Process for production of fluorescent substance

A technology of fluorescent substances and phosphors, applied in chemical instruments and methods, luminescent materials, nitrogen compounds, etc., can solve problems such as intractable, expensive compounds, chemical instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

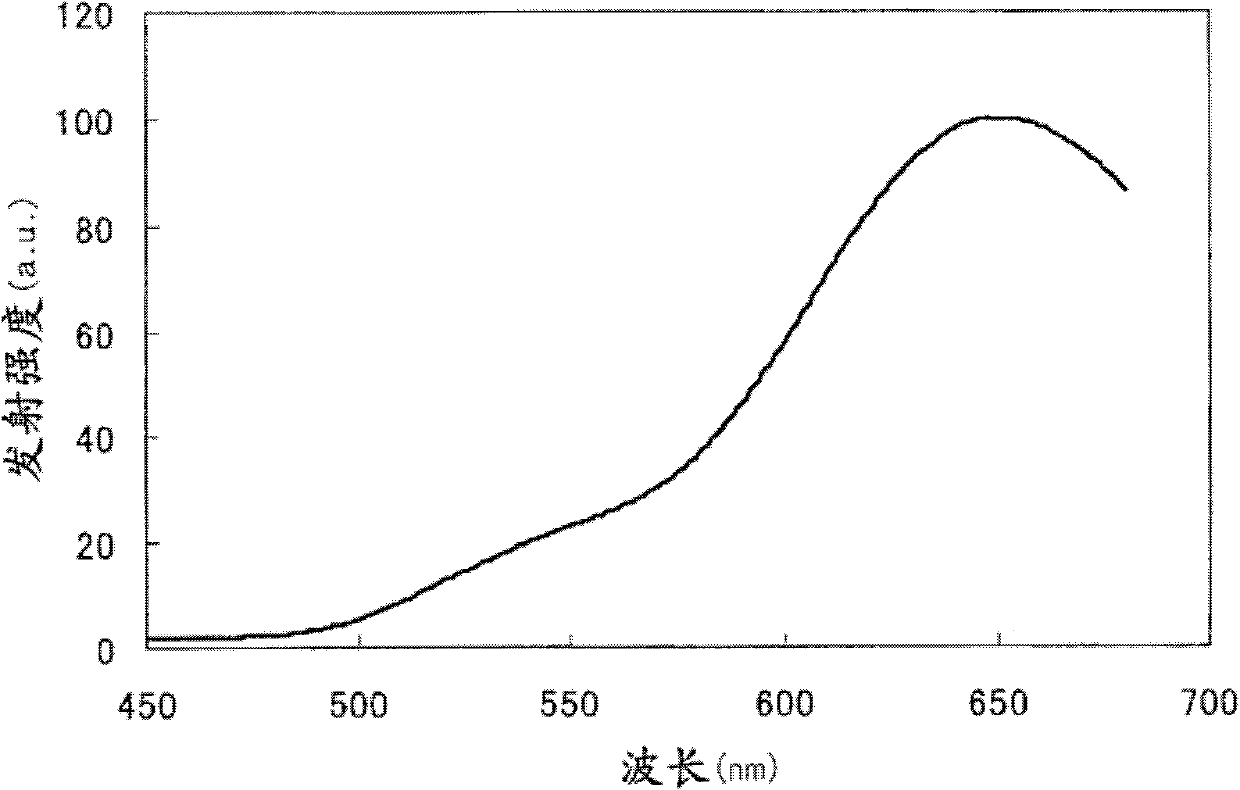

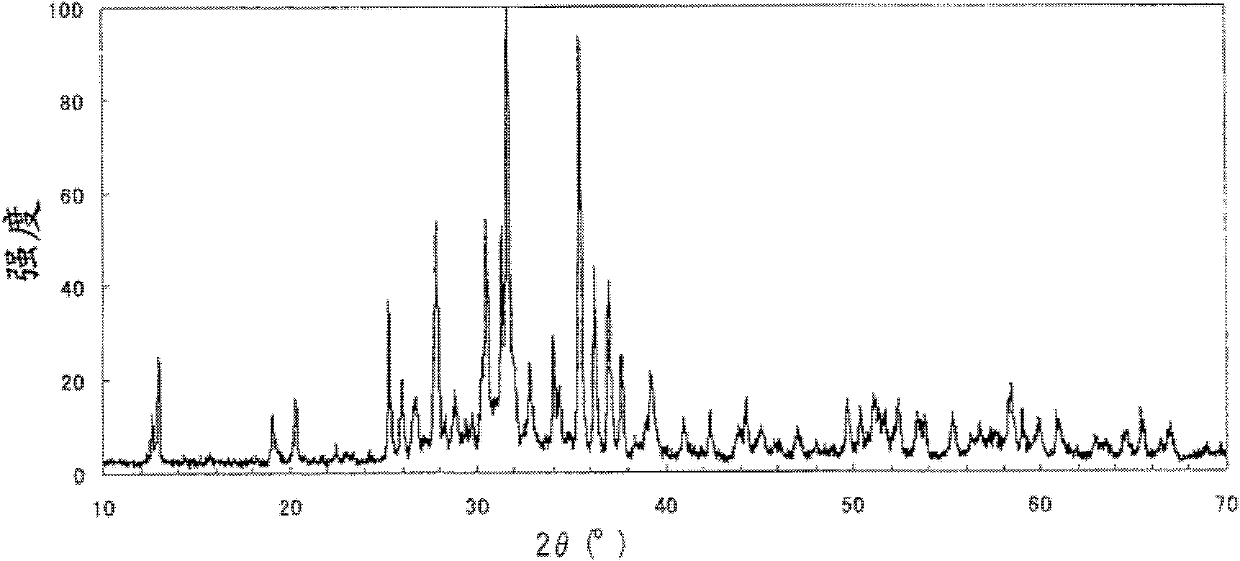

[0067] Weigh 7.46g SrO, 1.41g Eu respectively 2 o 3 and 5.62g Si powder as raw material and dry mixed. In the obtained mixture, the composition ratio (molar ratio) of elements Sr:Eu:Si was 1.8:0.2:5.0. Put the mixture in a BN container, and then place H in it at 1500°C under atmospheric pressure 2 and N 2 The flow rates were respectively 5 L / min and 5 L / min in a reducing atmosphere for 8 hours to obtain the intermediate product in the first step. This intermediate emits orange light with a peak at about 650 nm when excited by 365 nm UV light. The observed emission spectra are shown in figure 1 middle. In addition, the intermediate product was measured by X-ray diffraction using Cu-Kα line to obtain figure 2 The diffraction pattern shown. The diffraction pattern has many diffraction lines corresponding to the lines of the pattern shown by Xie et al. in Chem. 2 Si 5 N 8 components shown. This intermediate product was then subjected to compositional analysis to dete...

Embodiment 2

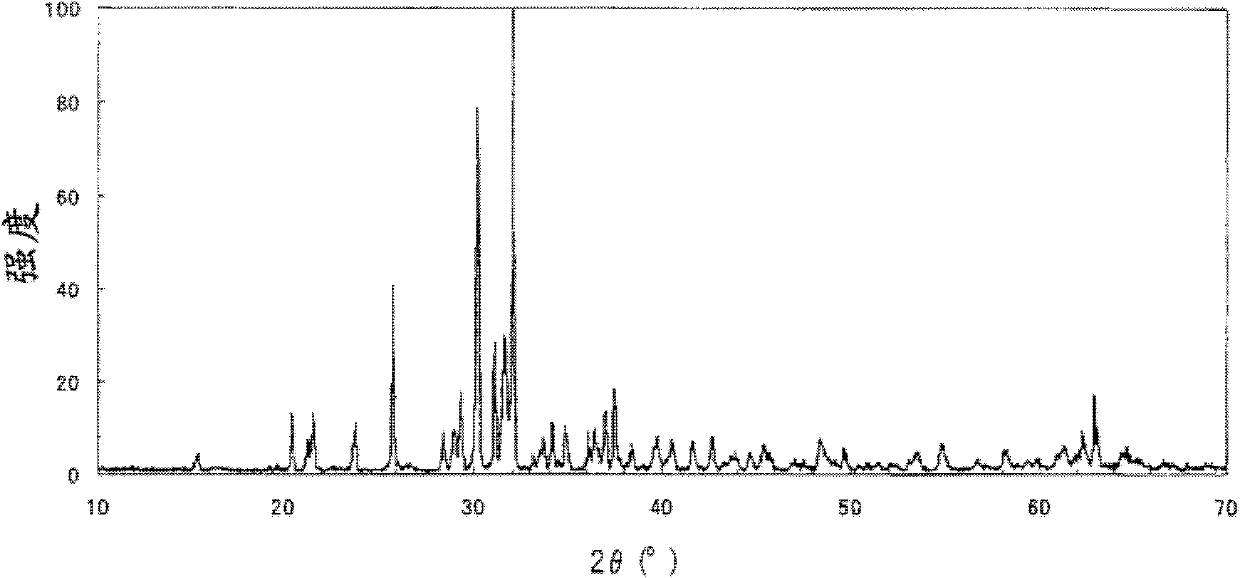

[0070] Weigh 9.33g SrO, 1.76g Eu respectively 2 o 3 and 4.68g Si 3 N 4 As raw material and dry blended. In the obtained mixture, the composition ratio (molar ratio) of elements Sr:Eu:Si was 0.9:0.1:1.0. Put the mixture in a container made of SiC, and then place H in it under atmospheric pressure at 1400°C 2 and N 2 The flow rates were respectively 5 L / min and 5 L / min in a reducing atmosphere for 8 hours to obtain the intermediate product in the first step. This intermediate emits orange light with a peak at about 640 nm when excited by 365 nm UV light. In addition, the intermediate product was subjected to X-ray diffraction measurement, thereby confirming that it contained (Sr, Eu) 2 Si 5 N 8 components shown. This intermediate product was then subjected to compositional analysis to determine the molar ratio of oxygen to the sum of strontium and europium. As a result, the ratio was found to be 0.73, thus proving that the intermediate product contained only a small a...

Embodiment 3 and 4

[0073] Weigh 10.95g Sr(OH) respectively 2 , 1.76g Eu 2 o 3 and 5.62g Si powder as raw material and dry mixed. In the obtained mixture, the composition ratio (molar ratio) of elements Sr:Eu:Si was 0.9:0.1:2.0. Put the mixture in a BN container, and then at 1600°C under atmospheric pressure, Hx and N 2The flow rates were respectively 5 L / min and 5 L / min in a reducing atmosphere for 8 hours to obtain the intermediate product in the first step. This intermediate emits yellow-orange light with a peak at about 650 nm when excited by 365 nm UV light. In addition, the intermediate product was subjected to X-ray diffraction measurement, and thus proved to contain (Sr, Eu) 2 Si 5 N 8 components shown. This intermediate product was then subjected to compositional analysis to determine the molar ratio of oxygen to the sum of strontium and europium. As a result, the ratio was found to be 0.34, thus proving that the intermediate product contained only a small amount of oxygen.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com