Method of forming a βSiAlON by spark plasma sintering

a technology of sintering and sialon, applied in the direction of sialons, nitrogen and non-metal compounds, etc., can solve the problem of inability to achieve the complete densification of the sisub>3/sub>nsub>4/sub>

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Experimental Procedure

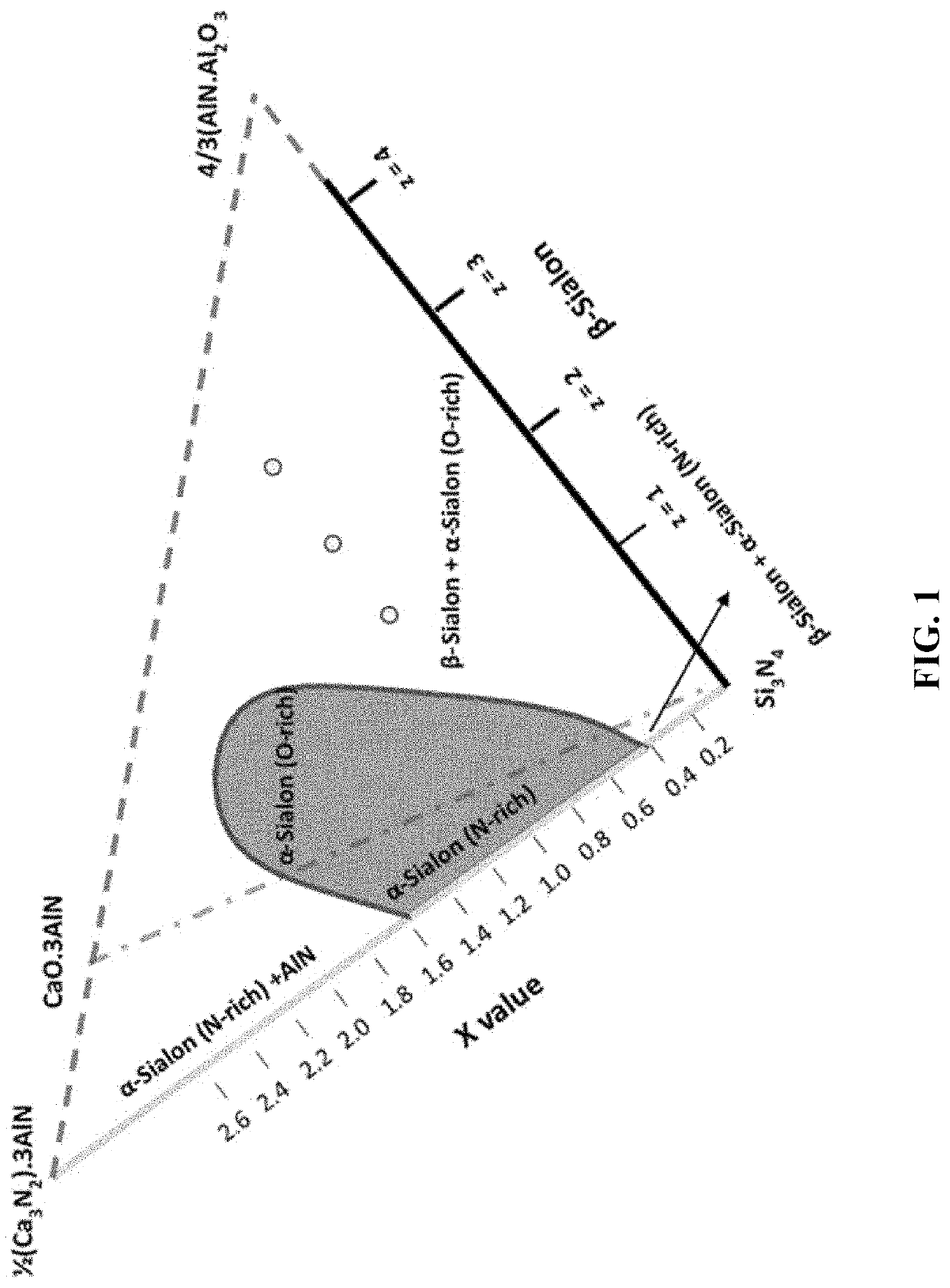

[0092]Two Si3N4 powders with different structures and sizes (β-Si3N4, particle size ˜44 μm, Sigma-Aldrich, Germany; amorphous Si3N4, particle size 20-40 nm, Chempur, Germany) were used as a starting powder. Other additives incorporated were AlN (size=50 nm, Chempur, Germany), Al2O3 (size2 (10-20 nm, Sigma-Aldrich, Germany) to synthesize β-Sialon (general formula of Si6−ZAlZOZN8−Z). In the following text, sample IDs (A-ZX-T or B-ZX-T) starting with “A” represent samples synthesized using amorphous Si3N4, whereas those starting with “B” represent samples synthesized using β-Si3N4. Moreover, “X” having the value of 1, 2, or 3, represents the value of the variable Z in the general formula of β-Sialon, whereas “T” represents the synthesis temperature in degrees Celsius. The schematic shown in FIG. 1 exhibits the selected compositions (marked by centrally-located circles) used in the present study. The weight percentage of the starting powders along with their respec...

example 2

Results and Discussion≤Characterization of as-Received Powder Precursors

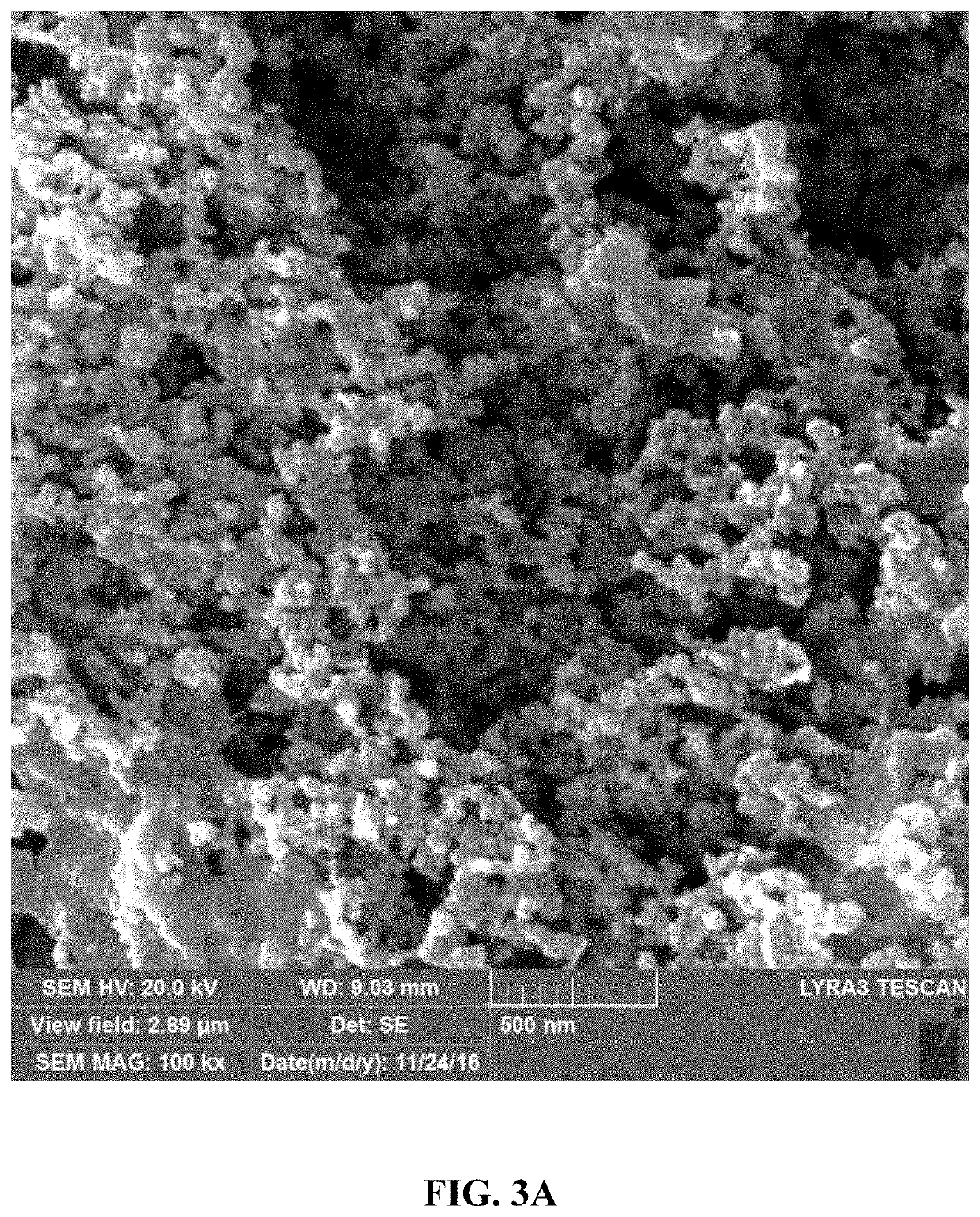

[0098]FESEM micrographs of the as-received nanosized amorphous Si3N4 at different magnifications are shown in FIGS. 3A-3B. The micrographs revealed that the particle size of the powder is uniform. Further investigation by TEM confirmed that the particle sizes of the amorphous Si3N4 and the SiO2 are in the ranges 20-40 nm and 10-20 nm, respectively (FIGS. 4A-4D). The superimposed selected-area electron diffraction (SAED) pattern confirms the presence of diffused rings and the amorphous nature of the as-received nanosized Si3N4 and SiO2 powders, as indicated by the absence of lattice fringes in the high-resolution TEM images (FIGS. 4B and 4D, respectively).

[0099]High-temperature XRD scans were performed to analyse the phase evolution of the starting powder mixtures at different temperatures. The XRD pattern in FIG. 5A is for the starting powder mixture containing nanosized amorphous Si3N4 (A-Z1). The low-intensity...

example 3

Results and Discussion—Density, Mechanical Properties, and Thermal Properties of the SPSed Samples

[0104]Table 3 shows the density, Vickers hardness (HV10), fracture toughness (KIc), thermal expansion coefficient values, and XRD phases for the β-Sialon samples (Z=1, 2, and 3) synthesized at 1400, 1500, and 1600° C. using amorphous Si3N4. The density was observed to increase as the synthesis temperature was increased from 1400 to 1600° C. for the same Z value. The Vickers hardness of the samples decreased with increasing synthesis temperature for the same Z values, and the Vickers hardness value decreased with increasing Z value for the same synthesis temperature. Dissolution of the AlN polytype phase at higher temperatures and the formation of coarser and more elongated grains was attributed to the decrease in Vickers hardness. The fracture toughness values were in the range 3.3-4.6 MPa·m1 / 2. The sample with Z=1 and a synthesis temperature of 1500° C. resulted in the highest Vickers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com