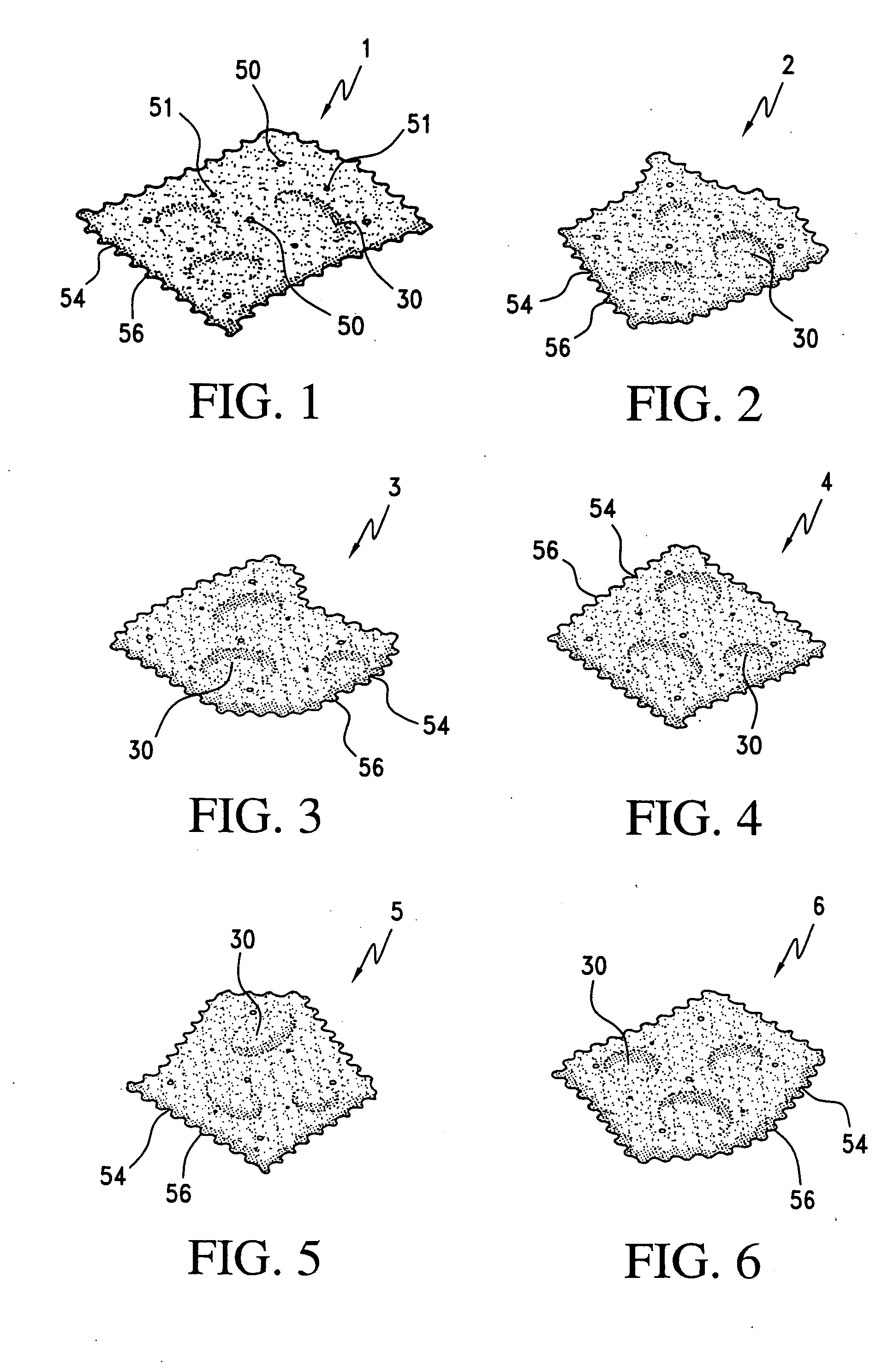

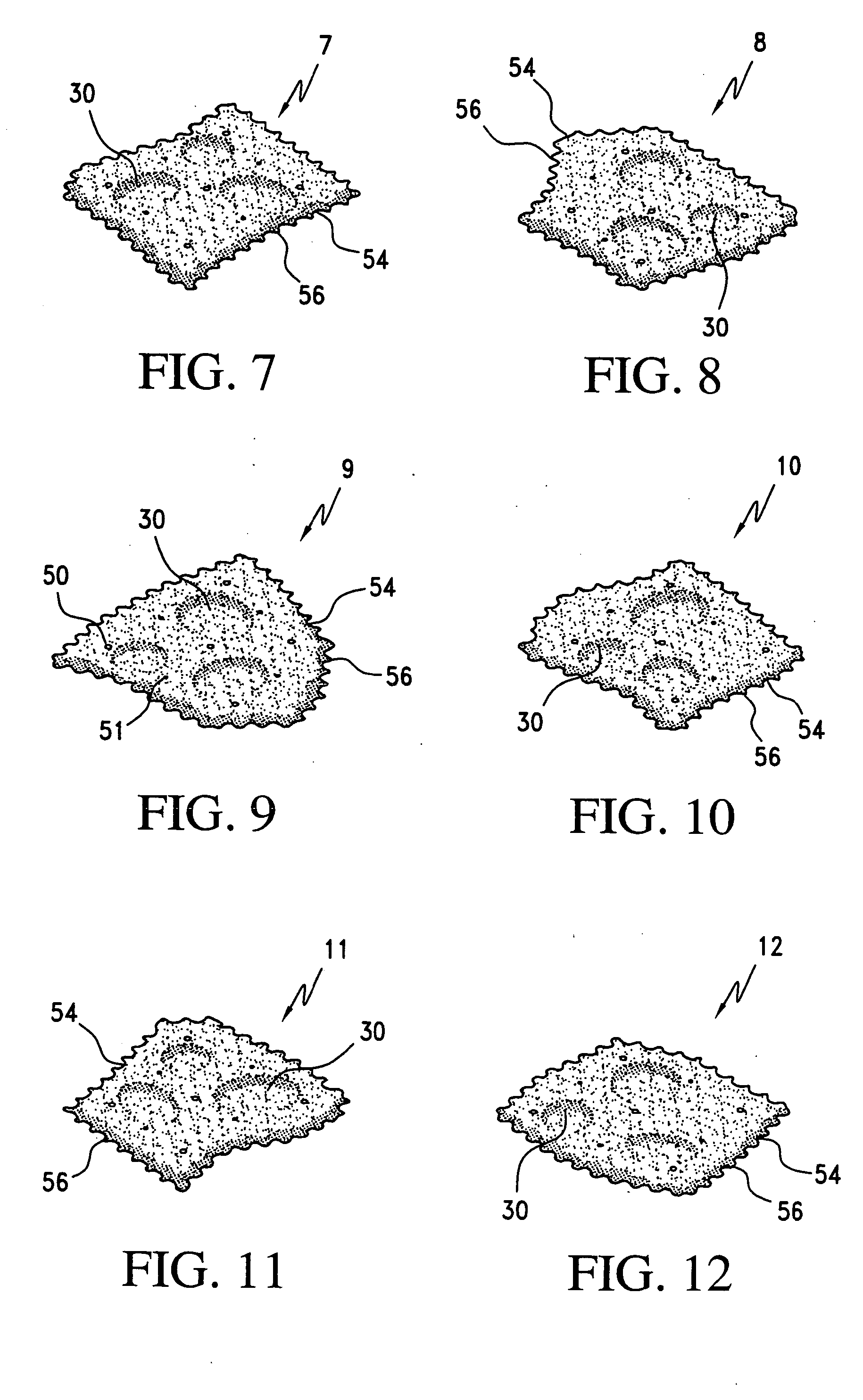

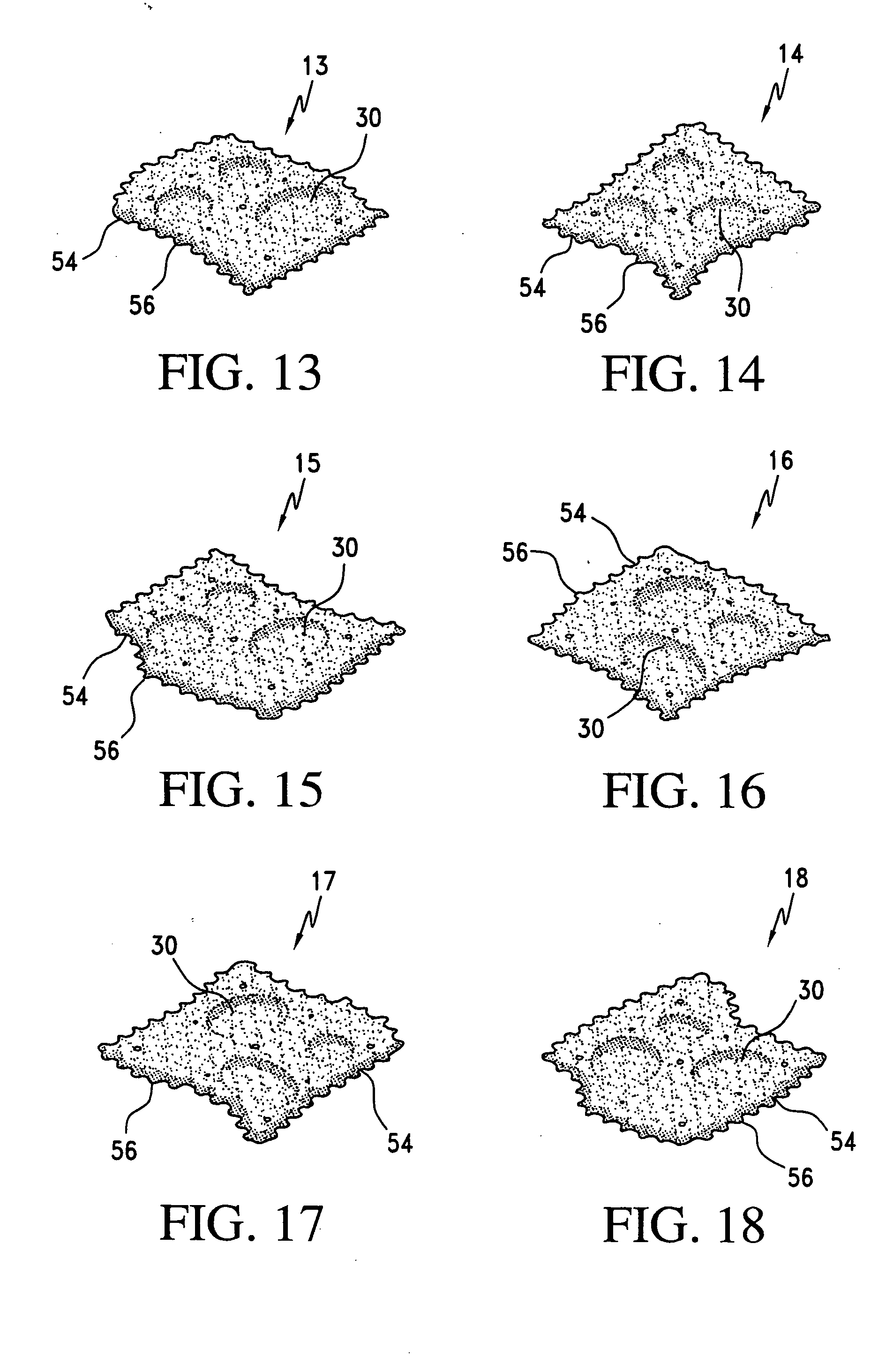

Production of thin, irregular chips with scalloped edges and surface bubbles

a technology of irregular chips and scalloped edges, which is applied in the field of baking snacks, can solve the problems of localized unleavened or thinned areas, and does not prevent the attainment of discrete bubbles, and achieve the effects of promoting surface bubble production, reducing or controlling bubbling, and being sufficiently hydrated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0055] The dough may be formed by first blending the sucrose, pregelatinized waxy maize starch, and pregelatinized potato starch via a mixer at low speed (about 20 rpm) for about 30 seconds. Paselli WA4 is an unmodified, non-crosslinked, pregelatinized potato starch that is cold water swelling. Paselli WA4 has a moisture content of about 8.75% by weight, a sulfated ash content of 0.8% maximum, and a pH in a 5% aqueous solution of about pH 6. The particle size distribution of Paselli WA4 may be less than or equal to 25% on a #45 screen.

[0056] About 75% by weight of the water may be preheated to a temperature of about 145-165° F. and admixed with the blend for about 2 minutes at a mixer speed of about 20 rpm to substantially hydrate the pregelatinized waxy maize starch and pregelatinized potato starch.

[0057] The soybean oil, high fructose corn syrup, and most of the remaining water may be admixed with the blend for about 1 minute at a mixer speed of about 20 rpm. The flour, salt, so...

examples 2-3

[0064] A dough may be made according to the process of Example 1. The baked dough may be topped with topping ingredients as follows:

Example 2WeightWeight %Baked Dough125 lbs. 3.90 oz 88.2 wt. %Soybean Spray Oil 14 lbs. 4.45 oz.10.1 wt. %Flour Salt 2 lbs. 7.08 oz. 1.7 wt. %

[0065]

Example 3WeightWeight %Baked Dough125 lbs. 3.63 oz79.0 wt. %Soybean Spray Oil 23 lbs. 12.44 oz.15.0 wt. %Sour Cream and Onion 9 lbs. 8.17 oz. 6.0 wt. %Seasoning

[0066] The dough of Examples 2 and 3 may be sheeted and fed to water-chilled final gauge rollers having a gap of 0.034 inches to obtain an average dough sheet thickness of 0.0345 inch (0.030 inch minimum and 0.042 inch maximum). The chilled water temperature for the final gauge rollers may be about 40° F. to about 42° F. The temperature of the dough in the lay-time conveyor may be about 97° F. The temperature of the dough after the four-roll sheeter may be about 92° F. The temperature of the dough just before the final gauge rollers may be about 88° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com