Miniature fan or micro-fan

a fan or micro-fan technology, applied in the direction of mechanical equipment, electrical equipment, dynamo-electric machines, etc., can solve the problems of large motor in relation to the overall, disadvantageous in terms of flow rate (v/t), pressure increase p of the fan, etc., and achieve the effect of increasing the number of functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

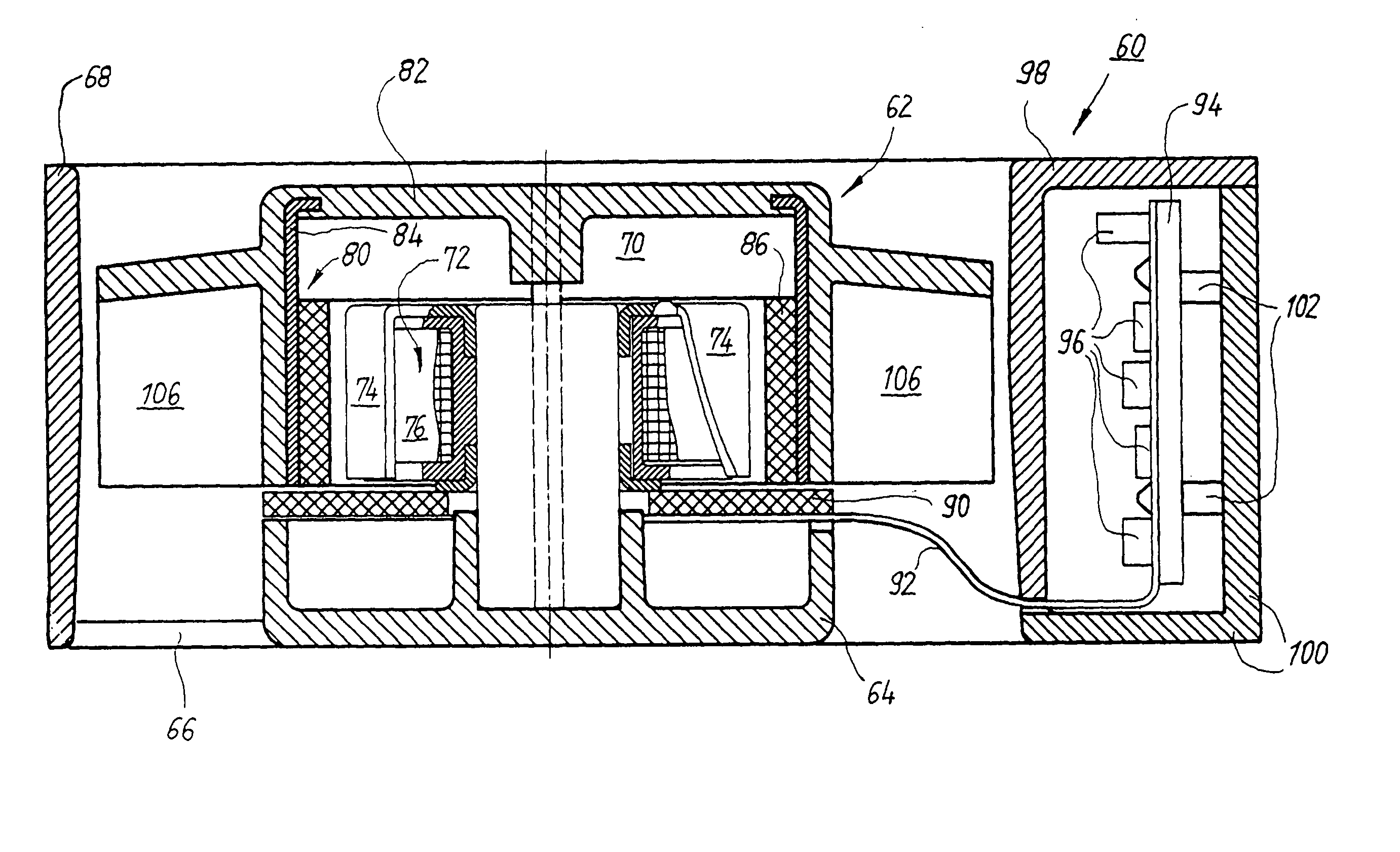

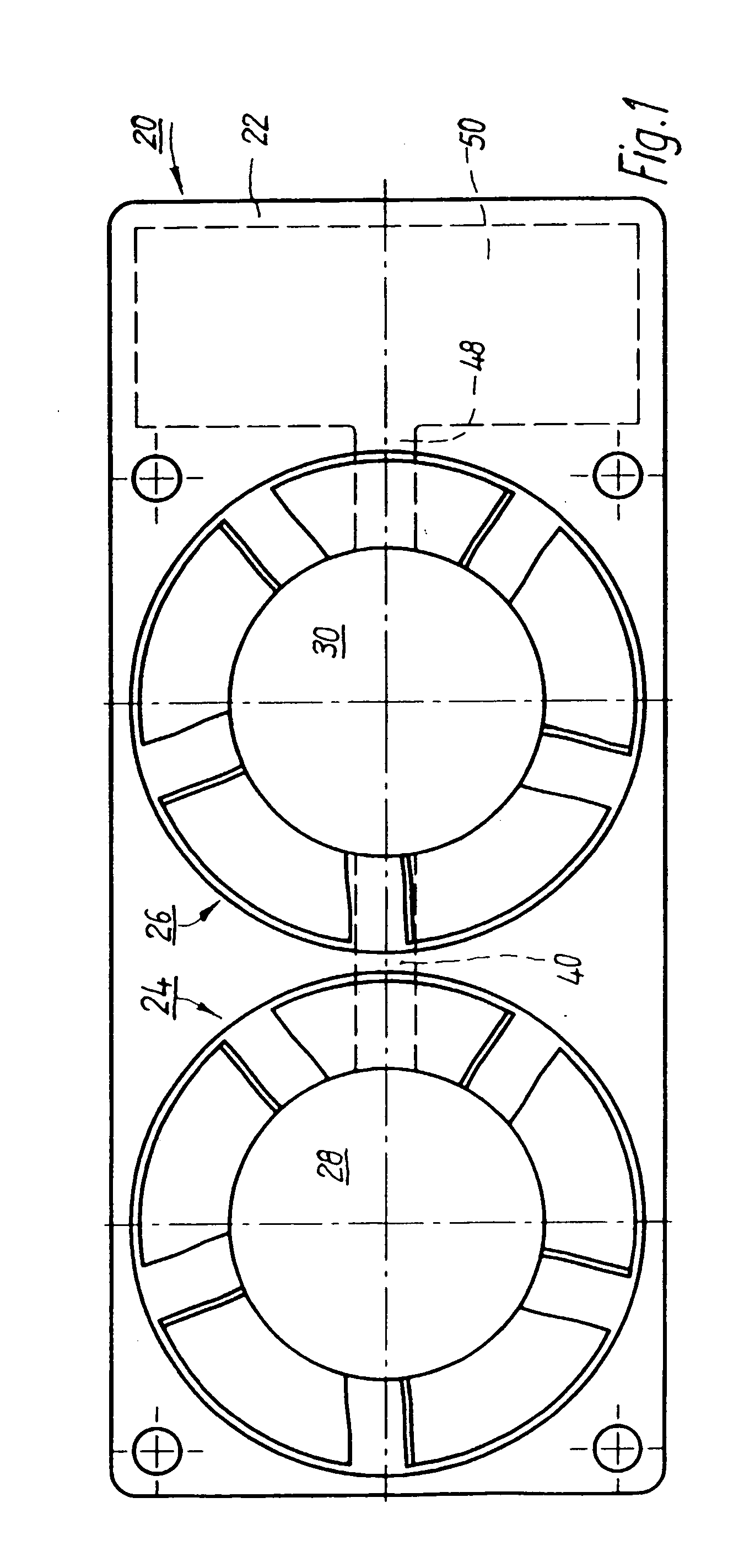

[0024]FIG. 1 shows, at greatly enlarged scale, a double fan 20 comprising a housing 22 in which two miniature fans or micro-fans 24, 26, each driven by an electronically commutated external-rotor motor 28, 30, are arranged next to one another. These motors 28, 30 are rigidly connected to housing 22 by way of struts (not depicted).

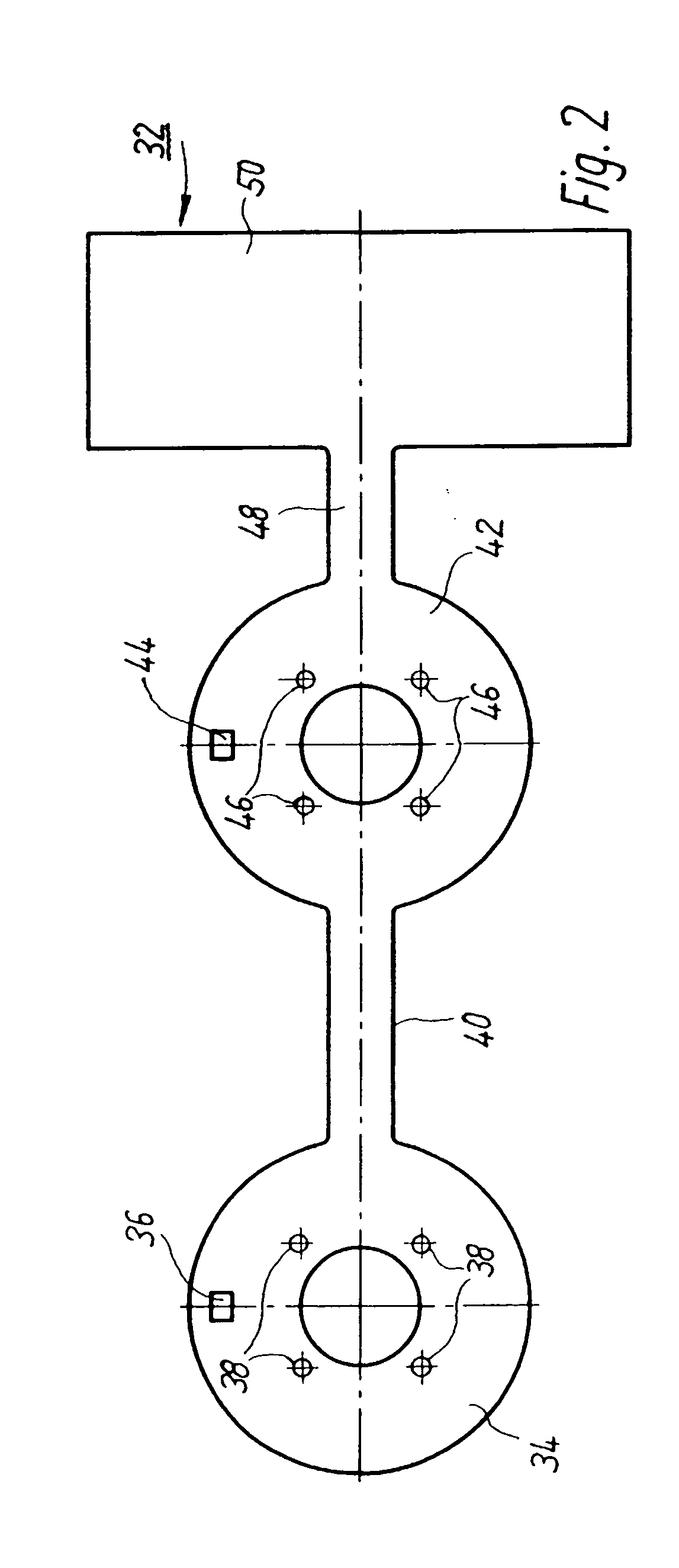

[0025] According to the invention and as shown in FIG. 2, a circuit board 32 that has, for motor 28, a first approximately annular part 34, on which a Hall IC 36 and four attachment points 38 for the winding ends of motor 28 are provided, is used in the double fan of FIG. 1. Part 34 is connected, via a first bridge 40 comprising printed conductors (not depicted), to a second approximately annular part 42 on which are located a Hall IC 44 and four attachment points 46 for the winding ends (not depicted) of motor 30.

[0026] Part 42 is connected, via a second bridge 48 comprising printed conductors (not depicted), to an (in this case, rectangular) part 50 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com