Testing device for barium film air-breathing capability of getter in kinescope

A capability testing and testing device technology, applied in the direction of measurement/testing in the manufacturing process, can solve problems such as the decline in the ability of emitting electrons, poor cathode emission, and faded contrast, and achieve the effect of fast information feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

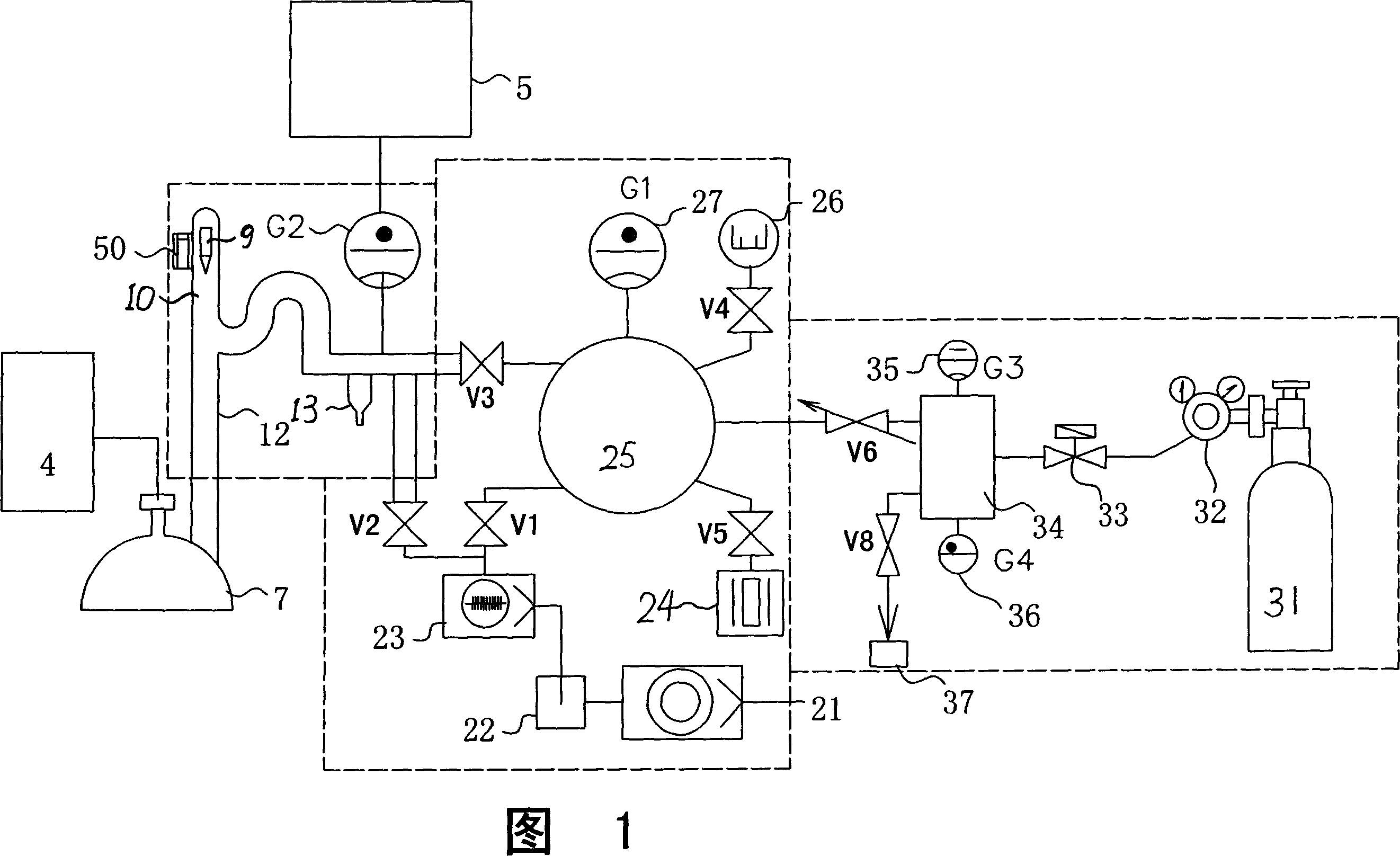

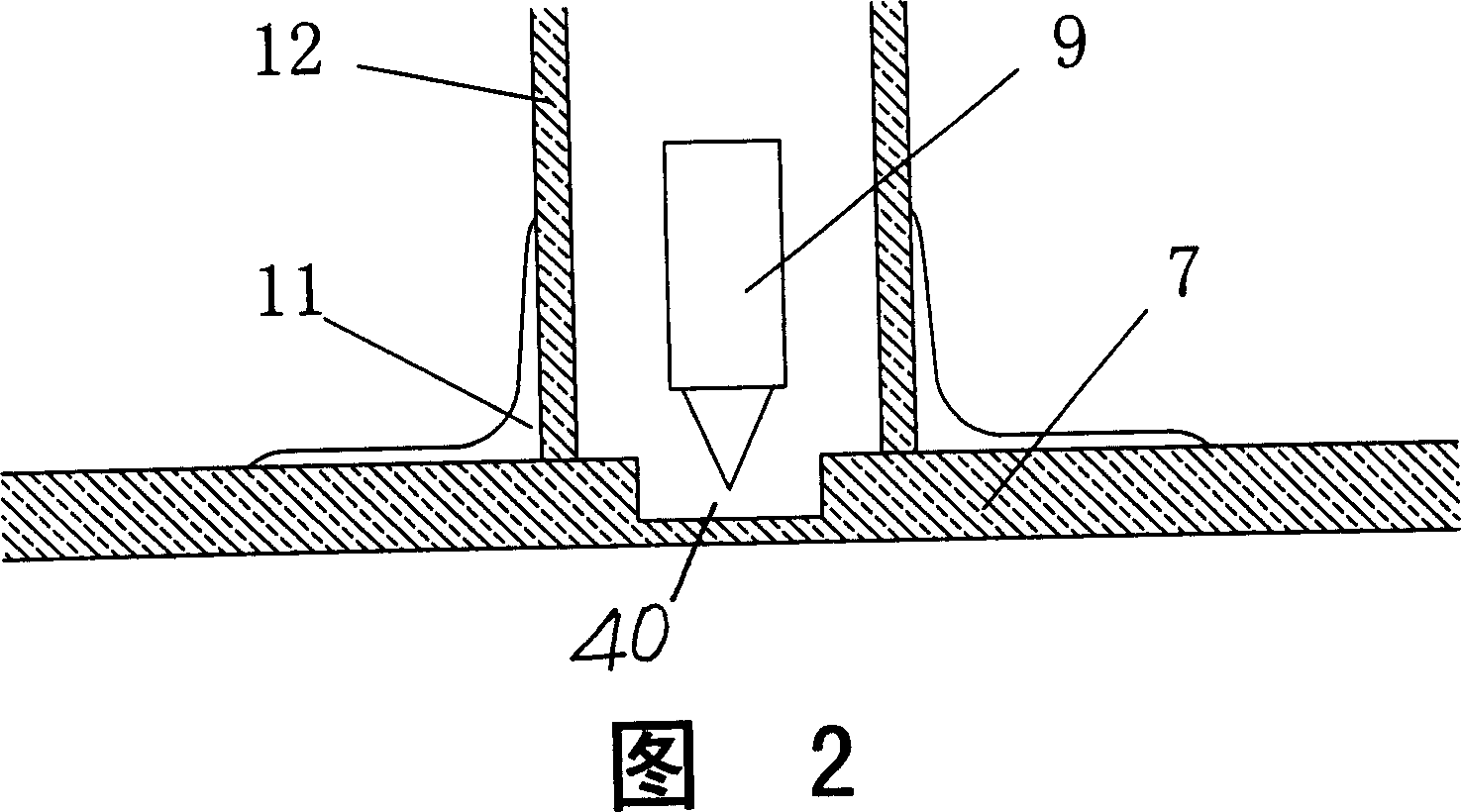

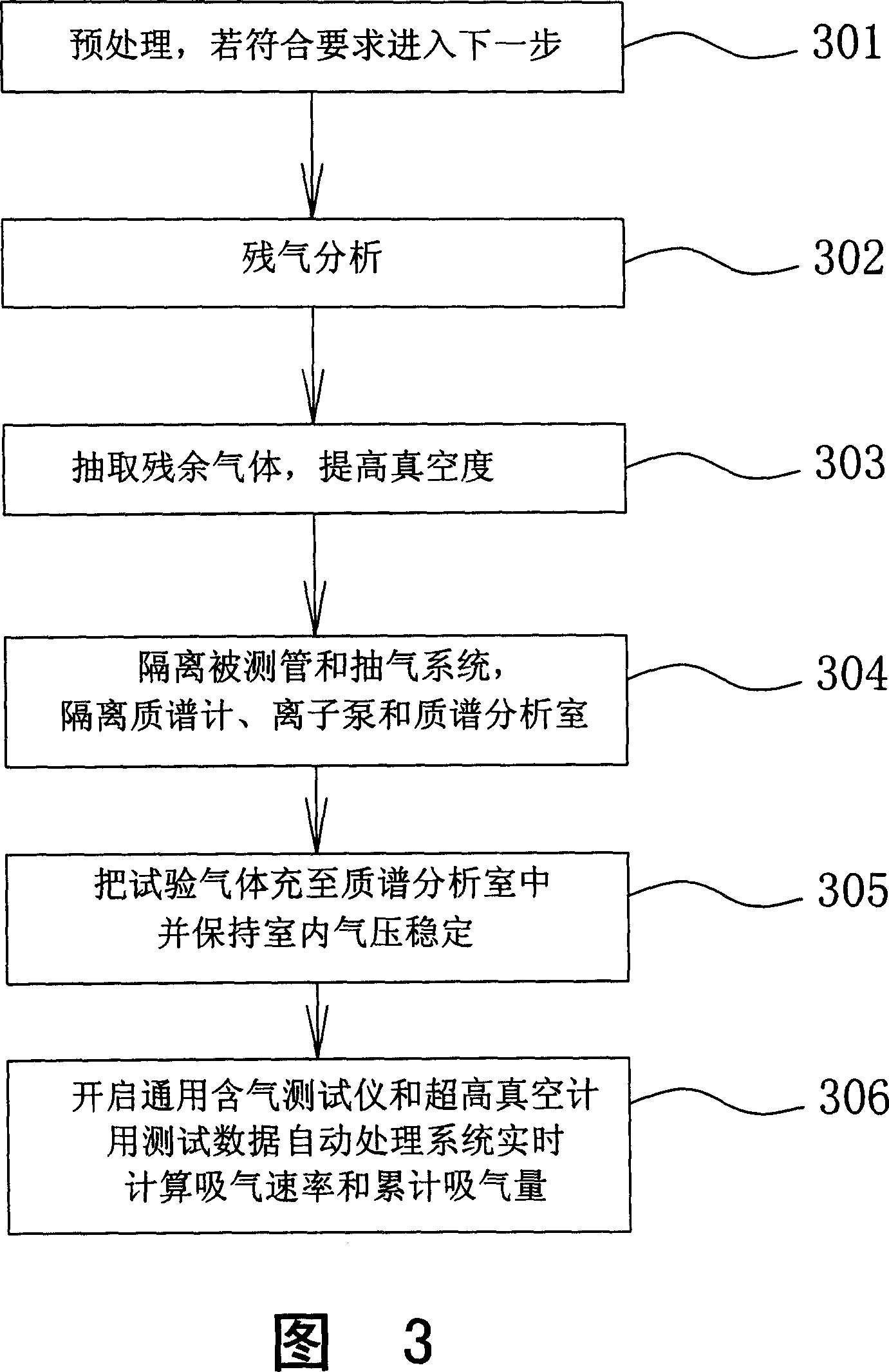

[0033] Fig. 1 shows the test device of the barium film getter performance of the present invention. As shown in FIG. 1 , the sampling system is mainly composed of a picture tube 7 to be tested, a sampling glass tube 12 and a breaking hammer 9 . In the present invention, the tested picture tube 7 is not a blank glass tube, but a finished color picture tube. Please refer to FIG. 2 again, a pit 40 is drilled at a certain position of the cone of the tested color display tube, the diameter of the pit 40 is 6mm, and the remaining wall thickness is 0.5mm. A section of sampling glass tube 12 is bonded around the pit 40 with low vapor pressure epoxy resin sealant 11 . A breaking hammer 9 is also placed in the sampling glass tube 12, and the breaking hammer 9 is made of ferromagnetic material, and the cone is arranged downward. Returning to Fig. 1, there is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com