Alpha-siaion powder and method for producing the same

A manufacturing method, Sialon technology, applied in chemical instruments and methods, Sialon, luminescent materials, etc., can solve the problems of deterioration of luminescence characteristics, influence of fluorescence characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In Example 1, as raw material powders, (a) silicon nitride powder (manufactured by Ube Industries, E10 grade), (b) aluminum nitride powder (manufactured by Tokuyama, F grade), (c) calcium carbonate powder (Kanto Chemical manufacture, special grade reagent), (d) europium oxide powder (manufactured by Shin-Etsu Chemical Industry, RU grade) to prepare α-Sialon powder. The mixing ratio is set to (a) silicon nitride (Si 3 N 4 ): (b) aluminum nitride (AlN): (c) calcium carbonate (CaCO 3 ): (d) europium oxide (Eu 2 o 3 )=52.3:36.2:10.9:0.6 (molar ratio), in an ethanol solvent, carry out 1 hour of wet ball milling with a silicon nitride pot and ball, filter, and dry to obtain a mixed powder.

[0062] 25 g of the mixed powder was filled into a boron nitride crucible with an inner diameter of 50 mm and a height of 40 mm, and lightly tapped. At this time, the bulk density of the mixed powder calculated from the filling height is 0.45g / cm 3 . A cap made of boron nitride was ...

Embodiment 2

[0066] In embodiment 2, the internal diameter of 25g of the same mixed powder raw material as in embodiment 1 is carried out under the pressure of 20MPa under the mold of 40mm to carry out uniaxial compression molding, and the obtained bulk density is 1.2g / cm 3 of shaped objects. This molded product was placed in the same crucible as in Example 1, and heat-treated under the same conditions. The bulk density of the molded product after heat treatment becomes 1.4g / cm 3 , slightly densified compared with that before heat treatment. Then, in the same manner as in Example 1, it was ground in a mortar so that it could pass through a sieve with a mesh size of 45 μm to obtain a synthetic powder. The pulverization of the product of Example 2 is slightly worse than that of Example 1.

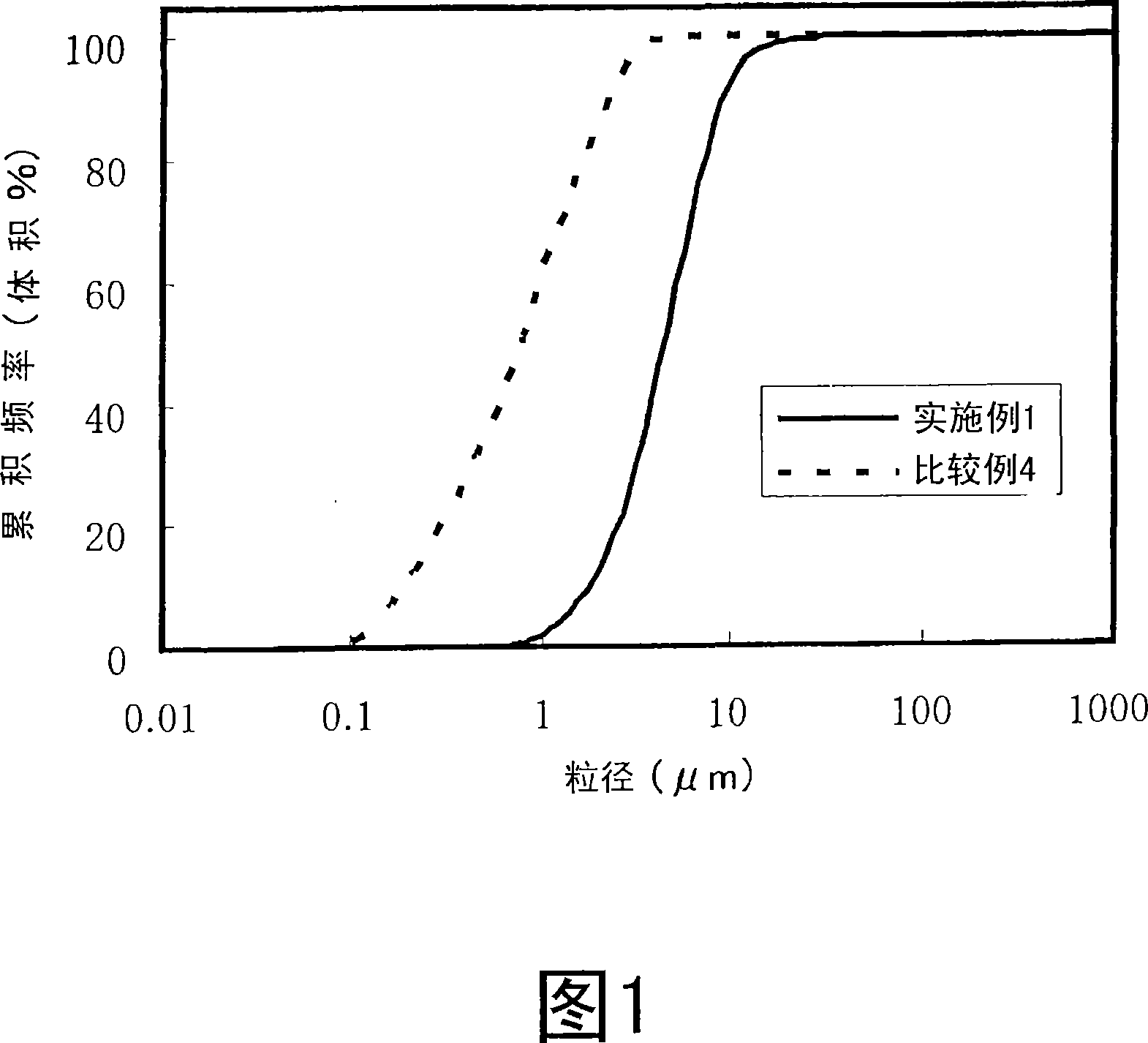

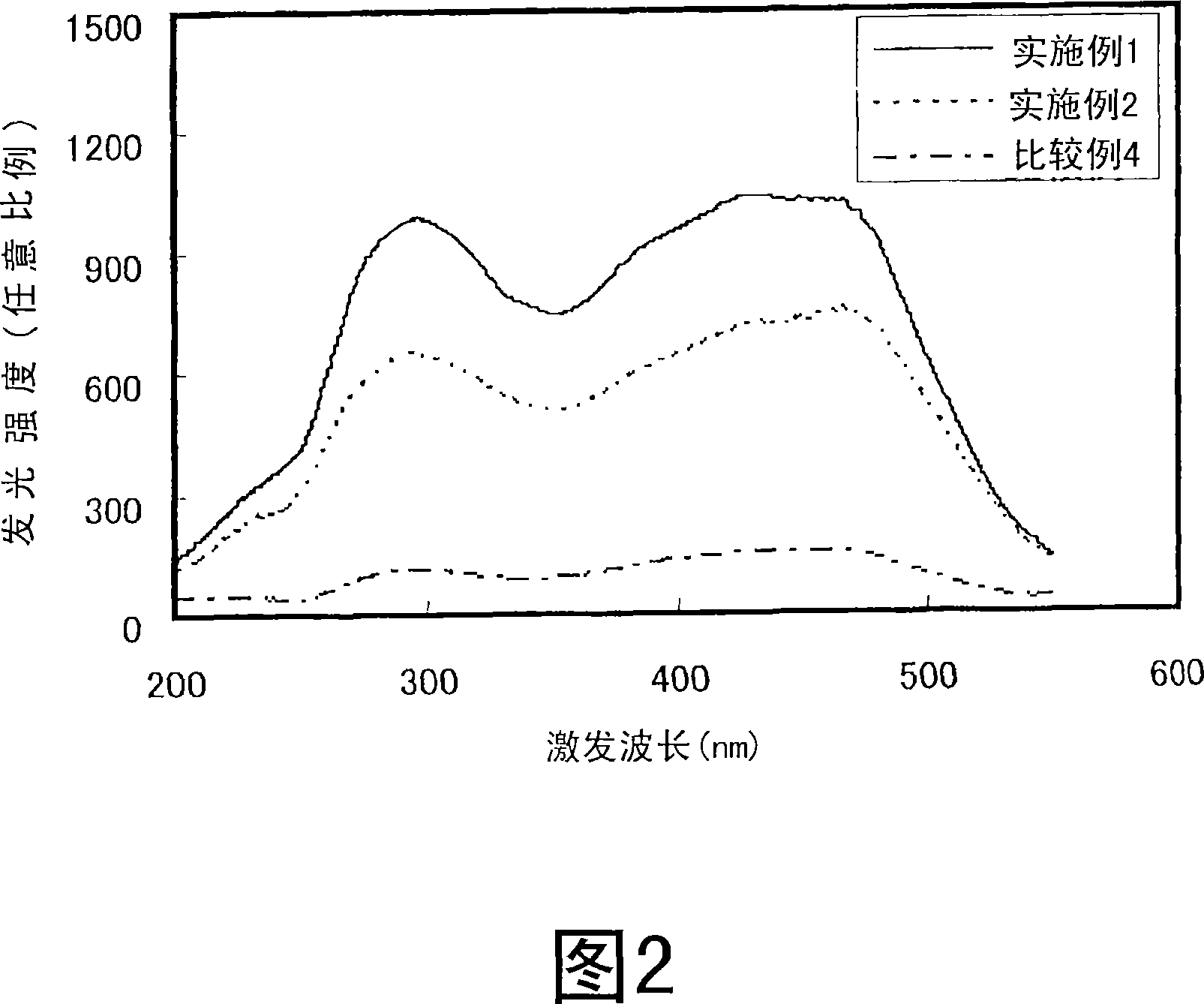

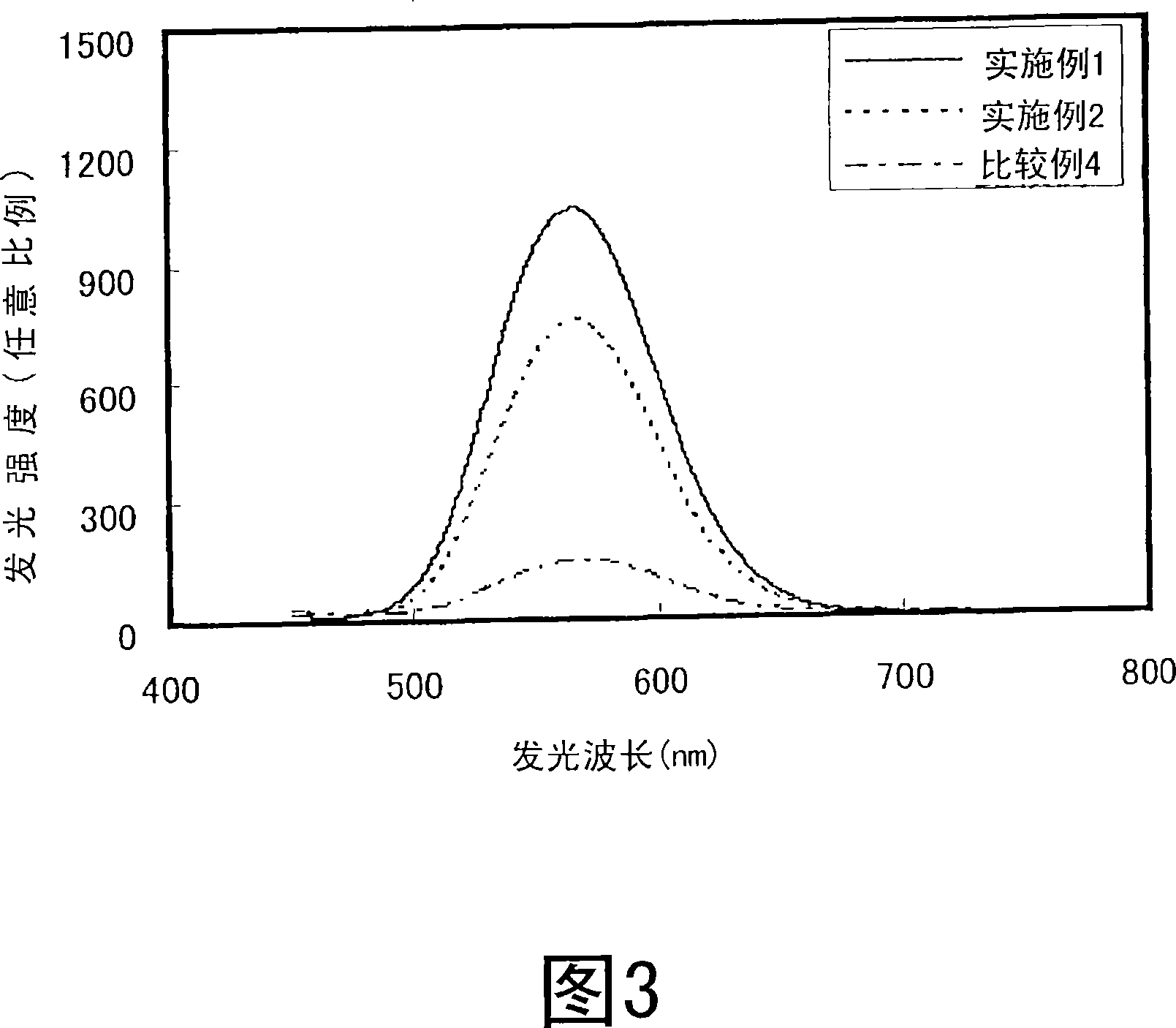

[0067] According to the XRD measurement, it can be seen that the crystal phase of the product of Example 2 is a single phase of α-Sialon. According to the particle size distribution measurement of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com