Ashless stationary gas engine lubricant

a stationary gas engine and lubricant technology, applied in the field of lubricating oil compositions, can solve problems such as inacceptable piston deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

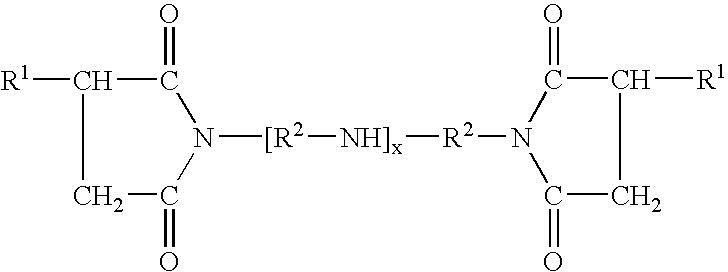

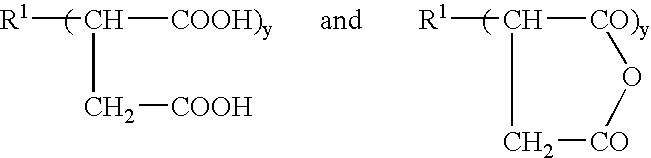

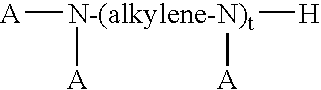

Method used

Image

Examples

example 1

A formulation is prepared in a 650N mineral base oil, comprising the following additive components, amounts expressed in percent by weight: 4.24% high TBN condensed amine succinimide dispersant, containing 40% oil. 1.0% Ca Sulfonate detergent, TBN 13, containing 50% oil. 0.5% Triphenyl phosphite, containing 0% oil 1.0% Hindered phenol-ester antioxidant, commercially available product <0.01% Commercially available silicone defoamer

The formulation contains 0.05 percent by weight phosphorus and 0.5 percent substrate.

example 2 & 3

are commercially available products comprising dispersant(s), antioxidants and anti wear agents.

The above formulation(s) are subjected to the panel coker test, which is a test used to indicate deposit buildup. This is a test that involves splashing test oil at 105° C. for 4 hours onto an aluminum panel maintained at 325° C. Digital imaging of resulting deposits provides a Universal Rating on a scale of 0-100, with higher ratings indicating better performance. Example 1 formulation has a Universal Rating of 68, while Examples 2 and 3 have Universal Ratings of 3 and 9 respectively. It is clear that the invention highlighted in Example 1 illustrates lower deposit build-up, which is particularly desirable.

The formulations are further subjected to an inhibiting oxidation and nitration test. This is a test that involves adding acid and metal napthanate to a fully-formulated oil and mixing at high speed for 60 sec. The mixed samples is heated at 145° C. and purged with NOx for 22 hours....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com