Ultrapurification high nitrogen austenitic stainless steel and its preparation method

A high nitrogen austenite and nitrogen austenite technology is applied in the field of nickel-free high nitrogen austenitic stainless steel and vacuum induction furnace smelting process, which can solve the problems of reducing cost, being difficult to achieve, and increasing smelting cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] According to the chemical composition range set by the present invention, 5 heats of steel were smelted in a 25 kg vacuum induction furnace, and its specific chemical composition is as shown in Table 1. These 5 furnaces of steel were respectively poured into a φ120×450 steel ingot, and processed according to the above processing and heat treatment specifications.

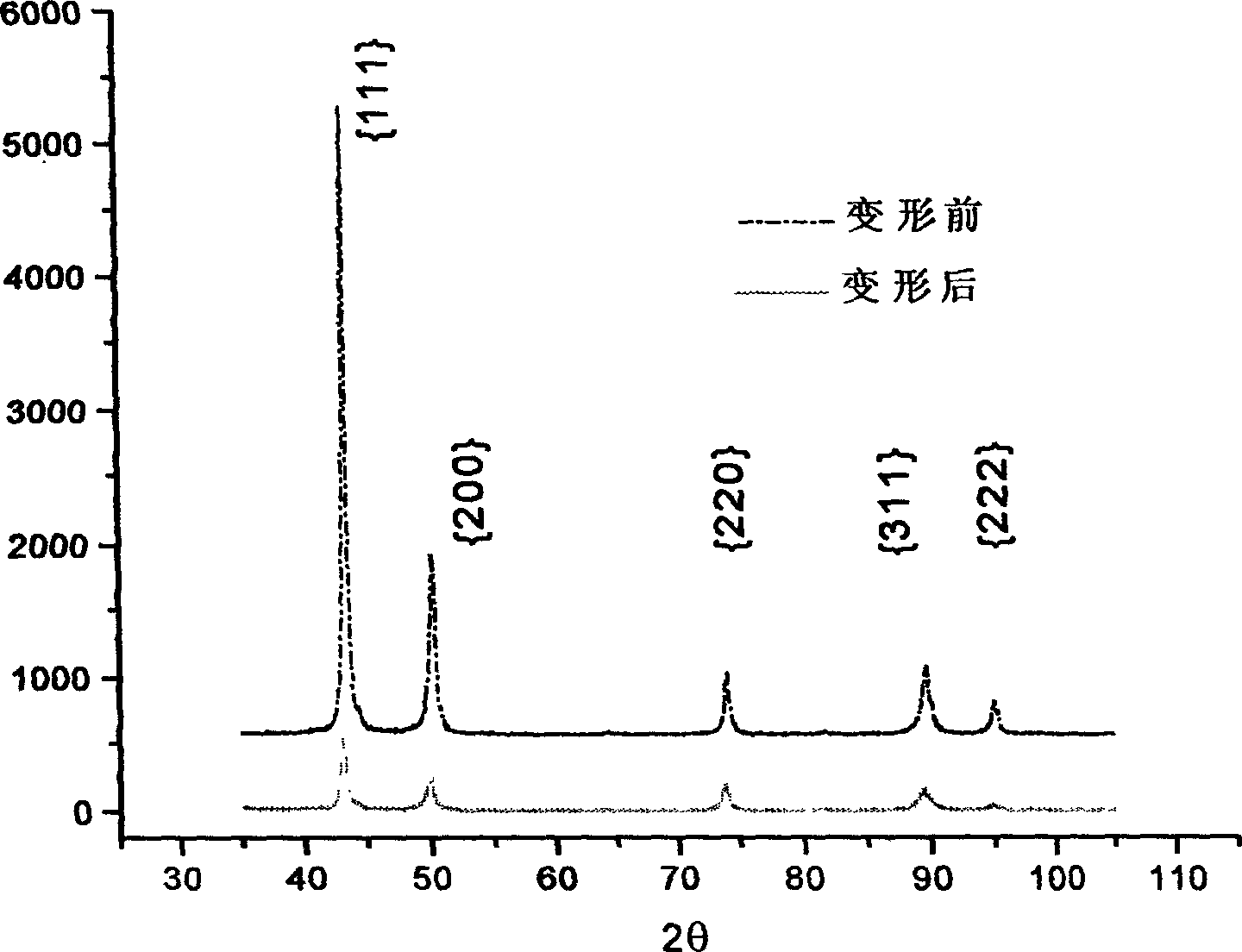

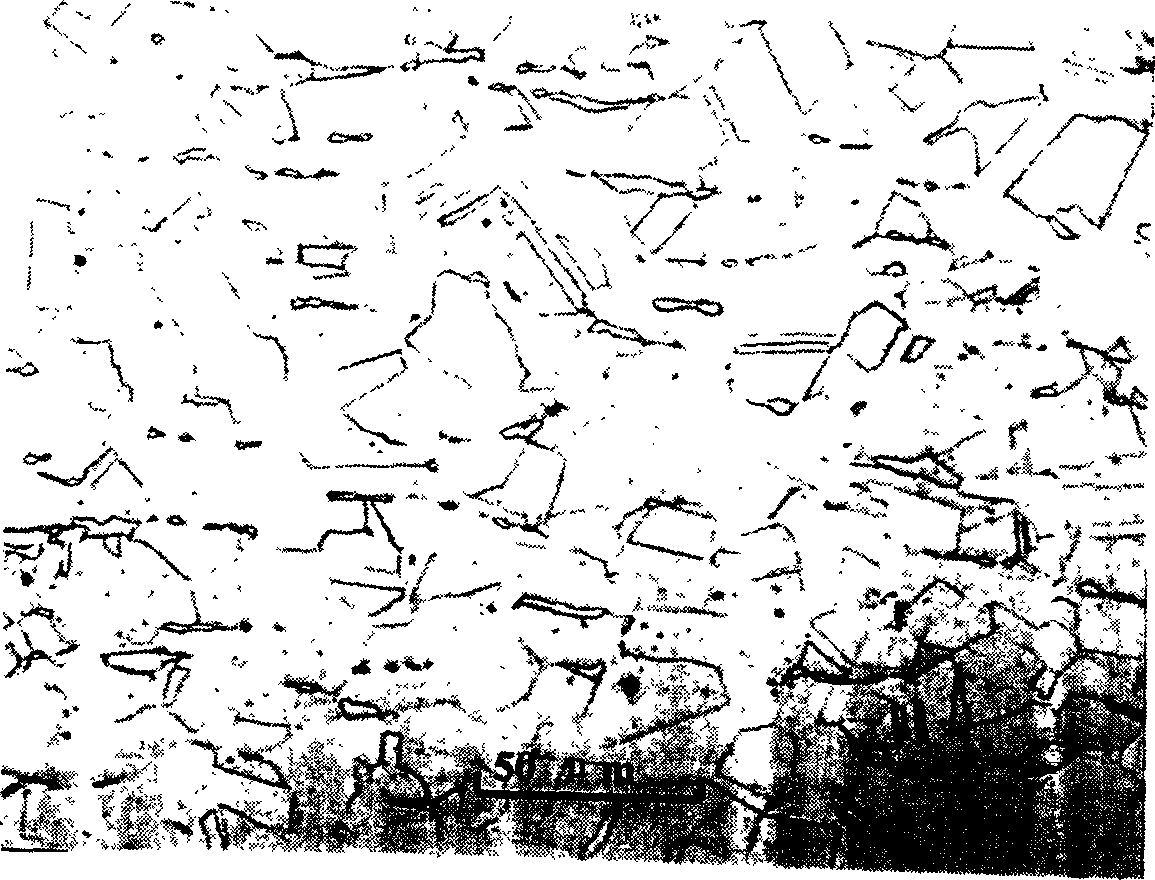

[0029] All test specimens are sampled vertically along the rolling direction, and steel of the present invention is a single austenitic structure (such as figure 1 , figure 2 Shown), the measured mechanical properties of nickel-free high-nitrogen austenitic stainless steel are shown in Table 2. It can be seen from the examples that the strength, toughness and plasticity of the nickel-free austenitic stainless steel smelted in the present invention have reached or exceeded the level of traditional nickel-chromium stainless steel. The addition of nitrogen effectively replaces the role of nickel and increases...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com