A high strength cast aluminum alloy with accelerated response to heat treatment

a technology of accelerated response and cast aluminum, which is applied in the field of high-performance cast aluminum alloys with an accelerated can solve the problems of reducing the variability of the response to heat treatment, and achieve the effects of dimensional stability, reduced aging times, and enhanced thermal growth kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

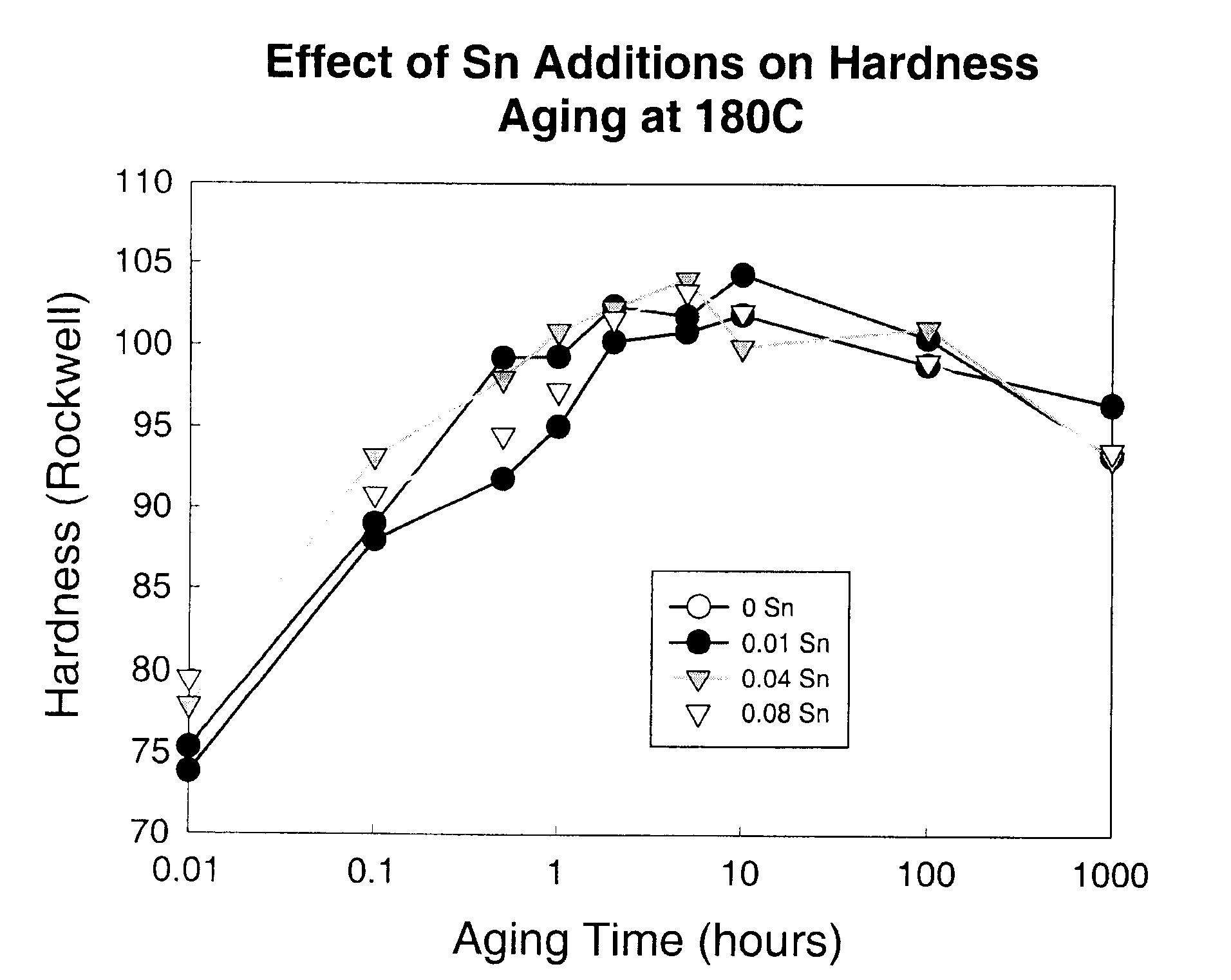

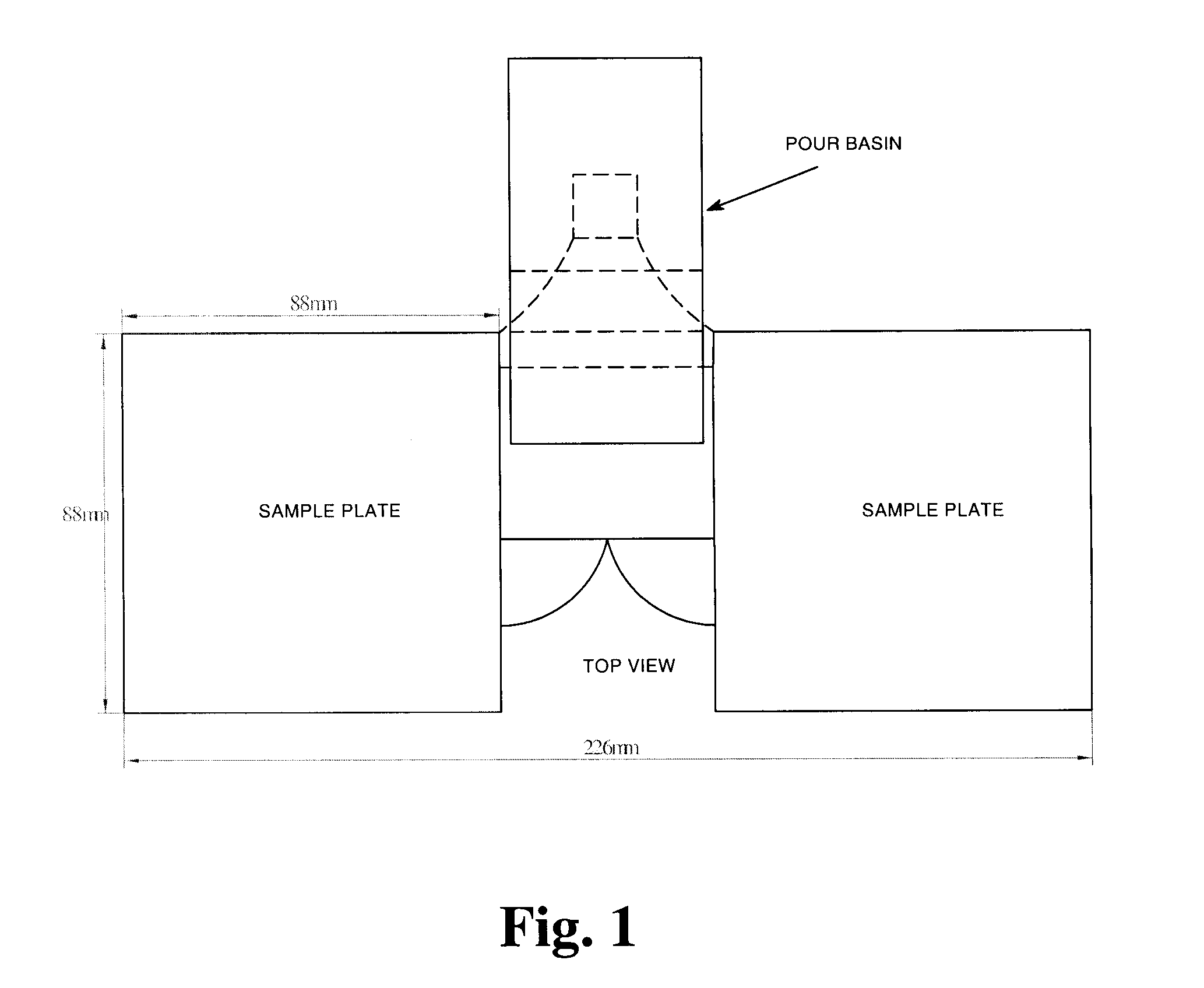

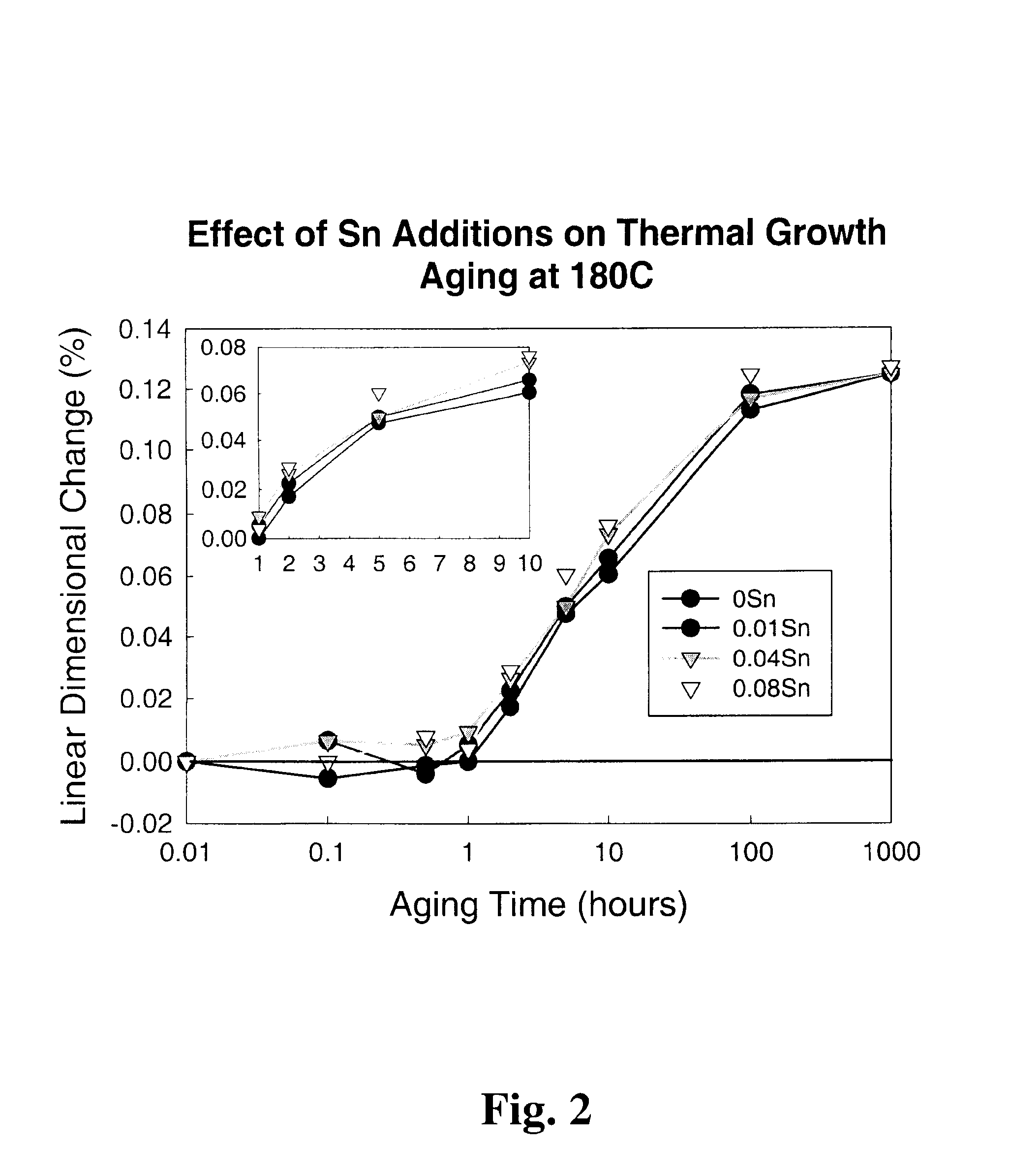

[0025] As a comparative example, an Al--Si--Cu--Mg casting alloy was selected to illustrate the concepts described here. An alloy generally conforming to but having a more limited range of composition as A320, identified as W319 aluminum, was obtained from Alchem Aluminum, Inc. Four target Sn concentrations were used for comparison: (1) "base," (2) "0.01 addition," (3) "0.04 addition," and (4) "0.08 addition," where the additions are in weight percent. These concentrations were obtained by adding 99.9% pure Sn to the W319 material. To determine the chemical compositions of the alloys, optical emission spectrometer analysis is sufficient for compositions having levels greater than 1000 ppm. However, for lower level compositions, the more accurate analysis by a glow discharge mass spectrometry is preferred. Both techniques were used for comparative purposes. Table 1, set forth below, provides the chemical composition of base alloy and Sn additions used for comparison. All reported com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com