Apparatus for reshaping an optical beam bundle

a bundle and optical beam technology, applied in optics, condensers, instruments, etc., can solve the problems of unconditioned output laser beams that are rarely adapted for particular applications, laser beams that suffer most from lack of brightness, etc., to reduce output beam divergence and/or total cross-sectional area, and increase laser beam brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

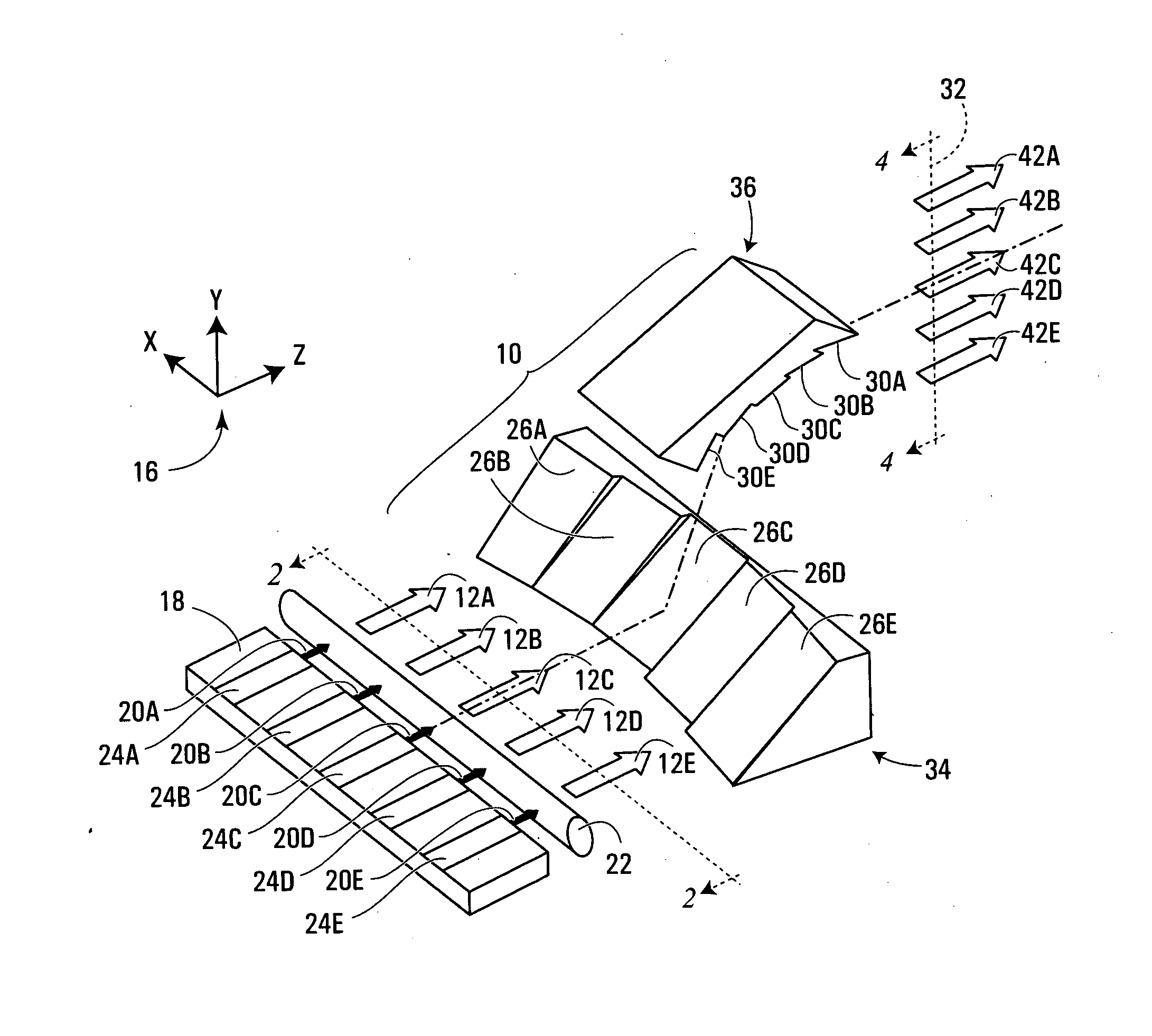

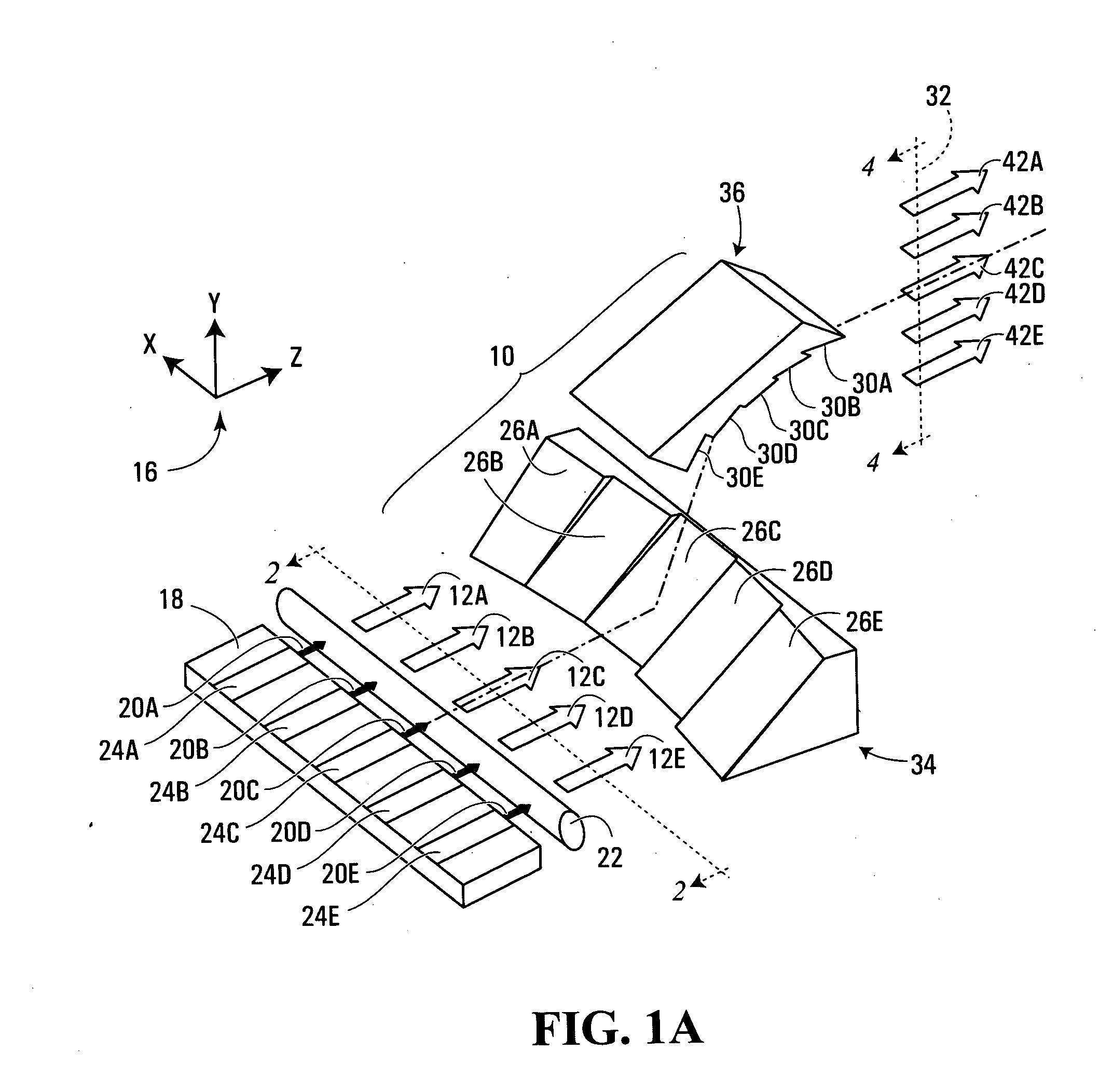

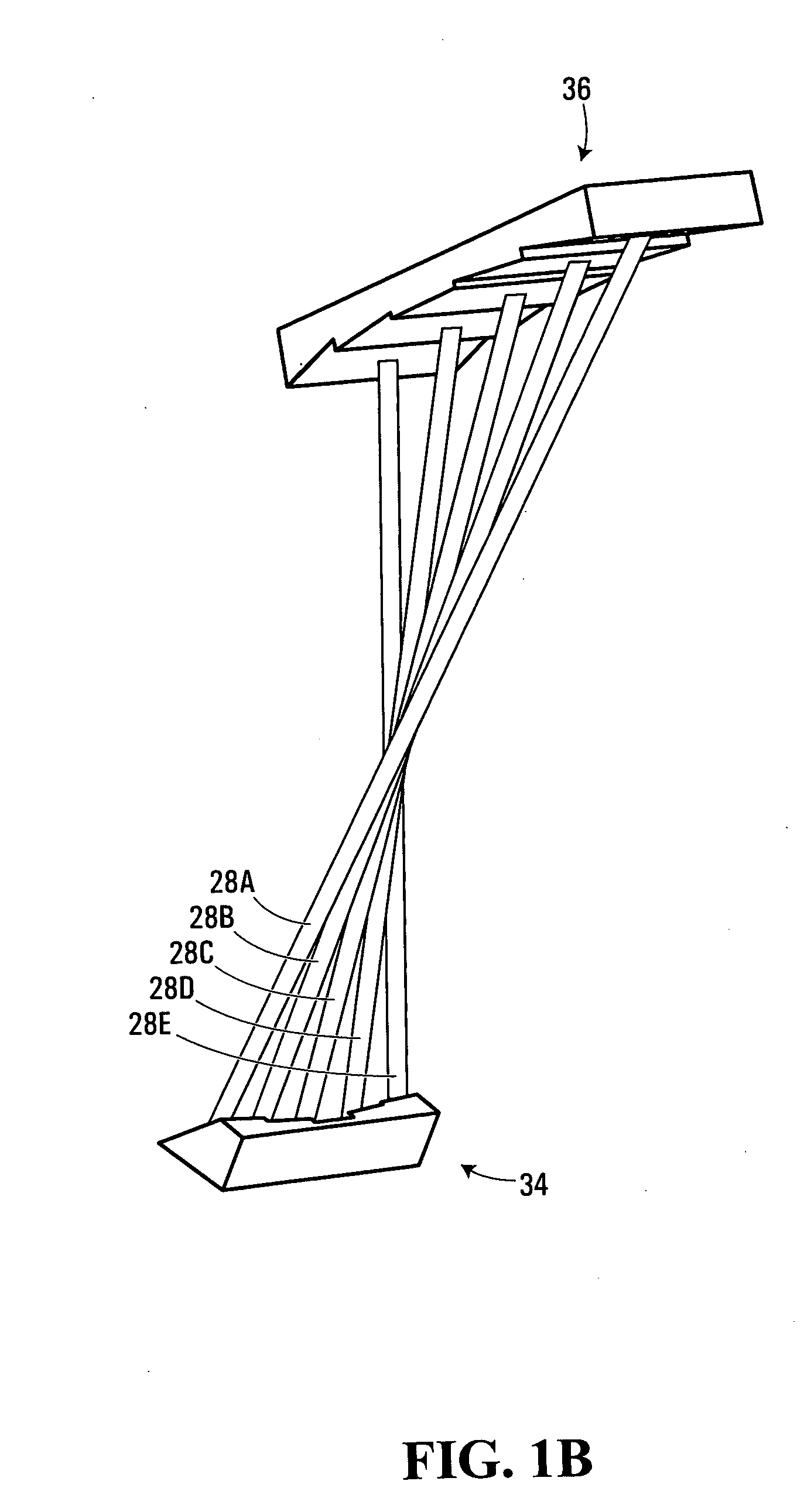

[0029] In FIGS. 1A through 7B, a three-dimensional orthogonal reference system 16 with three directions (axes) x, y and z has been defined for the purposes of convenience. As seen inFIG. 1A, an optical emitter 18 (e.g., a laser diode bar) emits a plurality of beamlets 20a-e travelling generally in the z-direction of the orthogonal reference system 16, within a common x-z plane. In different embodiments, the beamlets 20a-e may all have the same wavelength, or they may each have different wavelengths, or they may each occupy a range of wavelengths.

[0030] Despite travelling generally in the z-direction, the beamlets 20a-e emitted by the emitter 18 are typically divergent in the y-direction and also, although somewhat less strongly, in the x-direction. Accordingly, beam-collimating optics 22 may be provided for reducing the divergence of the plurality of beamlets 20a-e, resulting in the creation of respective input optical beams 12a-e forming part of an input optical beam bundle. Toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com