Electrically conductive pressure sensitive adhesives, method of manufacture, and use thereof

a technology of pressure sensitive adhesives and adhesives, applied in the direction of non-metal conductors, semiconductor/solid-state device details, conductors, etc., can solve the problems of difficult incorporation of enough fillers to produce desired conductivity, and achieve significant adverse effects on composition properties such as peel strength, tack, and shear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

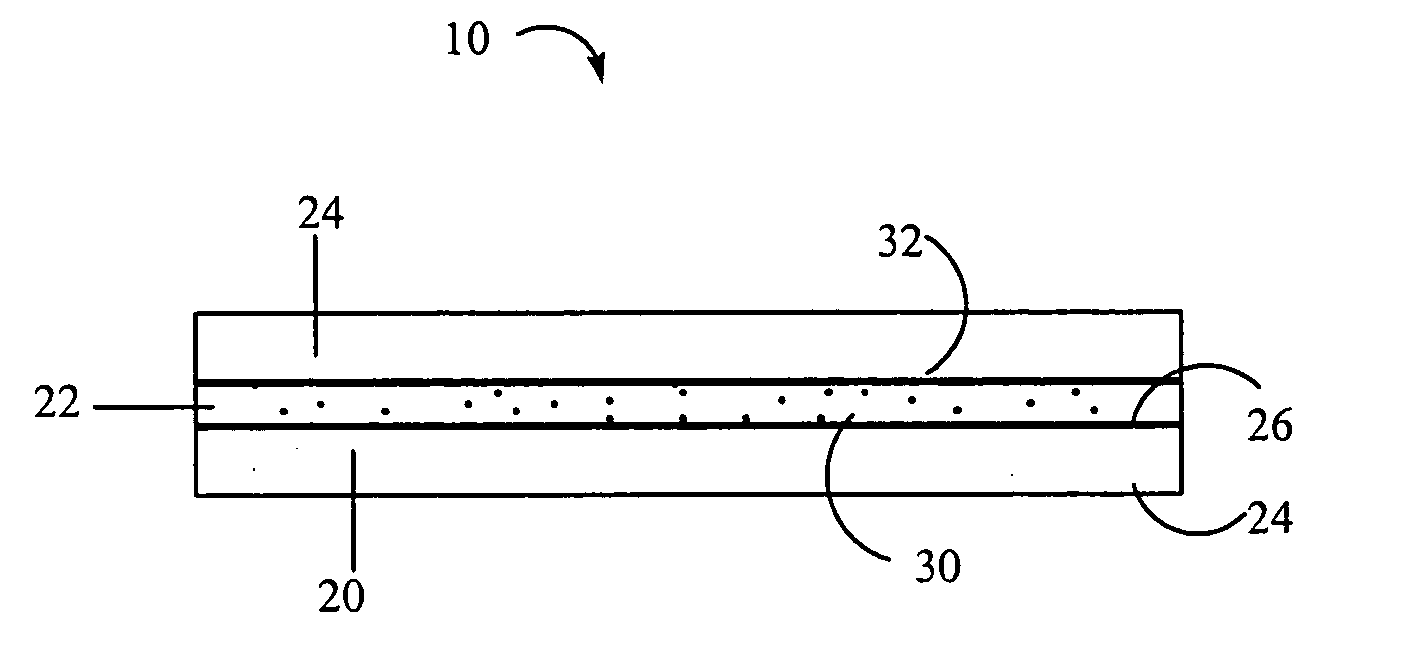

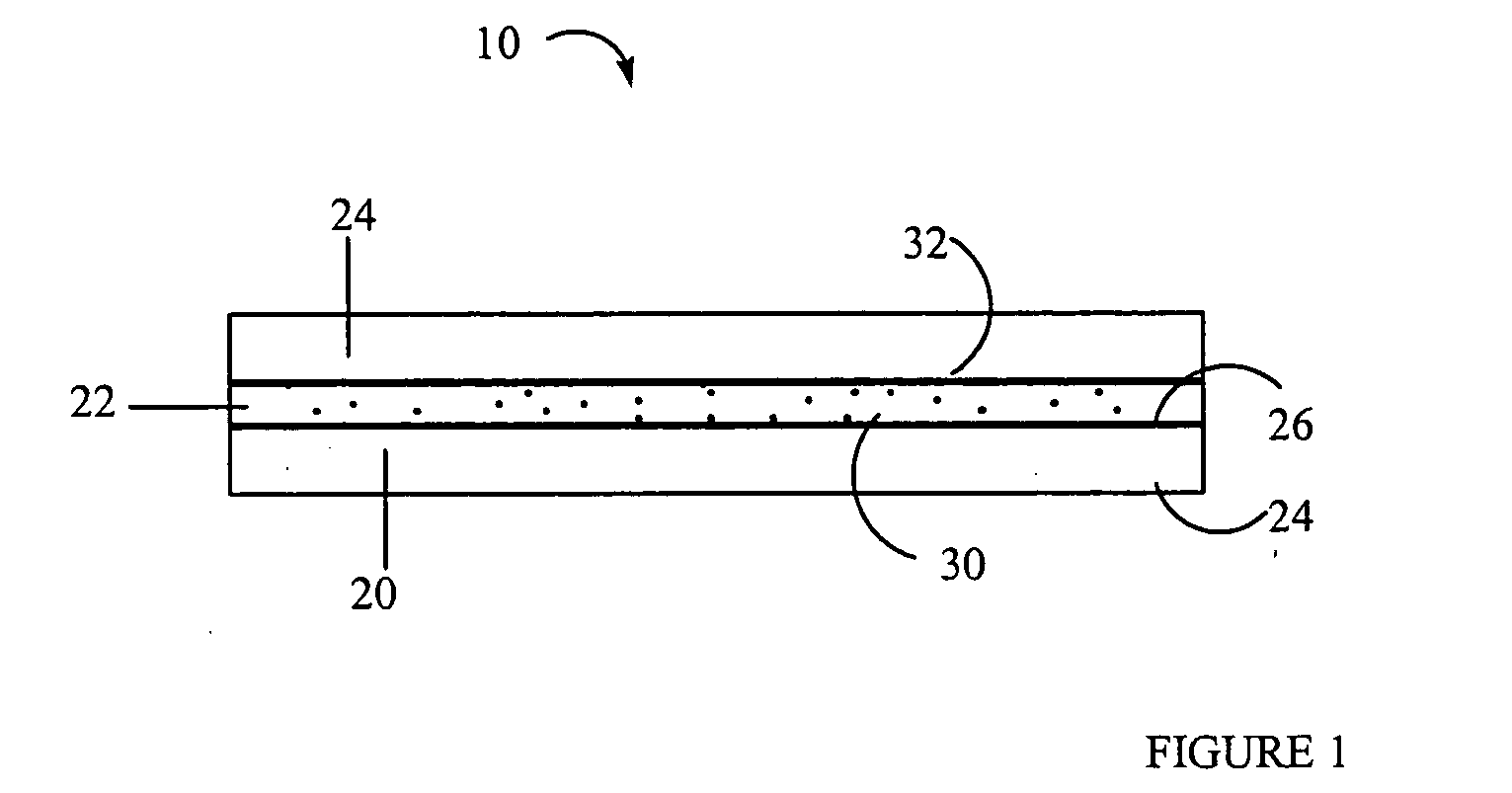

Image

Examples

examples

As is known, particular values for volume resistivity and electrostatic shielding will depend on the particular test methods and conditions. For example, it is known that volume resistivity and shielding effectiveness may vary with the pressure placed on the sample during the test. Useful electrical equipment and test fixtures to measure volume resistivity in the sample below are as follows. The fixture is a custom fabricated press with gold plated, 2.5 cm×2.5 cm (1 inch×1 inch) square, and electrical contacts. The fixture is equipped with a digital force gauge that allows the operator to control and make adjustments to the force that is applied to the surface of the sample. The Power supply is capable of supplying 0 to 2 amps to the sample surface. The Voltage drop and ohms across the sample are measured using a HP 34420A Nano Volt / Micro Ohmmeter. The electronic components of the fixture are allowed to warm up and, in the case of the HP 34420 A, the internal calibration checks are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Sound / signal amplitude | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com