Water-based ink-receptive coating

a technology of ink-receptive coating and water-based ink, which is applied in the field of coatings, can solve the problems of no coating, and achieve the effects of increasing the receptivity of the film, preventing agglomeration, and increasing the receptivity of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

A latex formulation was prepared according to the following Table I for use as ink receptive coating A.

TABLE Icomponent% solidsgrams% by weightDI water0171585.75core / shell latexa34206.510.23n-Methyl Pyrrolidone05.00.25Rhodacal DS-10b103.00.15Baytron Pc171.03.55Surfynol S-420d106.00.30

a= an ethyl acrylate - isobornyl acrylate core with a methyl methacrylate - isobornyl acrylate - ethyl acrylate shell

b= sodium dodecylbenzenesulfonate (Rhodia)

c= 3,4-polyethyendioxythiophene-polystyrenesulfonate (Bayer)

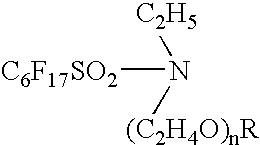

d= a mixture containing ethoxylated acetylenic diols

example ii

A latex formulation was prepared according to the following Table II for use as an ink receptive coating B.

TABLE IIcomponent% solidsgrams% by weightDI water0171585.75core / shell latexa34206.510.23n-Methyl Pyrrolidone05.00.25Rhodacal DS-10b103.00.15polar polymer #1302.40.12Surfynol S-420d106.00.30

a= an ethyl acrylate - isobornyl acrylate core with a methyl methacrylate - isobornyl acrylate - ethyl acrylate shell

b= sodium dodecylbenzenesulfonate (Rhodia)

#1 = poly(styrene-alt-maleic acid) sodium salt (Aldrich)

d= a mixture containing ethoxylated acetylenic diols

example iii

A latex formulation was prepared according to the following Table III for use as an ink receptive coating C.

TABLE IIIcomponent% solidsgrams% by weightDI water0171585.75core / shell latexa34206.510.23n-Methyl Pyrrolidone05.00.25Rhodacal DS-10b103.00.15polar polymer #21000.70.04Surfynol S-420d106.00.30

a= an ethyl acrylate - isobornyl acrylate core with a methyl methacrylate - isobornyl acrylate - ethyl acrylate shell

b= sodium dodecylbenzenesulfonate (Rhodia)

#2 = poly(sodium 4-styrene sulfonate) (Aldrich)

d= a mixture containing ethoxylated acetylenic diols

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com