Cold-rolled double-surface stainless steel composite plate having excellent comprehensive performances and manufacturing method

A comprehensive performance, stainless steel technology, applied in the direction of metal rolling, etc., can solve the problem that it is difficult to meet the elongation technical requirements of stainless steel clad sheet, the difficulty in controlling the thickness uniformity of the clad layer of cold-rolled stainless steel clad plate, and the uneven structure of carbon steel base material and other problems, to achieve the effect of excellent surface quality, stable control of grain size, and uniform structure of carbon steel substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0041] Table 1 shows the composition and compounding ratio of the base plate and double plate steel of the embodiment of the present invention and the comparative example, and Table 2 shows the key manufacturing process and performance of the composite plate of the embodiment of the present invention and the comparative example.

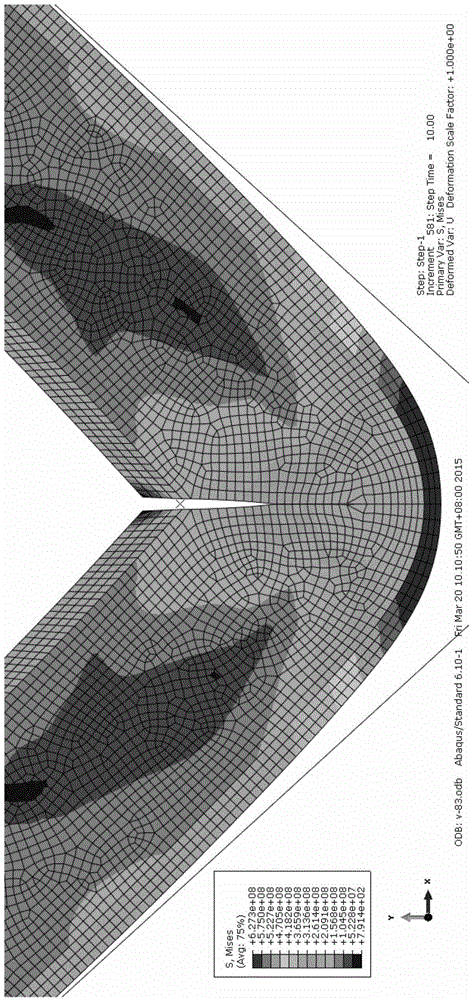

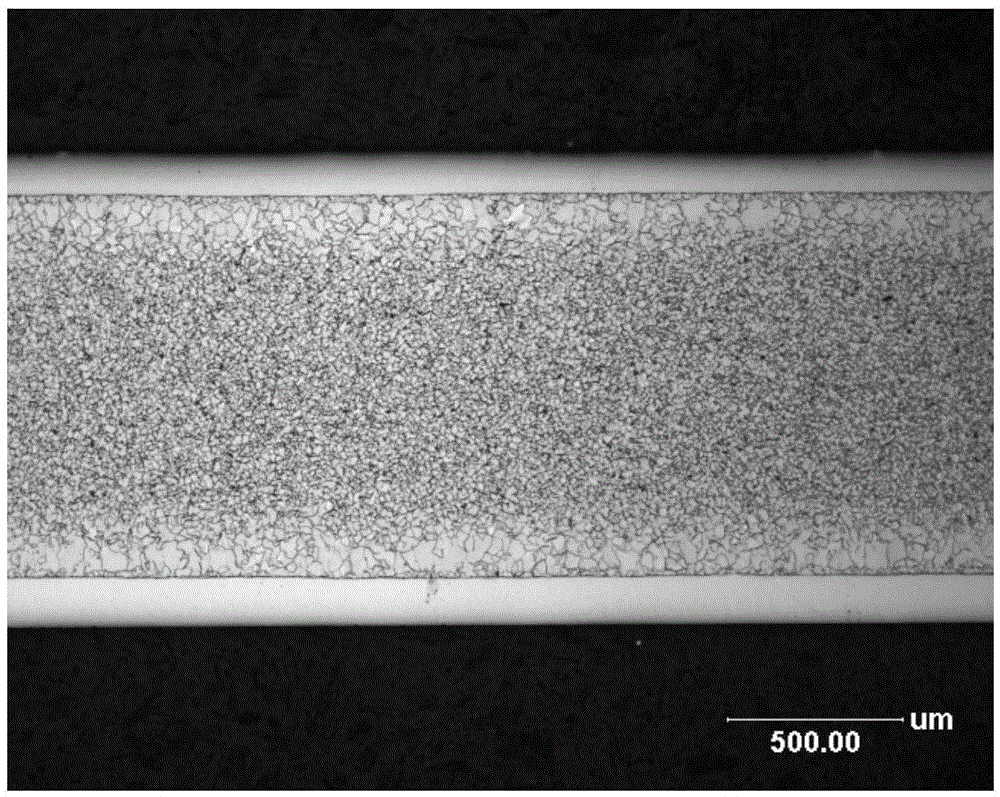

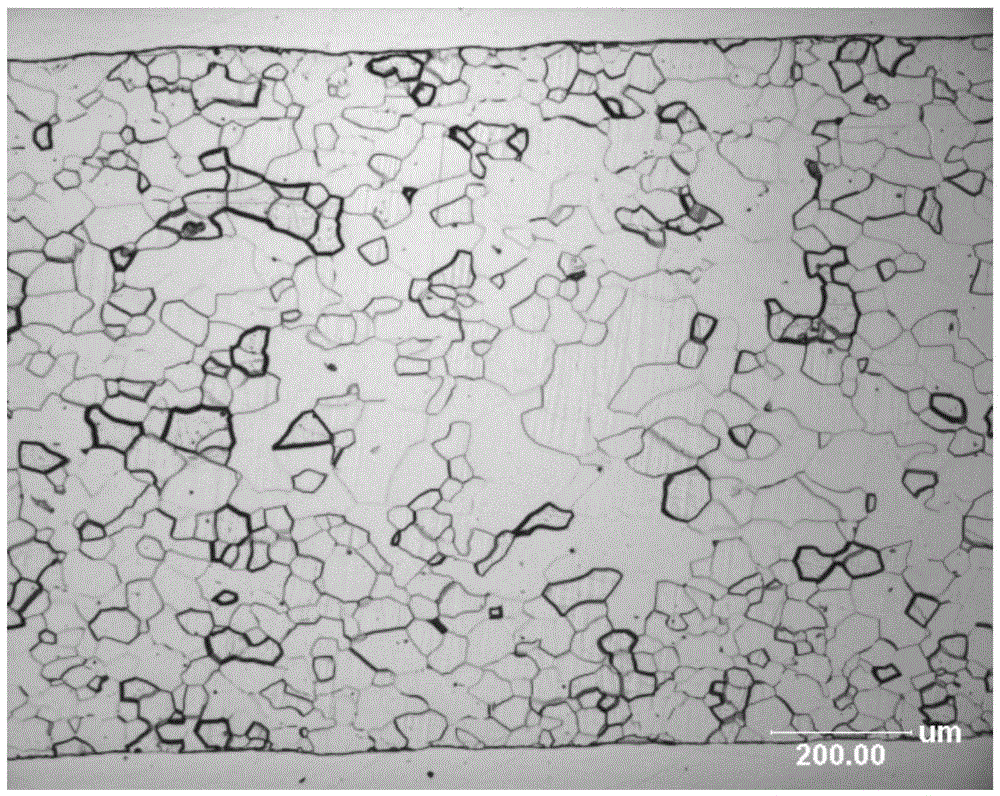

[0042] According to the composition in Table 1 and the composite ratio of the total thickness of the composite board accounting for 10-30% of the total thickness of the composite board, select and process the carbon steel substrate and the stainless steel doubler board, and then make double-sided stainless steel by explosion, diffusion welding or vacuum welding. Composite blanks are made by vacuum electron beam welding firstly. After hot rolling, annealing after hot rolling + pickling and cold rolling, they are made into hard-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com