High power light emitting diode device

a light-emitting diode, high-power technology, applied in semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of reduced led efficiency, excessive heat generation of high drive currents, and light output dropping, so as to facilitate heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

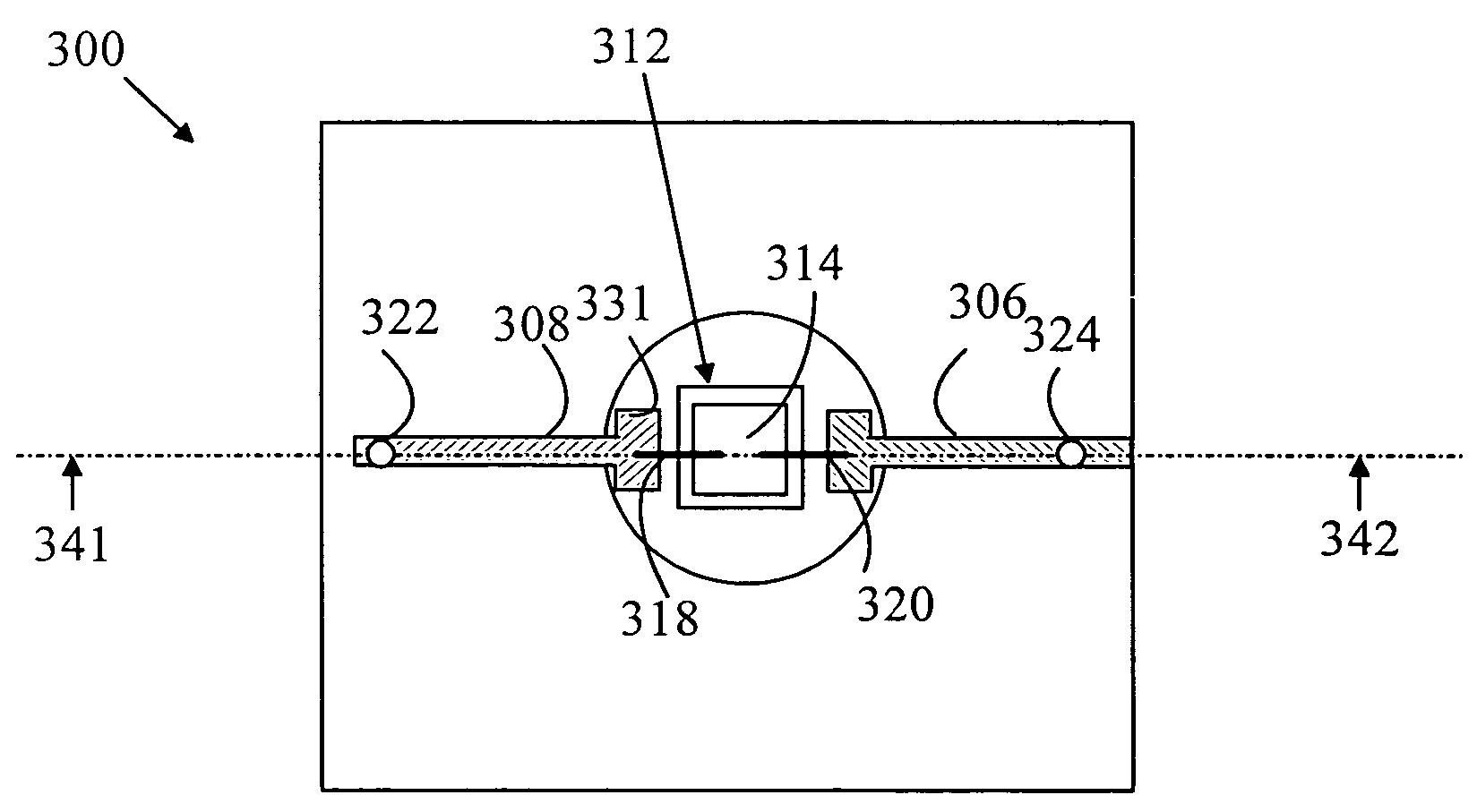

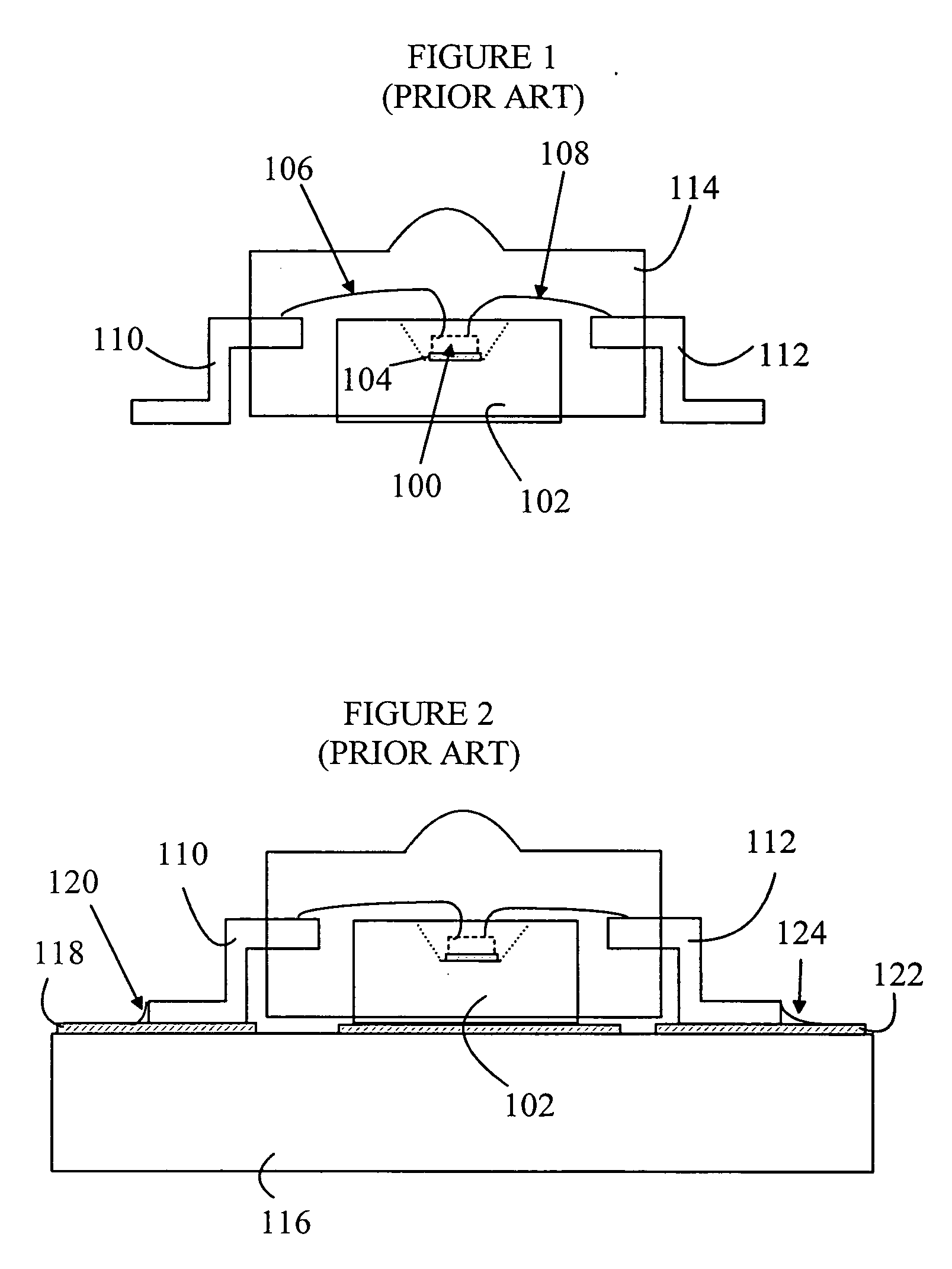

[0018] The manner in which the present invention provides its advantages can be more easily understood with reference to FIGS. 1 and 2, which illustrate the manner in which one class of prior art LED provides heat dissipation. Refer now to FIG. 1, which is cross-sectional view of a packaged LED according to one prior art design. An LED 100 is mounted in a cavity of a substrate 102 using a conductive medium 104. A first bond wire 106 electrically connects one terminal of the LED 100 to one electrical contact 110 while a second bond wire 108 electrically connects a second terminal of LED 100 to another electrical contact 112. An encapsulating body 114 substantially encases the LED, the bond wires, the substrate and the contacts to provide protection for the LED.

[0019] Refer now to FIG. 2, which is a cross-sectional view of the packed LED shown in FIG. 1 attached to a typical printed circuit board (PCB) 116. The base of substrate 102 is mounted on a PCB 116 so that it is in direct con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com