Patents

Literature

37results about "Sialons" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphor, method of producing the same, and light emitting apparatus

ActiveUS20080258602A1Improve efficiencyStable characteristicsMaterial nanotechnologyDischarge tube luminescnet screensLength waveNitride phosphor

There are provided a phosphor which is a divalent europium-activated oxynitride phosphor substantially represented by General formula (A): EuaSibAlcOdNe, a divalent europium-activated oxynitride phosphor substantially represented by General formula (B): MIfEugSihAlkOmNn or a divalent europium-activated nitride phosphor substantially represented by General formula (C): (MIIl-pEup)MIIISiN3, having a reflectance of light emission in a longer wavelength region of visible light than a peak wavelength of 95% or larger, and a method of producing such phosphor; a nitride phosphor and an oxynitride phosphor which emit light efficiently and stably by the light having a wavelength ranging from 430 to 480 nm from a semiconductor light emitting device by means of a light emitting apparatus using such phosphor, and a producing method of such phosphor; and a light emitting apparatus having stable characteristics and realizing high efficiency.

Owner:DENKA CO LTD +1

Phosphor and use thereof

ActiveUS20090066230A1Increase brightnessLight brightness is lessDischarge tube luminescnet screensCathode ray tubes/electron beam tubesChemical compositionPhosphor

A phosphor which emits light having high brightness, serves as an excellent orange or red phosphor whose light brightness is less decreased when exposed to an excitation source contains a crystal phase having the chemical composition expressed by the general formula [1]:(1−a−b)(Ln′pMII′1−pMIII′MIV′N3)·a(MIV′(3n+2) / 4NnO)·b(AMIV′2N3) [1]wherein Ln′ represents a metal element selected from the group consisting of lanthanoids, Mn, and Ti; MnII′ represents a divalent metal element except the Ln′ element; MIII′ represents a trivalent metal element; MIV′ represents a tetravalent metal element; A represents a metal element selected from the group consisting of Li, Na, and K; 0<p≦0.2; 0≦a, 0≦b, a+b>0, 0≦n, and 0.002≦(3n+2)a / 4≦0.9.

Owner:MITSUBISHI CHEM CORP +1

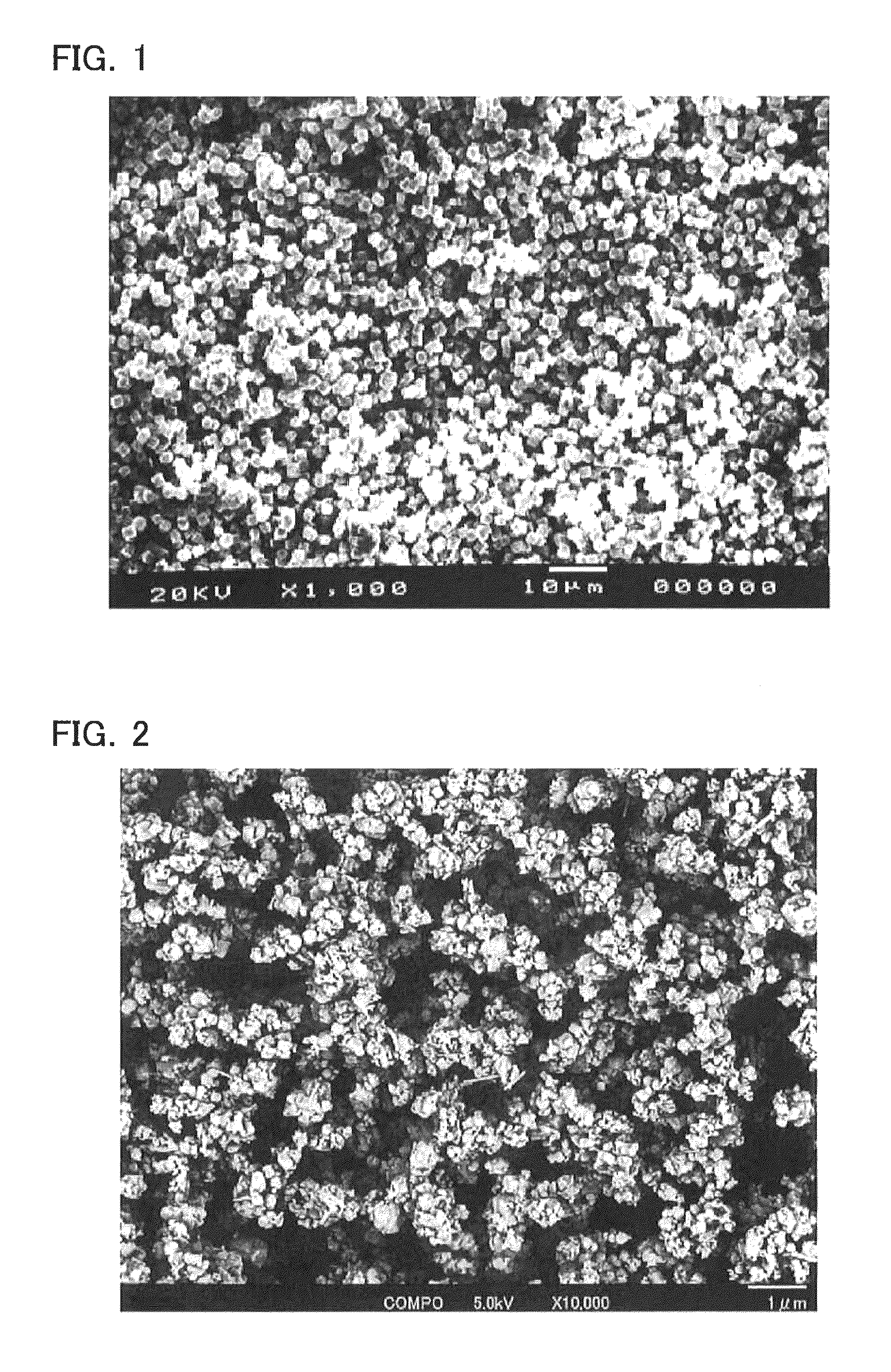

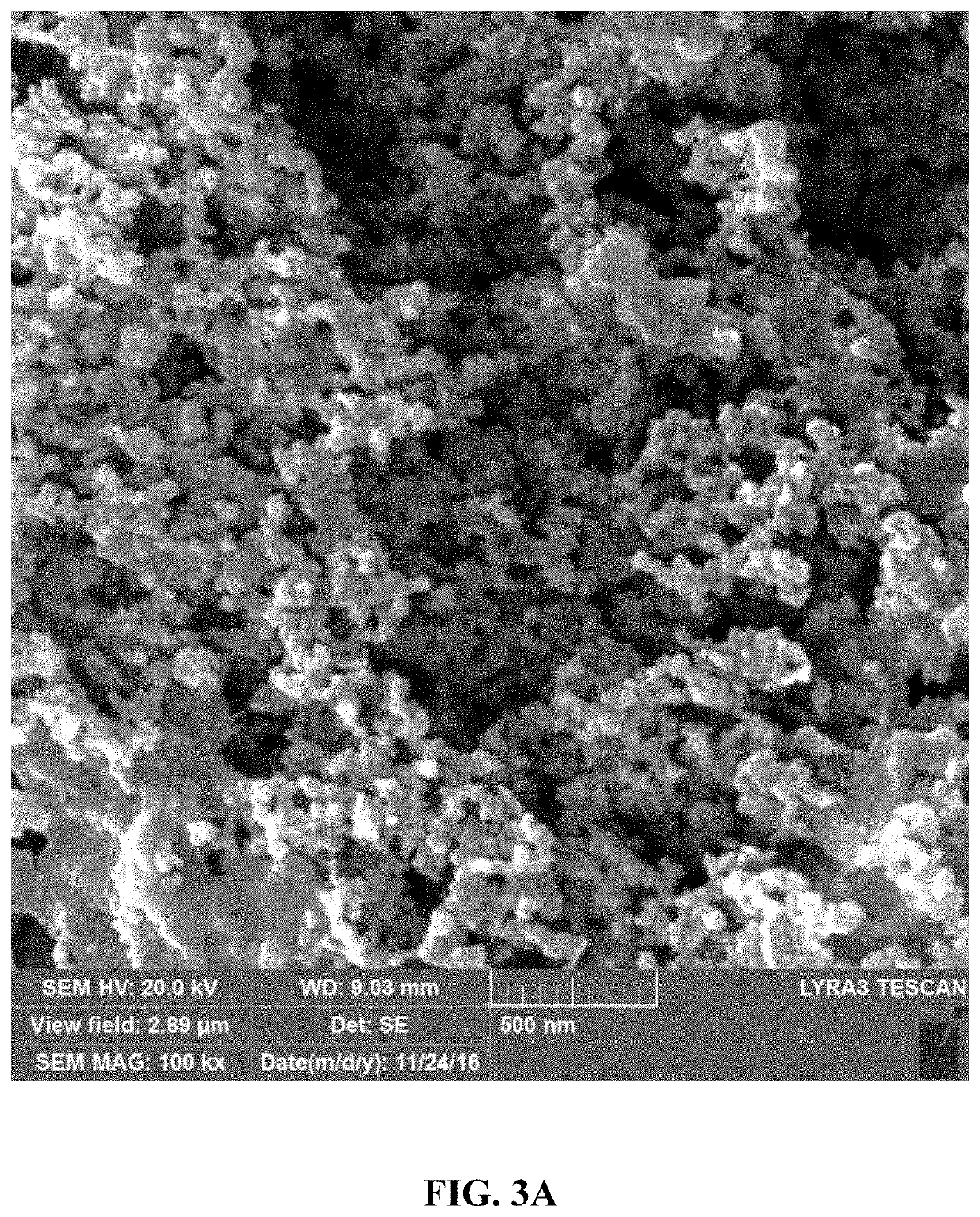

Oxynitride powder and production method thereof

ActiveUS20070166218A1Low oxygenHigh nitrogen contentAluminium compoundsAluminium silicatesPhosphorNitrogen

It is aimed at providing an oxynitride powder, which is suitable for usage as a phosphor, is free from coloration due to contamination of impurities, and mainly includes a fine α-sialon powder. An oxynitride powder is produced by applying a heat treatment in a reducing and nitriding atmosphere, to a precursor compound including at least constituent elements M, Si, Al, and O (where M is one element or mixed two or more elements selected from Li, Mg, Ca, Sr, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu), thereby decreasing an oxygen content and increasing a nitrogen content of the precursor.

Owner:NAT INST FOR MATERIALS SCI

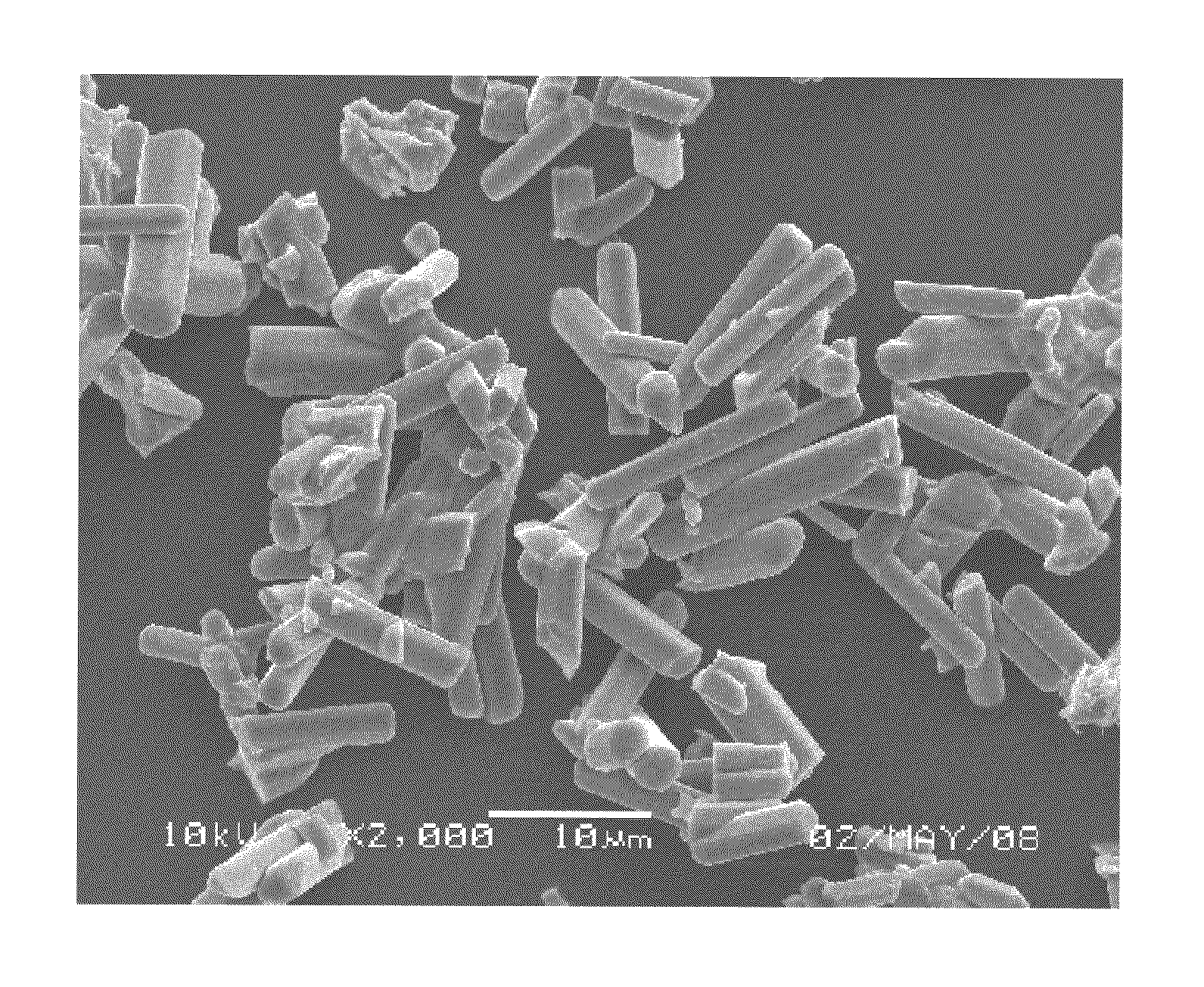

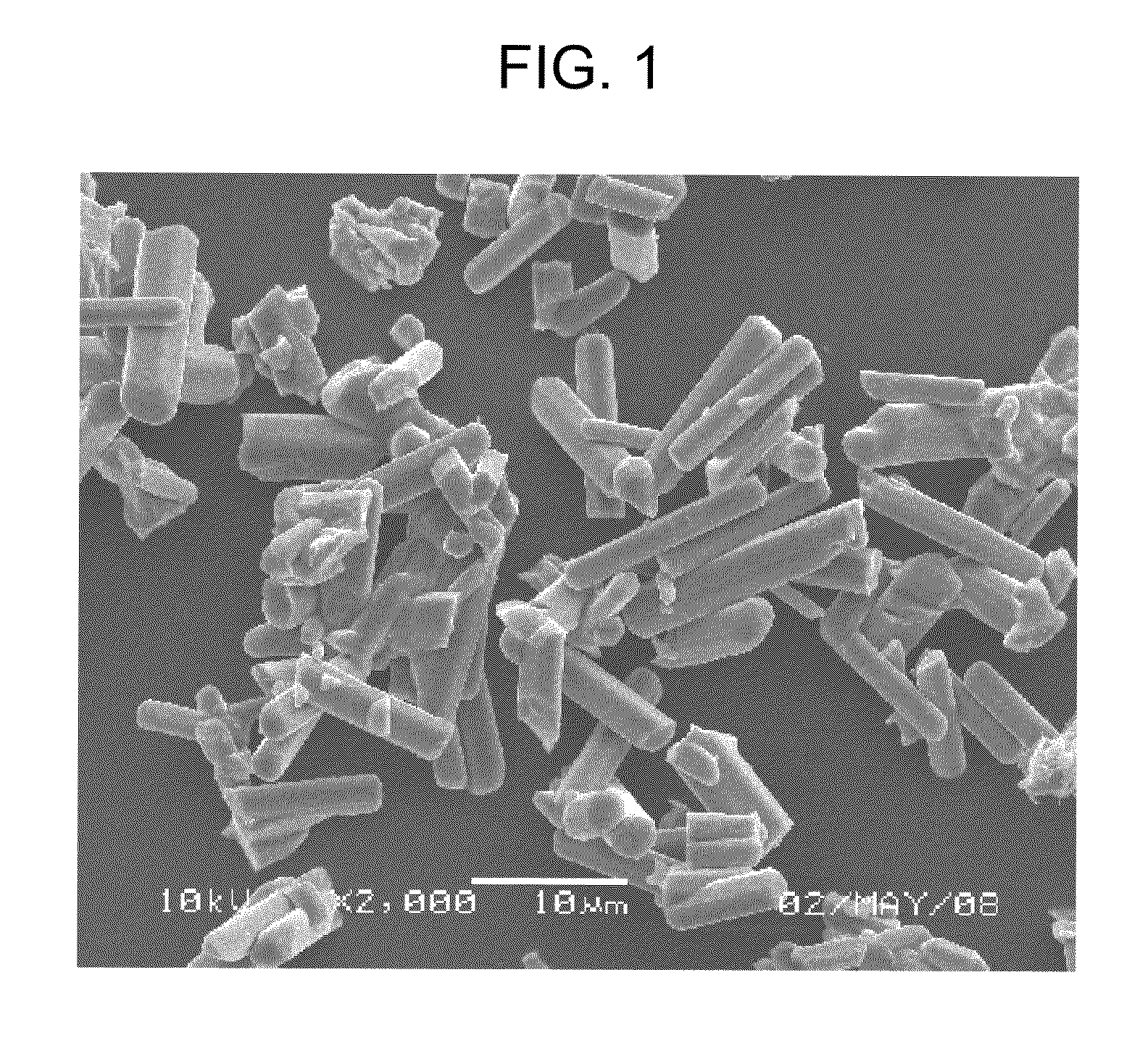

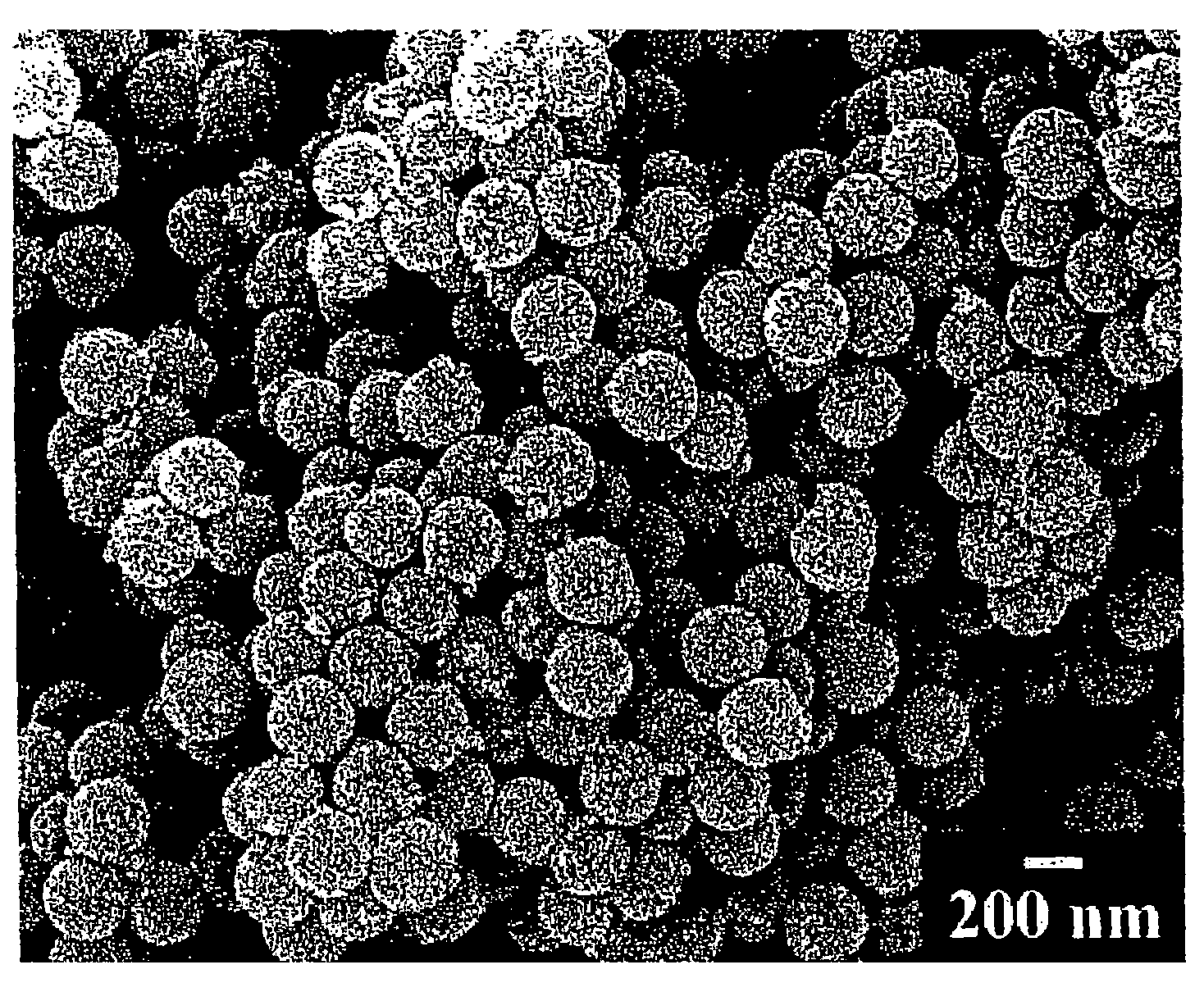

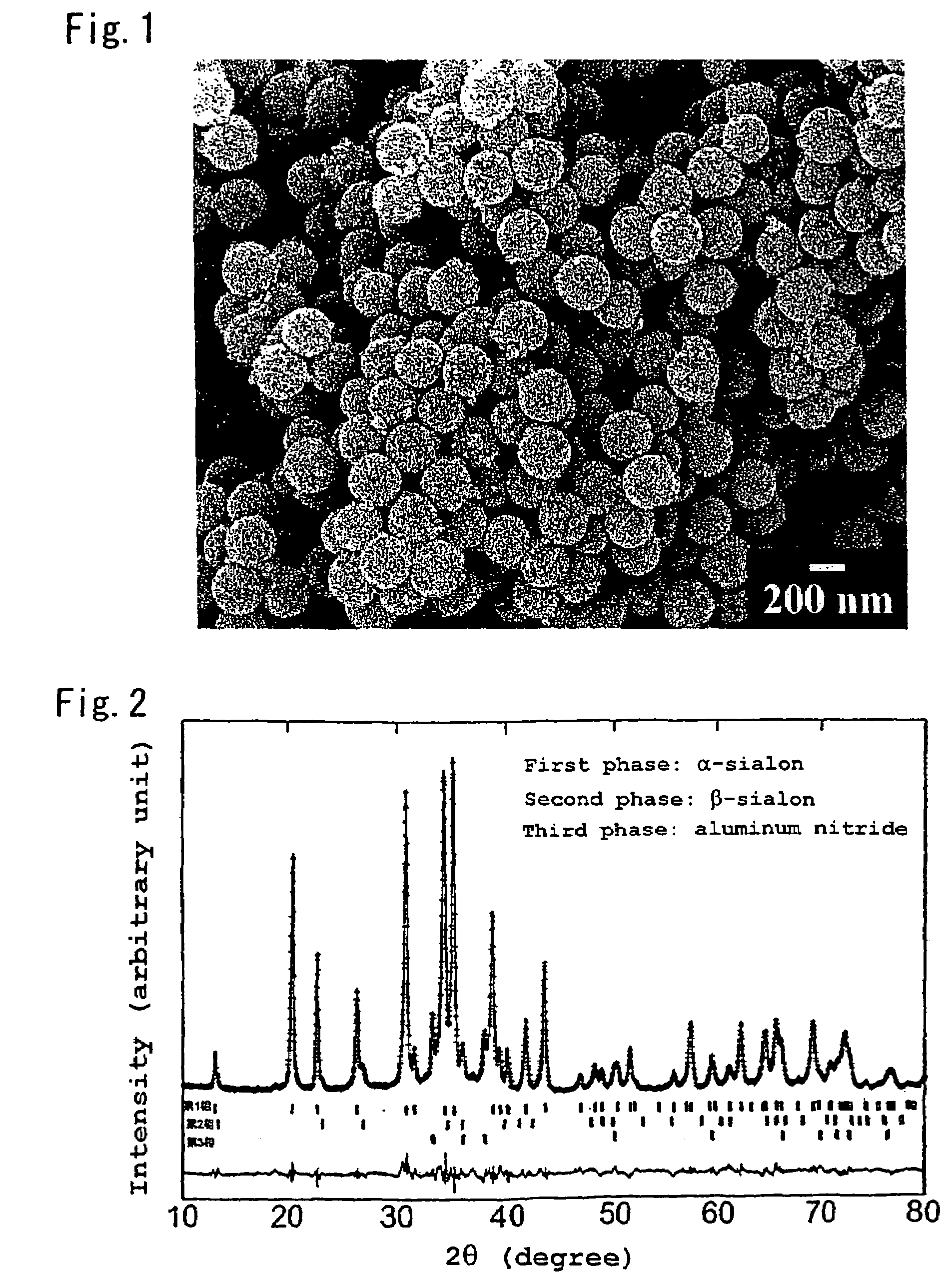

Beta-sialon phosphor powder and production method thereof

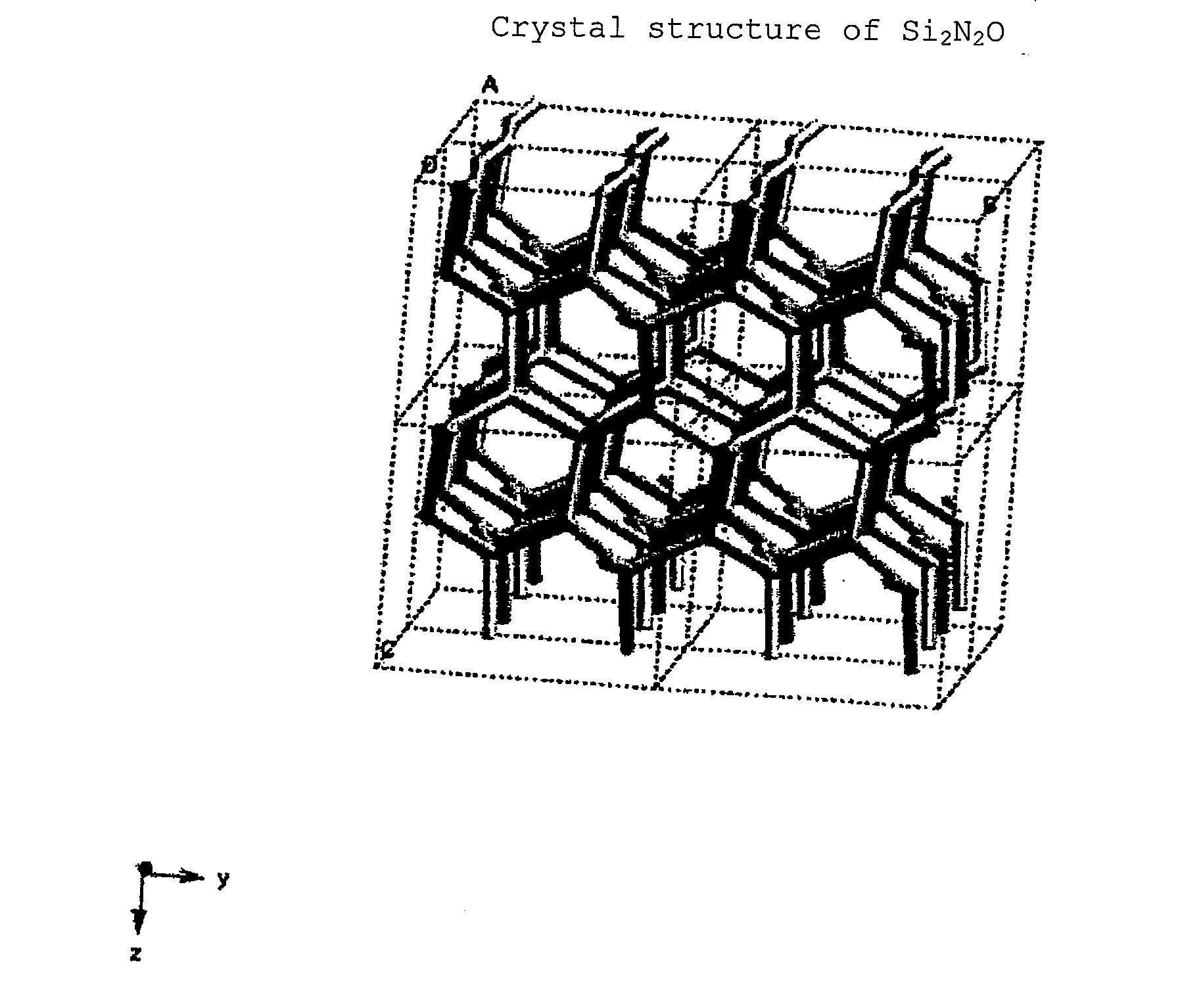

ActiveUS20100213820A1Small aspect ratioIncrease brightnessDischarge tube luminescnet screensElectroluminescent light sourcesGreek letter betaCrystal structure

A β-sialon phosphor particle in which Eu (europium) is solid-soluted in a crystal having a β-type Si3N4 crystal structure, wherein the median diameter (D50) in the particle size distribution curve of the primary particle is from 3.0 to 10 μm and the aspect ratio is less than 1.5.

Owner:DENKA CO LTD

Alpha-Siaion Powder and Method for Producing the Same

InactiveUS20070248519A1Excellent phosphor materialShine wellRare earth metal compoundsLuminescent compositionsFluorescenceLanthanide

An α-sialon which is represented by general formula: (M1)x (M2)y (Si, Al)12 (O, N)16 (wherein M1 represents one or more elements selected from the group which consists of Li, Mg, Ca, Y and lanthanoid (except La and Ce) and M2 represents one or more elements selected from the group which consists of Ce, Pr, Eu, Tb, Yb and Er and wherein 0.3<X+Y<1.5 and 0<Y<0.7) is synthesized by loading a container with a mixed powdery material of silicon nitride, aluminum nitride, an M1 containing compound and an M2 containing compound and at need aluminum oxide so that its bulk density is not more than 1.5 g / cm3, heat-treating the mixed powdery material at 1,600 to 2,000° C. in a nitrogen atmosphere. The α-sialon is pulverized to make an α-sialon powder, which can be utilized as a phosphor material for a while LED which uses a blue or an ultraviolet LED as its light source.

Owner:NAT INST FOR MATERIALS SCI +1

Phosphor and use thereof

ActiveUS8206611B2Increase brightnessAvoid excessive brightnessDischarge tube luminescnet screensCathode ray tubes/electron beam tubesChemical compositionPhosphor

A phosphor which emits light having high brightness, serves as an excellent orange or red phosphor whose light brightness is less decreased when exposed to an excitation source contains a crystal phase having the chemical composition expressed by the general formula [1]: (1−a−b)(Ln′pMII′1−pMIII′MIV′N3).a(MIV′(3n+2) / 4NnO).b(AMIV′2N3) [1] wherein Ln′ represents a metal element selected from the group consisting of lanthanoids, Mn, and Ti; MnII′ represents a divalent metal element except the Ln′ element; MIII′ represents a trivalent metal element; MIV′ represents a tetravalent metal element; A represents a metal element selected from the group consisting of Li, Na, and K; 0<p≦̸0.2; 0≦̸a, 0≦̸b, a+b>0, 0≦̸n, and 0.002≦̸(3n+2)a / 4≦̸0.9.

Owner:MITSUBISHI CHEM CORP +1

Phosphor particle group and light emitting apparatus using the same

ActiveUS20100176713A1Improve efficiencyExcellent color gamut (NTSC ratio)Discharge tube luminescnet screensLamp detailsParticle physicsGreen-light

Provided is a phosphor particle group of divalent europium-activated oxynitride green light emitting phosphor particles each of which is a β-type SiAlON substantially represented by a general formula: EuaSibAlcOdNe, where 0.0055≦a≦0.4, b+c=12, d+e=16, wherein 60% or more of the phosphor particle group is composed of the phosphor particles in which a value obtained by dividing a longer particle diameter by a shorter particle diameter is greater than 1.0 and not greater than 3.0. A high-efficiency and stable light emitting apparatus using a β-type SiAlON, which includes a light converter using the phosphor particle group, and a phosphor particle group therefor are also provided.

Owner:DENKA CO LTD +1

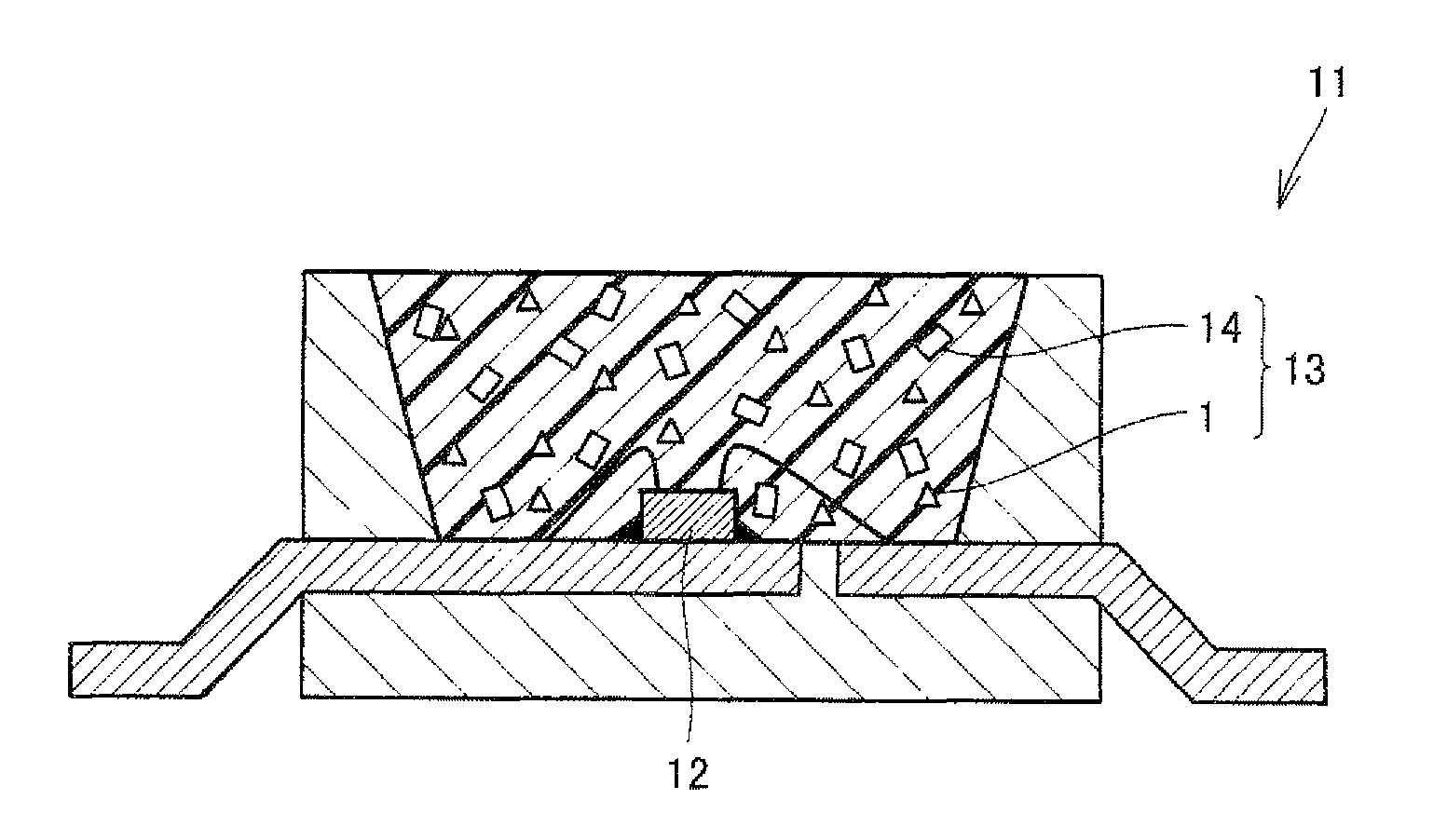

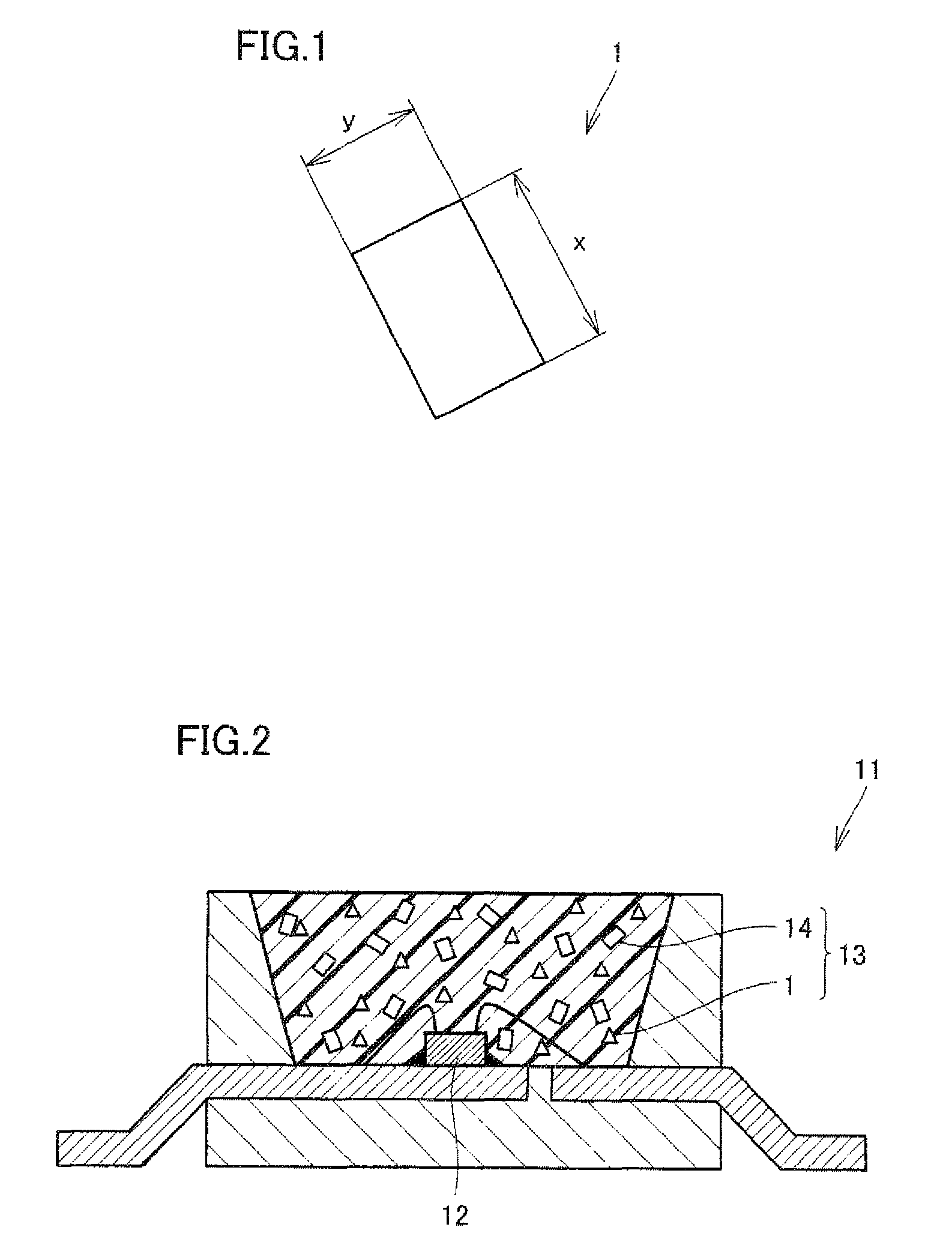

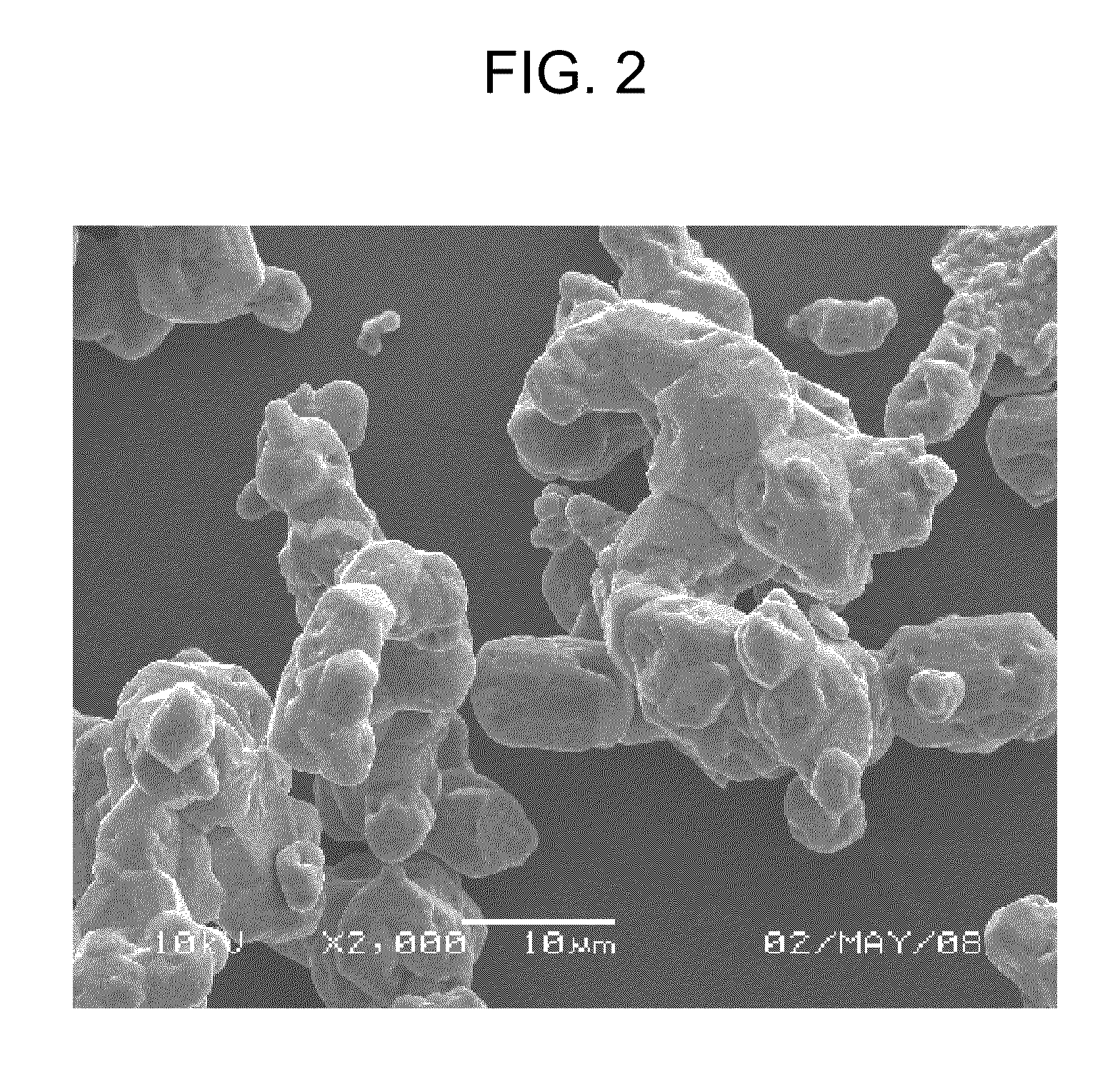

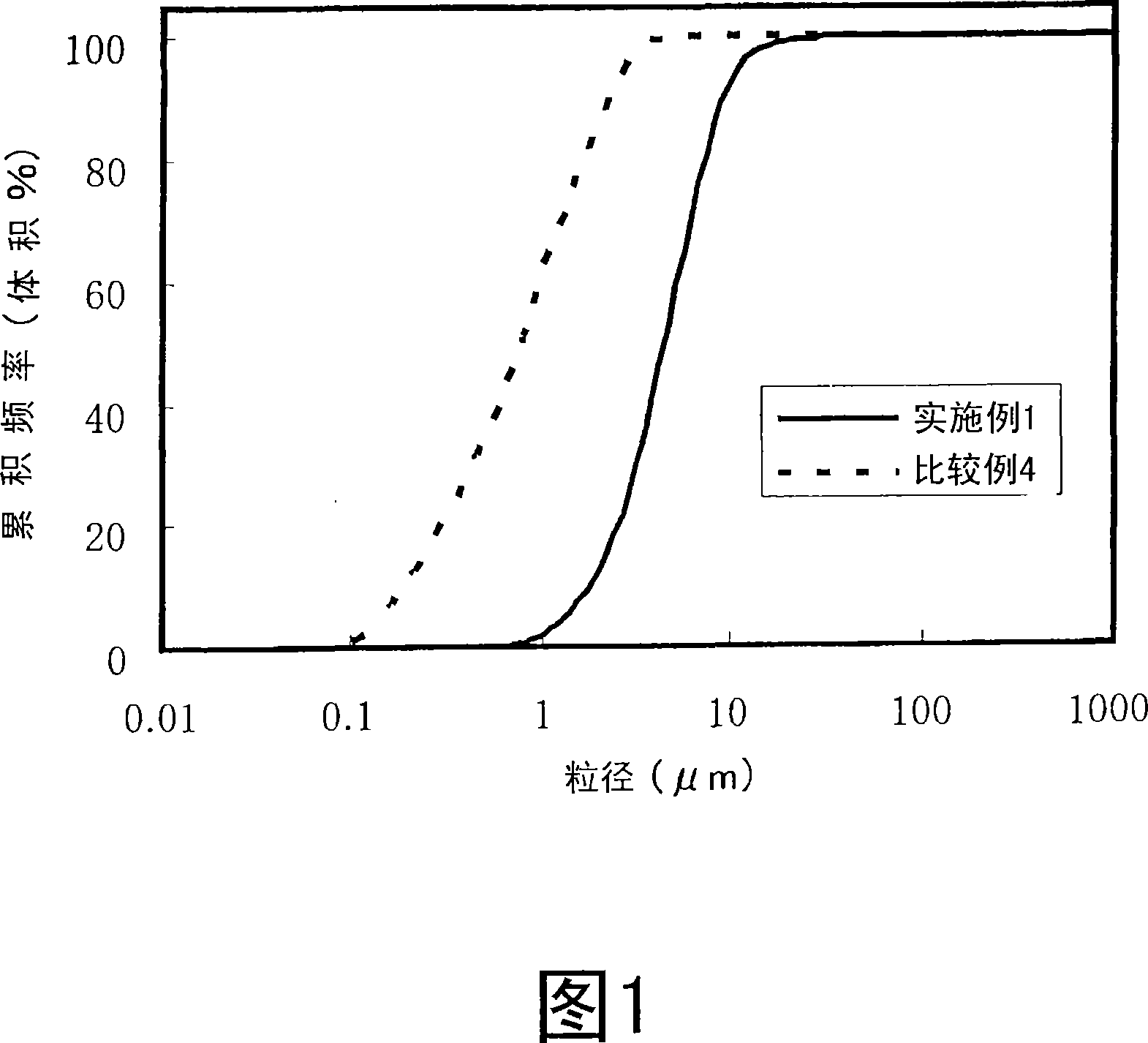

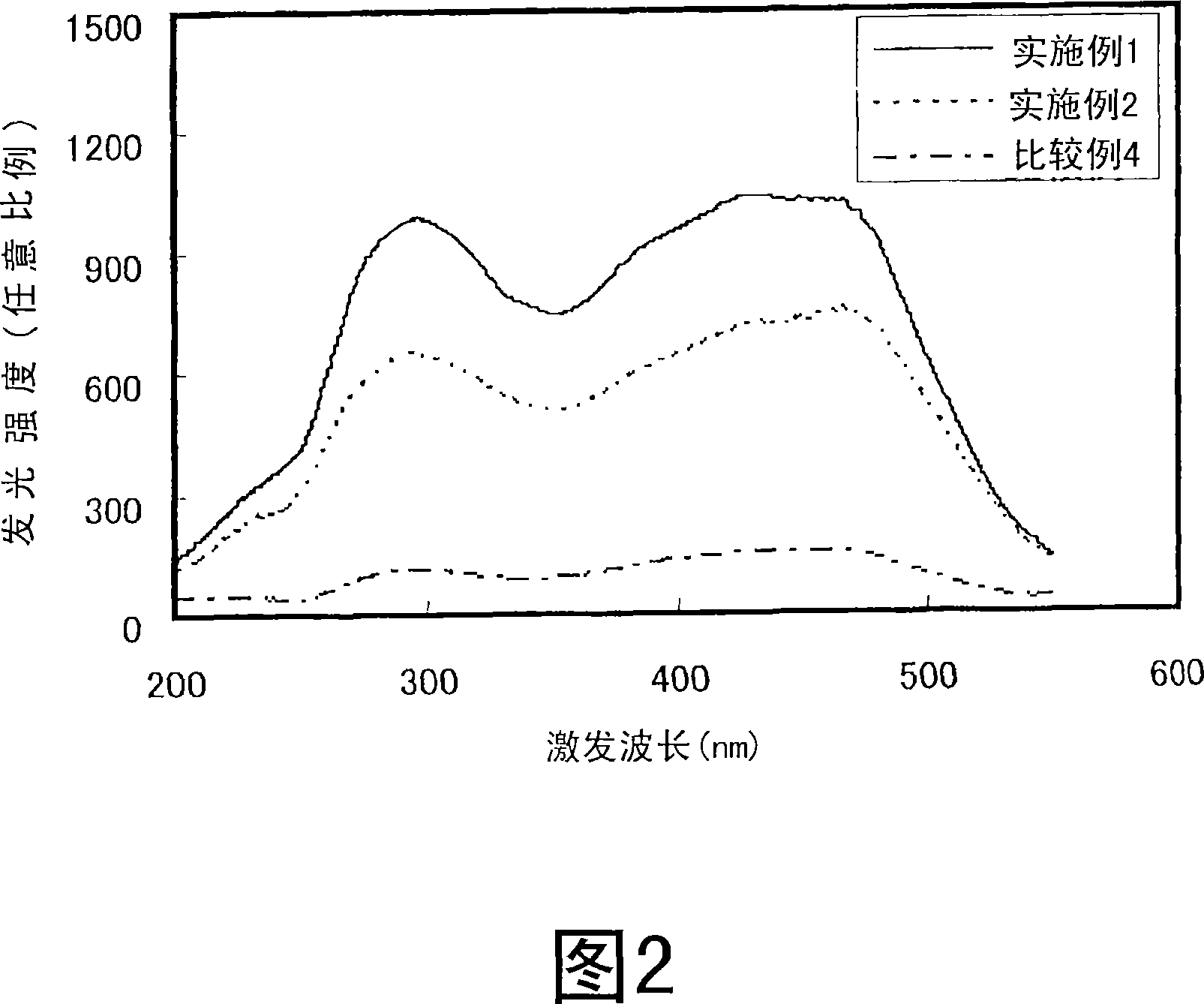

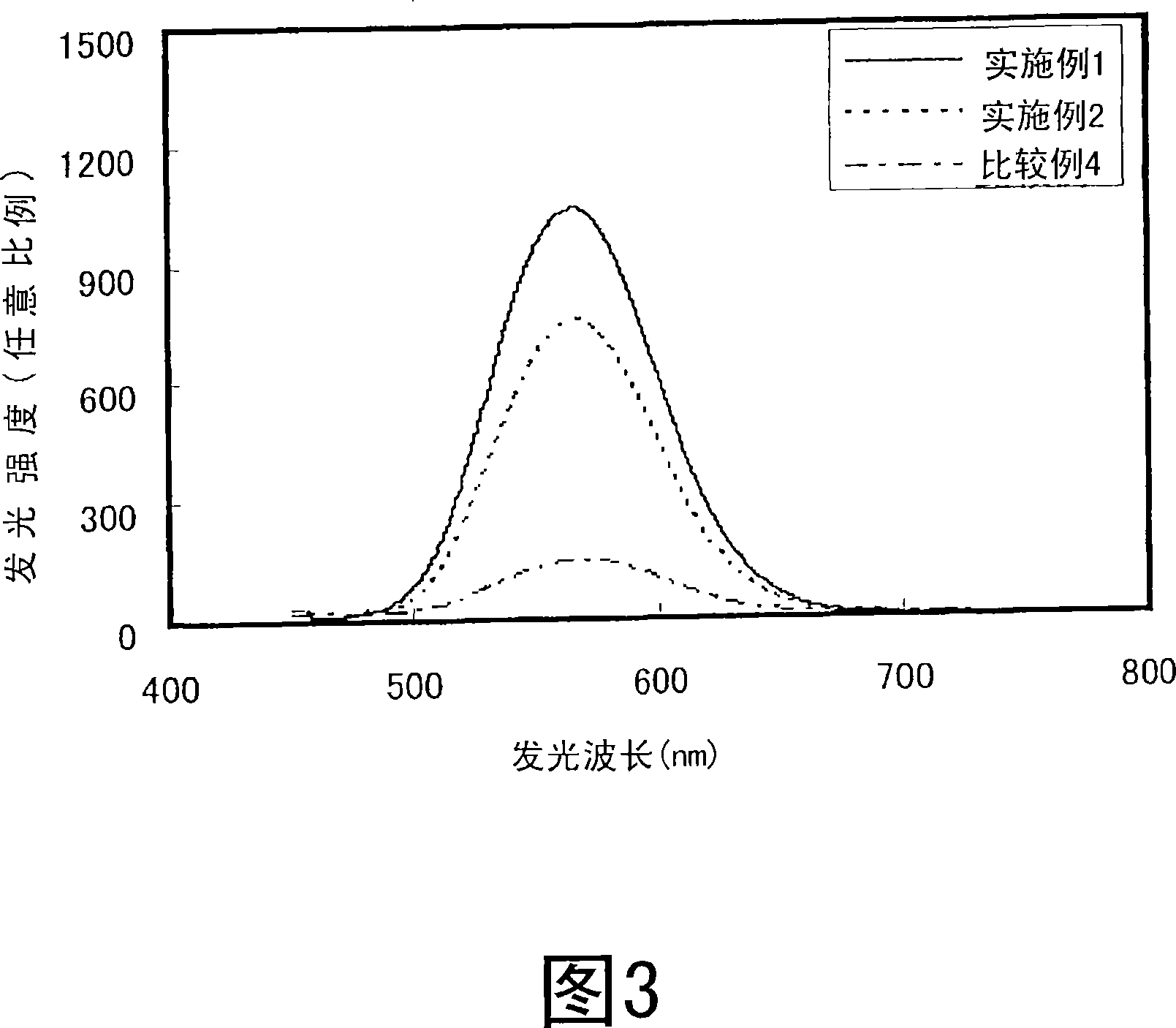

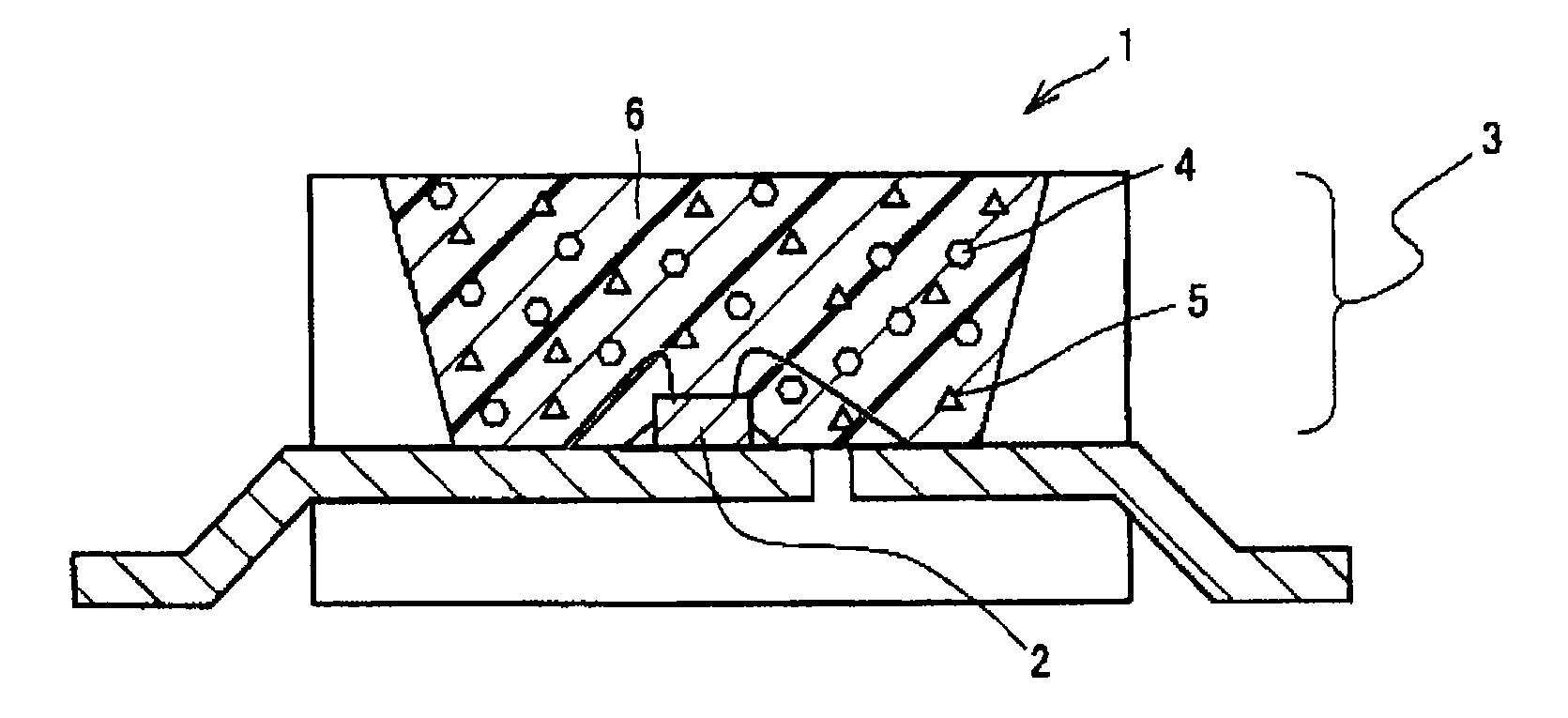

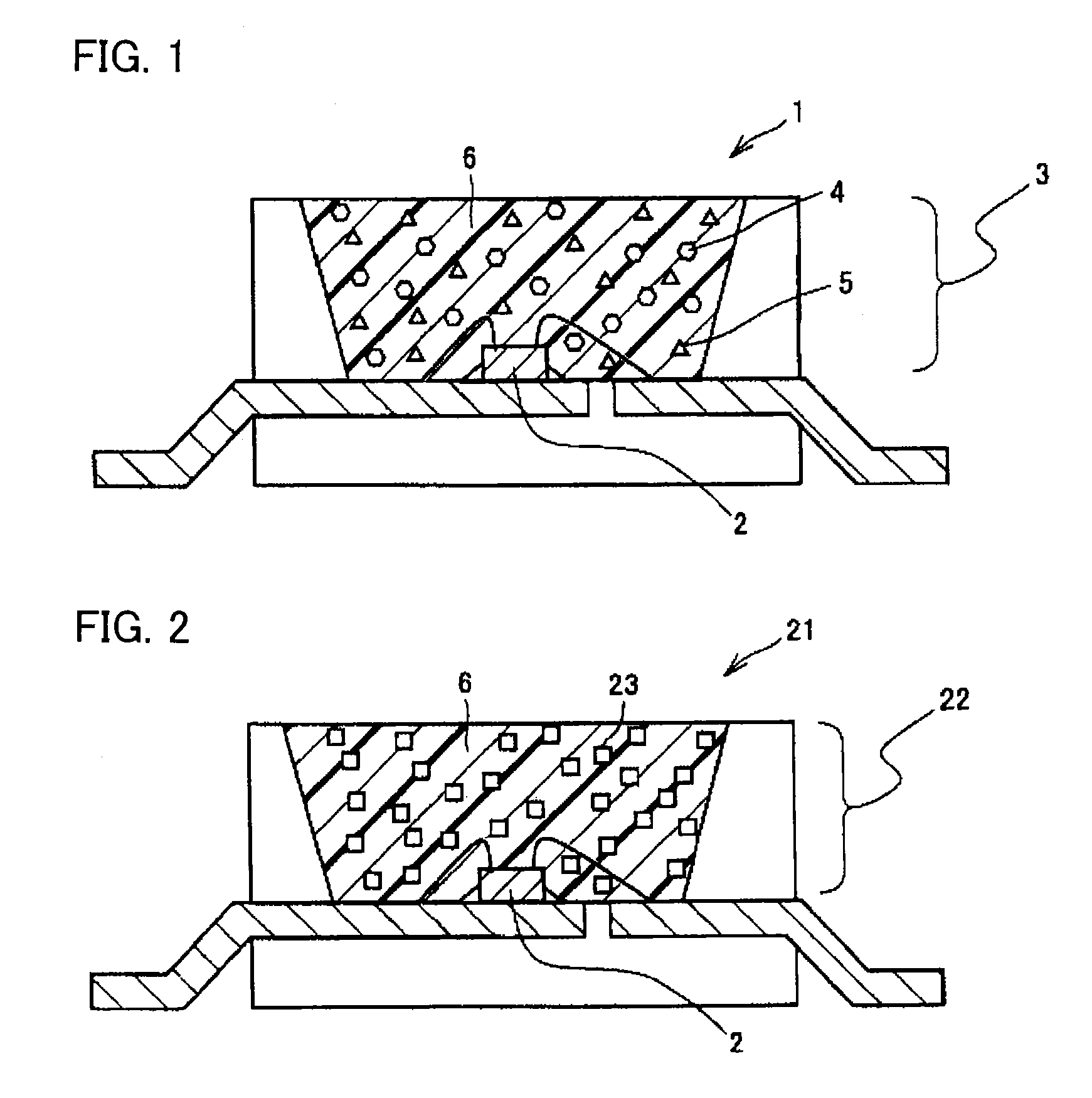

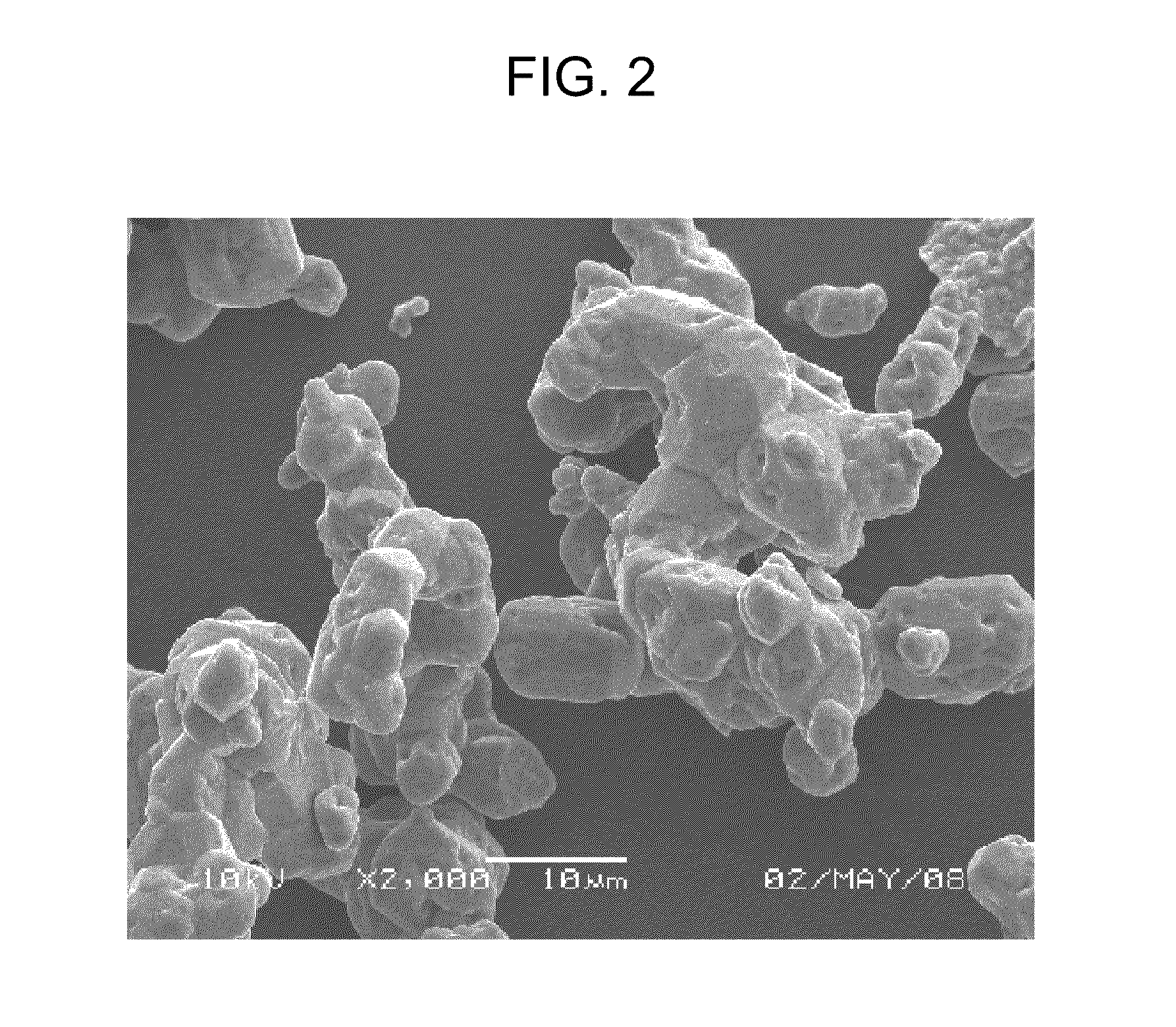

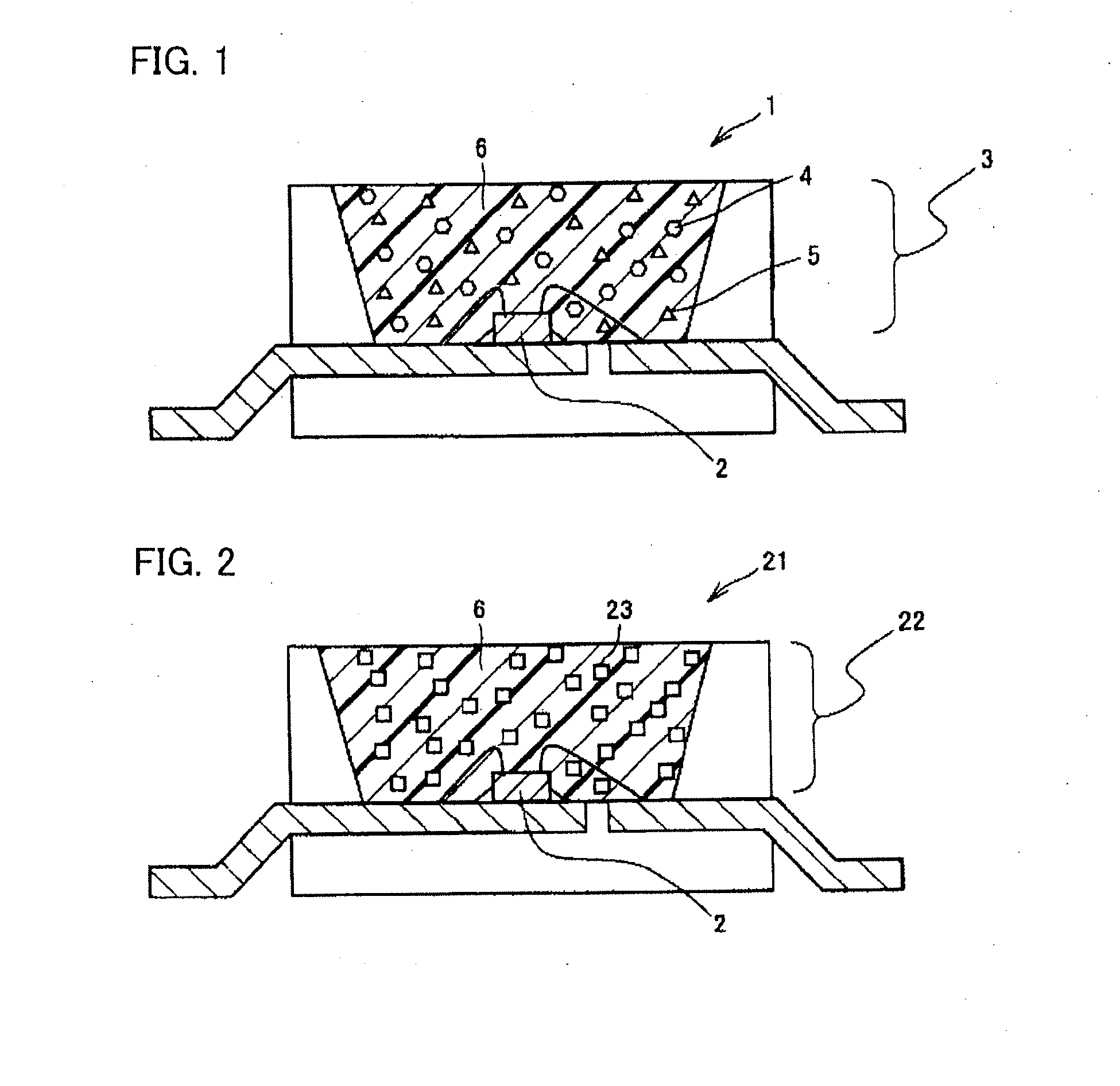

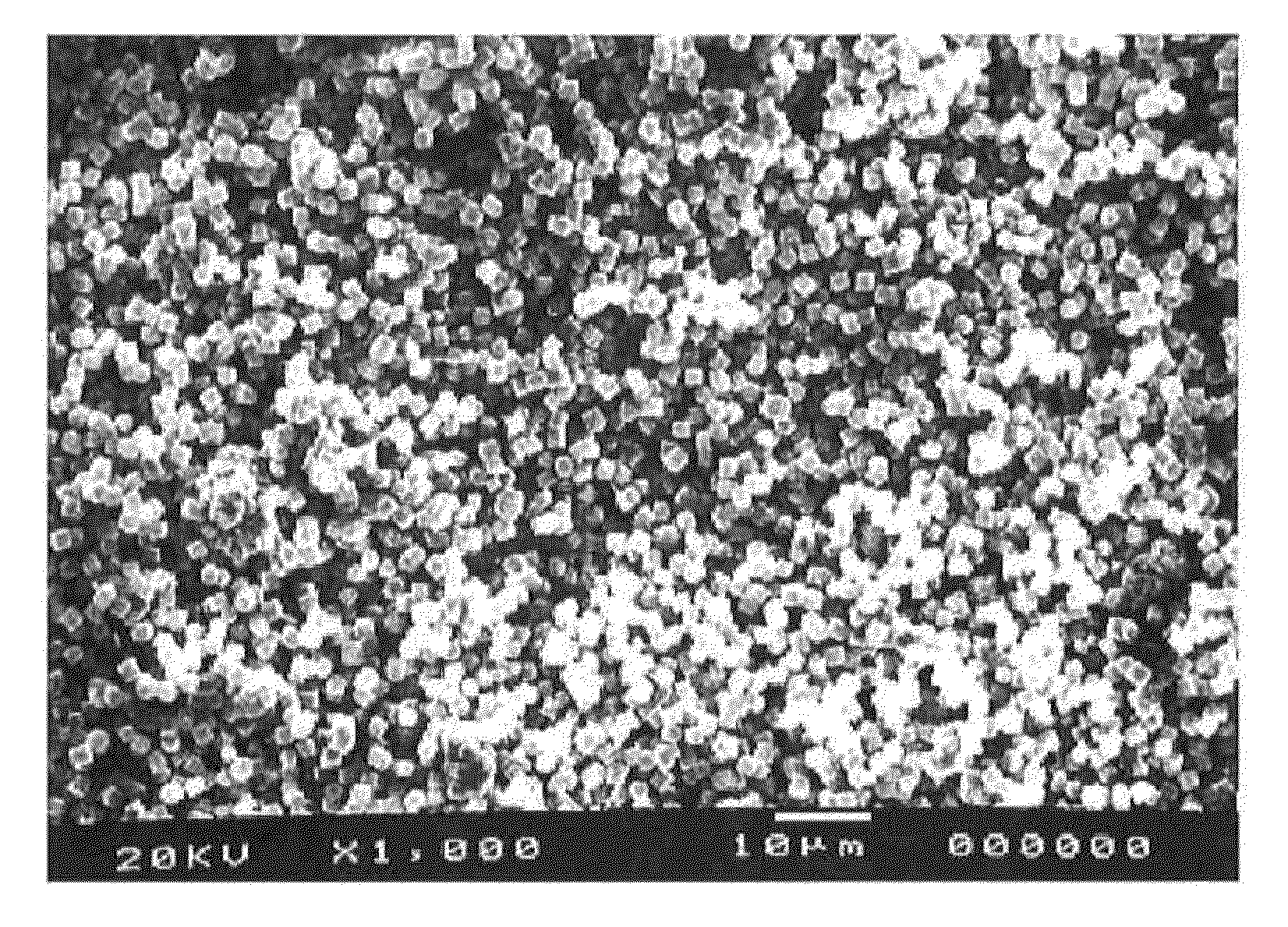

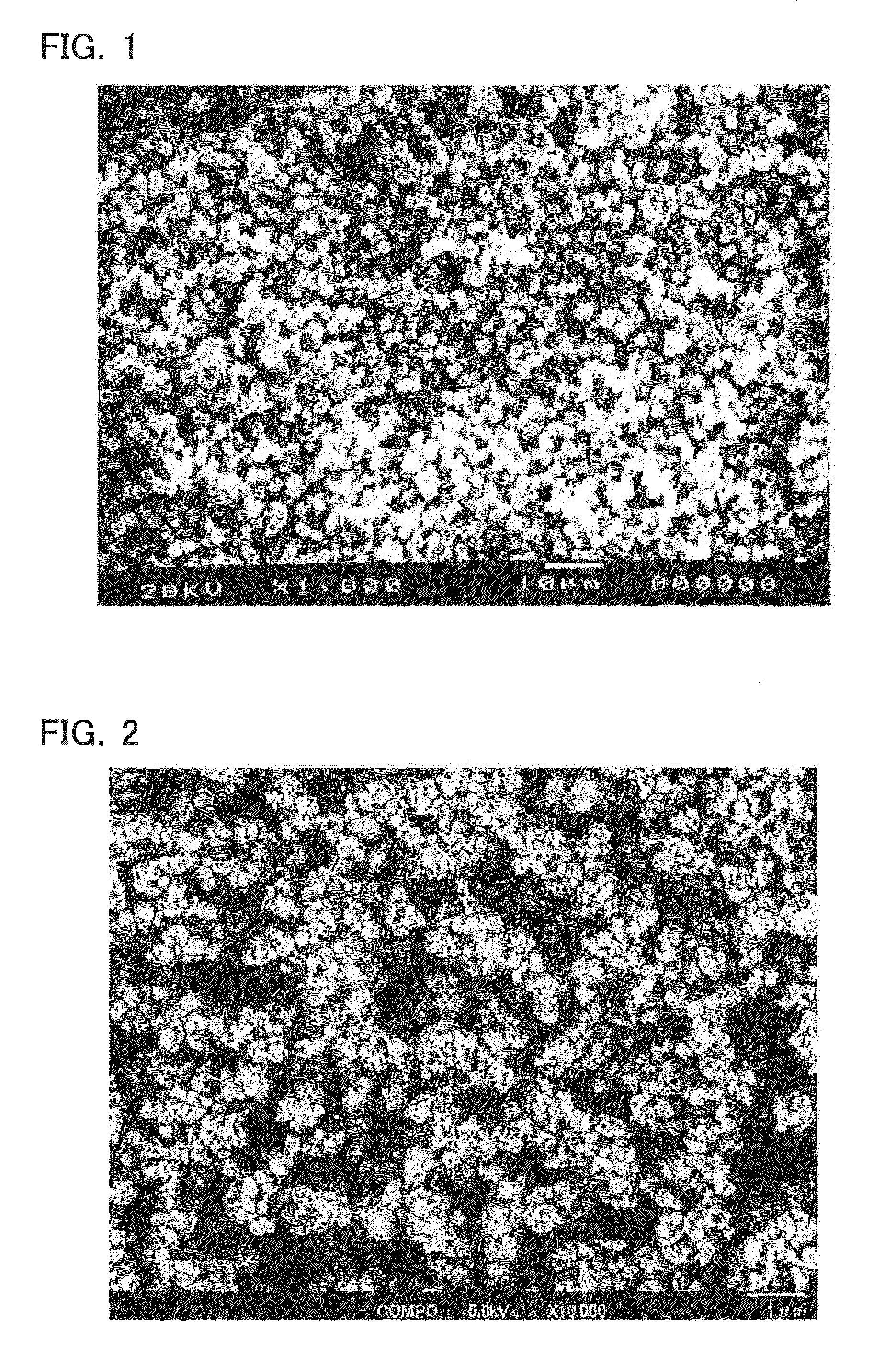

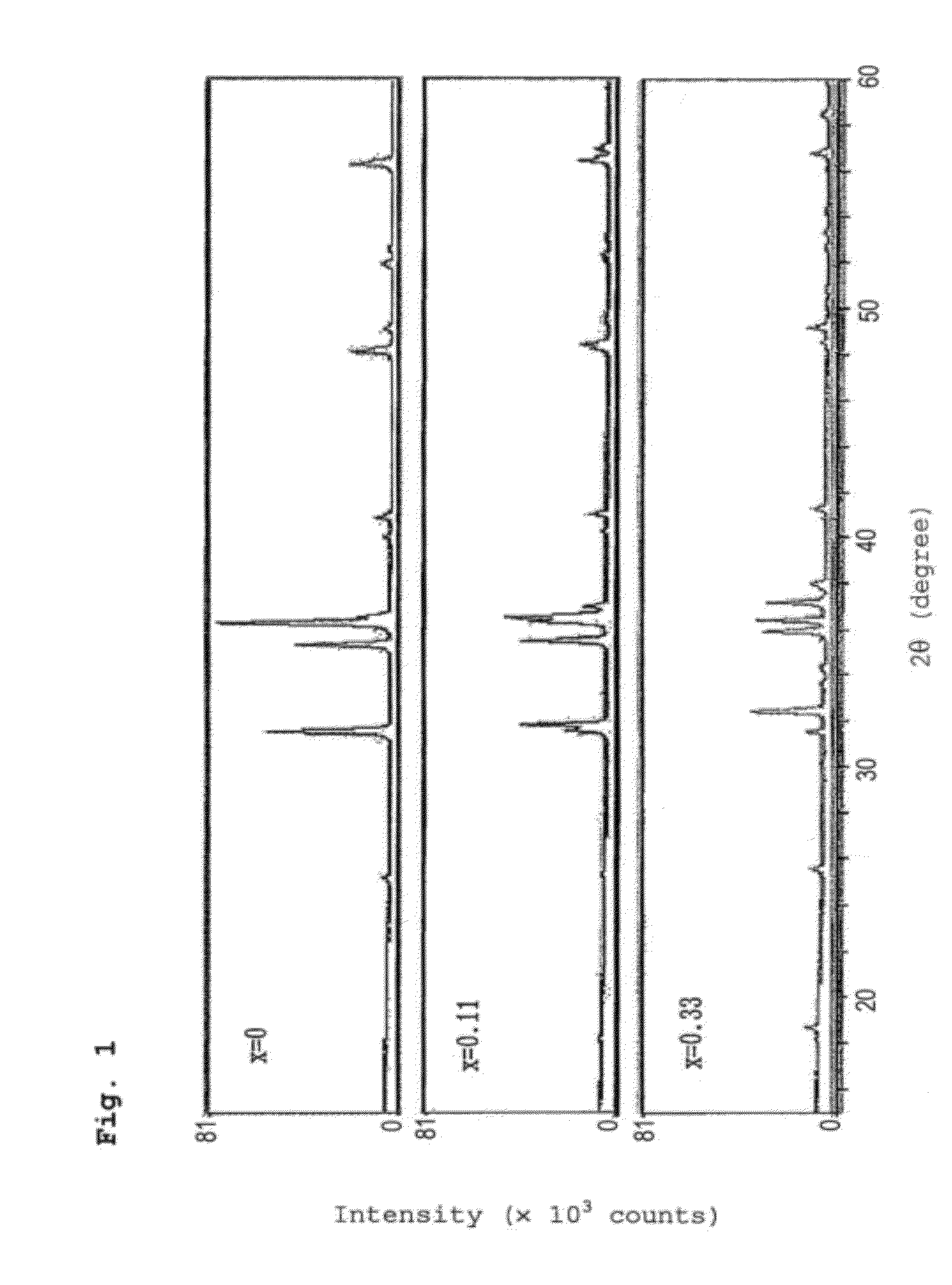

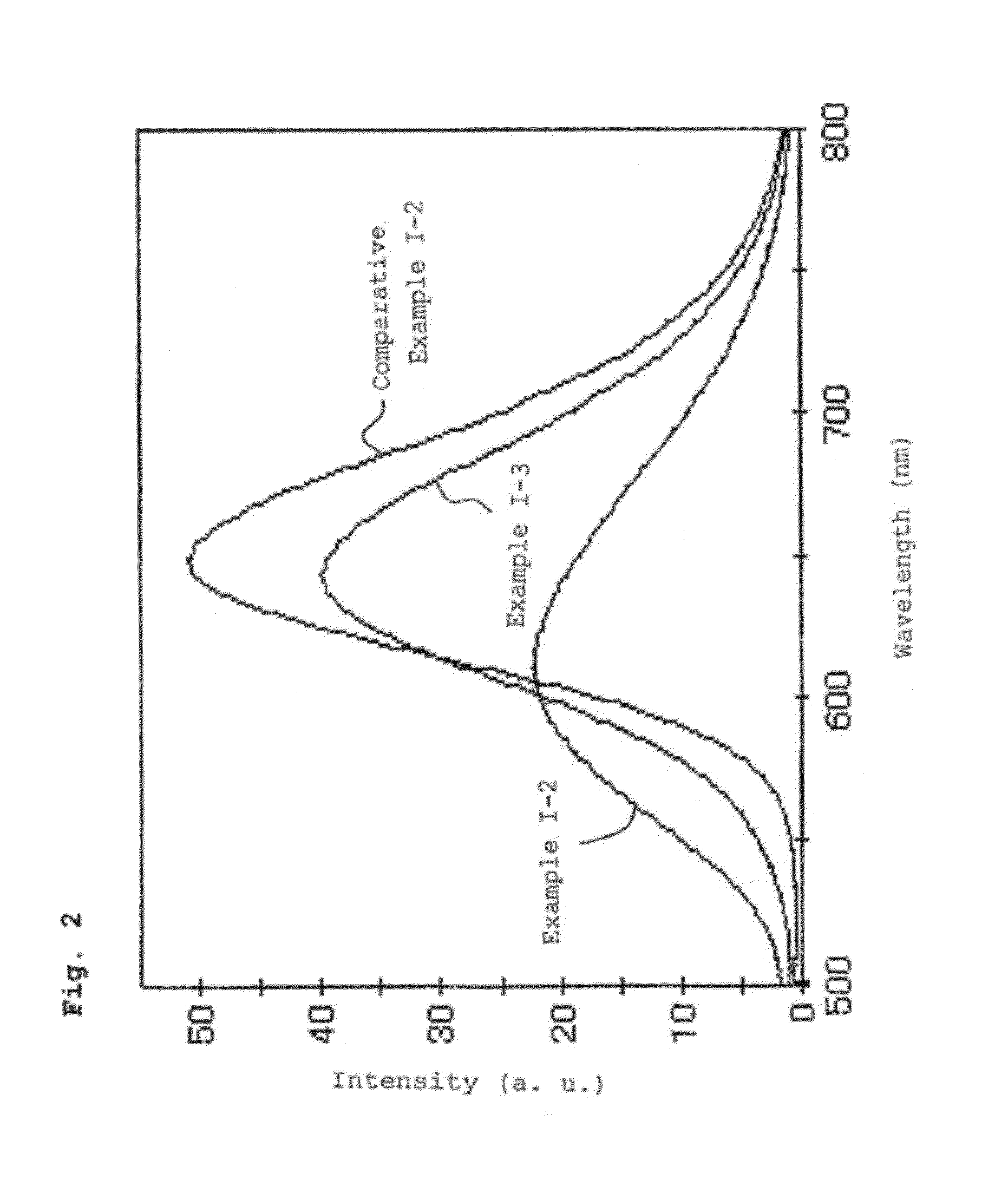

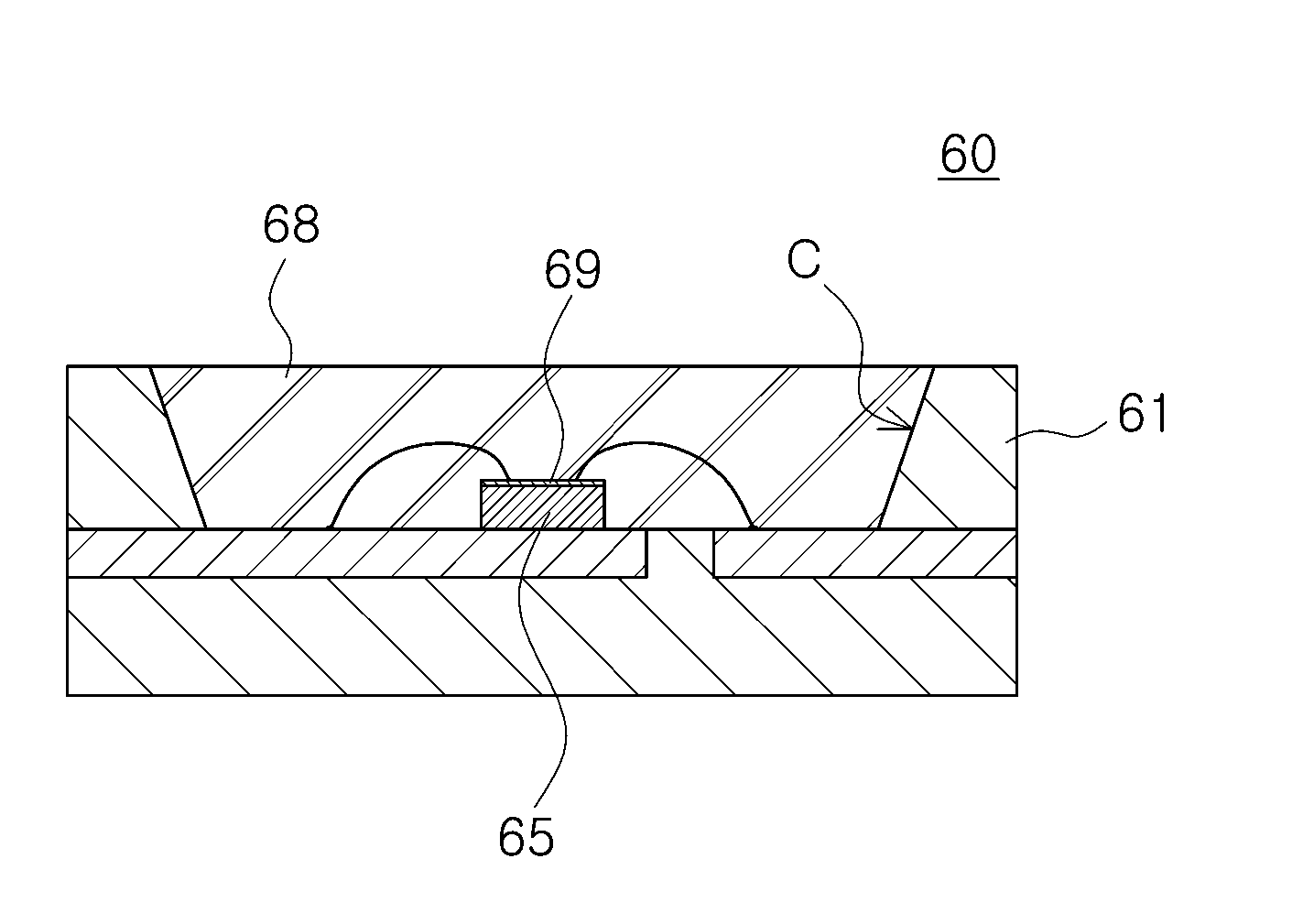

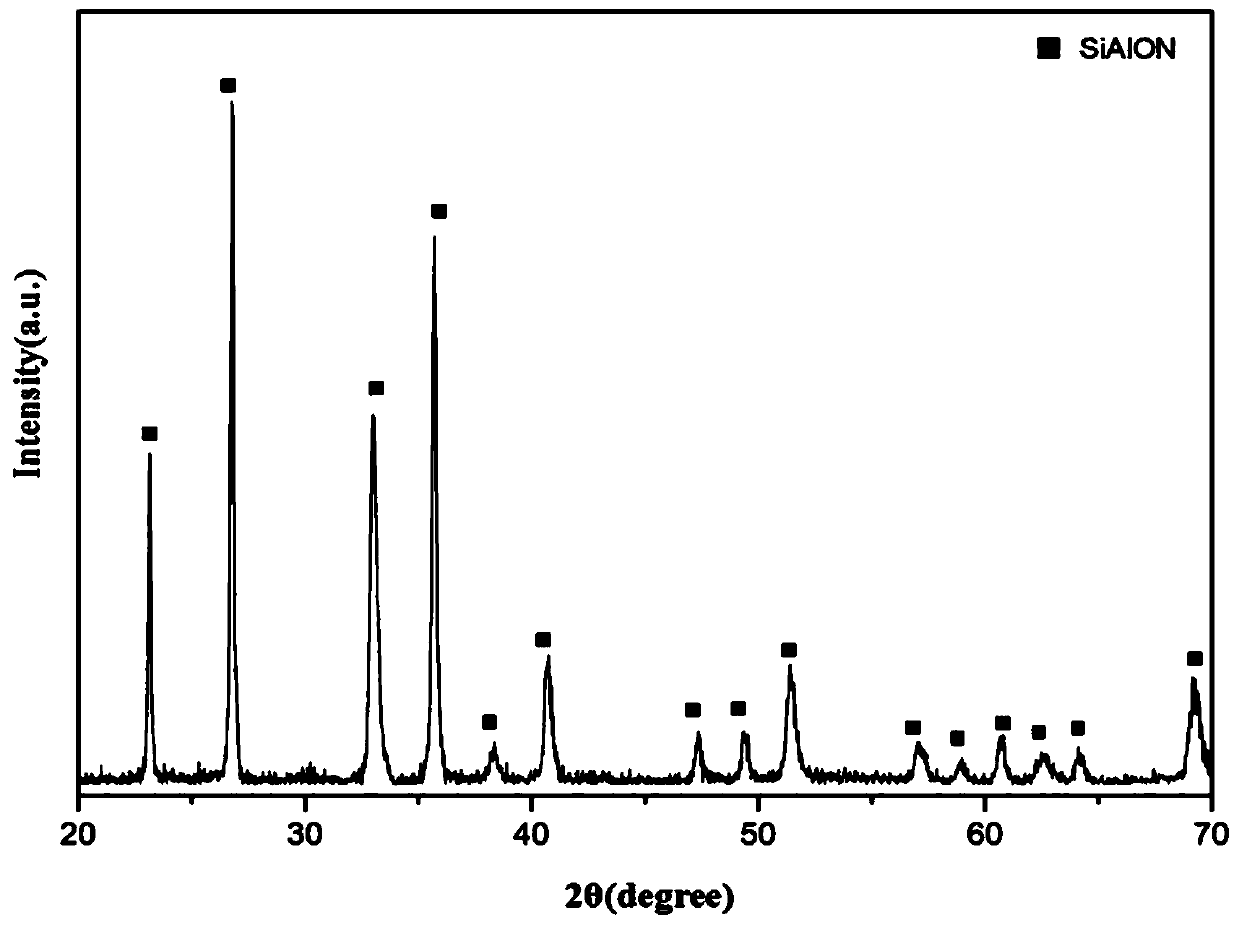

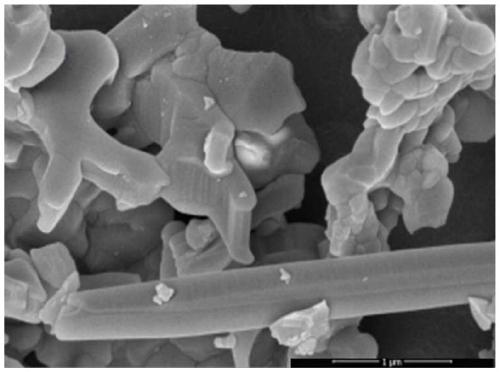

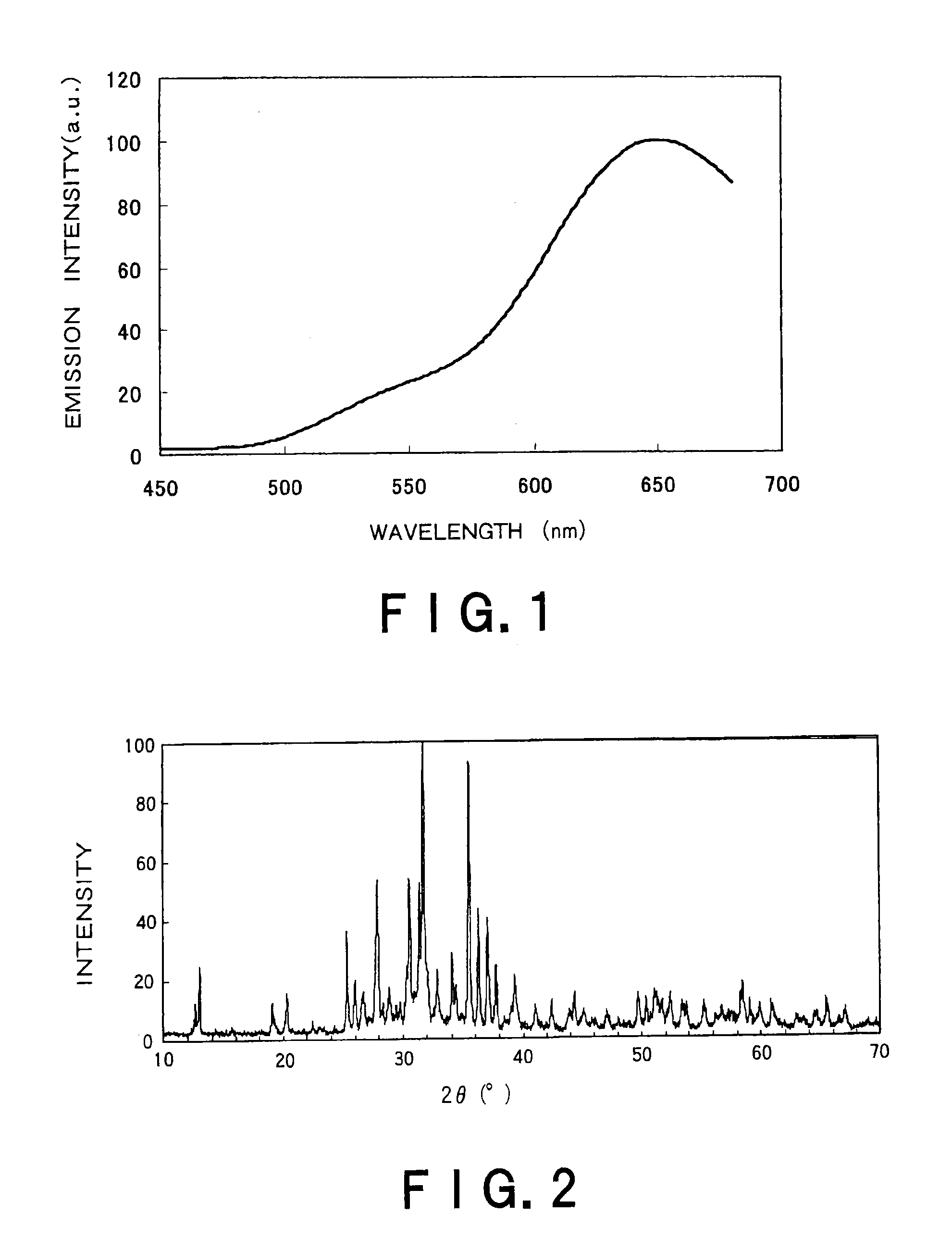

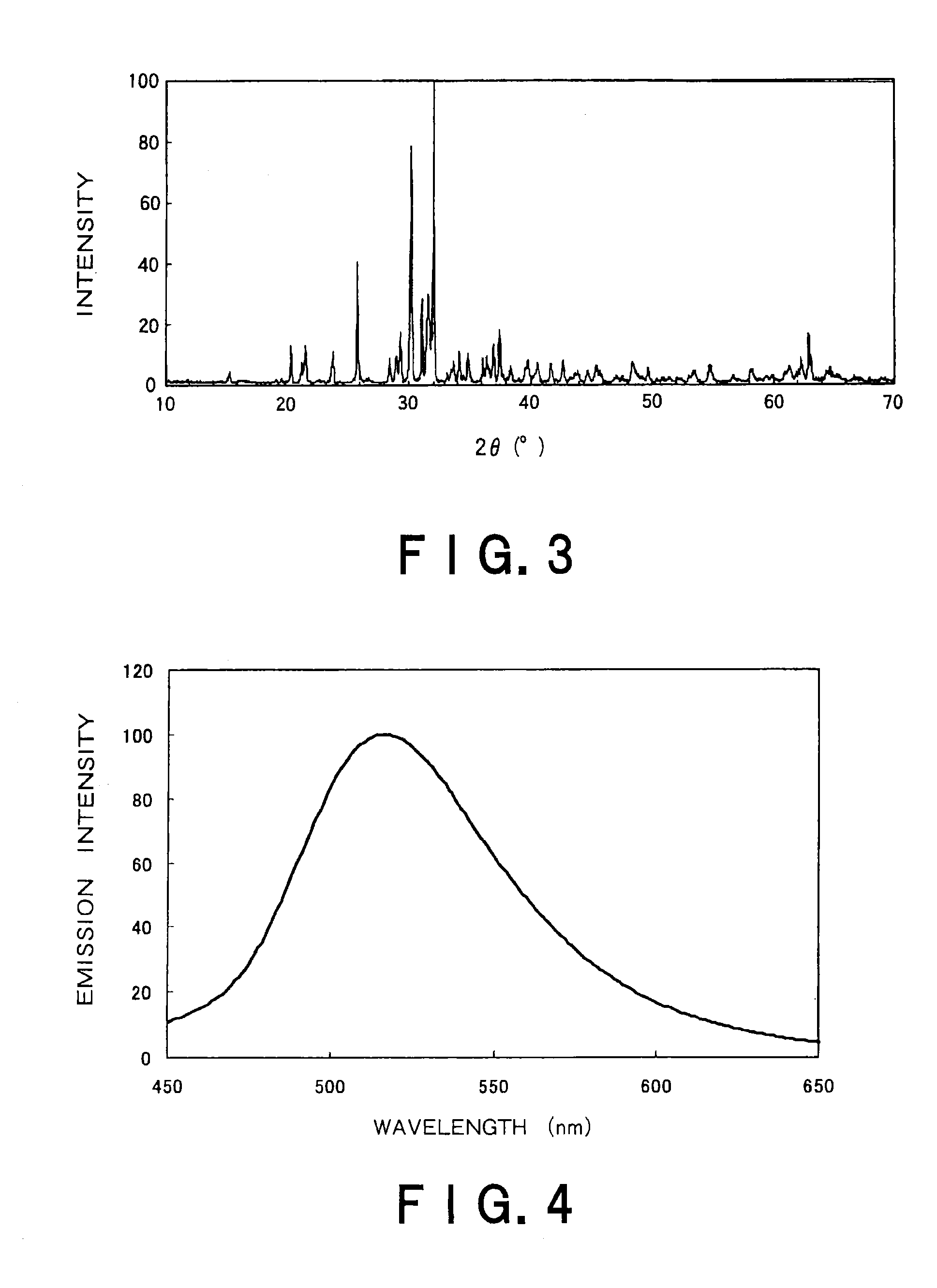

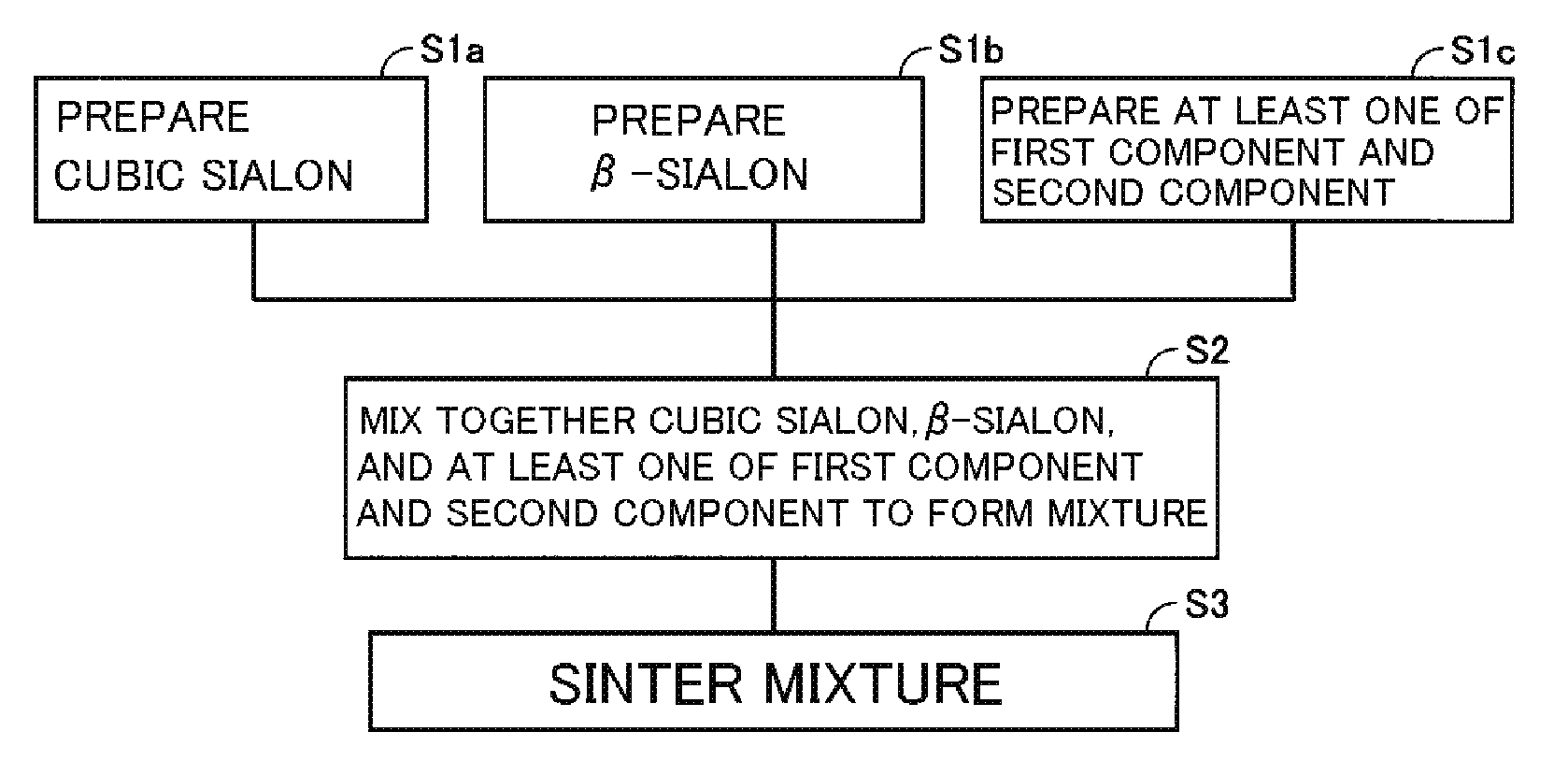

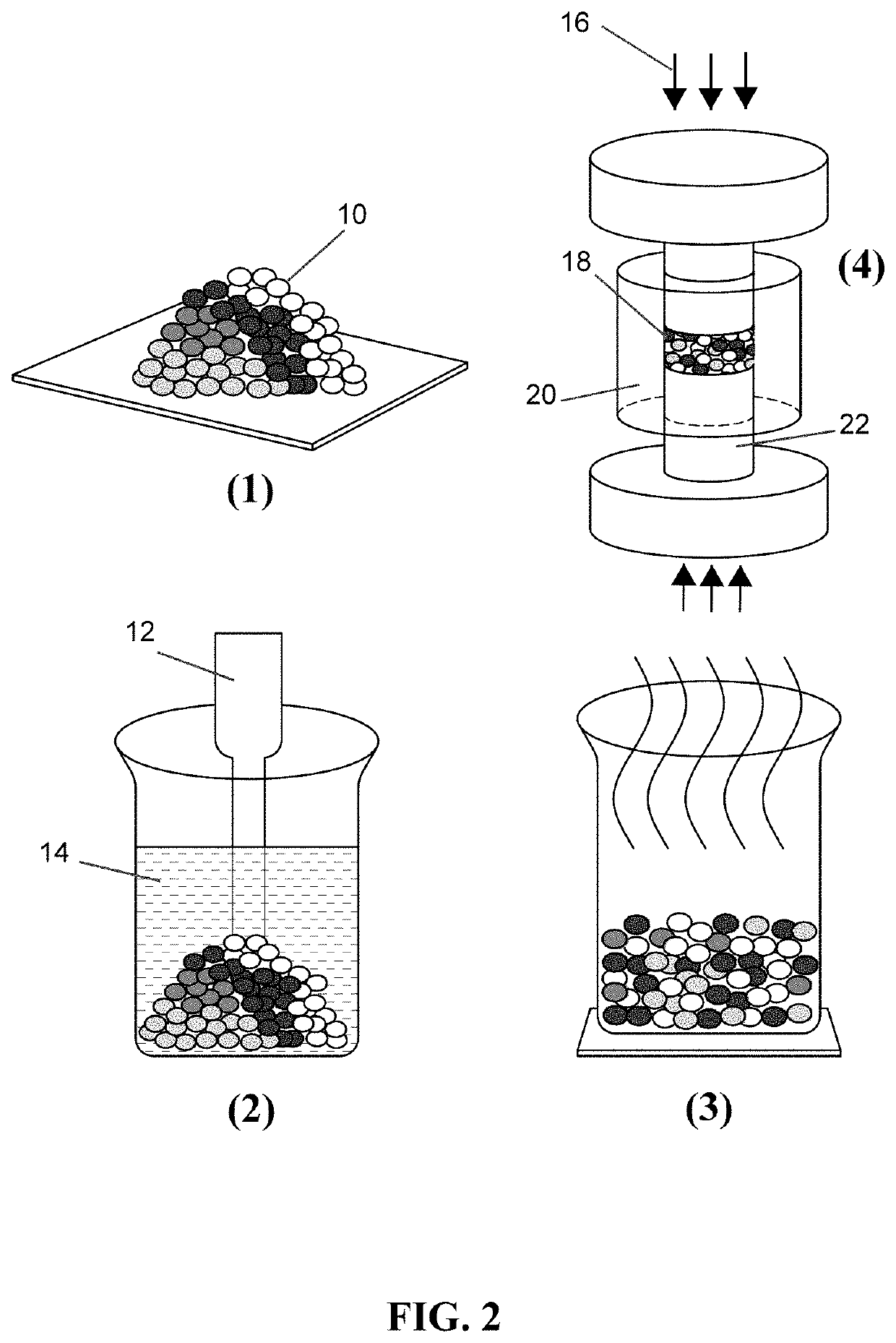

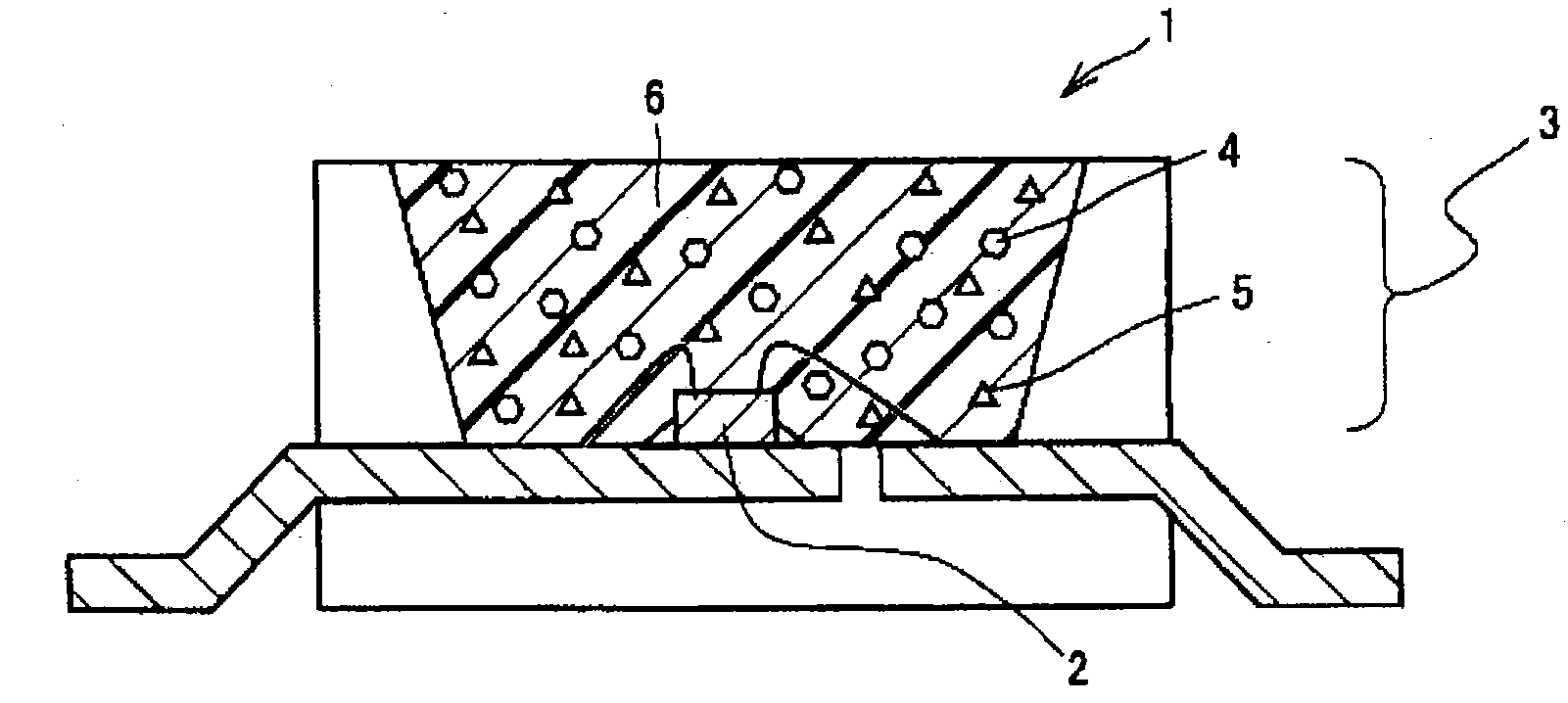

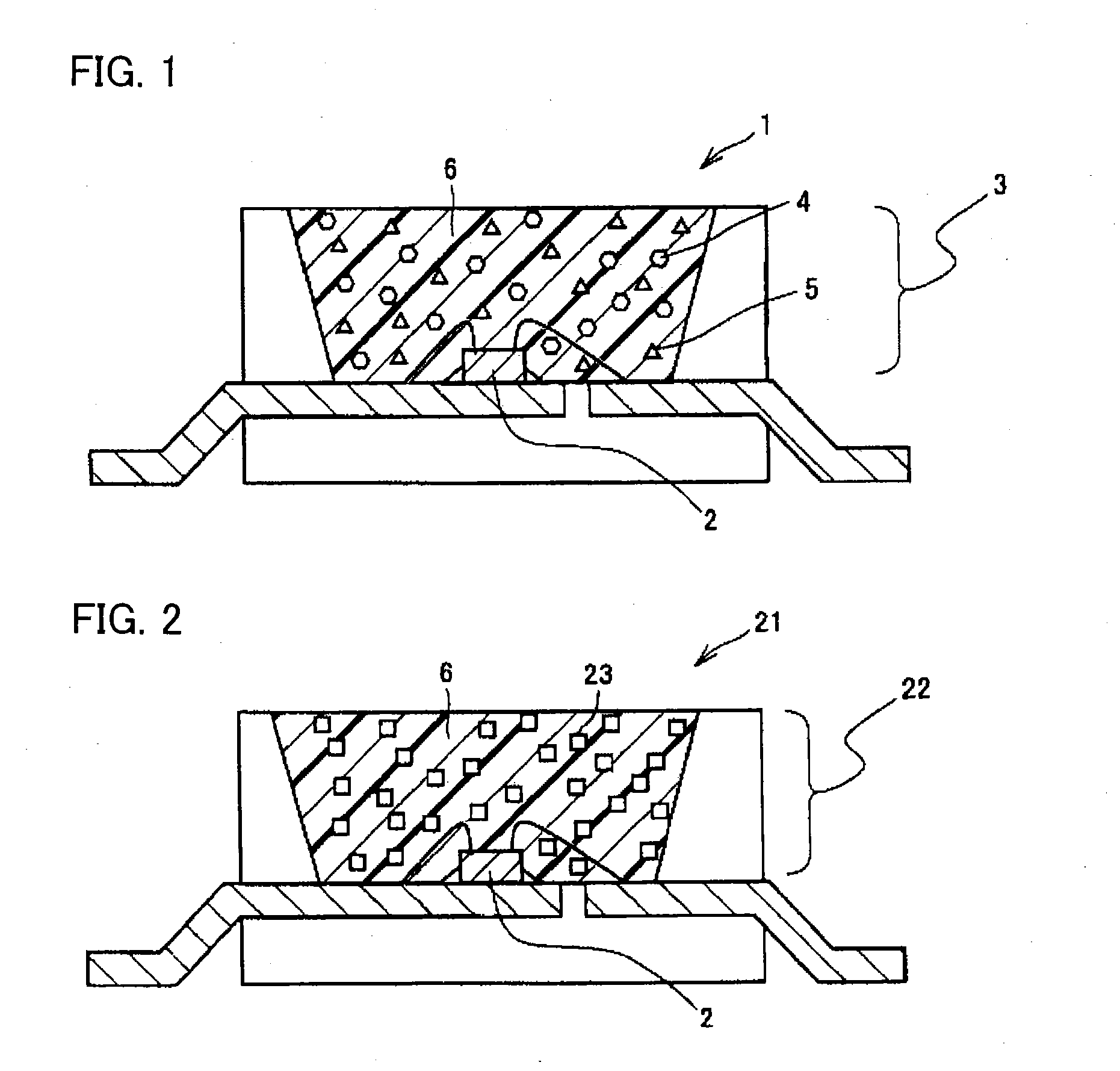

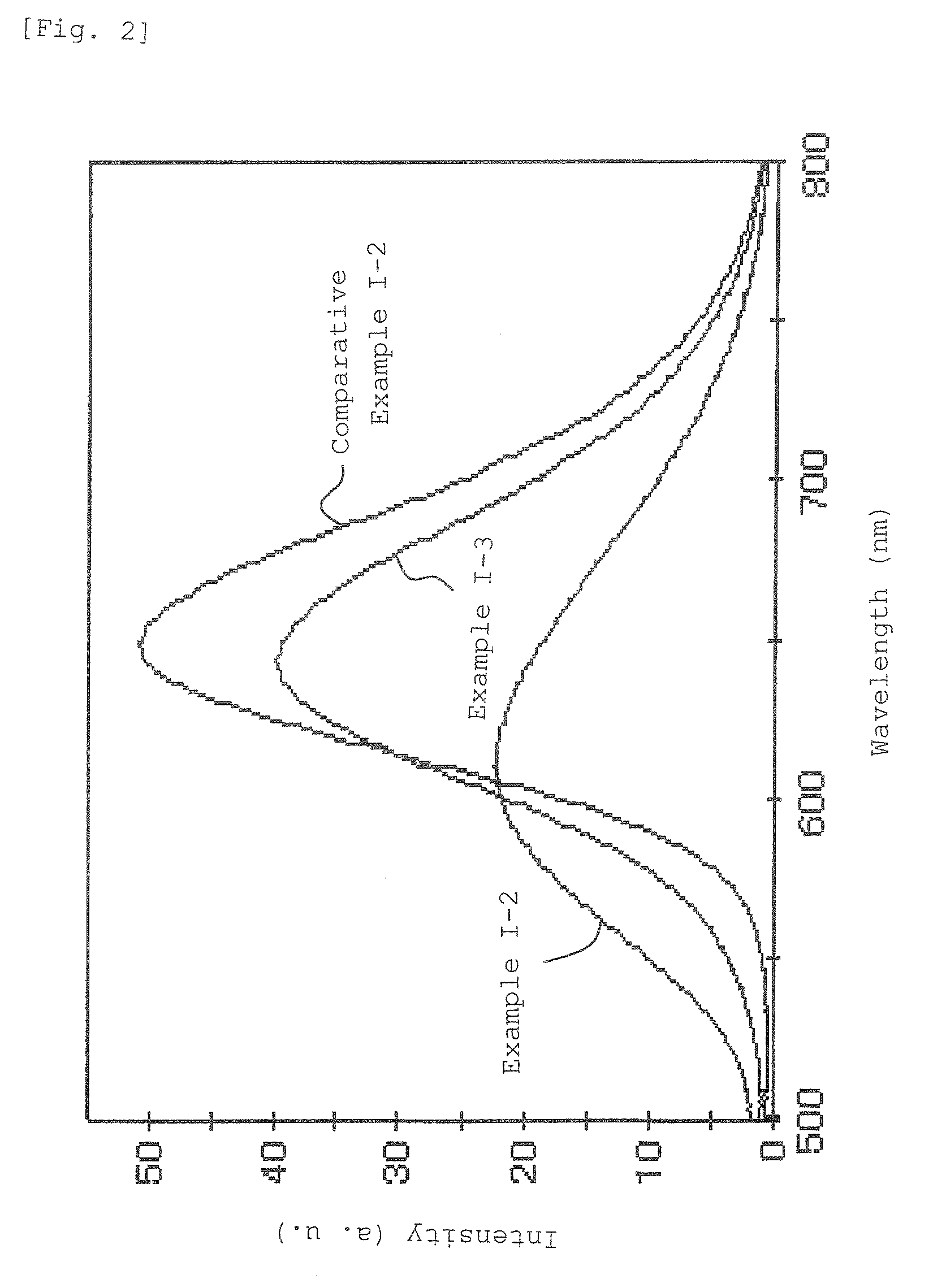

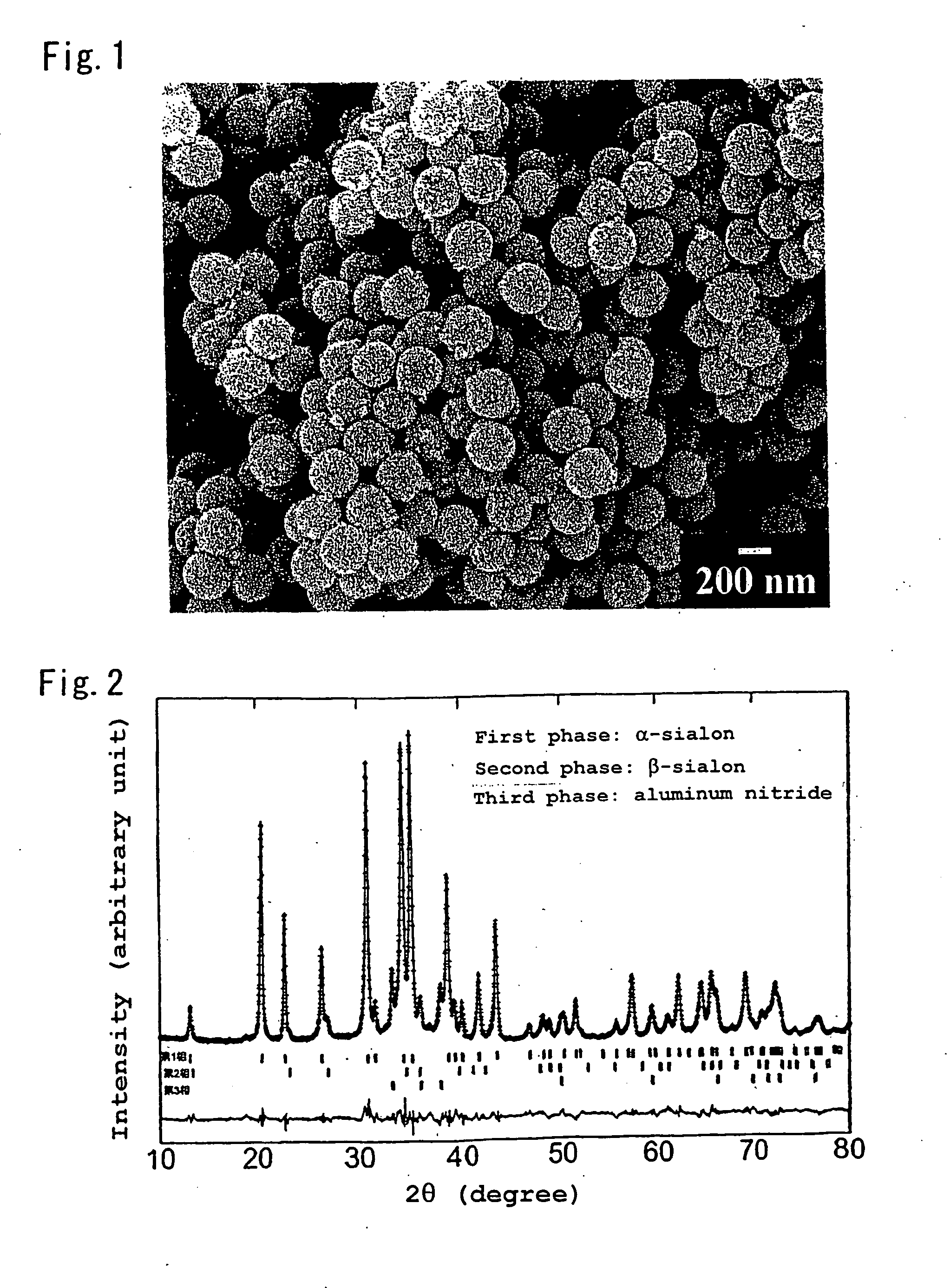

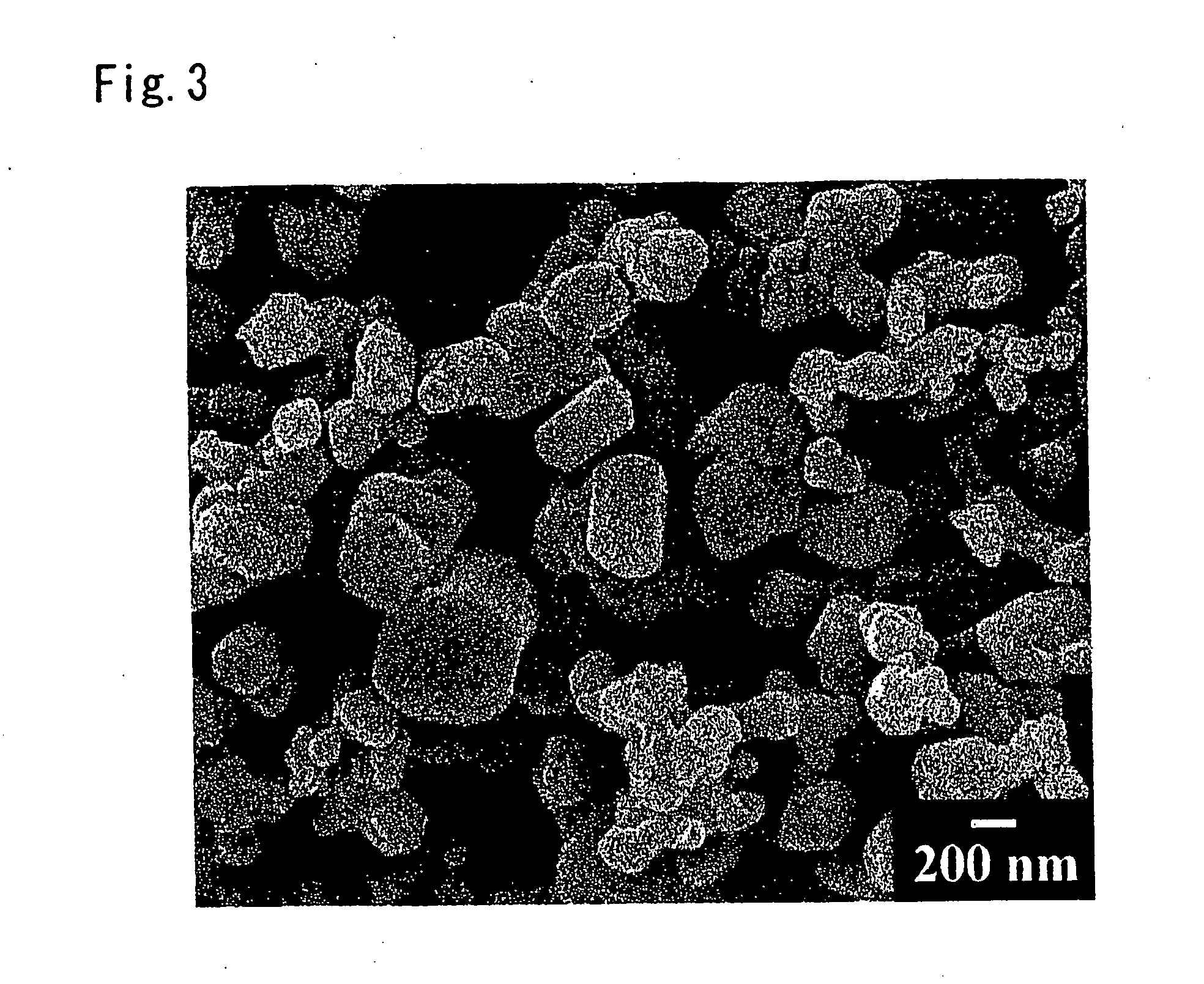

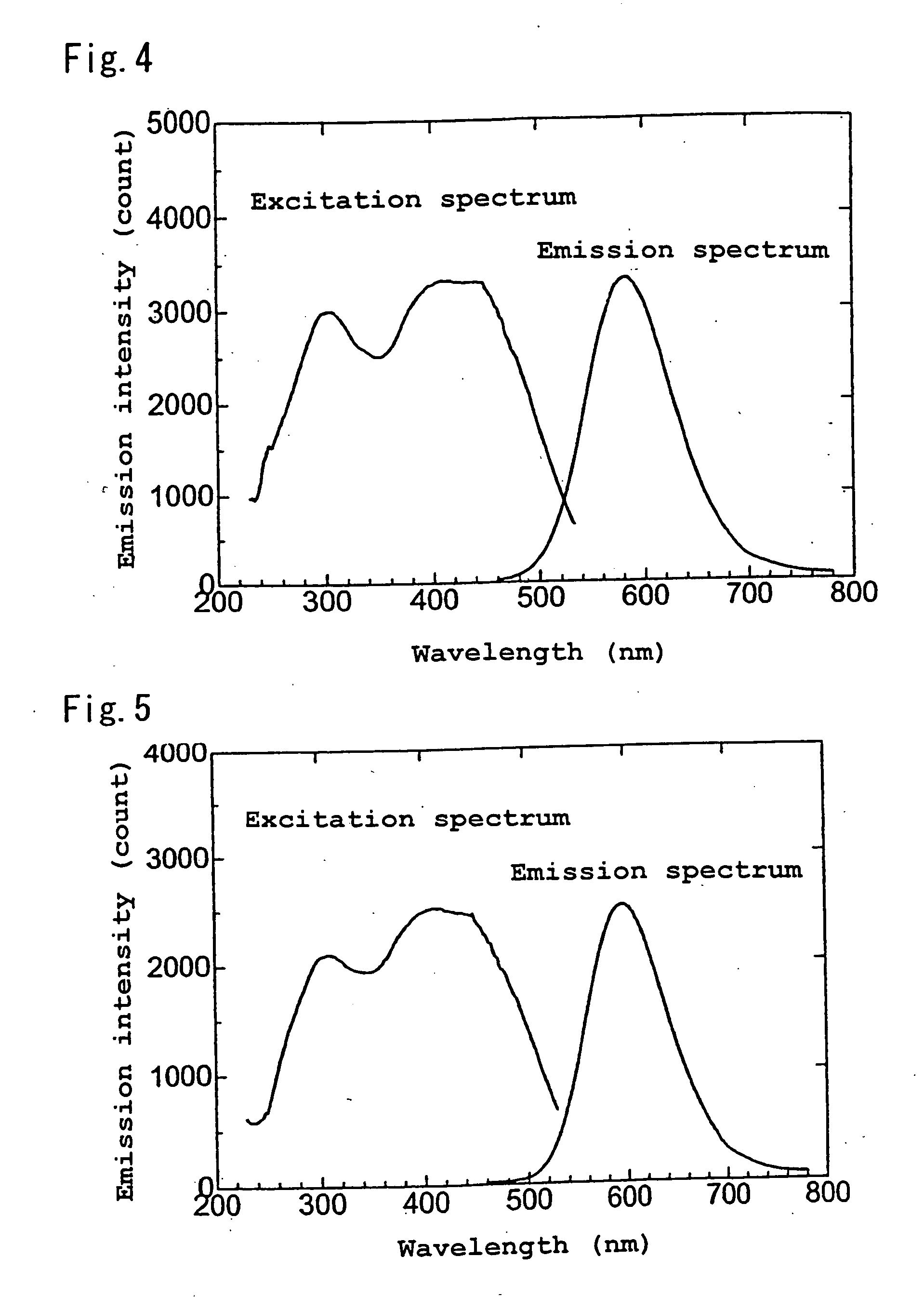

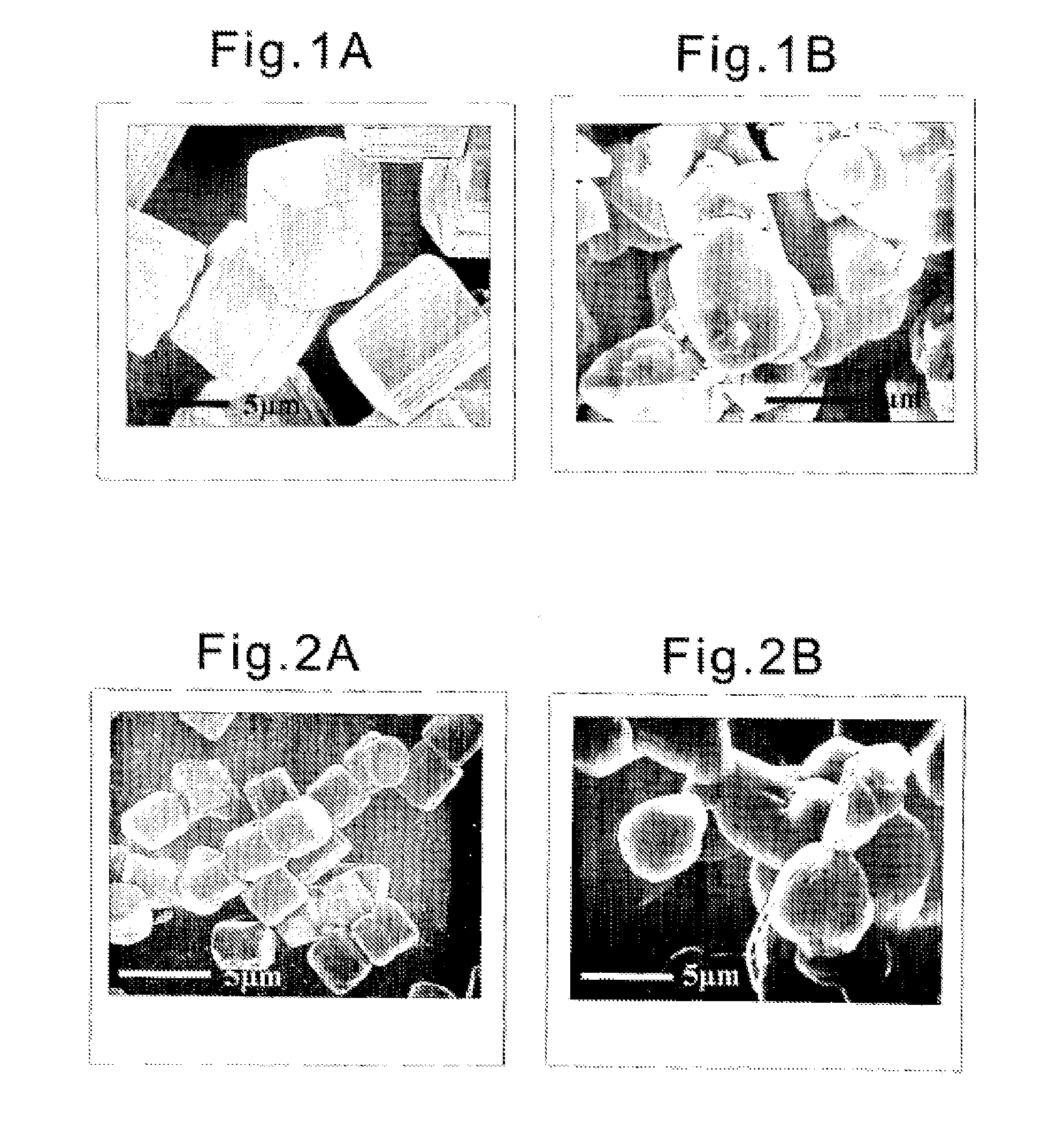

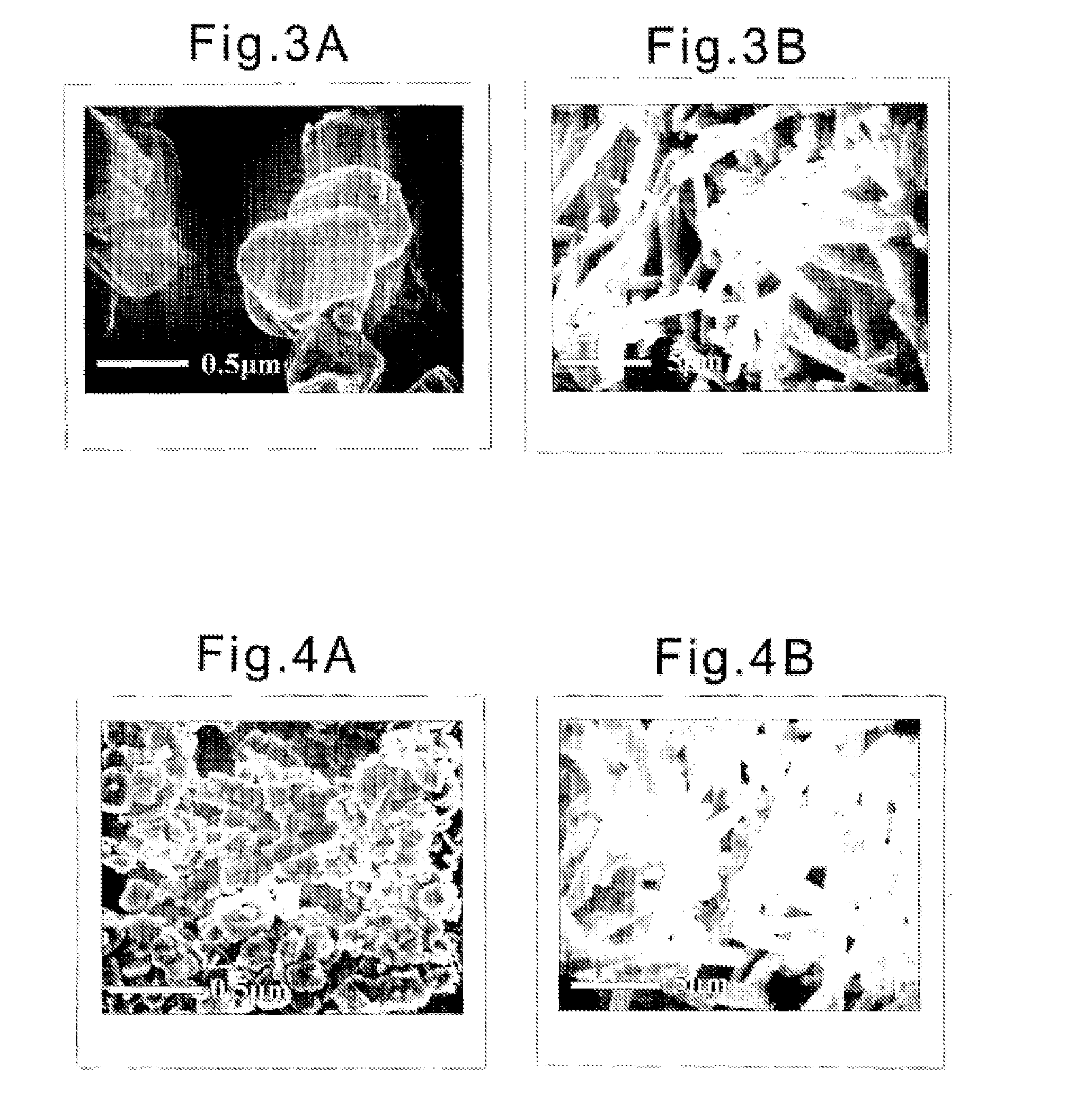

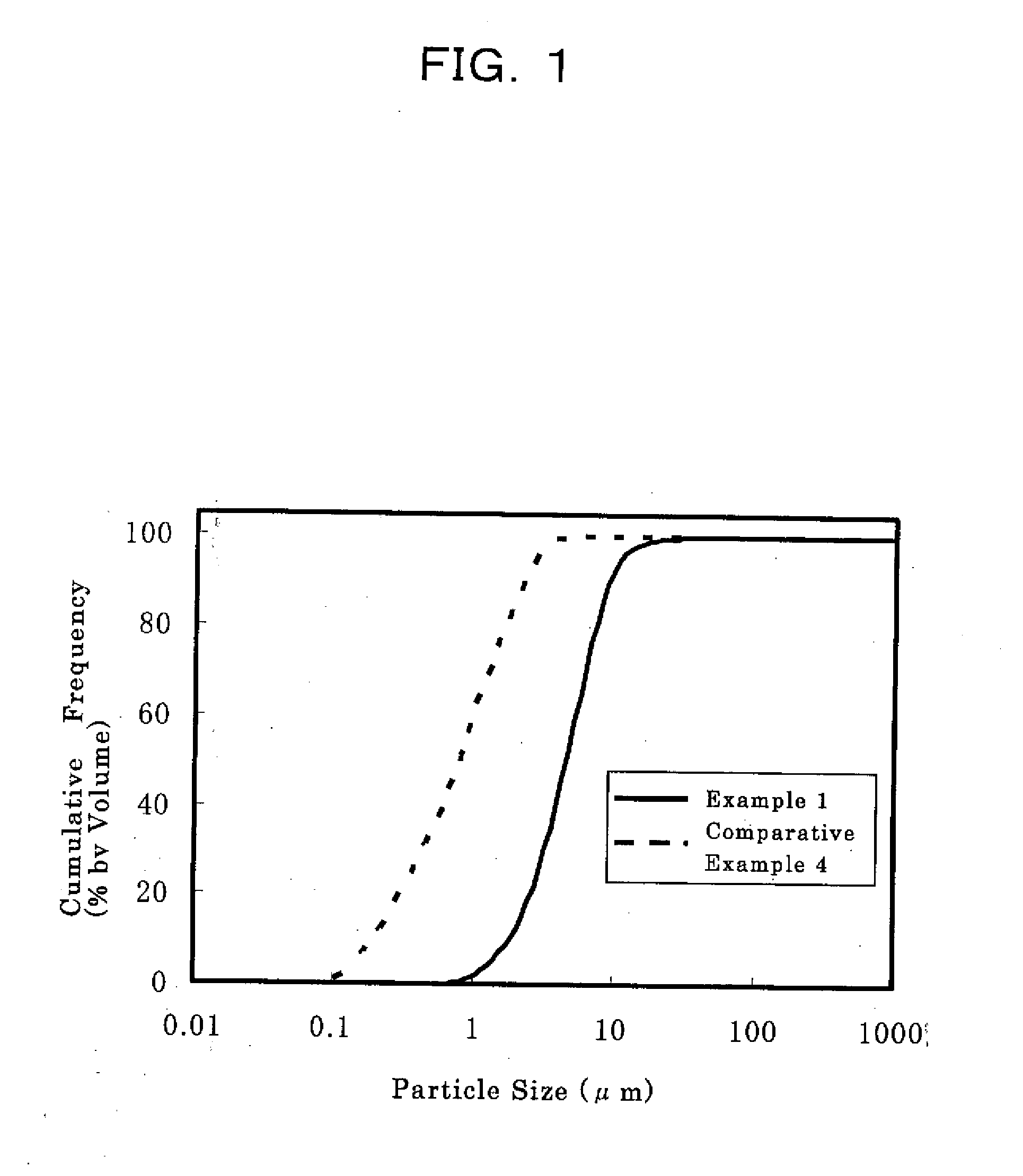

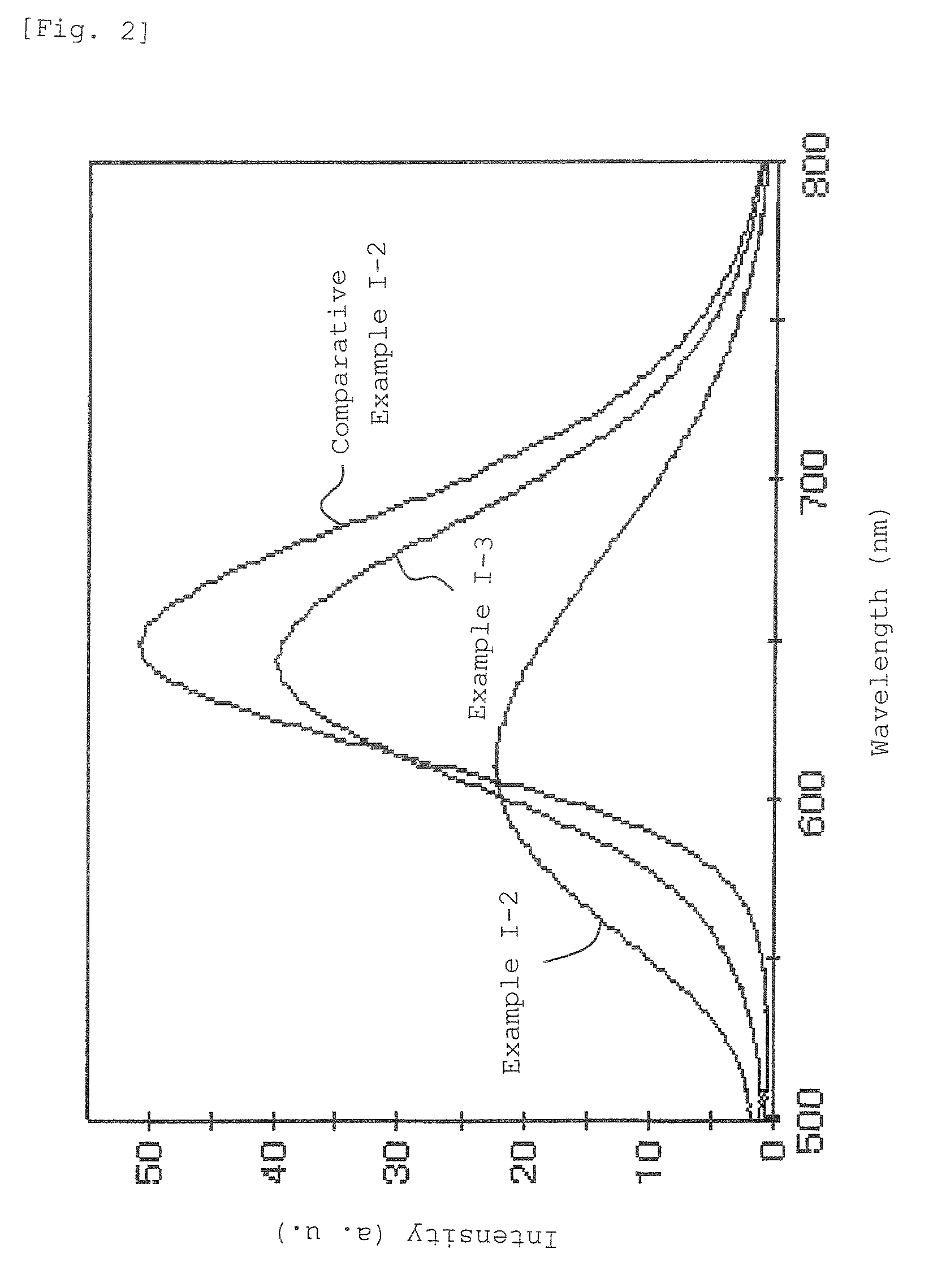

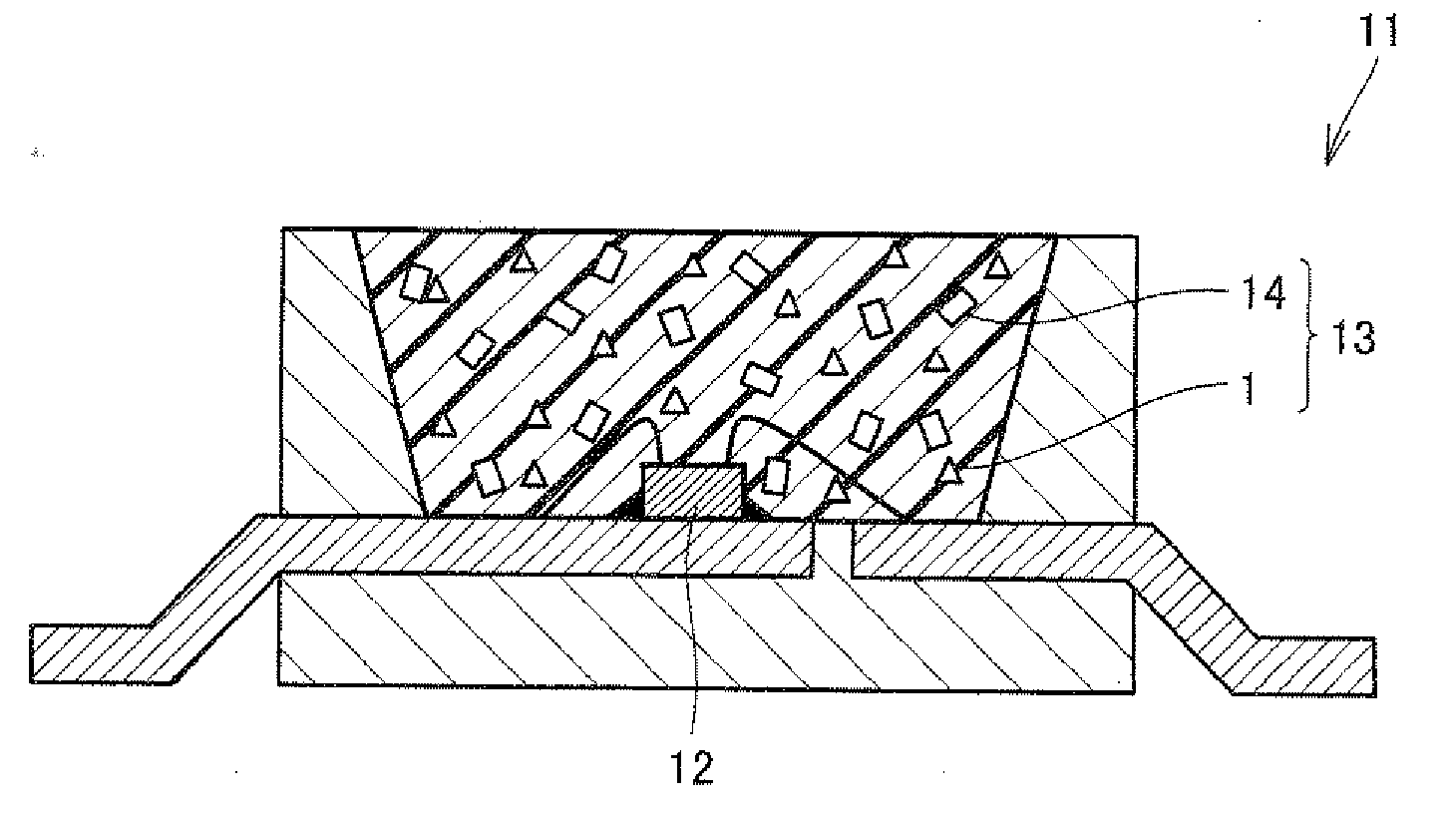

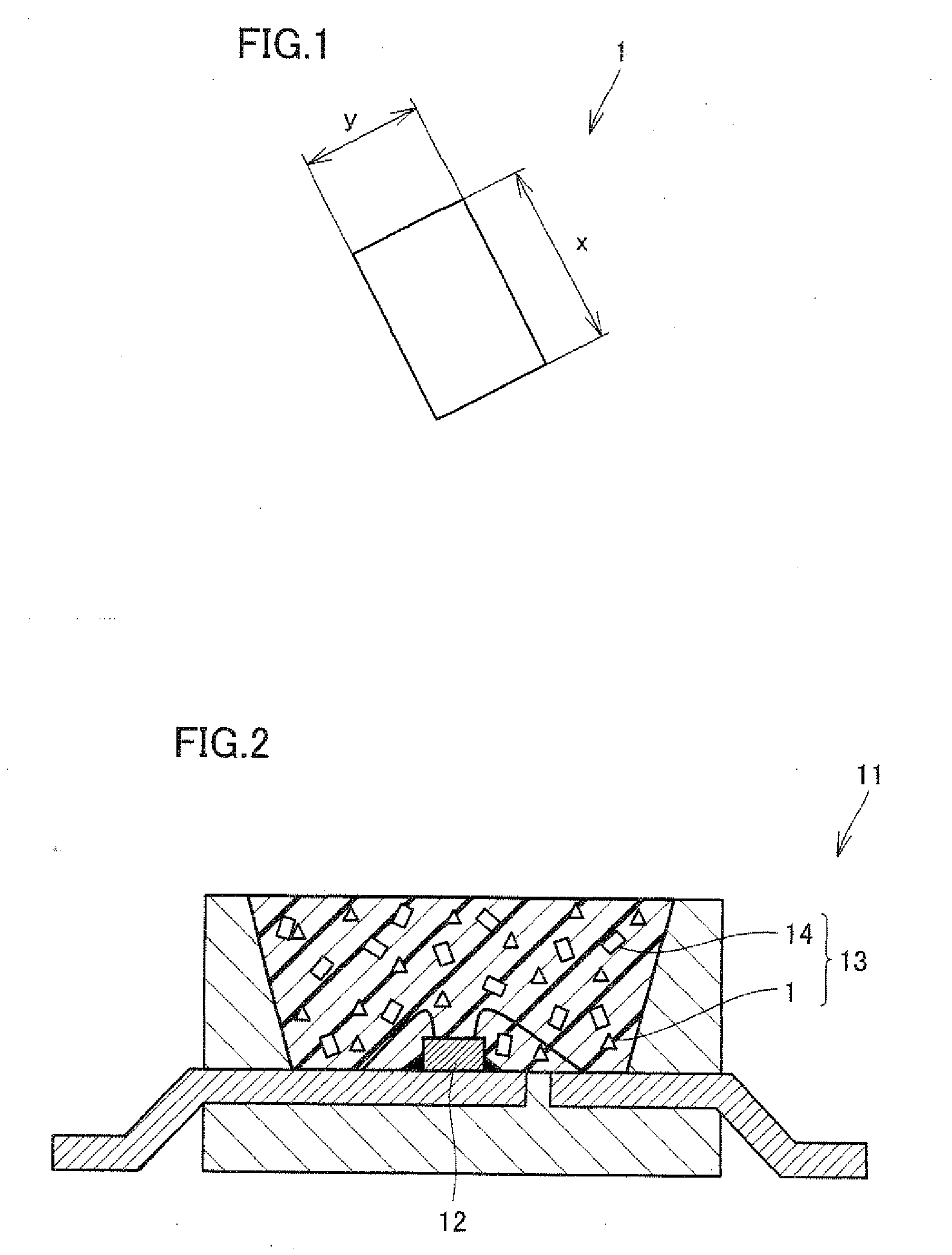

[beta]-sialon phosphor powder and process for production of the same

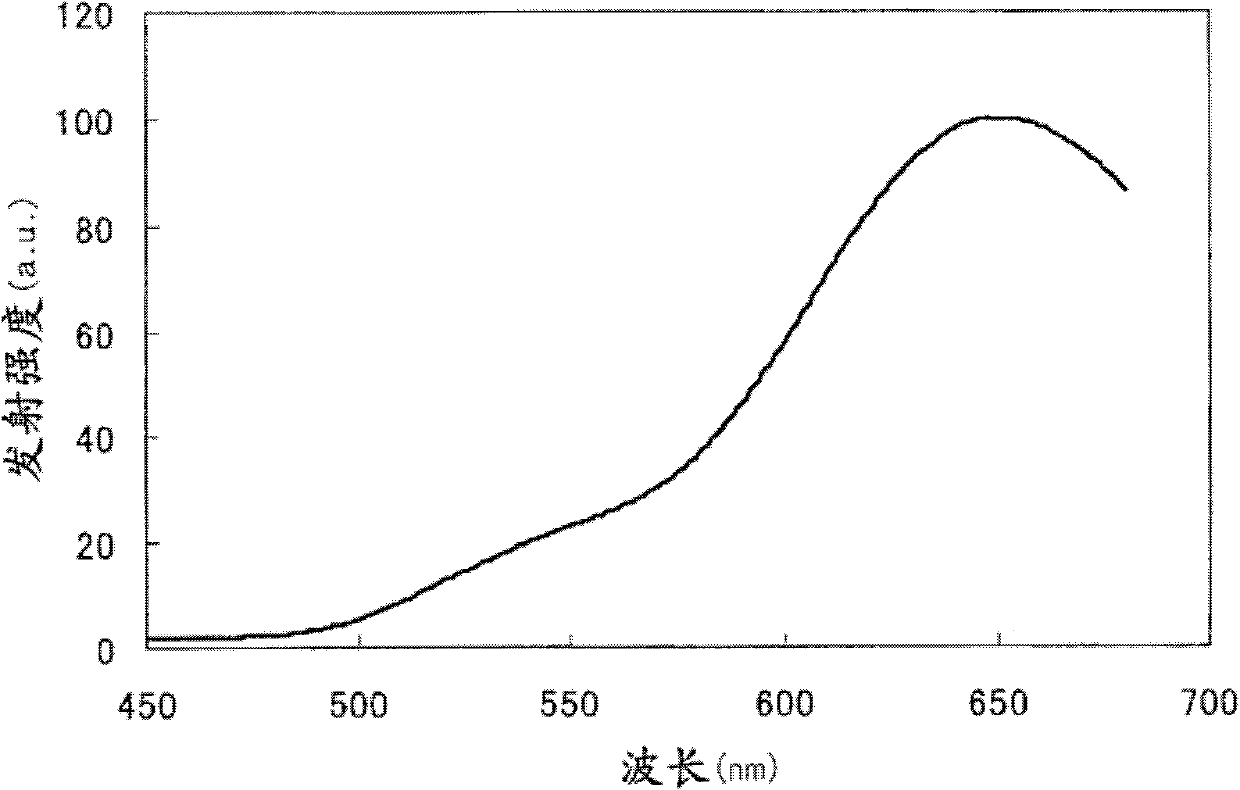

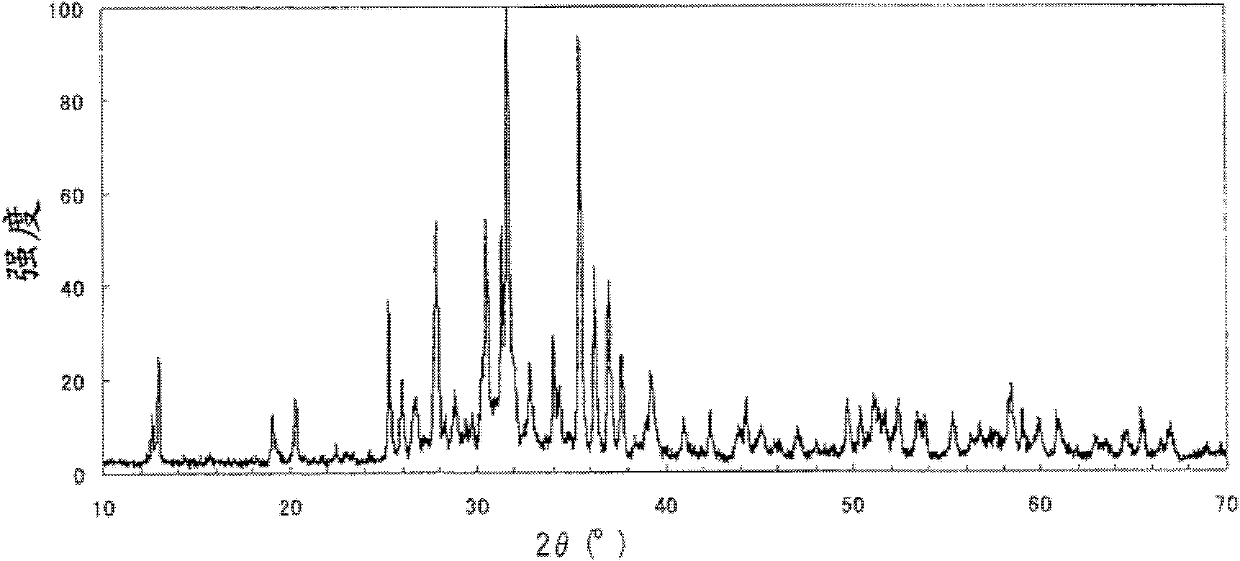

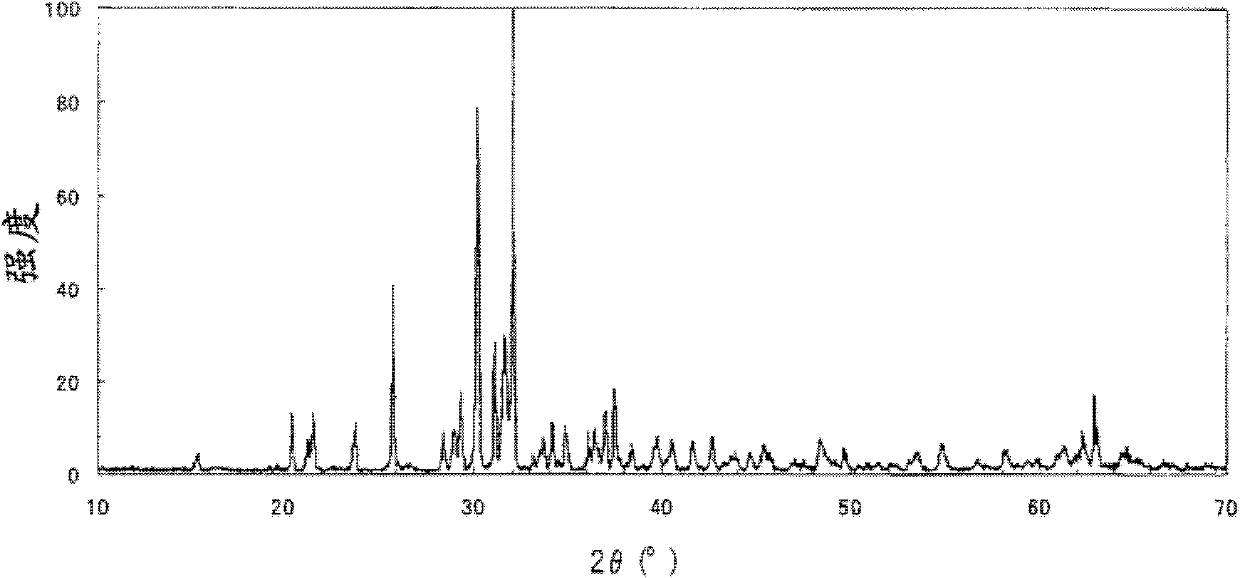

ActiveCN101821356ADischarge tube luminescnet screensElectroluminescent light sourcesFluorescenceDisplay device

The invention provides a ss-sialon phosphor exhibiting higher luminance which is usable in vacuum fluorescent displays (VFD), field emission displays (FED), plasma display panels (PDP), cathode ray tubes (CRT), light emitting diodes (LED), and so on. A novel high-luminance ss-sialon phosphor powder having an average aspect ratio of less than 1.5 can be obtained by mixing a-silicon nitride particles having particle diameters of 2[mu]m or above and an average aspect ratio of 1.3 or below with an AlN-containing aluminum source substance and either an oxide of metal Ln or a precursor capable of being converted into the oxide through pyrolysis in such a way as to give a composition represented by the general formula: Si6-zAlzOzN8-z:Lnx (wherein 0<z<4.2 and Ln is Eu) and firing the obtained mixture in a nitrogen atmosphere under a pressure of 0.05 to 100MPa at 1700 to 2100 DEG C.

Owner:DENKA CO LTD

Phosphor particle group and light emitting apparatus using the same

ActiveUS8084942B2Improve efficiencyRaise the ratioDischarge tube luminescnet screensElectroluminescent light sourcesParticle physicsGreen-light

Provided is a phosphor particle group of divalent europium-activated oxynitride green light emitting phosphor particles each of which is a β-type SiAlON substantially represented by a general formula: EuaSibAlcOdNe, where 0.0055≦a≦0.4, b+c=12, d+e=16, wherein 60% or more of the phosphor particle group is composed of the phosphor particles in which a value obtained by dividing a longer particle diameter by a shorter particle diameter is greater than 1.0 and not greater than 3.0. A high-efficiency and stable light emitting apparatus using a β-type SiAlON, which includes a light converter using the phosphor particle group, and a phosphor particle group therefor are also provided.

Owner:DENKA CO LTD +1

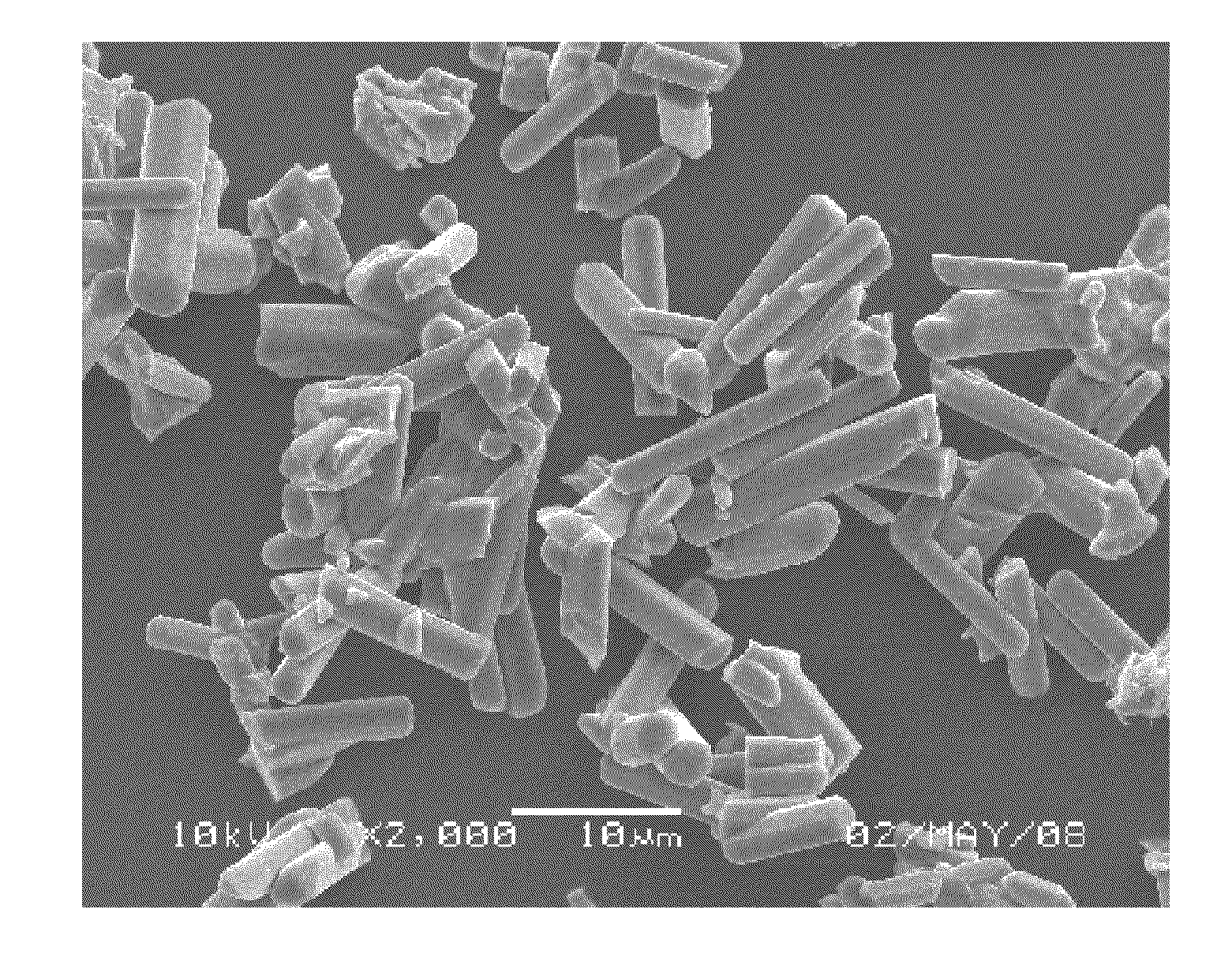

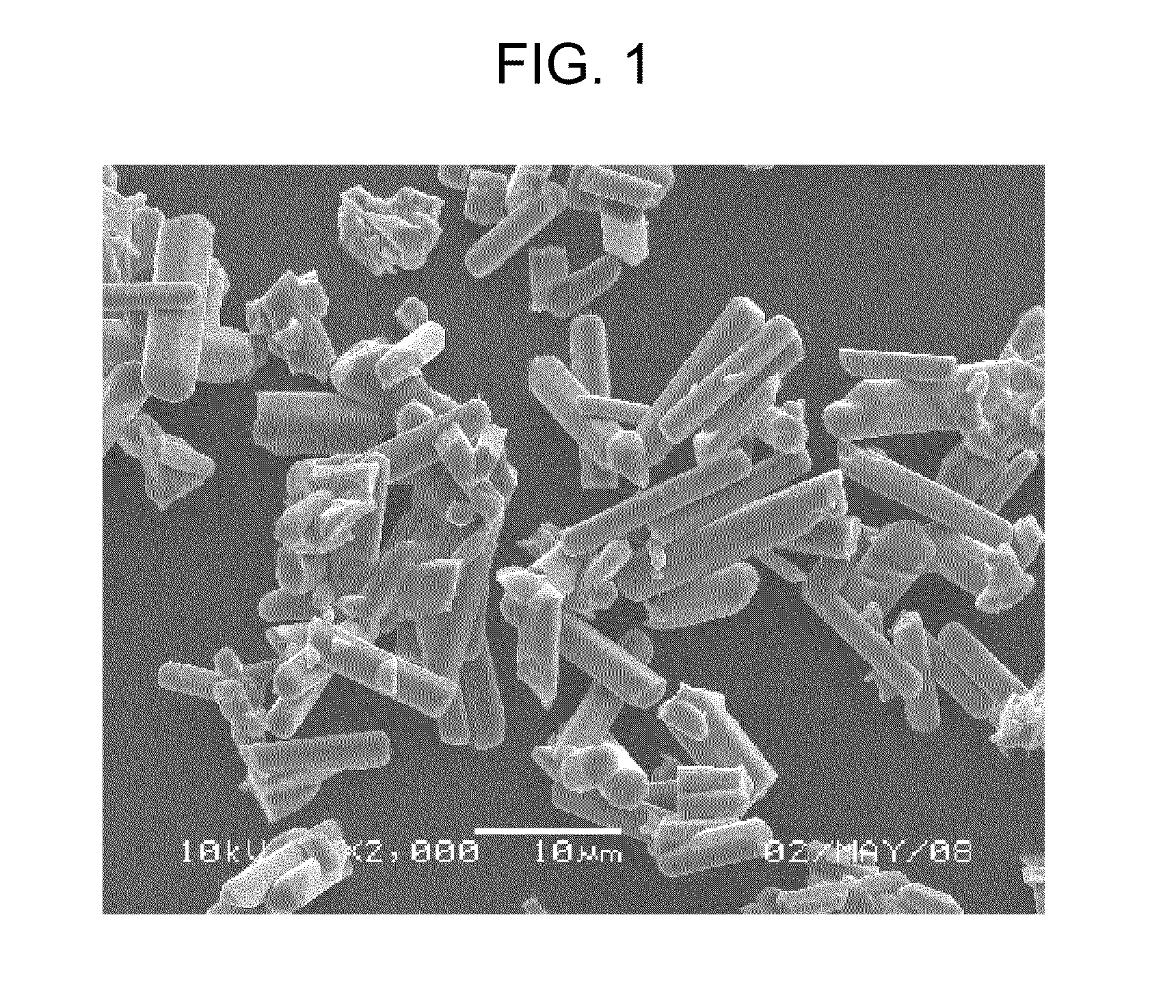

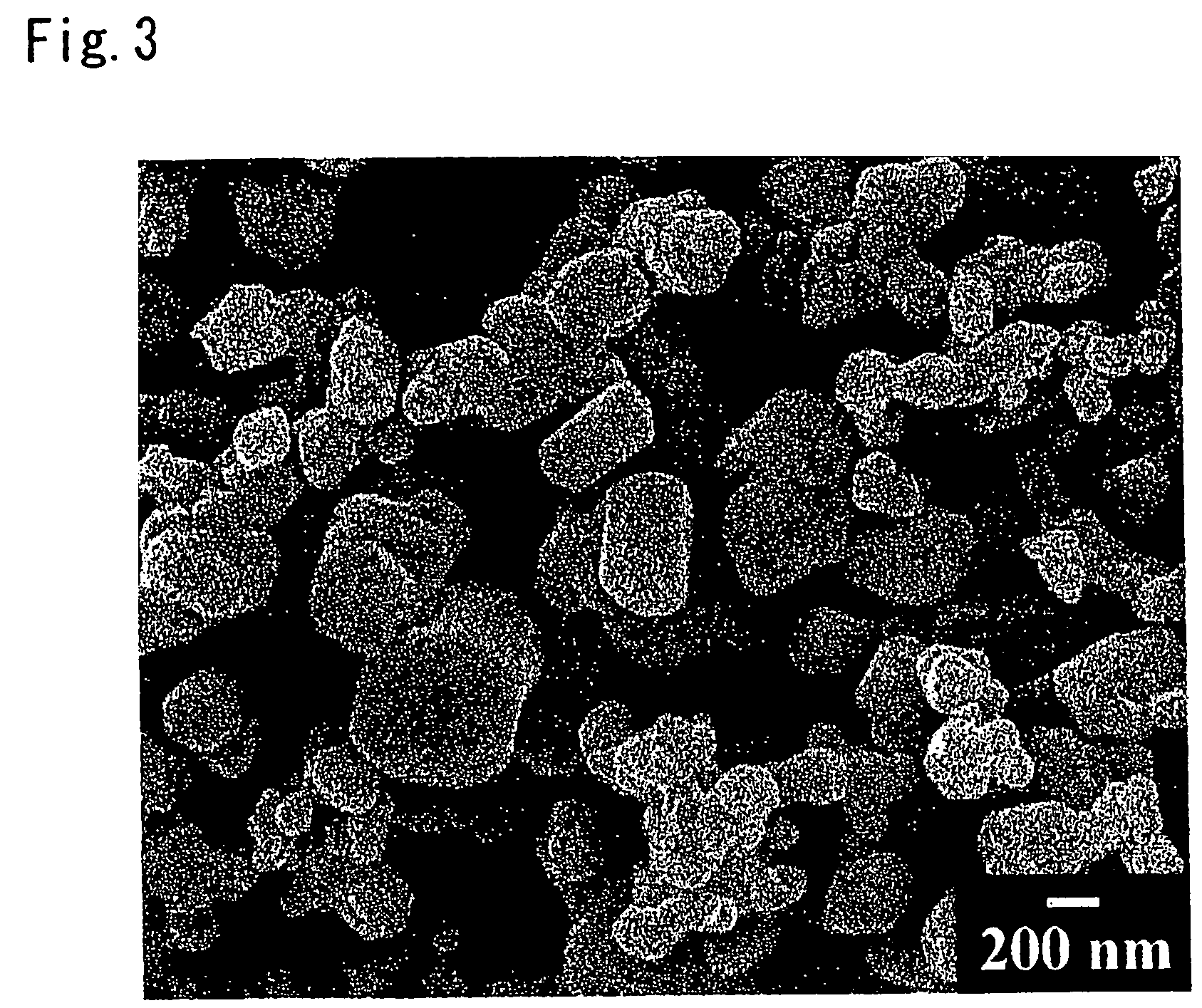

Alpha-sialon phosphor, method for producing same, and light-emitting device

ActiveUS8663500B2Reduce oxygen contentShine wellDischarge tube luminescnet screensLamp detailsPhosphorUltraviolet

α-sialon phosphor that is α-sialon represented by a general expression: (M)x(Eu)y(Si, Al)12(O, N)16 (where M is one or more types of elements selected from a group consisting of Li, Mg, Ca, and Y as well as lanthanide element (except for La and Ce) and including at least Ca), the α-sialon phosphor being structured so that an oxygen content is 1.2 mass % or less and primary particles constituting the α-sialon have a columnar shape. When the α-sialon phosphor receives ultraviolet rays or visible light having a wavelength from 250 to 500 nm as an excitation source, the α-sialon phosphor shows a fluorescent characteristic having a peak in a wavelength region from 595 to 630 nm.

Owner:DENKA CO LTD

Alpha-siaion powder and method for producing the same

An +--sialon which is represented by general formula: (M1)x (M2) Y (Si, Al) 12 (O, N) 16 (wherein M1 represents one or more elements selected from the group which consists of Li, Mg, Ca, Y and lanthanoid (except La and Ce) and M2 represents one or more elements selected from the group which consists of Ce, Pr, Eu, Tb, Yb and Er and wherein 0.3 < X + Y < 1.5 and 0 < Y < 0.7) is synthesized by loading a container with a mixed powdery material of silicon nitride, aluminum nitride, an M1 containing compound and an M2 containing compound and at need aluminum oxide so that its bulk density is not more than 1.5 g / cm 3 , heat-treating the mixed powdery material at 1,600 to 2,000 DEG C in a nitrogen atmosphere. The +--sialon is pulverized to make an +--sialon powder, which can be utilized as a phosphor material for a while LED which uses a blue or an ultraviolet LED as its light source.

Owner:NAT INST FOR MATERIALS SCI +1

Phosphor, method of producing the same, and light emitting apparatus

ActiveUS8663498B2Improve efficiencyStable characteristicsMaterial nanotechnologyDischarge tube luminescnet screensLength waveNitride phosphor

Owner:DENKA CO LTD +1

Alpha-sialon phosphor, method for producing same, and light-emitting device

ActiveUS20110279018A1Reduce oxygen contentShine wellDischarge tube luminescnet screensLamp detailsPhosphorFluorescence

α-sialon phosphor that is α-sialon represented by a general expression: (M)x(Eu)y(Si, Al)12(O, N)16 (where M is one or more types of elements selected from a group consisting of Li, Mg, Ca, and Y as well as lanthanide element (except for La and Ce) and including at least Ca), the α-sialon phosphor being structured so that an oxygen content is 1.2 mass % or less and primary particles constituting the α-sialon have a columnar shape. When the α-sialon phosphor receives ultraviolet rays or visible light having a wavelength from 250 to 500 nm as an excitation source, the α-sialon phosphor shows a fluorescent characteristic having a peak in a wavelength region from 595 to 630 nm.

Owner:DENKA CO LTD

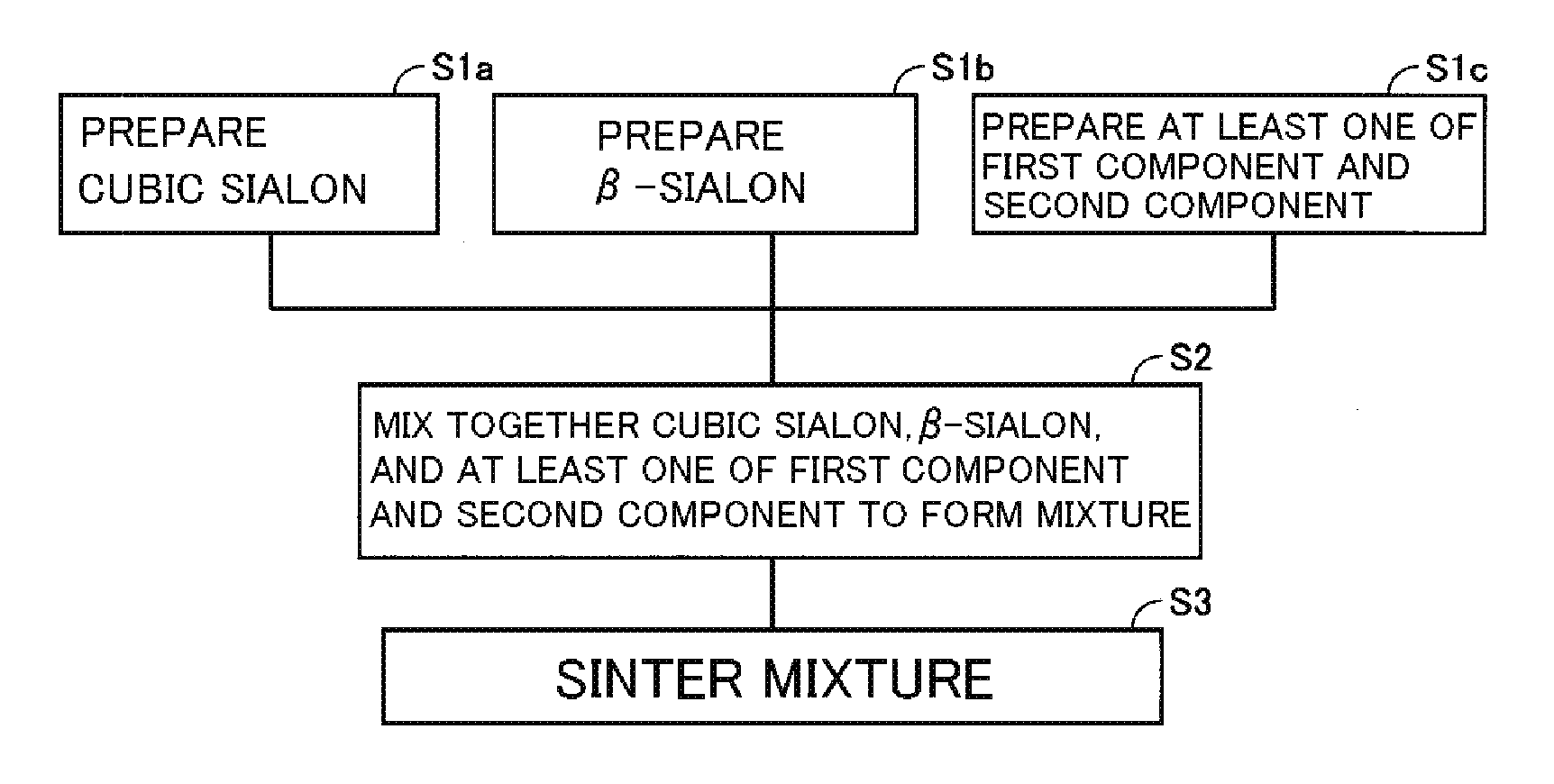

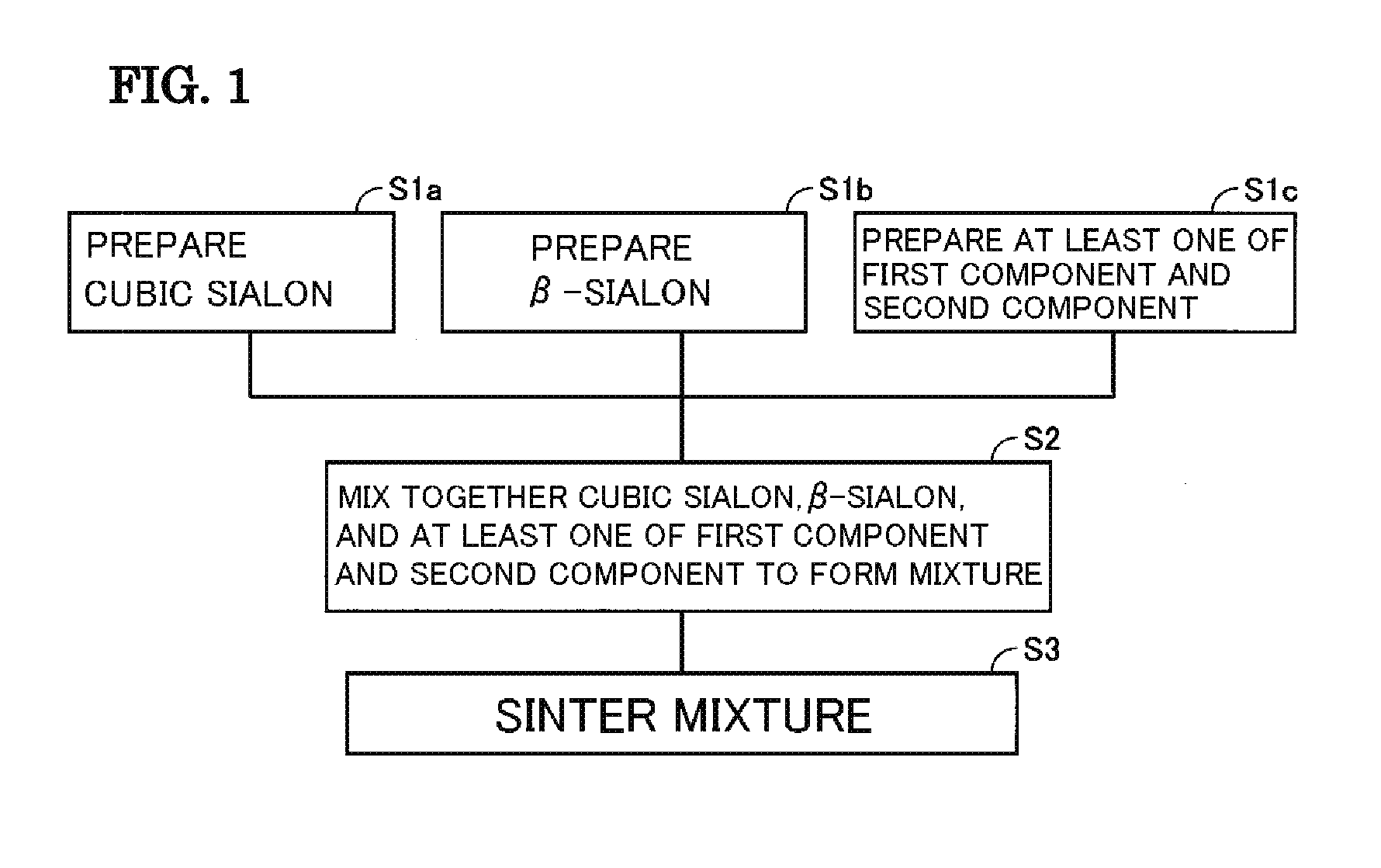

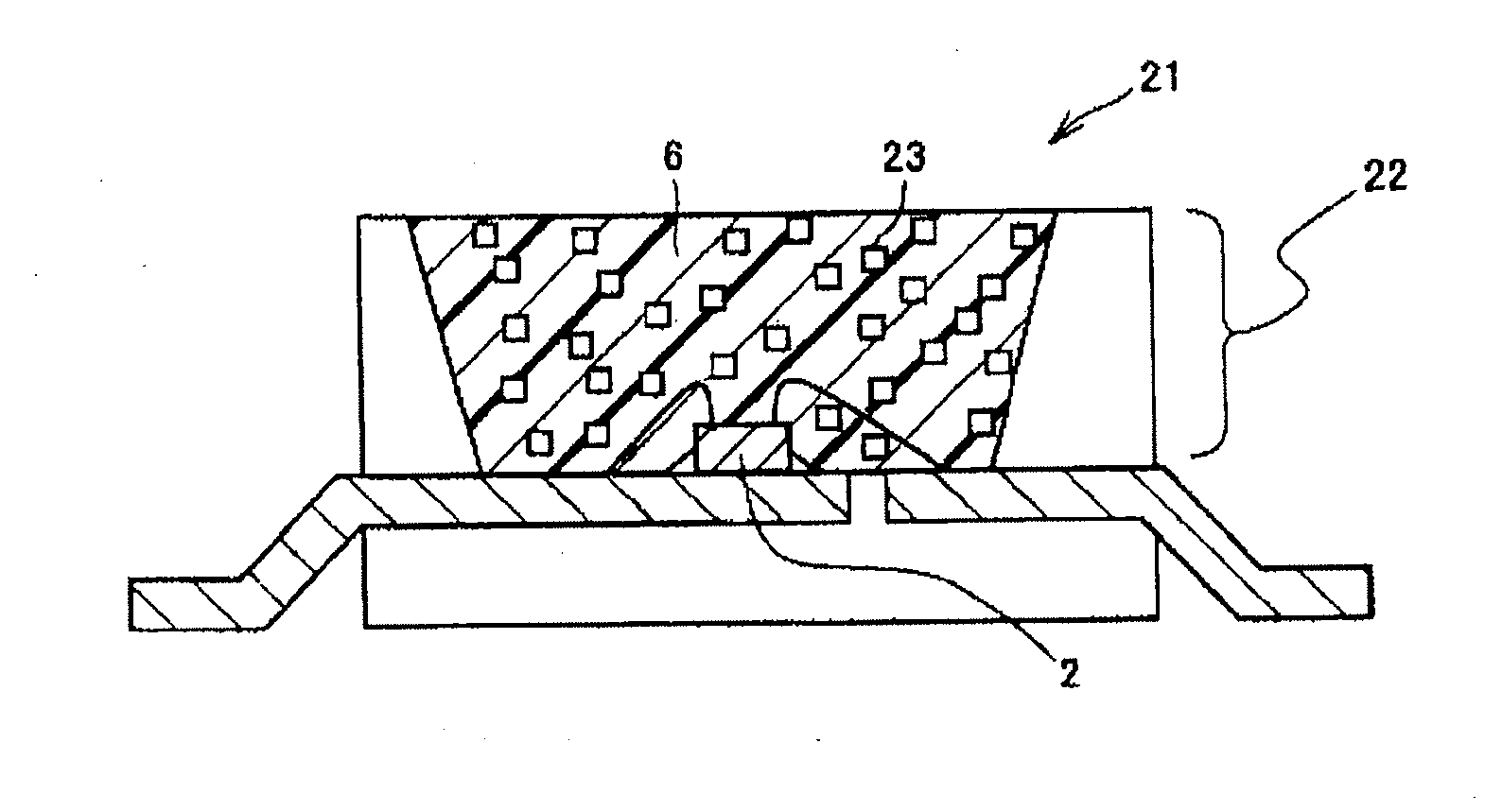

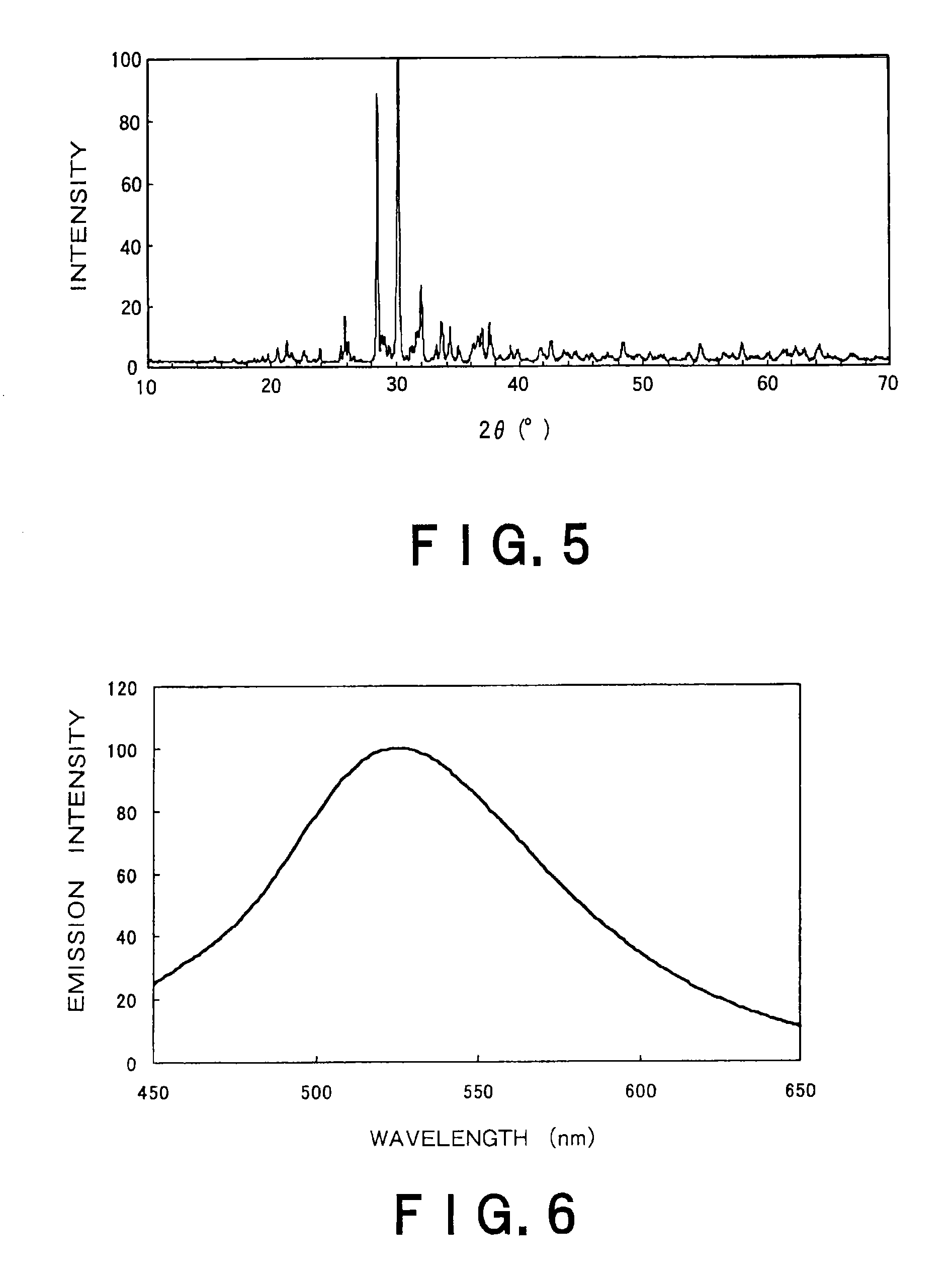

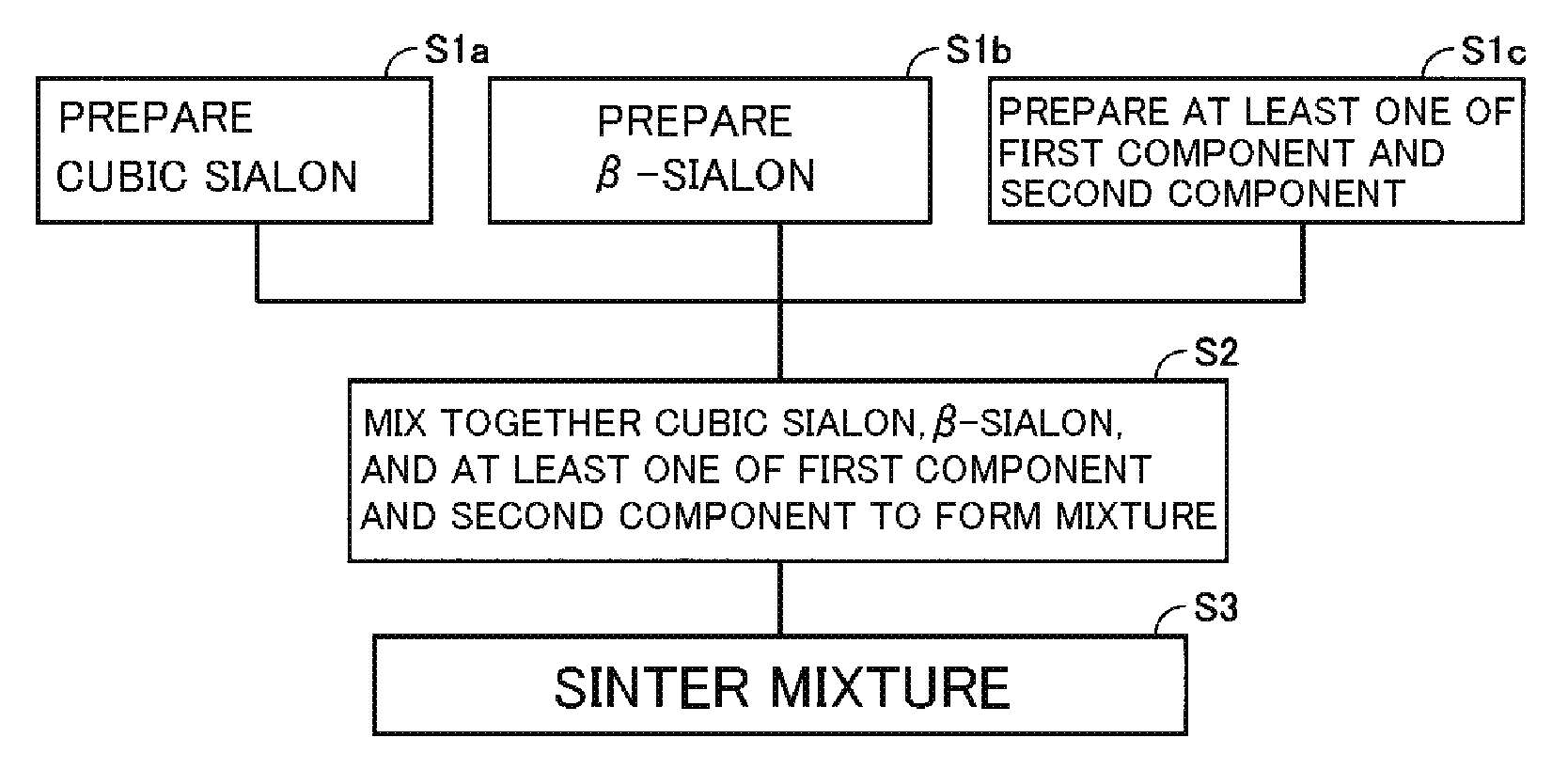

Sintered compact, cutting tool formed using sintered compact, and method for manufacturing sintered compact

ActiveUS20140178138A1Improve fracture resistanceImprove toughnessCeramic shaping apparatusTurning toolsChemical compoundNitrogen

A sintered compact contains cubic sialon, β-sialon, and at least one of a first component and a second component. The first component is at least one element selected from the group consisting of iron, cobalt, nickel, and group 4 elements, group 5 elements, and group 6 elements of the periodic table. The second component is at least one compound containing at least one element selected from the group consisting of group 4 elements, group 5 elements, and group 6 elements and at least one element selected from the group consisting of carbon, nitrogen, and boron.

Owner:SUMITOMO ELECTRIC IND LTD

Phosphor, method of producing the same, and light emitting apparatus

ActiveUS20140139101A1Improve efficiencyStable characteristicsMaterial nanotechnologyDischarge tube luminescnet screensEuropiumLight emission

Owner:DENKA CO LTD +1

Silicon Nitride Powder for Siliconnitride Phosphor, Sr3Al3Si13O2N21 Phosphor and B-Sialon Phosphor Both Obtained Using Same, and Processes for Producing These

InactiveUS20130153824A1Increase brightnessSynthetic resin layered productsCellulosic plastic layered productsFluorescenceDisplay device

Provided is a silicon nitride powder for siliconitride phosphor having high luminance, a Sr3Al3Si13O2N21 phosphor and a β-Sialon phosphor using the powder, which can be used for vacuum fluorescent displays (VFDs), field emission displays (FEDs), plasma display panels (PDPs), cathode ray tubes (CRTs), light emitting diodes (LEDs), or the like, and processes for producing these phosphors. The silicon nitride powder for the siliconitride phosphors is a crystalline silicon nitride powder for use as a raw material for producing siliconitride phosphors including a silicon element, a nitrogen element, and an oxygen element, and has an average particle diameter of 1.0 to 12 μm and an oxygen content of 0.2 to 0.9% by weight.

Owner:UBE IND LTD

Phosphor and use thereof

ActiveUS20120262648A1Increase brightnessAvoid excessive brightnessSolid-state devicesLuminescent compositionsChemical compositionDivalent metal

A phosphor which emits light having high brightness, serves as an excellent orange or red phosphor whose light brightness is less decreased when exposed to an excitation source contains a crystal phase having the chemical composition expressed by the general formula [1]:(1−a−b)(Ln′pMII′1-pMIII′MIV′N3).a(MIV′(3n+2) / 4NnO).b(AMIV′2N3) [1]wherein Ln′ represents a metal element selected from the group consisting of lanthanoids, Mn, and Ti; MnII′ represents a divalent metal element except the Ln′ element; MIII′ represents a trivalent metal element; MIV′ represents a tetravalent metal element; A represents a metal element selected from the group consisting of Li, Na, and K; 0<p≦0.2; 0≦a, 0≦b, a+b>0, 0≦n, and 0.002≦(3n+2)a / 4≦0.9.

Owner:MITSUBISHI CHEM CORP

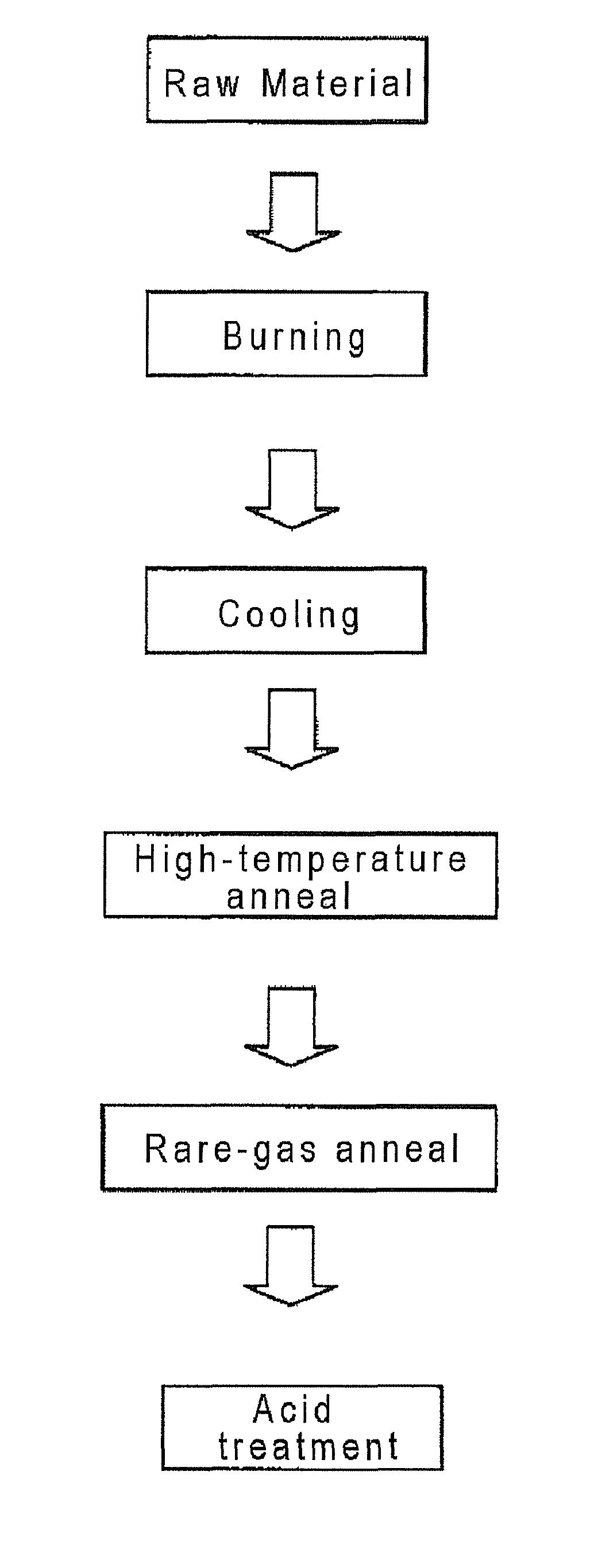

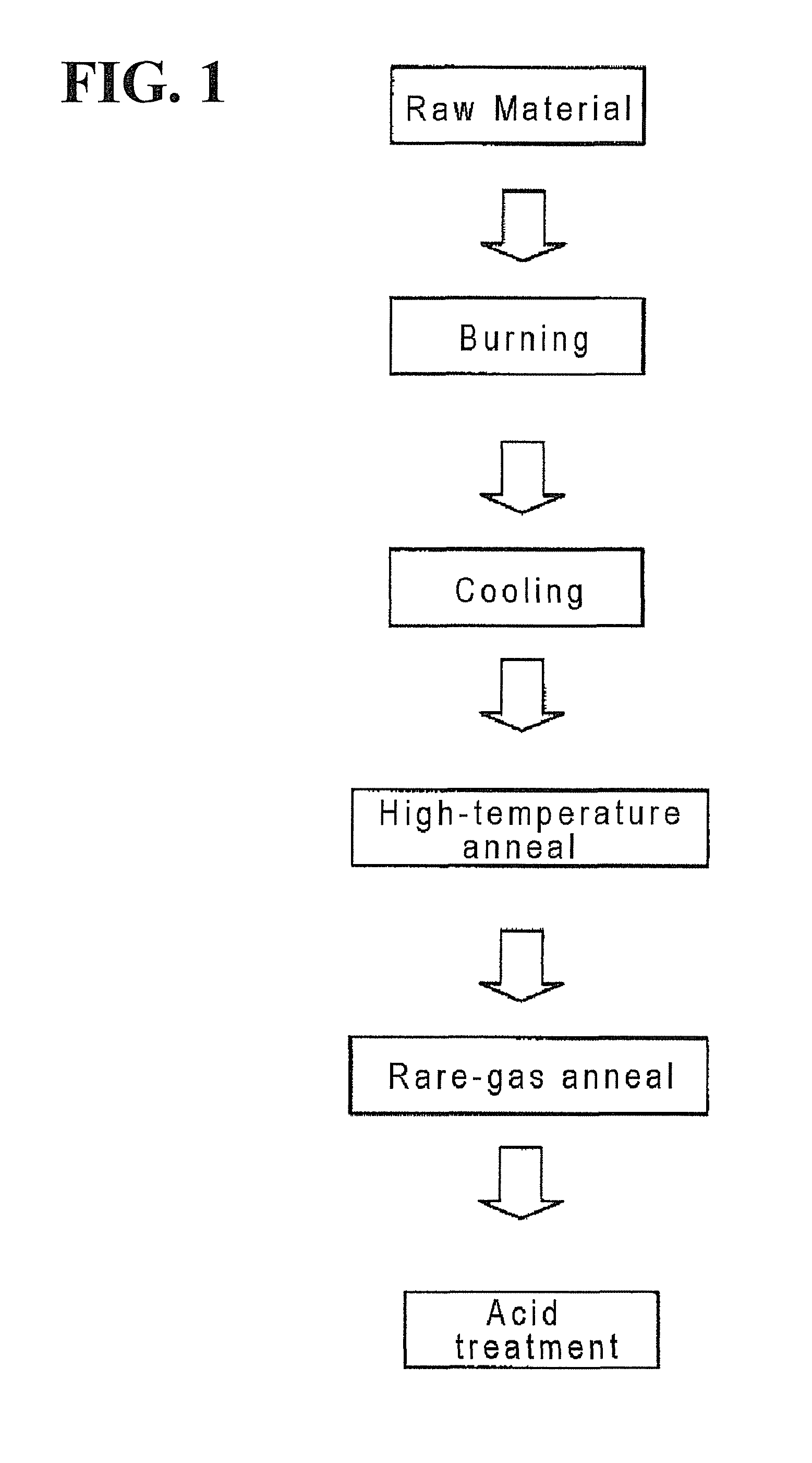

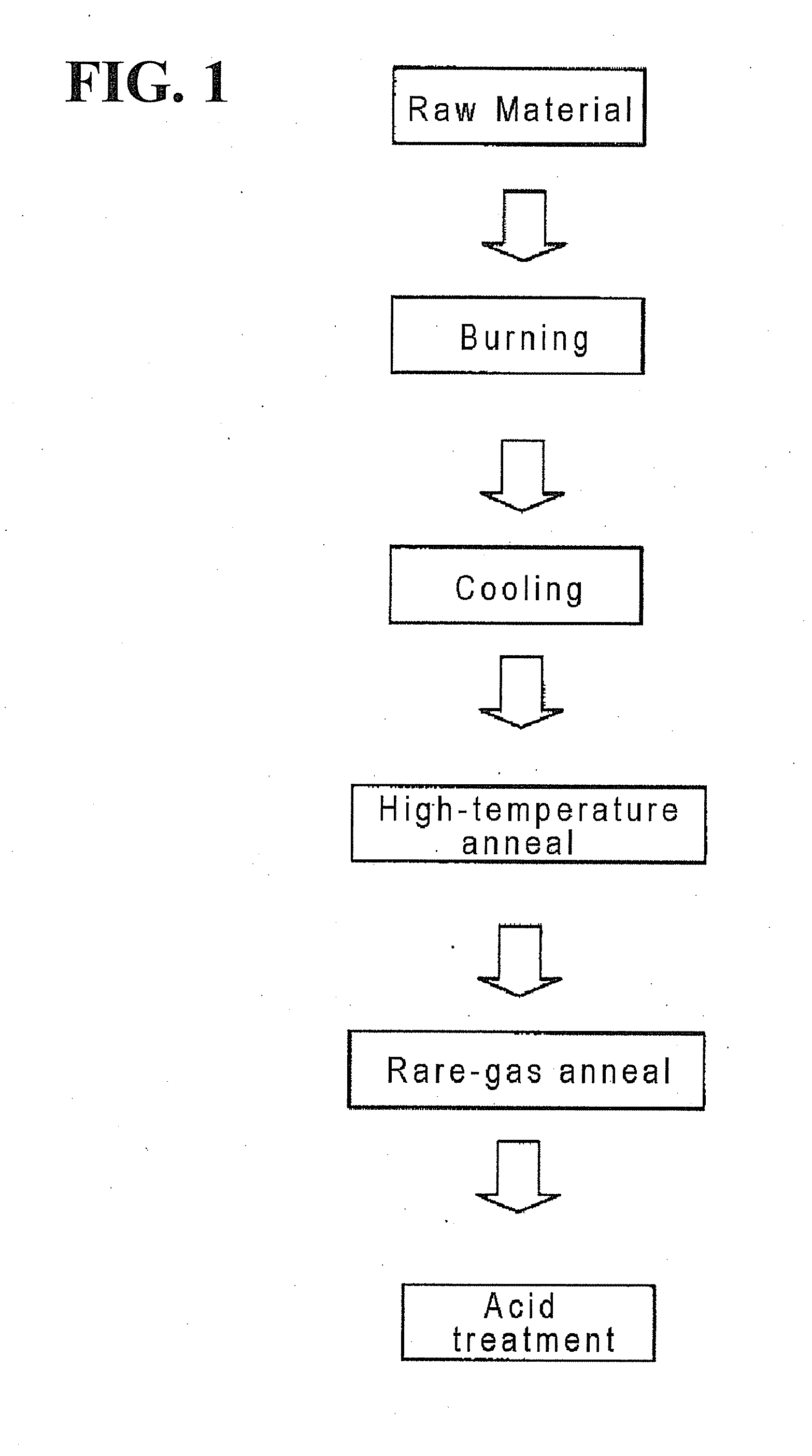

Process for producing .beta.-sialon fluorescent material

ActiveUS8709282B2High luminous intensityImprove featuresLuminescent compositionsSialonsNoble gasNitrogen gas

Provided is a production method of a β-type sialon fluorescent substance, where luminescence intensity can be improved without adding a metal element other than elements composing a β-type sialon fluorescent substance. Namely, in a production method of a fluorescent substance containing an optically-active element as the luminescence center in a crystal of nitride or acid nitride, a β-type sialon fluorescent substance is produced by a burning process for heat-treating a mixture including metal compound powder and an optically-active element compound; a high-temperature annealing process for heat-treating the burned product after cooling under a nitrogen atmosphere; a rare-gas annealing process for heat-treating the high-temperature annealed product under a rare gas atmosphere; and a process for treating the rare-gas treated product with an acid.

Owner:DENKA CO LTD

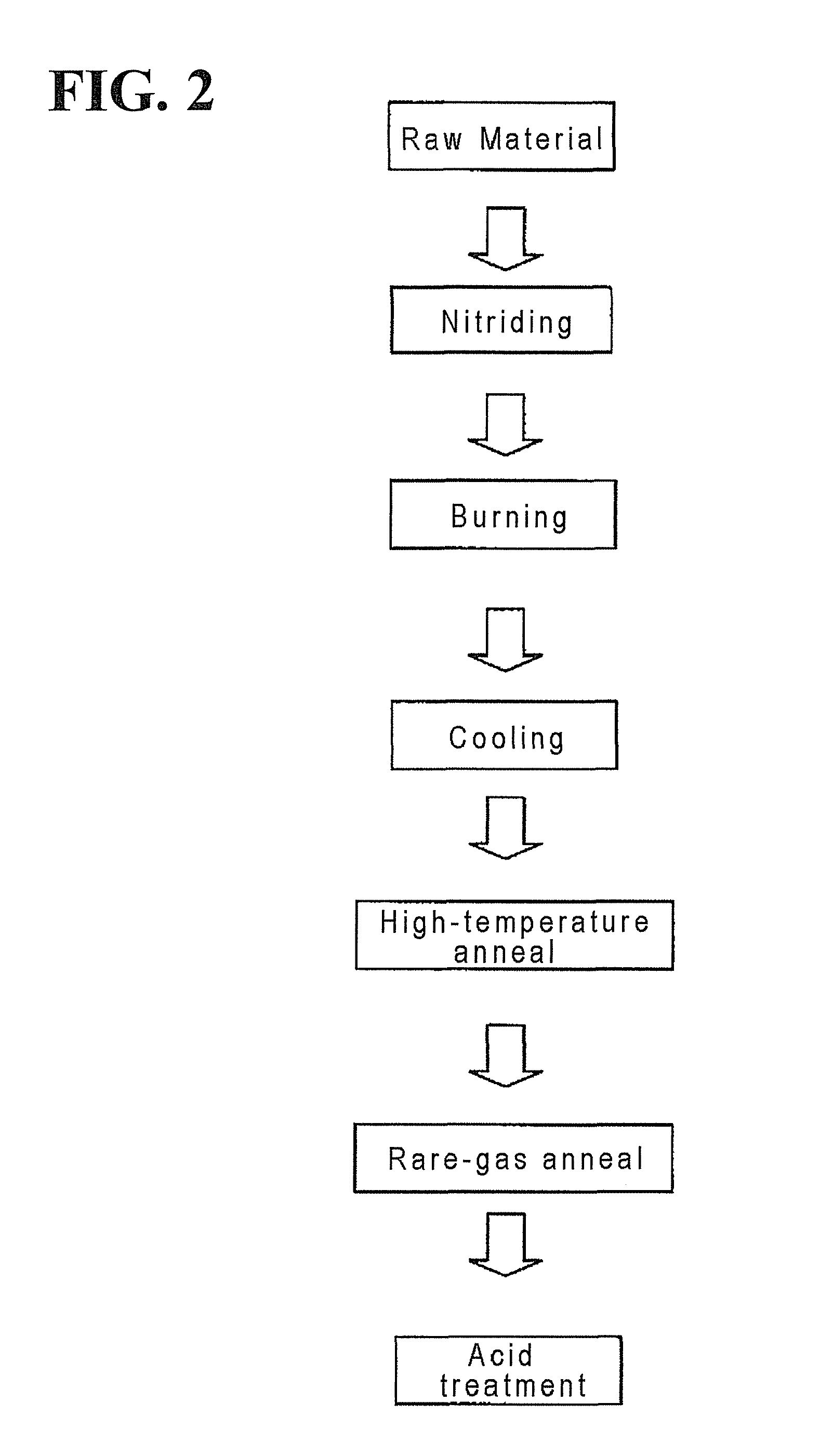

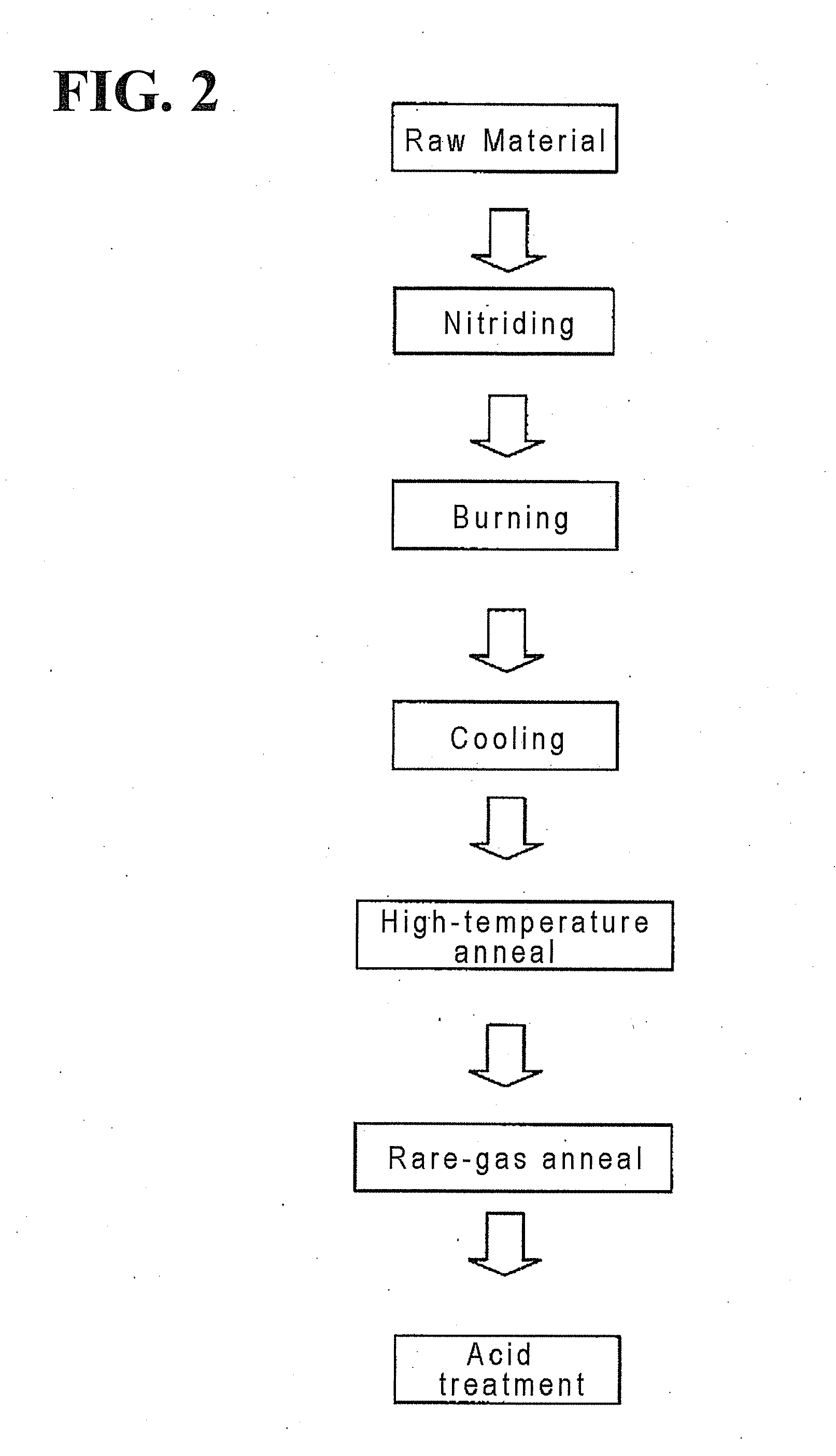

Process for producing beta-sialon fluorescent material

ActiveUS20120211700A1Sufficient improvement effect of luminescence intensityHigh luminous intensityLuminescent compositionsSialonsNoble gasNitrogen gas

Provided is a production method of a β-type sialon fluorescent substance, where luminescence intensity can be improved without adding a metal element other than elements composing a β-type sialon fluorescent substance. Namely, in a production method of a fluorescent substance containing an optically-active element as the luminescence center in a crystal of nitride or acid nitride, a β-type sialon fluorescent substance is produced by a burning process for heat-treating a mixture including metal compound powder and an optically-active element compound; a high-temperature annealing process for heat-treating the burned product after cooling under a nitrogen atmosphere; a rare-gas annealing process for heat-treating the high-temperature annealed product under a rare gas atmosphere; and a process for treating the rare-gas treated product with an acid.

Owner:DENKA CO LTD

Silicon nitride powder for siliconnitride phosphor, Sr3Al3Si13O2N21 phosphor and β-sialon phosphor both obtained using same, and processes for producing these

InactiveUS9023241B2Increase brightnessSynthetic resin layered productsCellulosic plastic layered productsFluorescenceLight-emitting diode

Provided is a silicon nitride powder for siliconitride phosphor having high luminance, a Sr3Al3Si13O2N21 phosphor and a β-Sialon phosphor using the powder, which can be used for vacuum fluorescent displays (VFDs), field emission displays (FEDs), plasma display panels (PDPs), cathode ray tubes (CRTs), light emitting diodes (LEDs), or the like, and processes for producing these phosphors. The silicon nitride powder for the siliconitride phosphors is a crystalline silicon nitride powder for use as a raw material for producing siliconitride phosphors including a silicon element, a nitrogen element, and an oxygen element, and has an average particle diameter of 1.0 to 12 μm and an oxygen content of 0.2 to 0.9% by weight.

Owner:UBE IND LTD

Oxynitride powder and production method thereof

ActiveUS7598194B2Low oxygenHigh nitrogen contentAluminium compoundsAluminium silicatesPhosphorNitrogen

It is aimed at providing an oxynitride powder, which is suitable for usage as a phosphor, is free from coloration due to contamination of impurities, and mainly includes a fine α-sialon powder.An oxynitride powder is produced by applying a heat treatment in a reducing and nitriding atmosphere, to a precursor compound including at least constituent elements M, Si, Al, and O (where M is one element or mixed two or more elements selected from Li, Mg, Ca, Sr, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu), thereby decreasing an oxygen content and increasing a nitrogen content of the precursor.

Owner:NAT INST FOR MATERIALS SCI

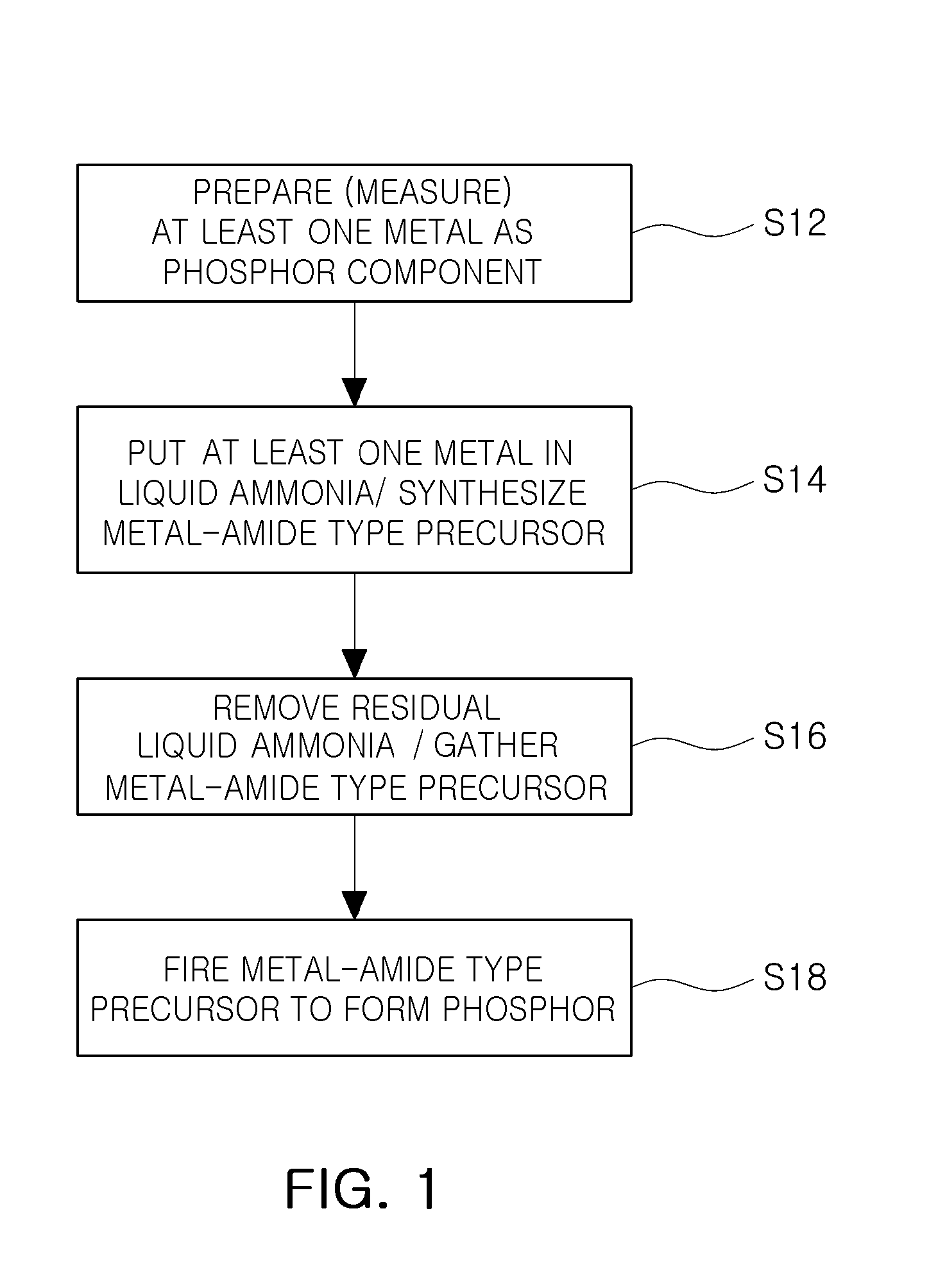

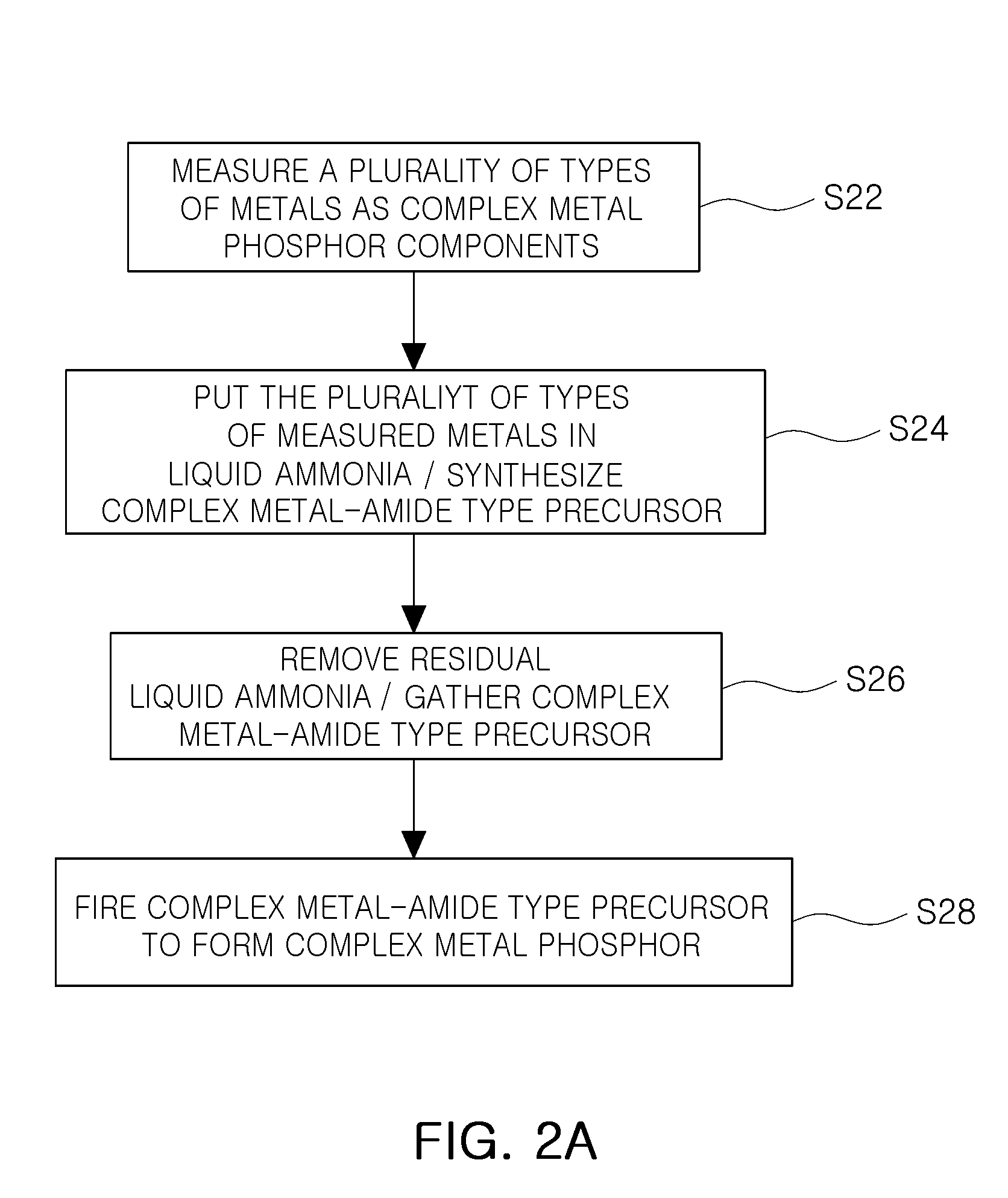

Method for preparing phosphor and light emitting device

InactiveUS20120138992A1Low-temperature processUniform compositionNitrogen-metal/silicon/boron binary compoundsSolid-state devicesPhosphorLight emitting device

A method for preparing a phosphor includes: dissolving at least one metal as a raw material of a desired phosphor in liquid ammonia to form a metal-amide type precursor; gathering the metal-amide type precursor; and firing the precursor to form a desired phosphor.

Owner:SAMSUNG ELECTRONICS CO LTD

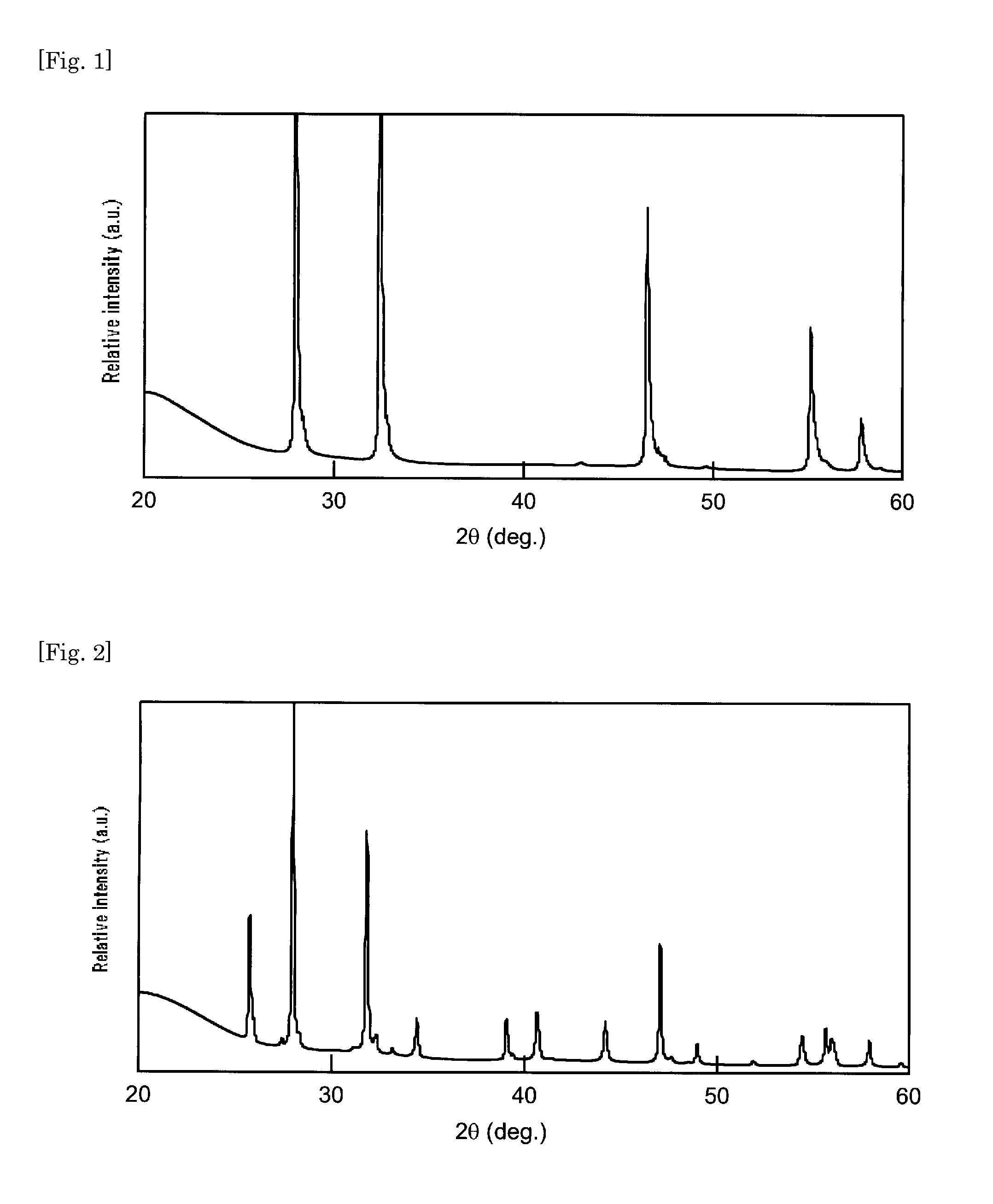

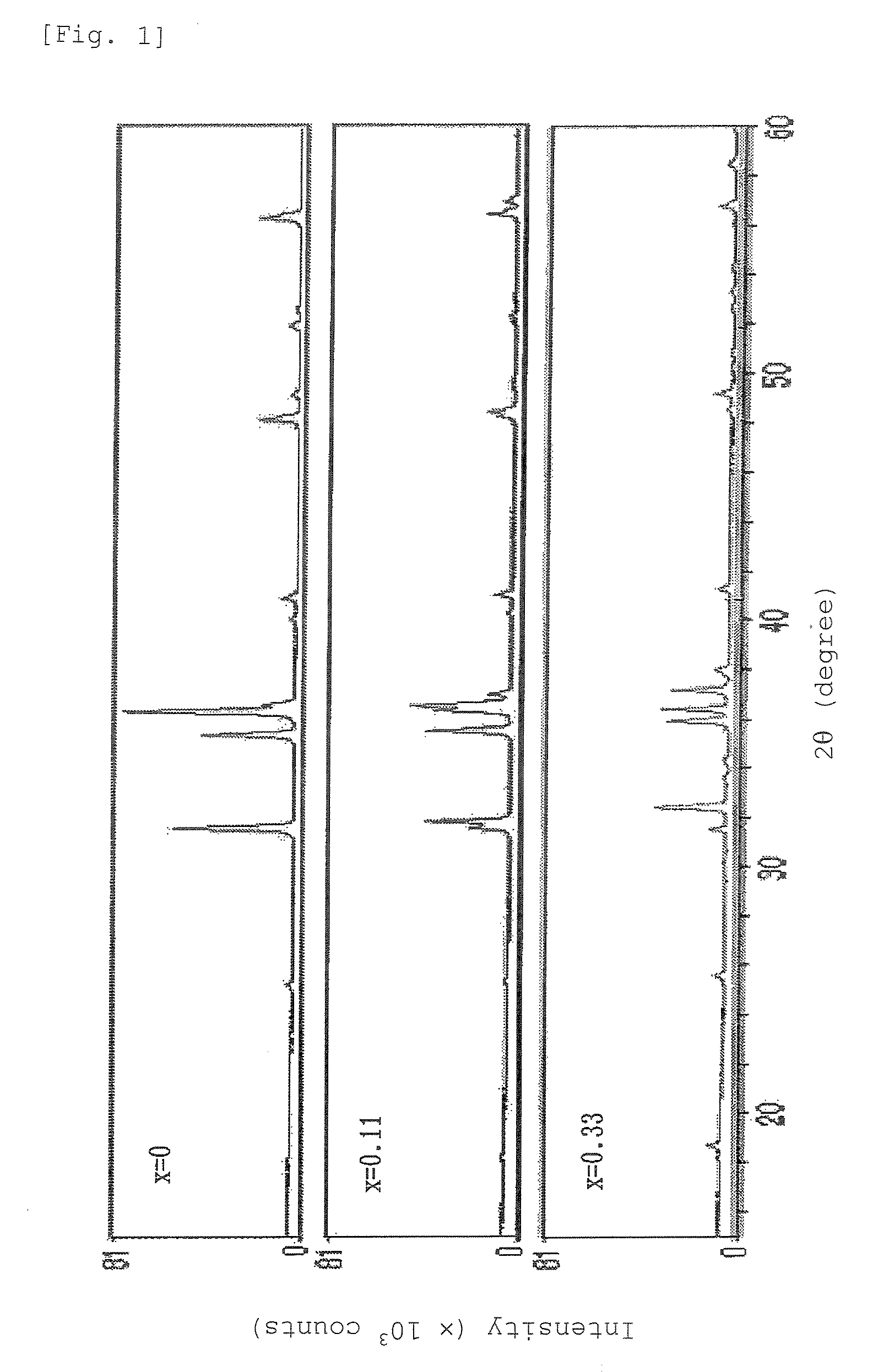

Method for producing phosphor

ActiveUS20150307353A1Increase productionHigh fluorescence peak intensitySilicon compoundsLuminescent compositionsProduction rateX-ray

Provided is a method for producing a phosphor, using a nitride raw material, that gives a high-reliability (Sr,Ca)AlSiN3-based nitride phosphor at a productivity higher than before.The method comprises a mixing step of mixing raw materials and a calcining step of calcining the mixture obtained in the mixing step and, in producing the phosphor having a crystalline structure substantially identical with that of (Sr,Ca)AlSiN3 crystal as the host crystal, a strontium nitride containing SrN, Sr2N, or the mixture thereof as the main crystalline phase, as determined by crystalline phase analysis by powder X-ray diffractometry, and having a nitrogen content of 5 to 12 mass % is used as part of the raw materials.

Owner:DENKA CO LTD

Method for preparing beta-SiAlON from aluminum ash residues

The invention relates to a method for preparing beta-SiAlON from aluminum ash residues. The method comprises the following steps: grinding the aluminum ash residues, adding a Si powder and a diluent Si3N4 powder in proportion, performing uniform mixing by a ball mill, adding the obtained mixture into a zirconia crucible, placing the crucible in a tubular atmosphere furnace, introducing nitrogen, carrying out ohmic heating to reach a reaction temperature, cooling the furnace to room temperature after a nitridation reaction is completed, and taking out the obtained product. The industrial solidwastes which are aluminum ash residues are used as the raw material to prepare high-purity beta-SiAlON powder, so the method has the advantages of simple process, realization of recycling of the aluminum ash residues, reduction of the environmental burden, and reduction of resource waste.

Owner:NORTHWEST A & F UNIV

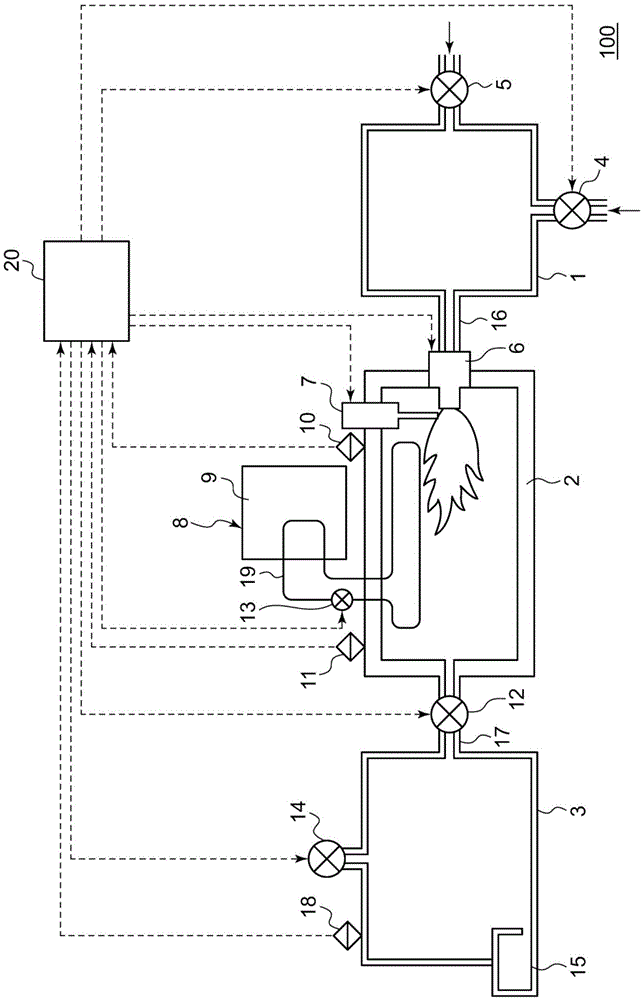

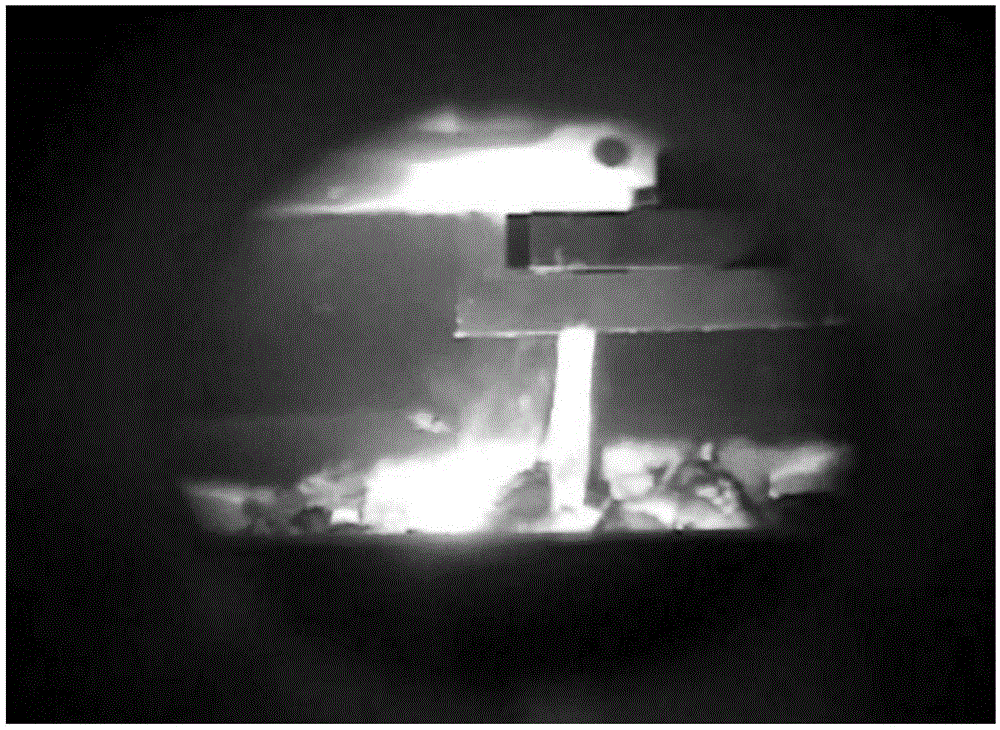

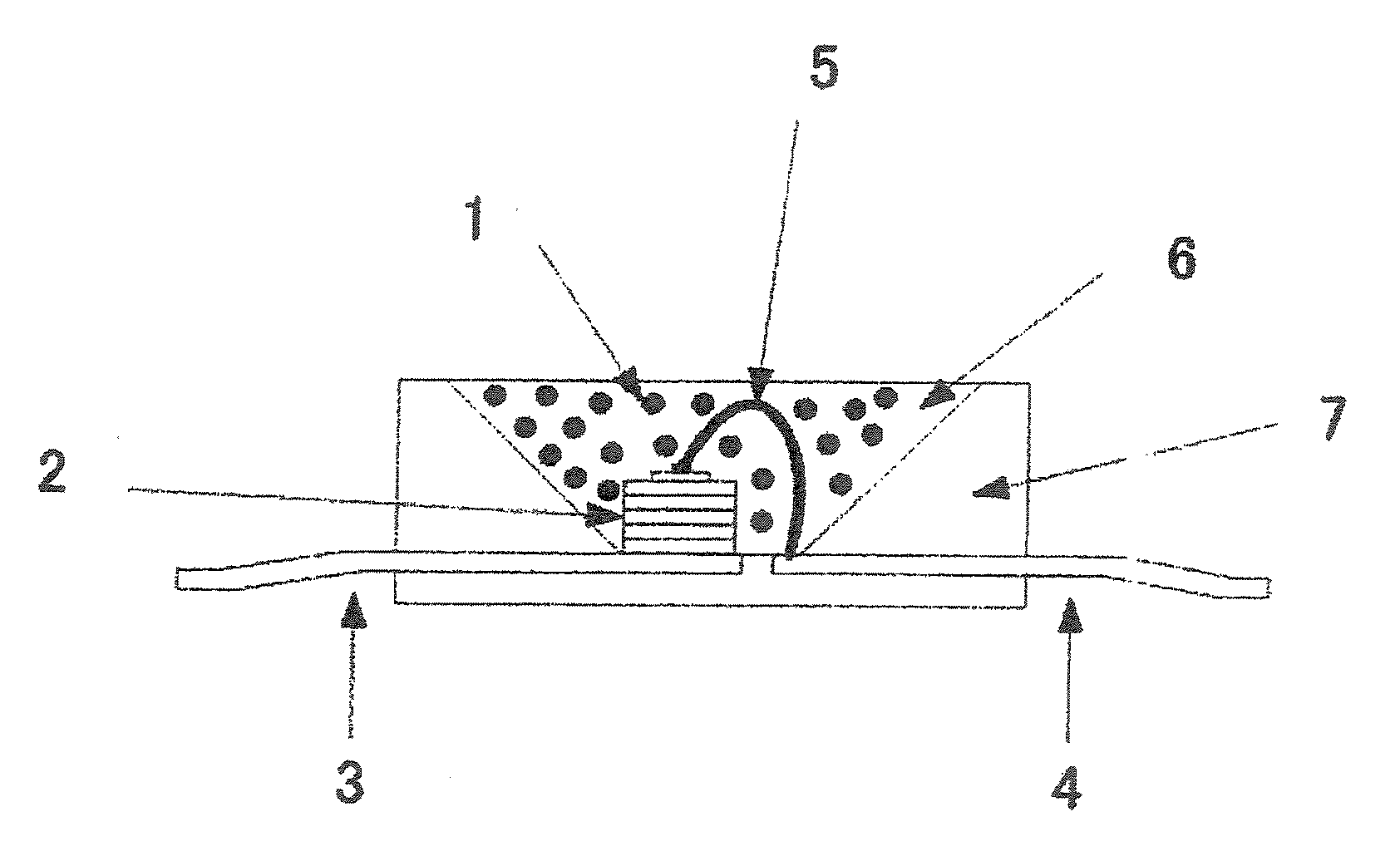

Combustion synthesis system, reaction product, article, combustion synthesis method, power-generating system, plasma-generating device, and power-generating device

InactiveCN105473498AEfficient use ofChemical/physical/physico-chemical stationary reactorsDynamo-electric machinesCombustionHeat resistance

A combustion synthesis system (100) is equipped with: a supply section (1) in which a particle powder containing Si is mixed with a particle powder containing SiO2 and a N2 gas to produce a mixture; a reaction section (2) which has heat resistance and pressure resistance, and in which combustion synthesis using, as a raw material, the mixture supplied from the supply section (1) proceeds; an ignition section (7) which can ignite the mixture supplied to the reaction section (2); and a heat extraction section (8) in which a reaction heat of the combustion synthesis reaction in the inside of the reaction section (2) is removed to the outside of the reaction section (2).

Owner:ADVANCED RESOURCES INST HLDG

Process for production of fluorescent substance

The embodiment provides a process for production of an oxynitride fluorescent substance. In the process, a compound represented by the formula: (Sr,Eu) 2 Si 5 N 8 , silicon nitride and aluminum nitride are mixed and then fired in a nitrogen atmosphere under high pressure.

Owner:KK TOSHIBA

Method for producing beta-sialon phosphor

ActiveUS20120223448A1High strengthReduce luminous intensityOptical articlesLuminescent compositionsPhosphorEuropium ion

Provided is a production method of a β-sialon phosphor that europium ions are solid-solved in β-sialon, including a mixing process for mixing raw materials of the β-sialon phosphor; a burning process for burning the raw materials after the mixing process to form the β-sialon phosphor; a HIP treatment process in which the β-sialon phosphor after the burning process is subjected to a HIP treatment; an annealing process in which the β-sialon phosphor after the HIP treatment process is subjected to an annealing treatment; and an acid treatment process in which the β-sialon phosphor after the annealing process is subjected to an acid treatment. According to the production method of a β-sialon phosphor, a β-sialon phosphor excellent in luminescence intensity is obtained.

Owner:DENKA CO LTD

Process for production of fluorescent substance

ActiveUS20140054500A1Rare earth metal compoundsLuminescent compositionsFluorescenceCompound (substance)

The embodiment provides a process for production of an oxynitride fluorescent substance. In the process, a compound represented by the formula: (Sr,Eu)2Si5N8, silicon nitride and aluminum nitride are mixed and then fired in a nitrogen atmosphere under high pressure.

Owner:KK TOSHIBA

Sintered compact, cutting tool formed using sintered compact, and method for manufacturing sintered compact

Owner:SUMITOMO ELECTRIC IND LTD

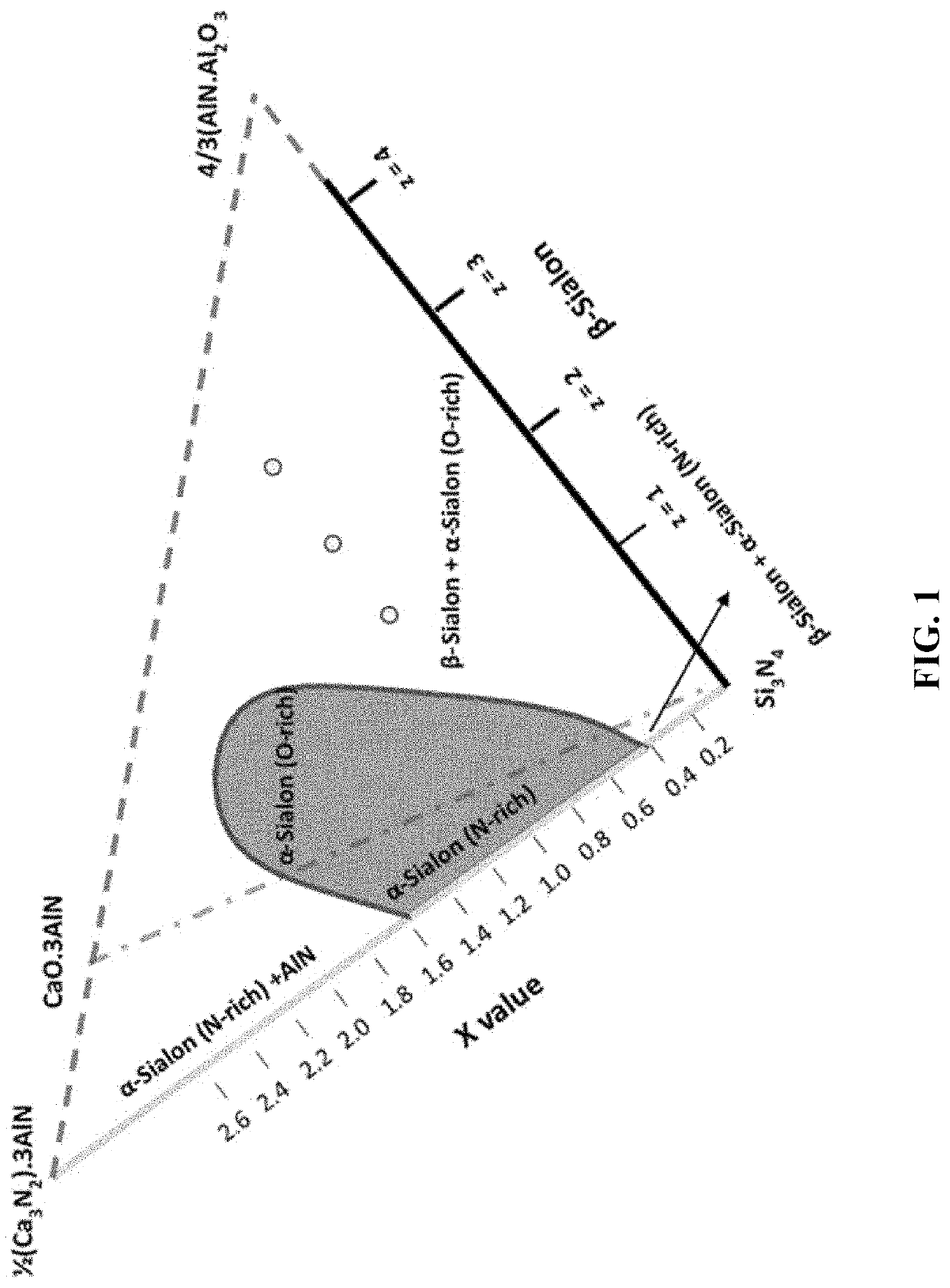

Method of forming a βSiAlON by spark plasma sintering

A method of making a β-SiAlON is described in involves mixing nanoparticles of AlN, Al2O3, and SiO2 with particles of Si3N4 and spark plasma sintering the mixture. The sintering may be at a temperature of 1450-1600° C. or about 1500° C. The particles of Si3N4 may be nanoparticles comprising amorphous Si3N4, or 25-55 μm diameter microparticles comprising β-Si3N4.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Popular searches

Non-linear optics Semiconductor devices for light sources Alternating current plasma display panels Cold-cathode tubes Alkaline-earth metal silicates Alkali metal silicates Alkali metal chlorides Oxygen/ozone/oxide/hydroxide Peroxides/peroxyhydrates/peroxyacids/superoxides/ozonides Gallium/indium/thallium compounds

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

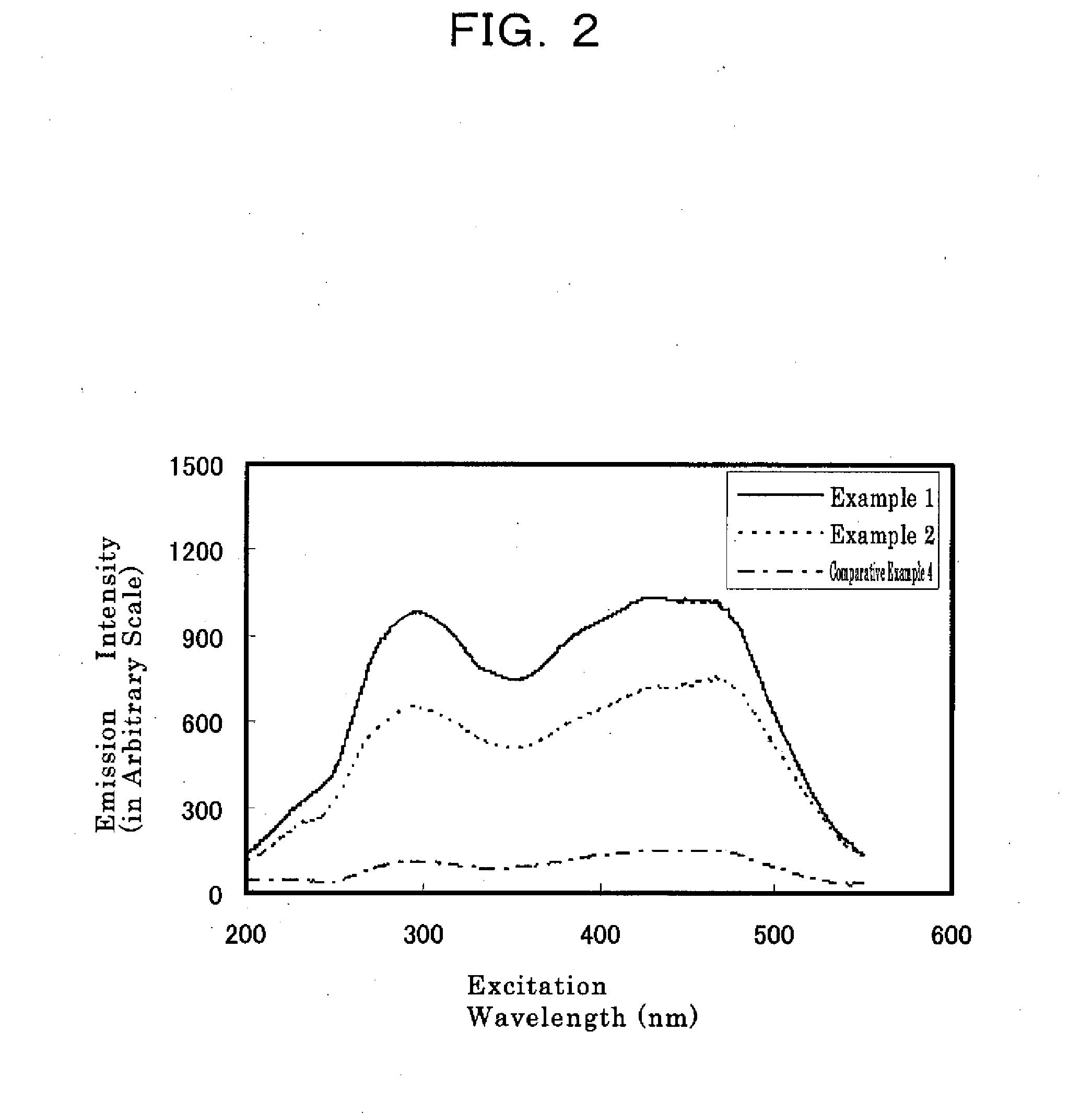

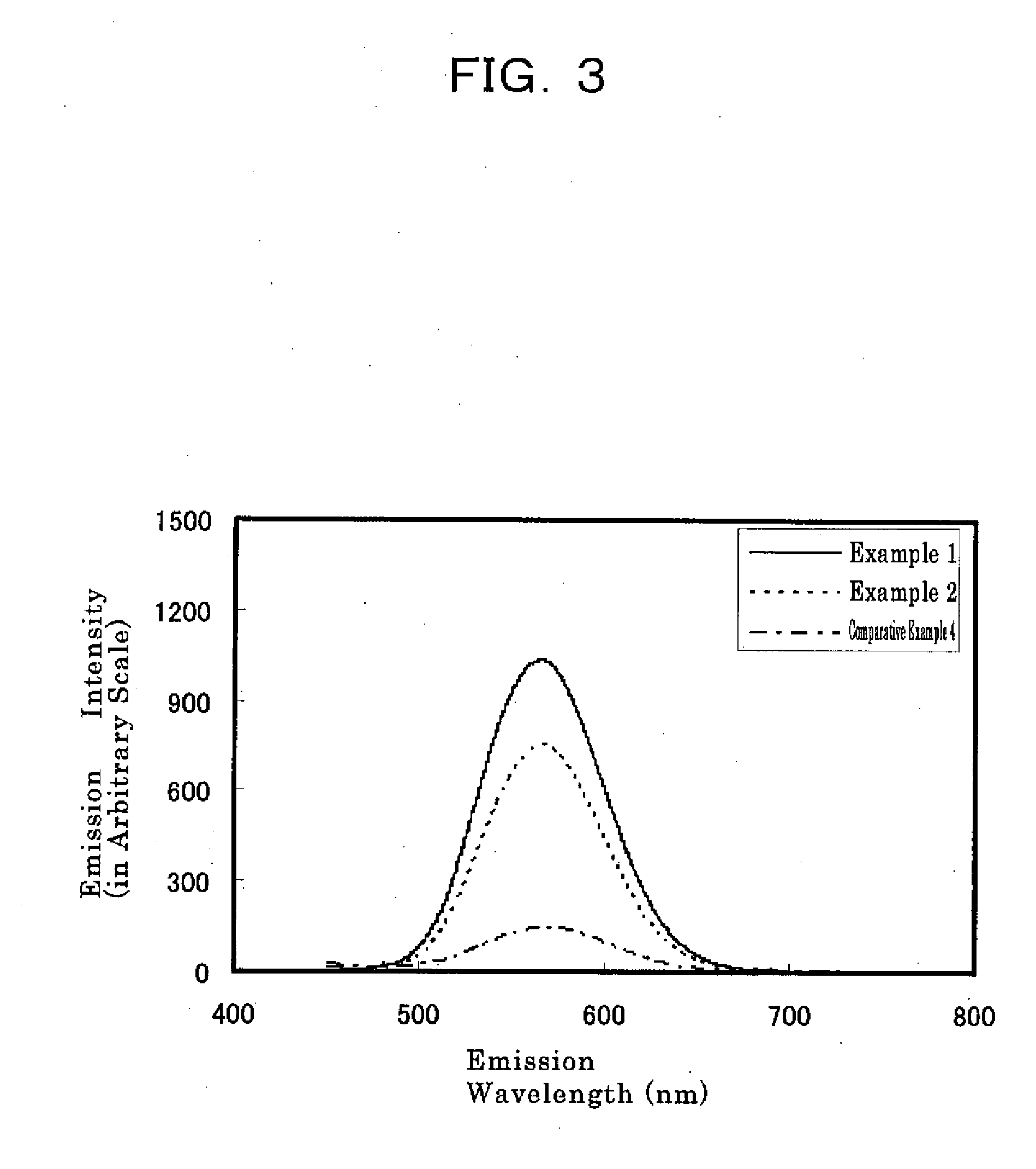

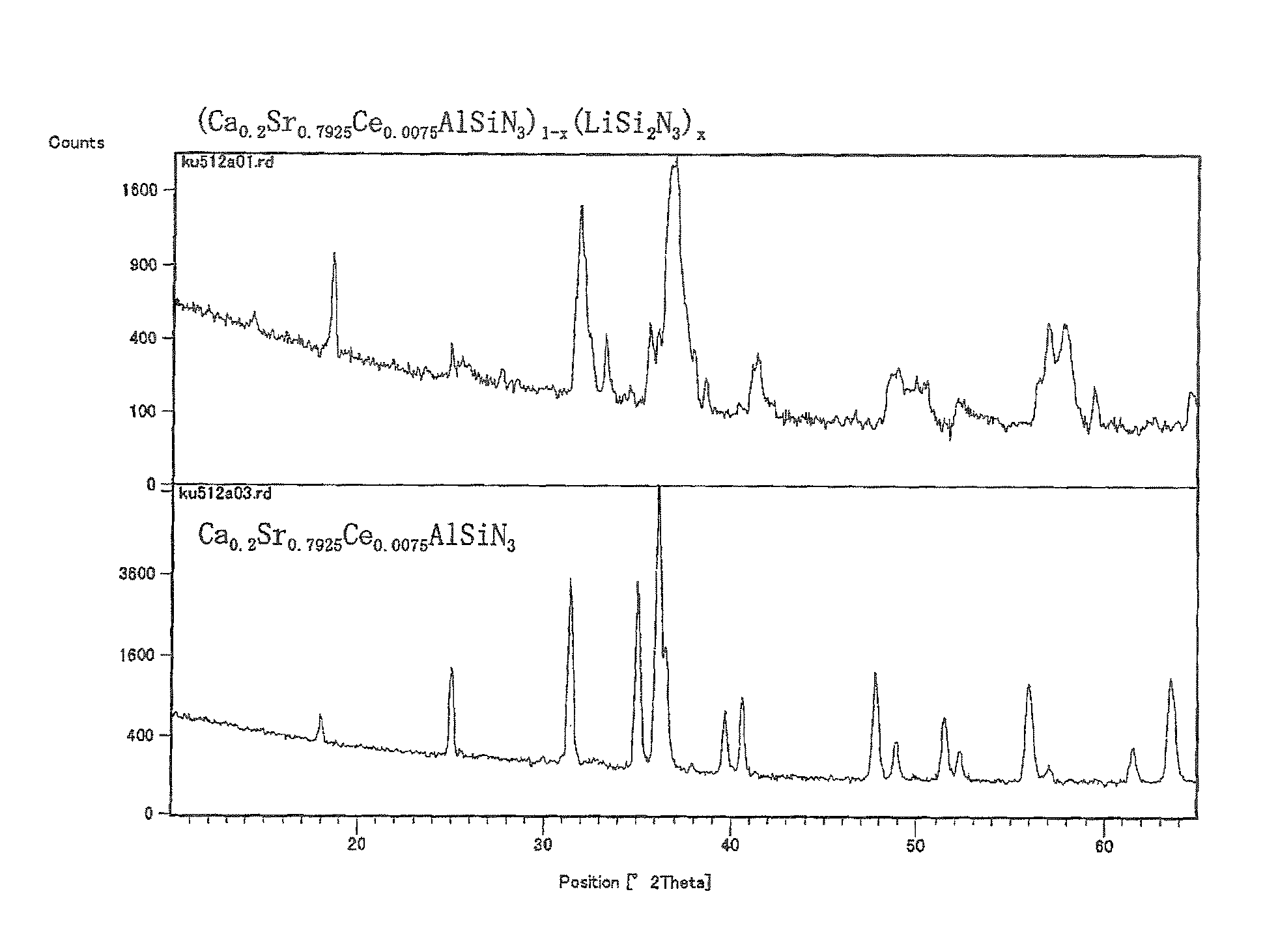

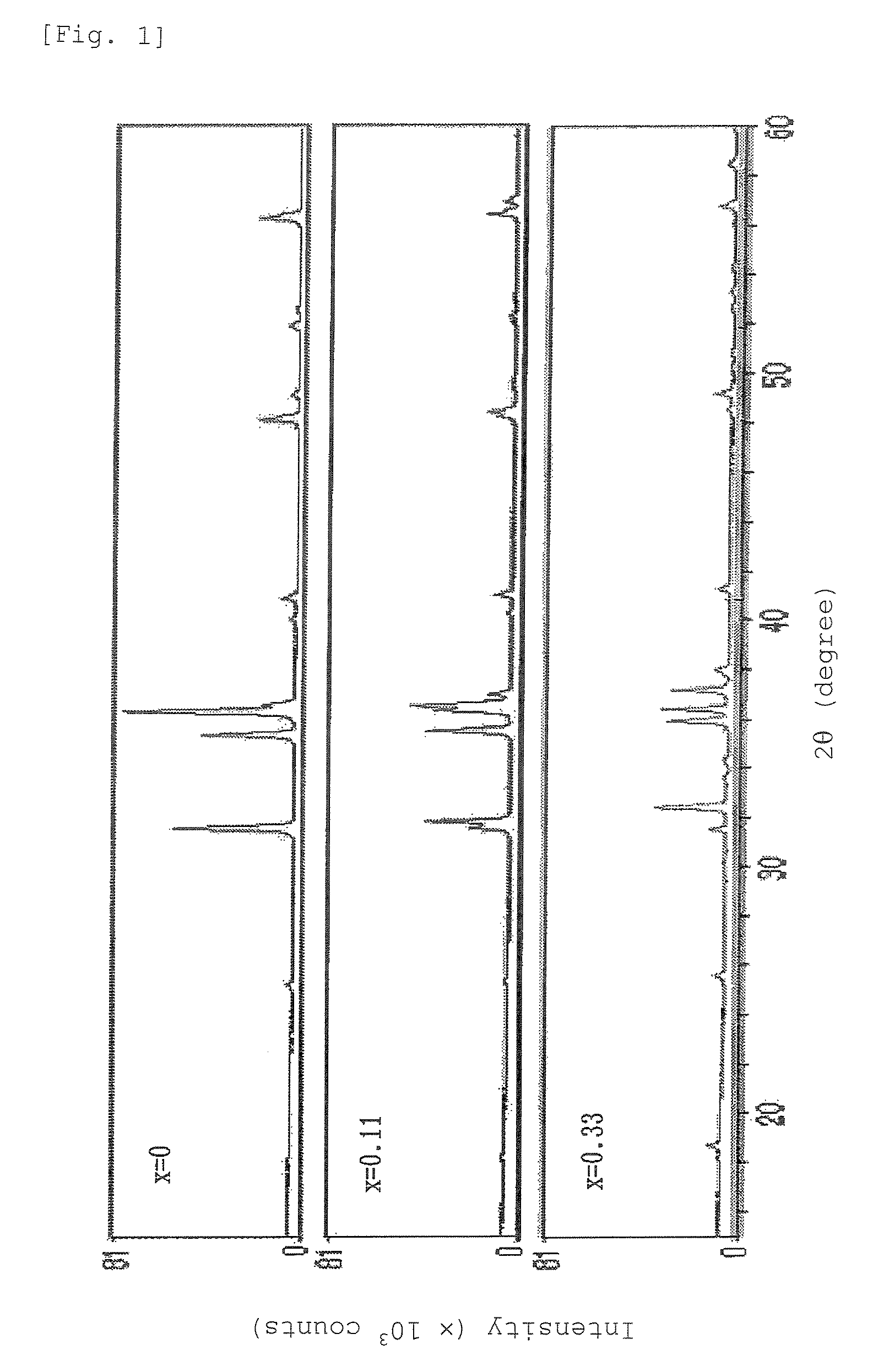

![[beta]-sialon phosphor powder and process for production of the same [beta]-sialon phosphor powder and process for production of the same](https://images-eureka.patsnap.com/patent_img/e2e493ac-f807-45ca-9026-91c5c3aeffaa/HPA00001091849200011.PNG)

![[beta]-sialon phosphor powder and process for production of the same [beta]-sialon phosphor powder and process for production of the same](https://images-eureka.patsnap.com/patent_img/e2e493ac-f807-45ca-9026-91c5c3aeffaa/HPA00001091849200012.PNG)

![[beta]-sialon phosphor powder and process for production of the same [beta]-sialon phosphor powder and process for production of the same](https://images-eureka.patsnap.com/patent_img/e2e493ac-f807-45ca-9026-91c5c3aeffaa/HPA00001091849200013.PNG)