Variable speed pyrolytic waste treatment system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

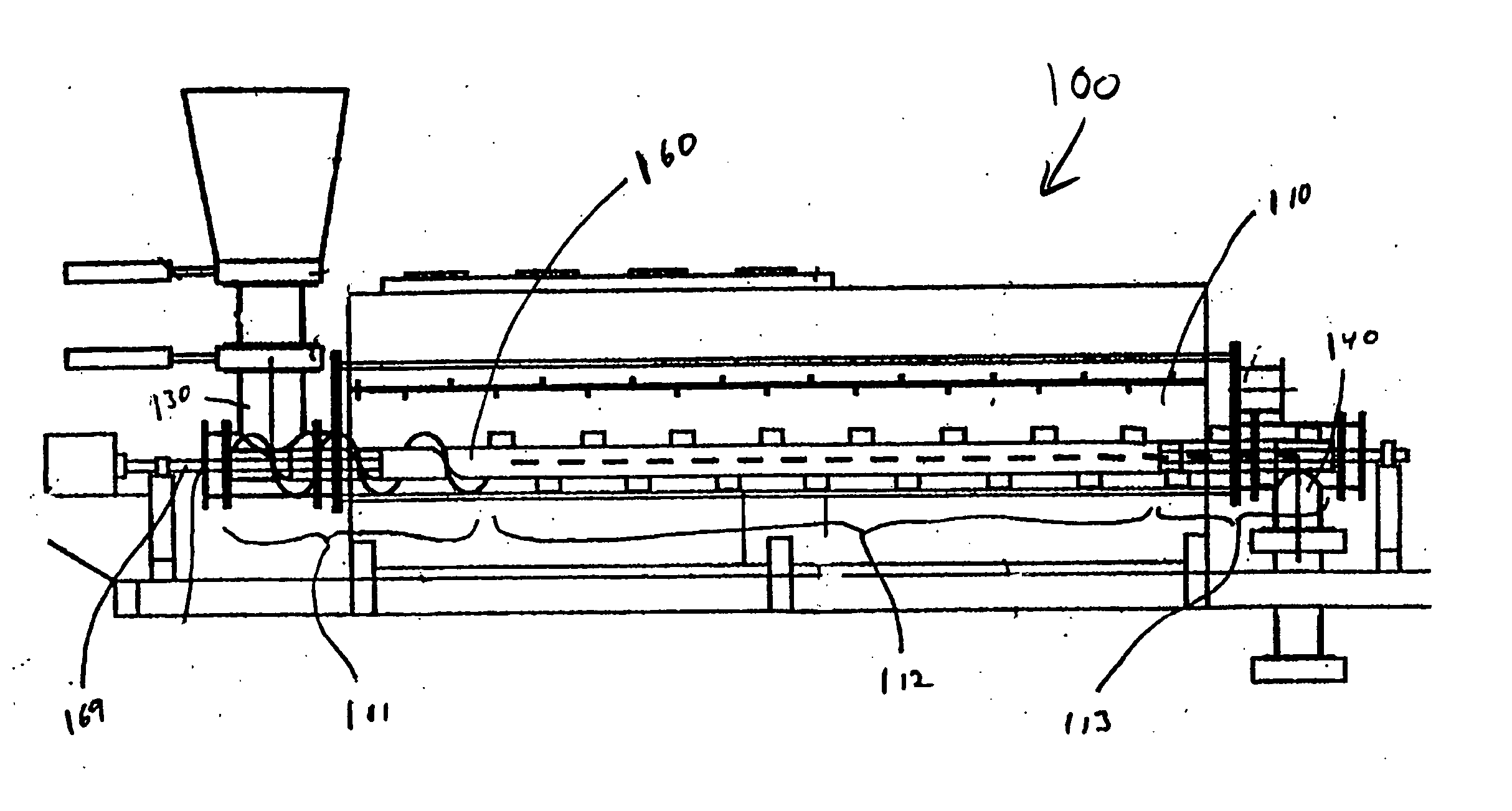

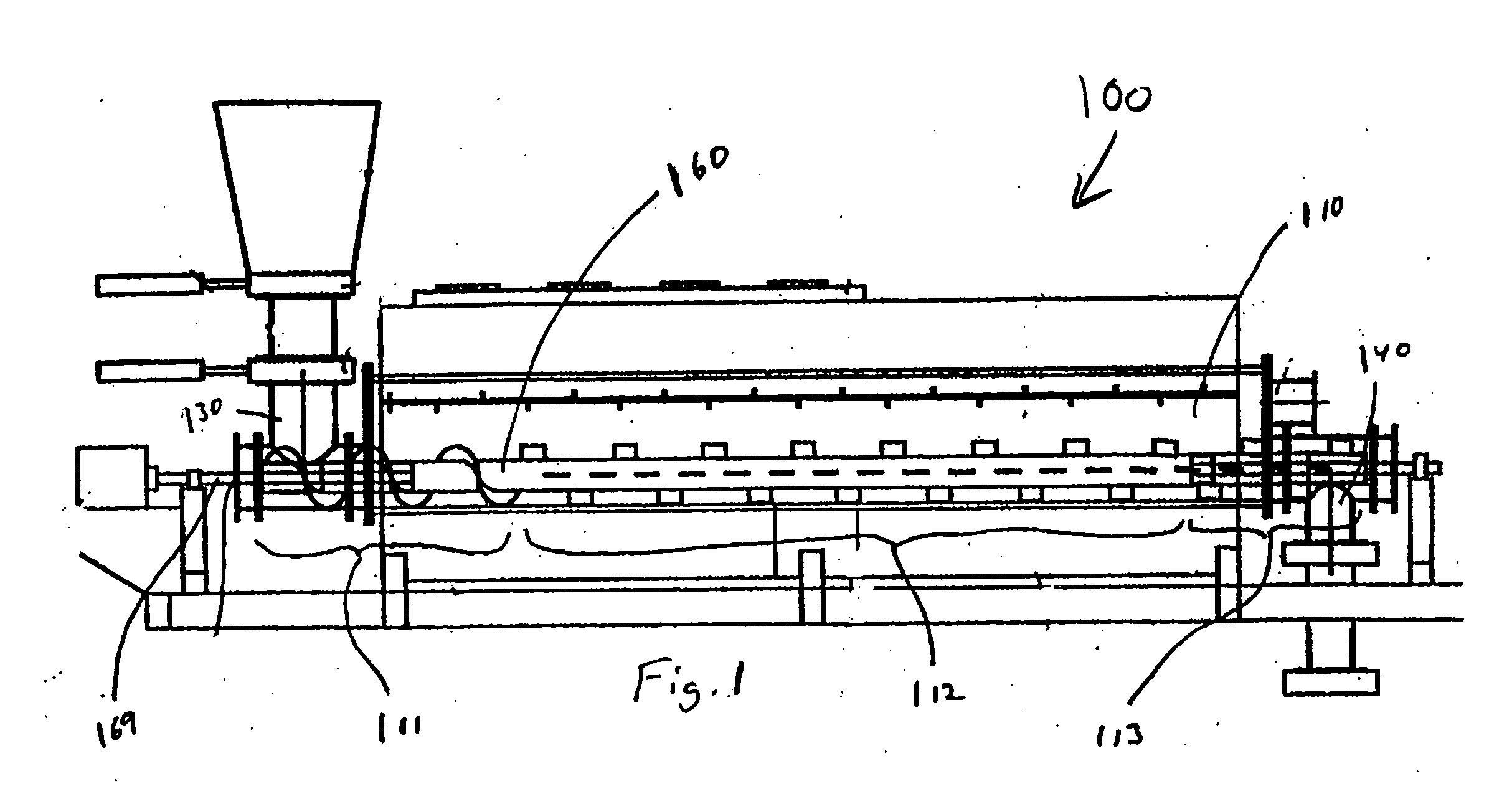

[0010] In FIG. 1, a pyrolytic waste treatment system 100 generally comprises a pyrolytic chamber 910 and a waste movement mechanism 960.

[0011] It is contemplated that it would be beneficial to vary the rate of movement of material through a pyrolysis chamber. In particular, material might move at a slower rate when it first enters the chamber and move at a faster rate after it has been heated and as is moved toward the chamber exit. It is contemplated that the use of paddles or a screw in which the pitch of the paddles or the screw threads varies from one end of the chamber to the other would prove beneficial. It should be recognized that other methods and devices may be used to move material through the chamber including, for example, using gravity, magnetism, and forced air. With regard to using magnetism, it is further contemplated that a product could be statically charged within a magnetic field. Other methods and devices are also contemplated so long as they move the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com