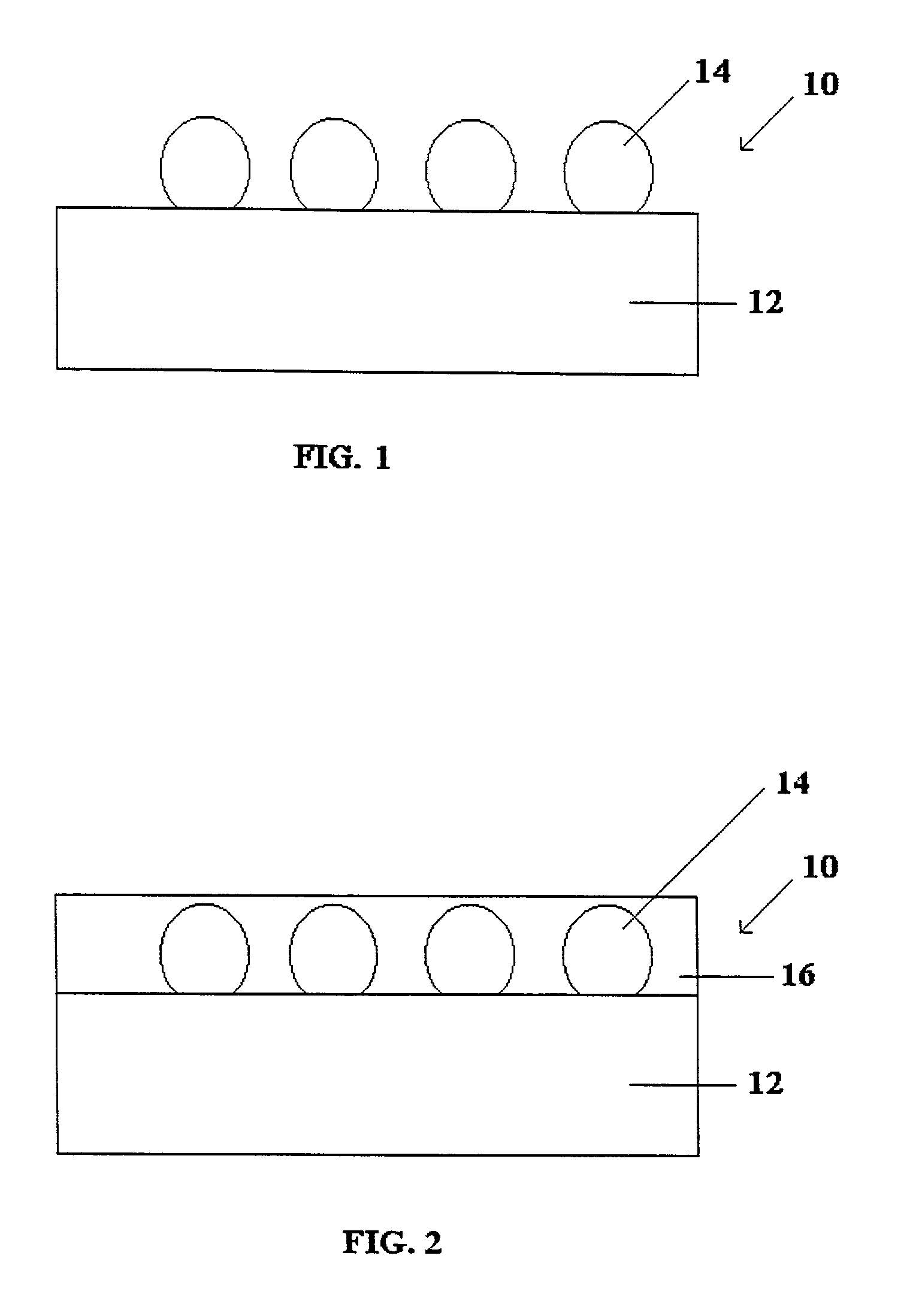

Flip chip with integrated flux and underfill

a technology of flux and underfill, which is applied in the field of flip chip design, can solve the problems of degrading device performance, affecting device completeness, and affecting device performance,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0042] Flux / Underfill Preparation

[0043] 20.4% by weight bisphenol A epoxy resin (Ciba, GT7074) was blended with 24.4% by weight dipropylene glycol methyl ether acetate (Dow). 0.7% by weight polyamide thixotropic agent (King Industries, Disparlon 6650) was dispersed in the epoxy resin solution at 65.degree. C. for 15 minutes. The blend was cooled to 25.degree. C. and 5.4% by weight 1,4-cyclohexane dicarboxylic acid, 0.4% by weight 2,4,6-triamino pyrimidine, 48.5% by weight 5-micron silica filler (LE-05, from Tatsumori Ltd., Tokyo, Japan), and 0.2% by weight epoxy silane (TS-100 from OSI Specialties, Friendly, W.Va.), were dispersed in the blend at high shear.

example 2

[0044] Flux / Underfill Preparation

[0045] This material was prepared in a manner similar to that of Example 1, however, 25% by weight bisphenol A and 20% by weight dipropylene glycol methyl ether acetate, were substituted for those amounts provided above. 2% by weight hydrogenated castor oil was substituted for the polyamide thixotropic agent. Additionally, following the cooling step, the additives of Example 1 were substituted with the following: 10% by weight adipic acid, 2% by weight 2,4,6-triamino pyrimidine, 40.9% by weight 5-micron silica filler and 0.1% by weight silane.

example 3

[0046] Flux / Underfill Preparation

[0047] This material was prepared in a manner similar to that of Example 1, however, 40% by weight bisphenol A epoxy resin (Shell, Epon 1007F) and 45% by weight dipropylene glycol methyl ether acetate, were substituted for those amounts provided above. 5% by weight hydrogenated castor oil was substituted for the polyamide thixotropic agent. Additionally, following the cooling step, 10% by weight adipic acid was added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermoplasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com