Magnetic filter and method for purifying and treating liquids using permanent magnetic balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

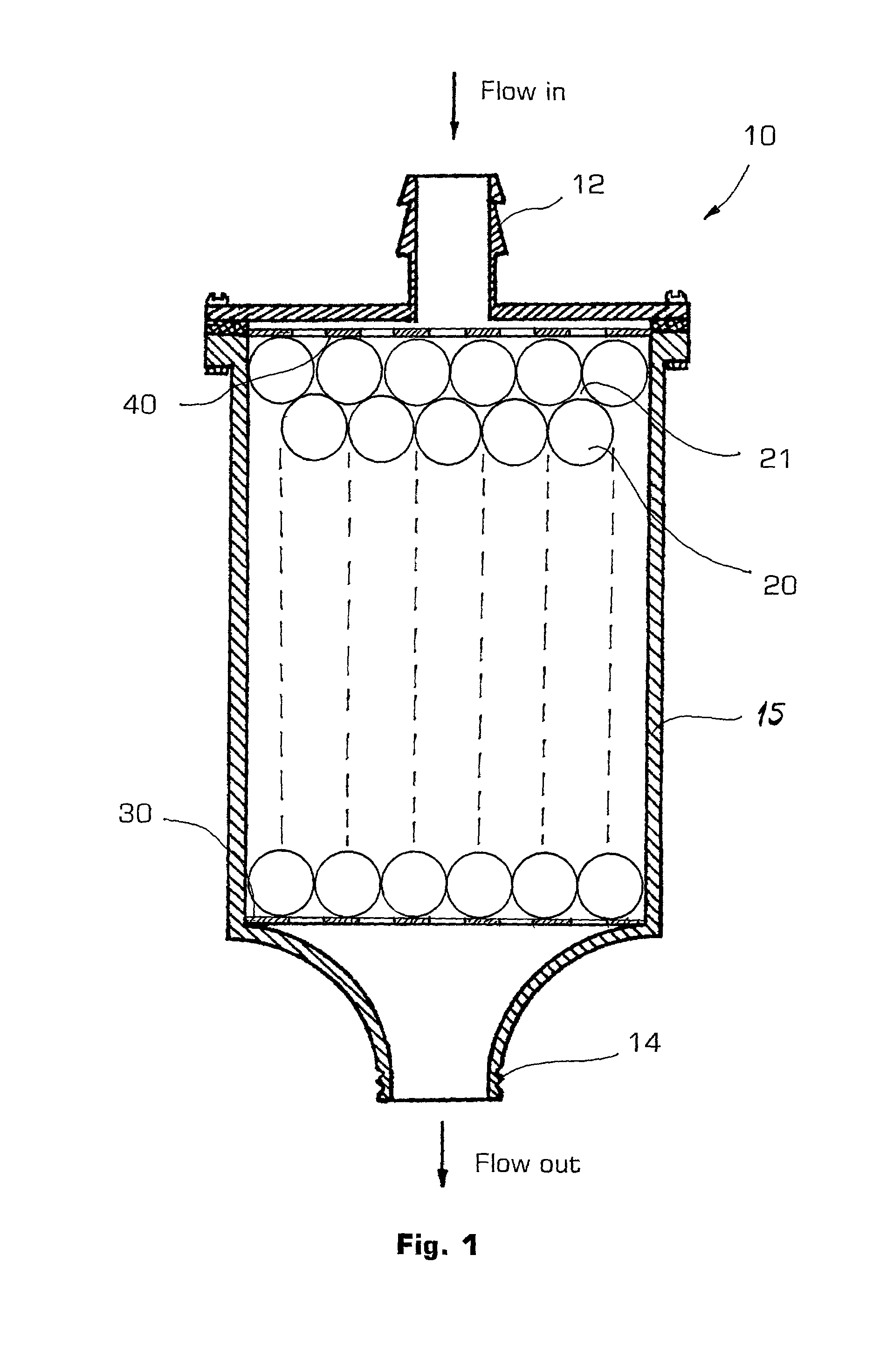

[0026] A detailed description of the most preferred embodiment of the present invention follows with reference to accompanying drawing on FIG. 1 in which like elements are indicated by like reference numerals.

[0027] According to the design and the method of the present invention, the filter (10) consists of a housing (15) having the flow inlet (12) and the outlet (14). Both inlet and outlet may be configured as a barbed connector as shown for example for the inlet (12). Alternately, as shown for the outlet (14), it may be configured as having attachment threads to connect to the lines of the rest of a hydraulic system. Multiple variations of the filter housing and attachments can be used for the filter of the present invention as can be readily apparent to the skilled in the art.

[0028] The housing (15) of the filter (10) contains a plurality of magnetic balls (20) having spaces (21) therebetween and located between two optional perforated plates (30) and (40). The purpose of plates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com