Non-magnetic austenitic stainless cast steel and manufacturing method of the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described specifically below based on examples.

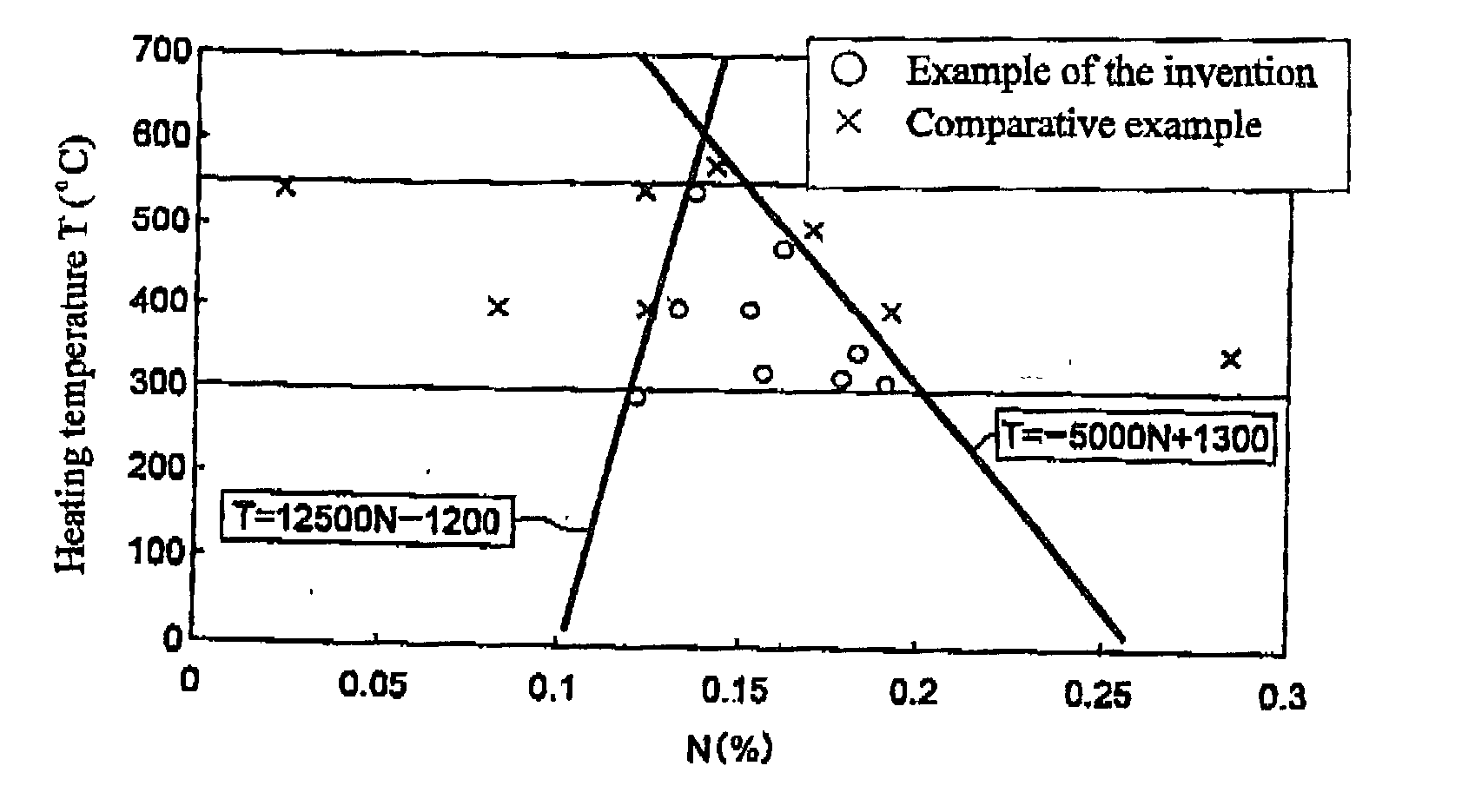

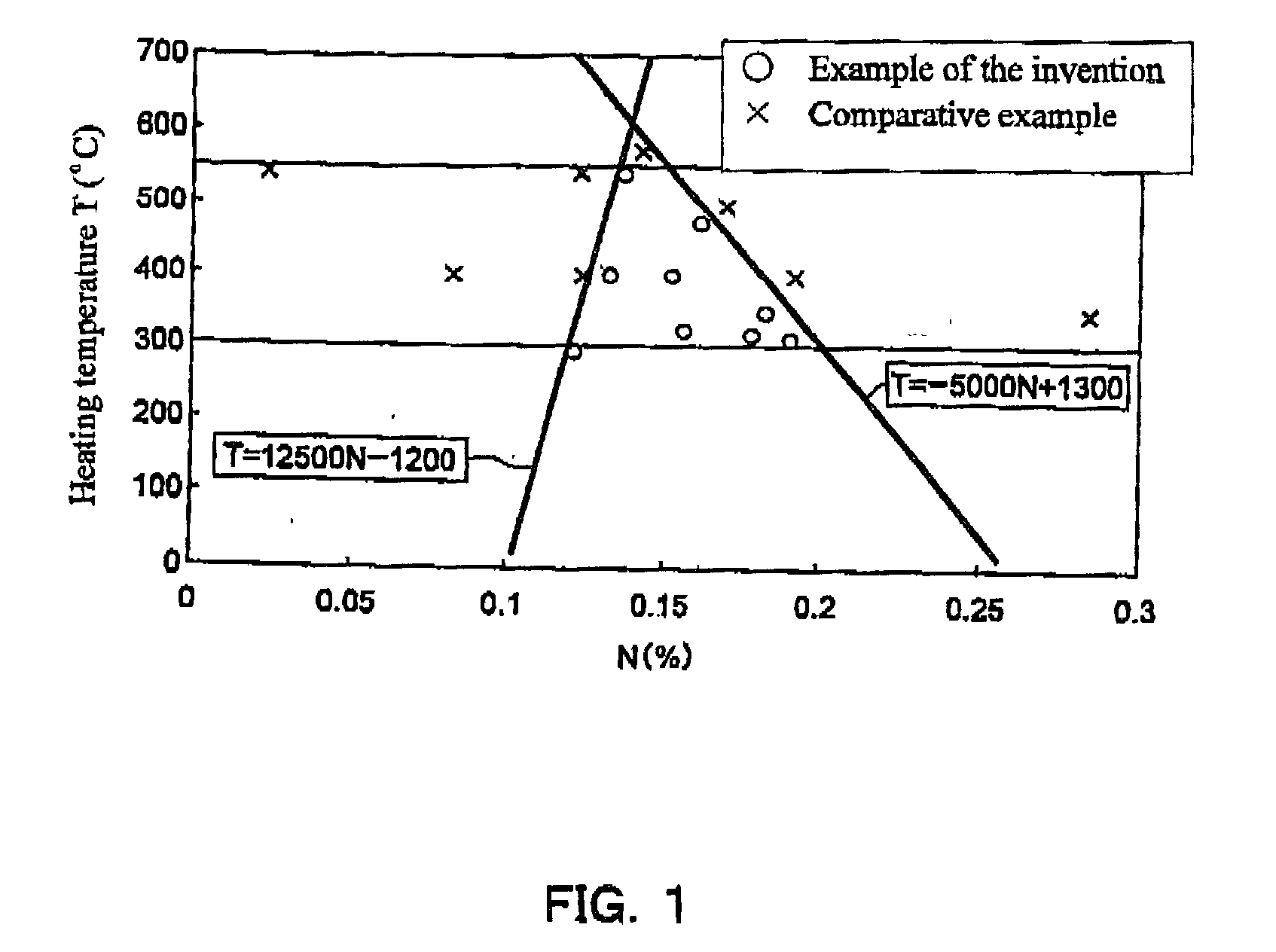

[0045] Samples prepared to have compositions shown in Table 1 are melted using a 30kVA high-frequency furnace, and are cast to JIS G5122B test specimens (hereinafter referred to as B specimens) using a CO.sub.2-silica mold. The B specimens are maintained at a heating temperature in a range of 300.degree. C. to 550.degree. C. for two hours, subsequently cooled to below 200.degree. C. by air-cooling or slow-cooling, and formed into ASTM G-tensile test specimens (with a parallel portion diameter of 6 mm).

[0046] The ASTM G-tensile test specimens are subjected to tensile tests at room temperature and liquid nitrogen temperature (77K). On the test specimens after the tensile test at room temperature, the relative magnetic permeability of a break portion is measured. Specimens with relative magnetic permeability having 1.10 or less were judged as a non-magnetic material. The heating temperature, cooling rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com