Stackable weight system

a weight system and stackable technology, applied in the field of stackable weight systems, can solve the problems of prone to collapse of the vertical column of multiple stackable plates on top of one another, difficult balance and control, and dangerous handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

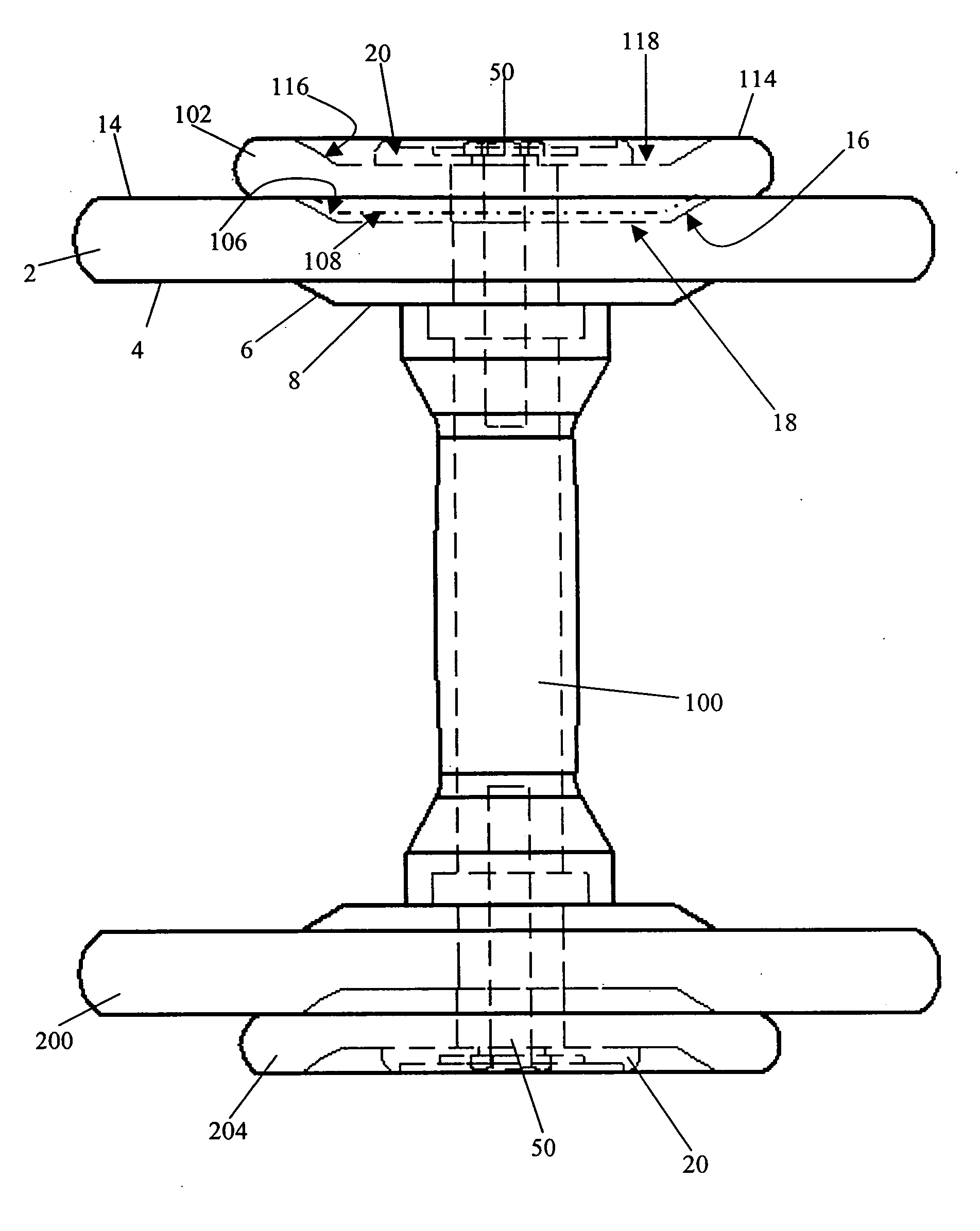

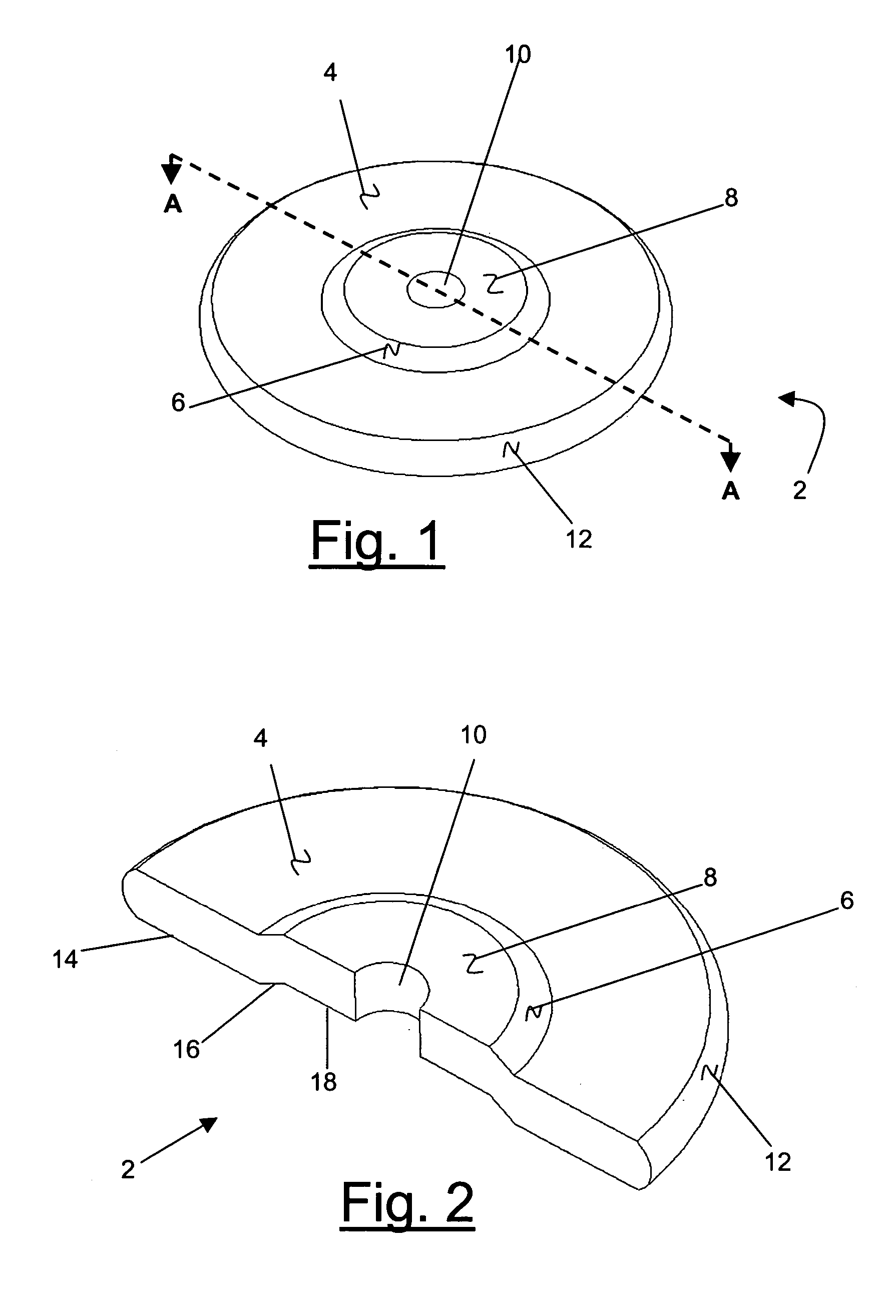

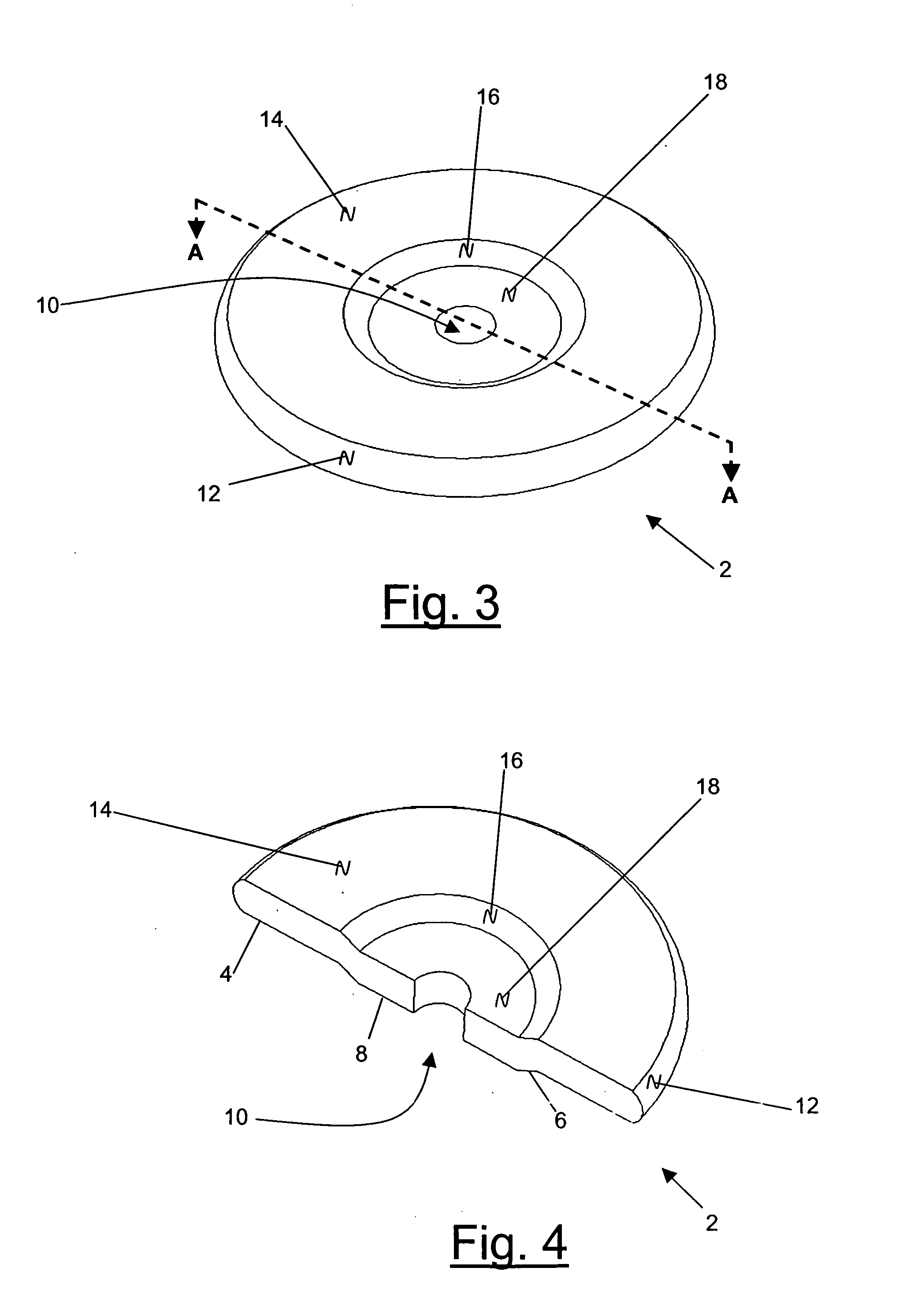

[0027] FIG. 1 is an exemplary perspective view of a top or front lateral face of a weight plate 2 in accordance with the present invention. The plate 2 is any entity of incremental mass to allow for graduation of lifting resistance. In general, weight plate 2 is comprised of a circular disc of varying thickness or density with rounded rims or edges 12 at its radial distal ends, and a circular central hole 10 at its radial center. The front lateral face or radial plane of the plate 2 is comprised of a conical protrusion 8 at a proximal end from its radial center, and a radial flat base 4 at a distal end thereof. The radial surface of the conical projection 8 along its radial longitudinal distal ends 6 bevel or slope radially downward towards the flat surface 4 of the plate 2. The conical projection 8, its oblique radial distal end surface 6, and the flat surface 4 of plate 2 are uniform, contiguous, and integral part of plate 2, forming a single piece. The cut-out section of plate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com