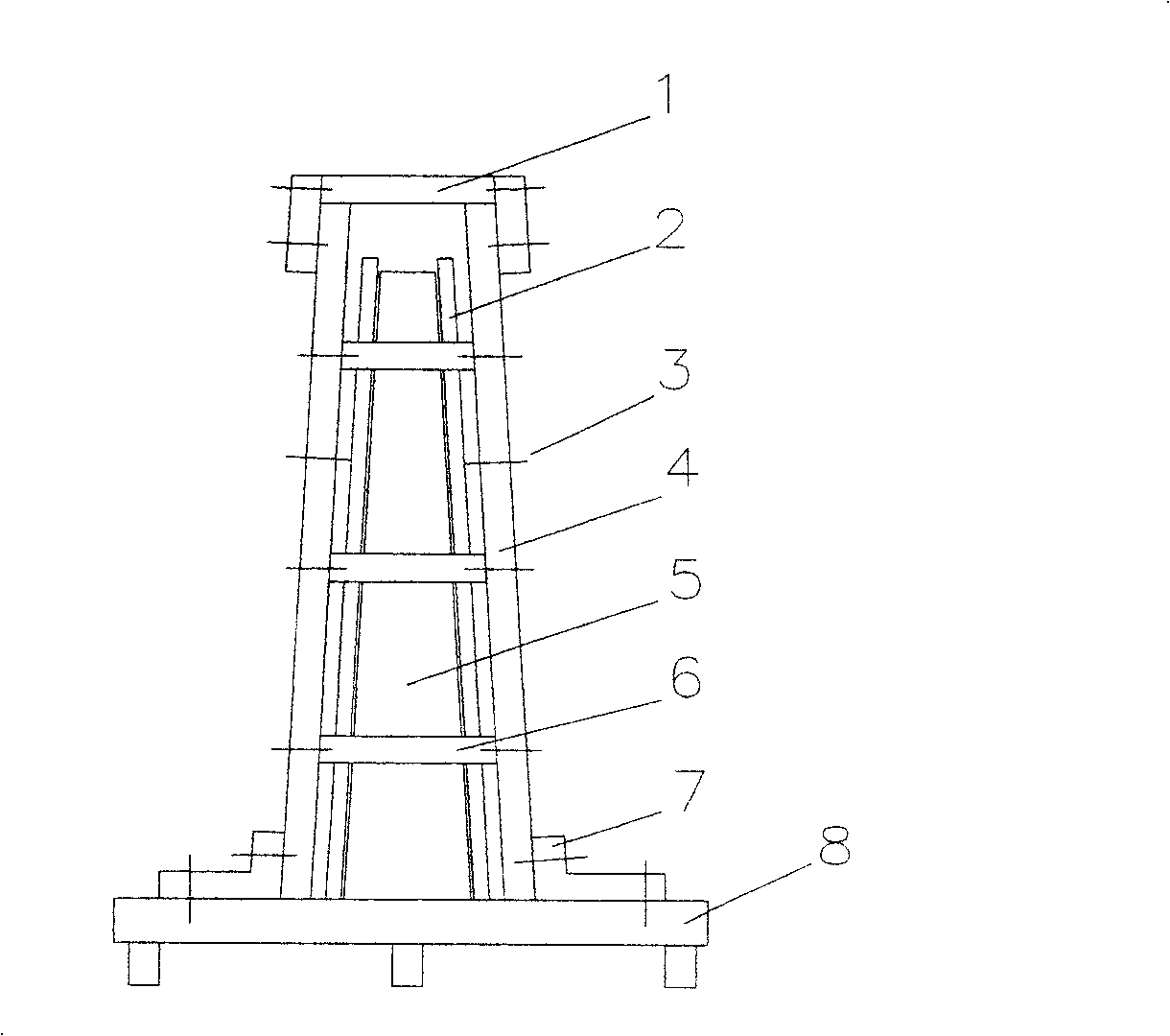

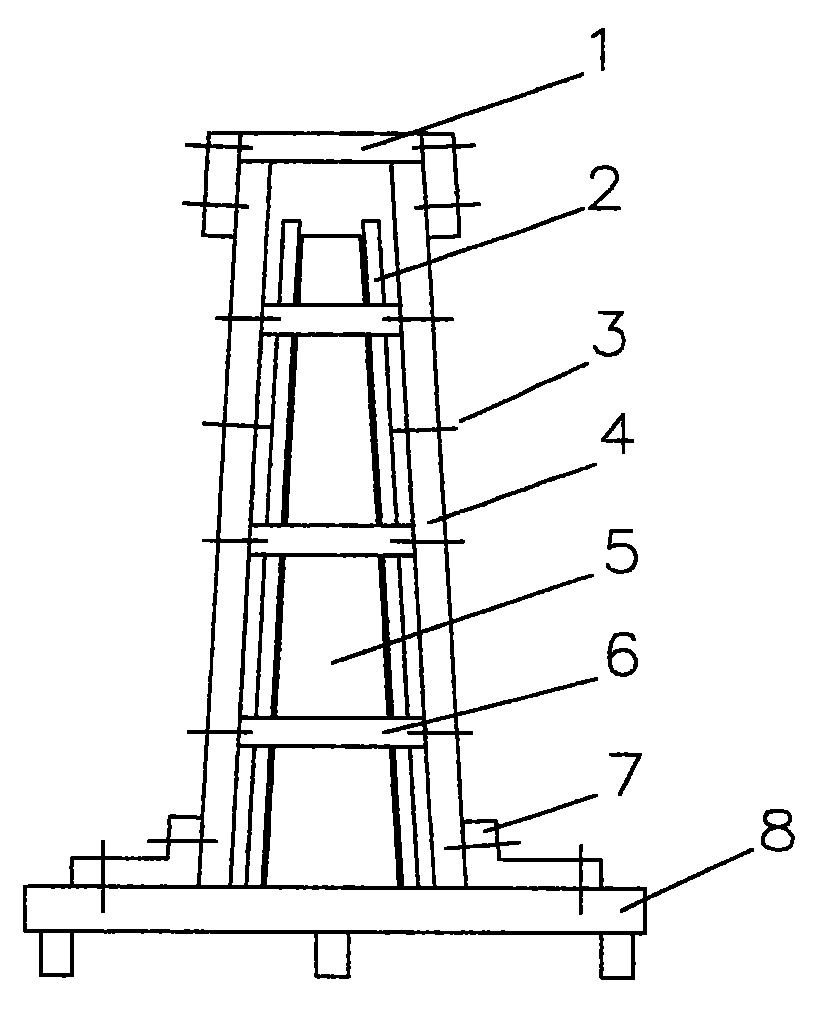

[0029] by figure 2 Shows a schematic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com