Cavity-structuralized silicon-carbon core-shell nanowire array, and preparation method and use thereof

A nanowire array and structured silicon technology, applied in nanotechnology, nanotechnology, structural parts, etc., can solve the problems of low area loading, short cycle life, and low material area specific capacity, achieving large capacity and low cost , the effect of improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

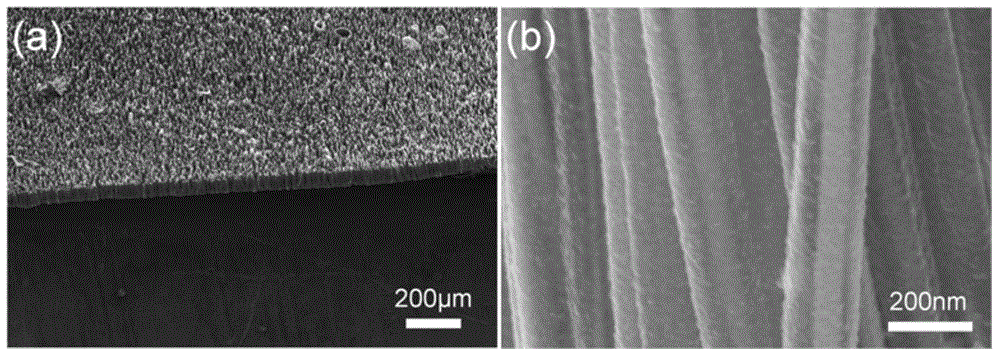

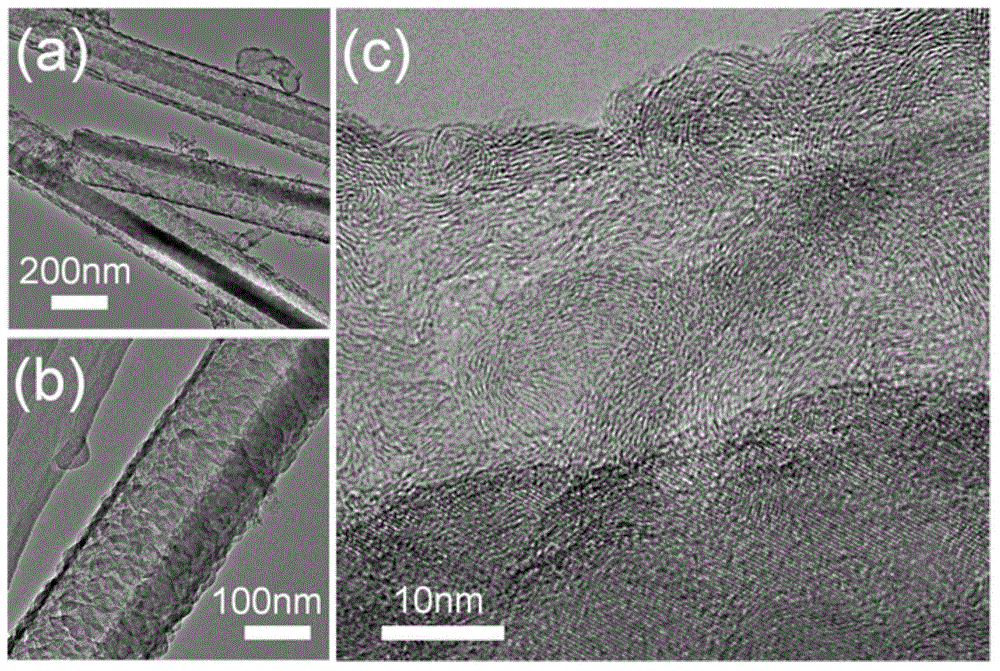

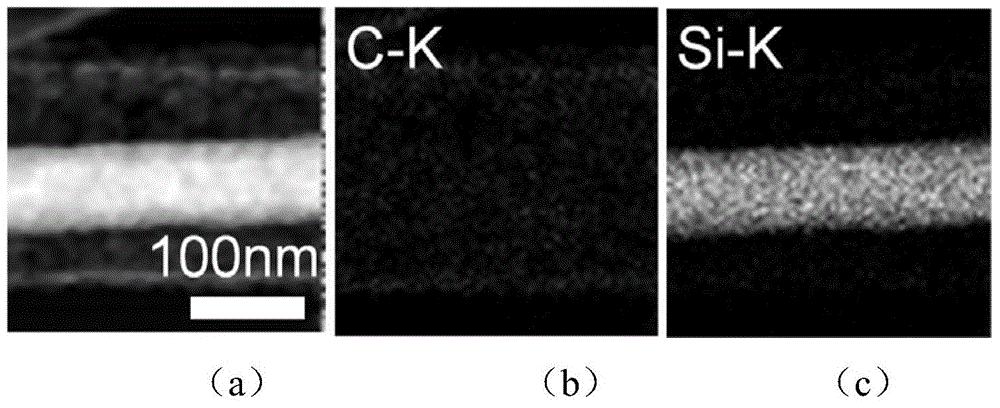

Embodiment 1

[0051] Take a single crystal silicon wafer, use evenly arranged polystyrene balls as a mask, deposit a gold film, put it in a plastic cup, add hydrogen peroxide and hydrofluoric acid aqueous solution, and keep it warm at 20°C for 60 minutes. A layer of silicon nanowire arrays is formed on the surface. After taking out the silicon wafer, rinse it with water, and then use aqua regia to remove the metal gold and then dry it. Then put it into a tube furnace, heat up to 700°C, keep it warm for 30 minutes, and then cool to room temperature. Inject argon-hydrogen mixed gas (2 / 1, v / v) with a total flow rate of 300 sccm. After the temperature is programmed to 1050° C., inject methane gas with a flow rate of 100 sccm. Turn off the methane gas after 5 minutes of constant temperature. After rapid cooling, take out the silicon wafer from the furnace, use hydrofluoric acid to remove silicon dioxide, and then immerse it in 5% sodium hydroxide aqueous solution at 90 ° C. After 60 minutes of r...

Embodiment 2

[0053] Take a single crystal silicon wafer, use uniformly arranged silicon oxide balls as a mask, deposit a gold film, put it in a plastic cup, add aqueous solution of hydrogen peroxide and hydrofluoric acid, keep it warm at 60°C for 30 minutes, the surface of the silicon wafer A layer of silicon nanowire array is formed, the silicon wafer is taken out, rinsed with water, and then dried with aqua regia to remove metal gold. Then put it into a tube furnace, raise the temperature to 500°C, keep it warm for 120 minutes and then cool it down. Inject argon-hydrogen gas mixture (1 / 1, v / v) with a total flow rate of 300 sccm. After the temperature is programmed to rise to 1050° C., methane begins to be introduced at a flow rate of 400 sccm. After constant temperature for 5 seconds, it is rapidly cooled. After cooling down to room temperature, take out the silicon wafer from the furnace, use hydrofluoric acid to remove silicon dioxide, and then immerse it in 5% sodium hydroxide aqueous...

Embodiment 3

[0055] Take a single crystal silicon wafer, use evenly arranged block copolymer (polystyrene-block-polyferrocenyldimethylsilane) balls as a mask, deposit a gold film, and put it in a plastic cup. Add an aqueous solution of hydrogen peroxide and hydrofluoric acid, keep warm at 45°C for 10 minutes, and a layer of silicon nanowire arrays is formed on the surface of the silicon wafer. After taking out the silicon wafer, rinse it with water, use aqua regia to remove the metal gold, and then dry it. Then put it into a tube furnace, raise the temperature to 300°C, keep it warm for 60 minutes and then cool it down. Hydrogen was introduced at a flow rate of 100 sccm. After the temperature was programmed to rise to 700° C., acetylene was introduced at a flow rate of 50 sccm. The temperature was kept constant for 5 minutes and then rapidly cooled. After cooling down to room temperature, take out the silicon wafer from the furnace, use hydrofluoric acid to remove the silicon dioxide, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com