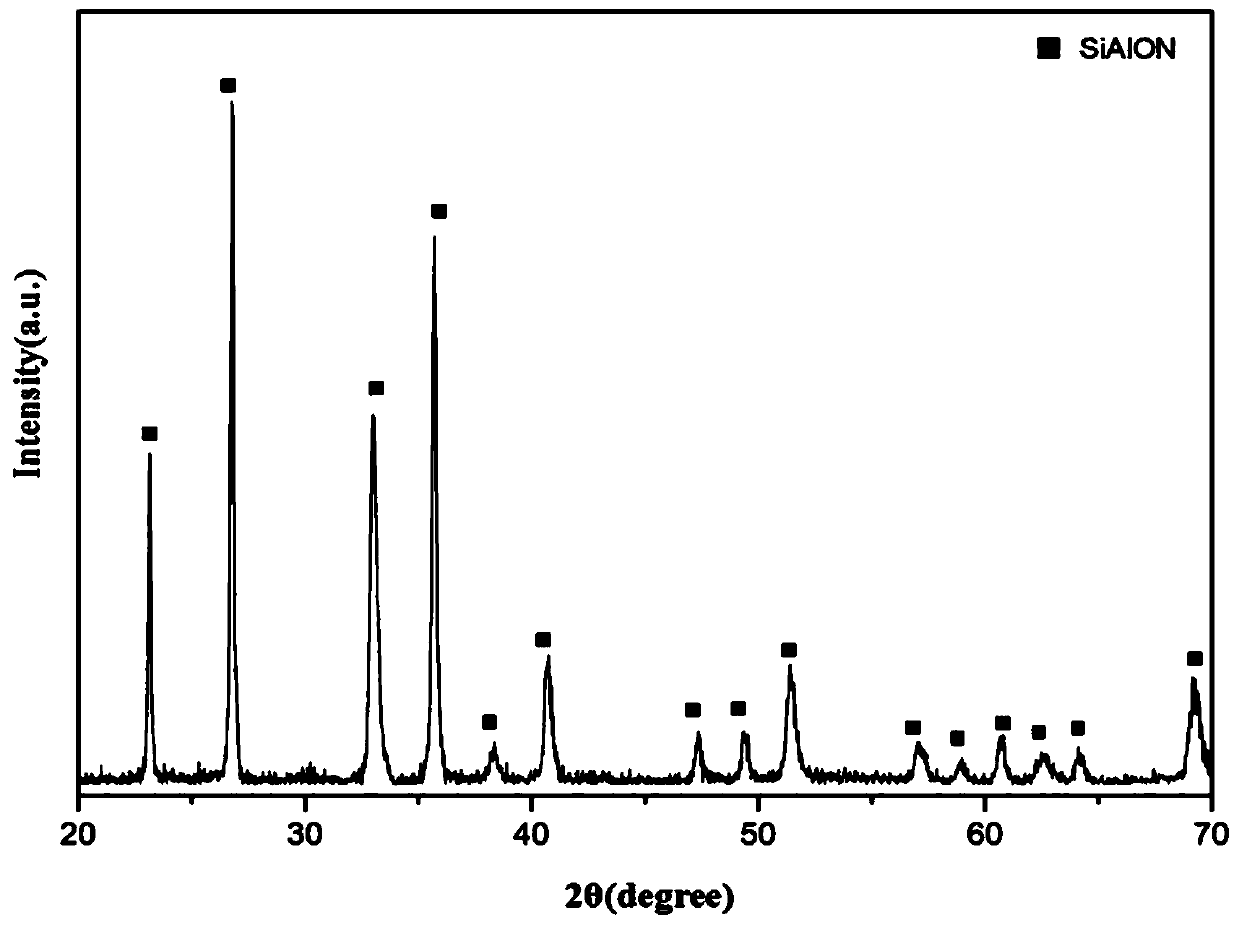

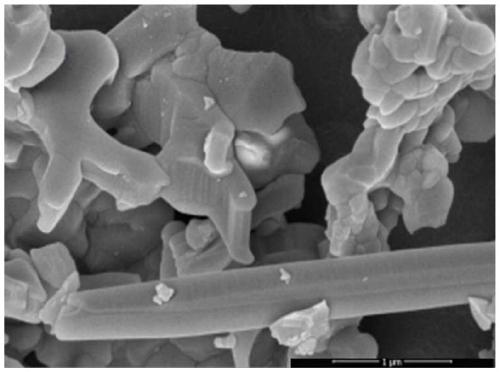

Method for preparing beta-SiAlON from aluminum ash residues

A technology of aluminum ash and aluminum elements, which is applied in the field of preparing β-SiAlON materials, can solve problems such as low purity, difficult process control, and complex raw material components, and achieve the effects of reducing resource waste, reducing environmental burden, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Aluminum slag treatment: aluminum slag is ground and passed through a 60-mesh sieve. According to the analysis results of the X-ray fluorescence spectrometer, the aluminum element in the aluminum slag used in this embodiment (from aluminum, aluminum oxide in the aluminum slag, Aluminum nitride, etc.) the mass fraction is 37.4%;

[0026] 2. Ingredients: According to the element molar ratio of Si powder and Al in aluminum ash slag is 1:1, the total weight of raw materials is 2g, after calculation, weigh 1.40g of aluminum ash slag, 0.54g of Si powder, and Si 3 N 4 0.06g (Si 3 N 4 Consumption is 3wt.% of raw material gross weight);

[0027] 3. Ball milling: Add the raw materials obtained in the previous step into a ceramic ball milling dish, the mass ratio of zirconia ceramic balls to raw materials is 3:1, and grind on a planetary ball mill at 500r / min for 10min;

[0028] 4. High-temperature nitriding reaction: Spread the uniformly ball-milled raw material in a cera...

Embodiment 2

[0031] 1. Aluminum slag treatment: the aluminum slag is ground and passed through a 60-mesh sieve. According to the analysis results of the X-ray fluorescence spectrometer, the mass fraction of aluminum in the aluminum slag used in this embodiment is 37.4%;

[0032] 2. Ingredients: According to the element molar ratio of Si powder and Al in aluminum ash slag is 2.5:1, the total weight of raw materials is 2g, after calculation, weigh 0.98g of aluminum ash slag, 0.96g of Si powder, and Si 3 N 4 0.06g (Si 3 N 4 Consumption is 3wt.% of raw material gross weight);

[0033]3. Ball milling: Add the raw materials obtained in the previous step into a ceramic ball milling dish, the mass ratio of zirconia ceramic balls to raw materials is 3:1, and grind for 15 minutes on a planetary ball mill at 500r / min;

[0034] 4. High-temperature nitriding reaction: Spread the uniformly ball-milled raw material in a ceramic (zirconia) crucible, send it into a tubular atmosphere furnace, and fill ...

Embodiment 3

[0037] 1. Aluminum slag treatment: the aluminum slag is ground and passed through a 60-mesh sieve. According to the analysis results of the X-ray fluorescence spectrometer, the mass fraction of aluminum in the aluminum slag used in this embodiment is 37.4%;

[0038] 2. Ingredients: According to the element molar ratio of Si powder and Al in aluminum ash slag is 5:1, the total weight of raw materials is 2g, after calculation, weigh 0.66g of aluminum ash slag, 1.28g of Si powder, and Si 3 N 4 0.06g (Si 3 N 4 Consumption is 3wt.% of raw material gross weight);

[0039] 3. Ball milling: add the raw materials obtained in the previous step into a ceramic ball milling dish, the mass ratio of zirconia ceramic balls to raw materials is 3:1, and grind on a planetary ball mill at 500r / min for 20min;

[0040] 4. High-temperature nitriding reaction: Spread the uniformly ball-milled raw material in a ceramic (zirconia) crucible, send it into a tubular atmosphere furnace, and fill it wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com