Polymer compositions with PBSA plasticizer

a technology of polymer compositions and plasticizers, applied in the field of polymer compositions, can solve the problems of plasticizers being problematic, affecting the health of workers, and affecting the quality of polymer compositions,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

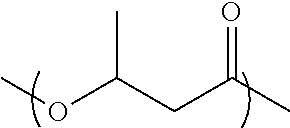

Image

Examples

example 1

[0046]A 5 gallon reactor equipped with a heat exchanger was charged with 1,4-butanediol (21 pounds), succinic acid (11.01 pounds), and adipic acid (20.43 pounds) and heated to 180° C. for 18 hours. During the first 4 hours, the vacuum was ramped down to 300 torr, after which it was gradually reduced to 1 torr. Water was collected in the receiver. When the acid number of the pre-polymer was ≤30, 45 grams of zirconium catalyst was added. The reaction was continued at 205° C. and 1 torr vacuum until the desired viscosity was achieved. Poly(butylene succinate) (2.1 pounds) was added to the reactor and stirred under nitrogen at 205° C. for 2 hours. The product was collected as a slightly translucent, white solid.

example 2

[0047]The process in Example 1 was repeated using titanium isopropoxide as the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com