Methods For Controlling The Fluid Loss Properties Of Viscoelastic Surfactants Based Fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

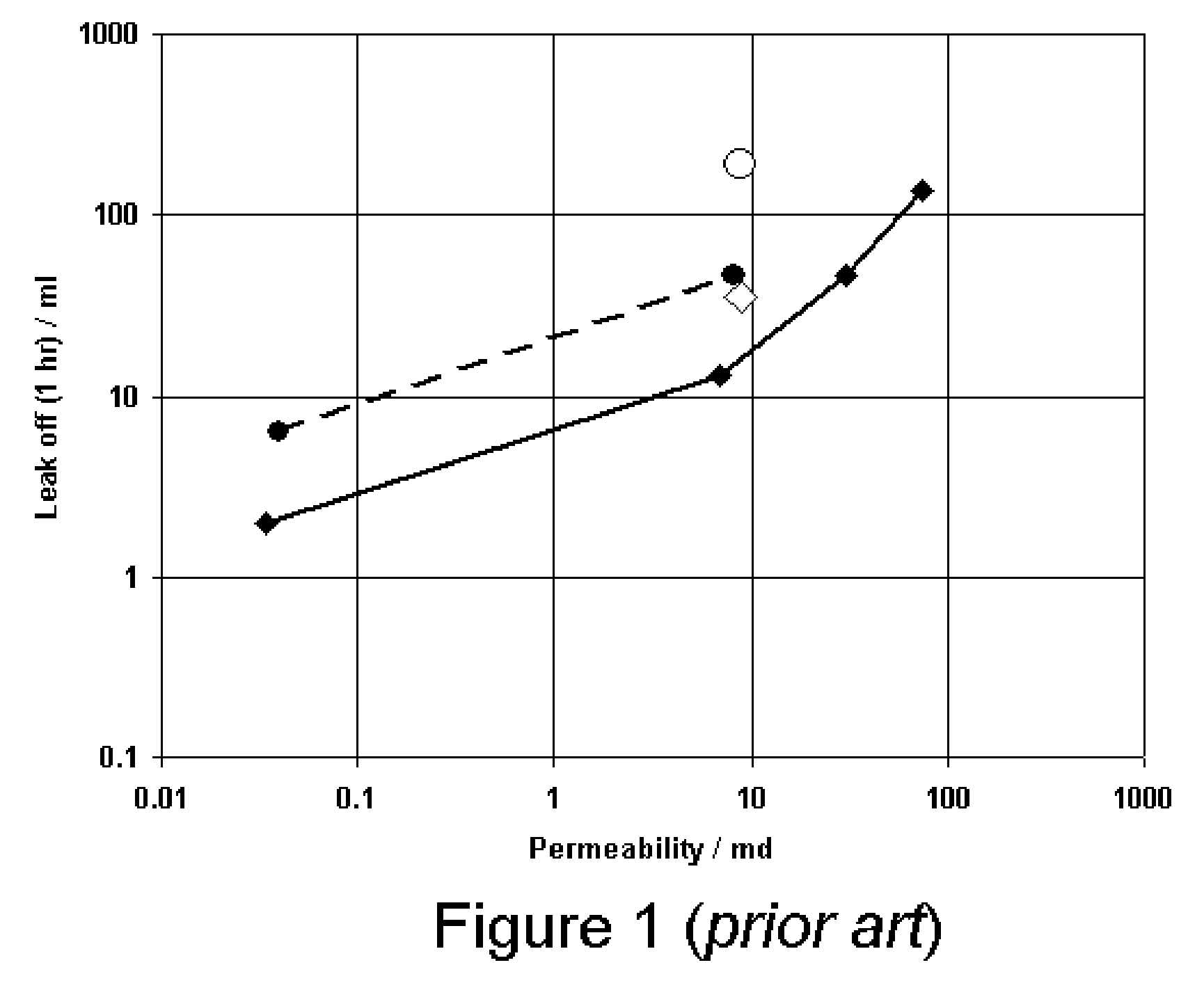

[0045]FIG. 1 presents the result of a comparison of the total fluid loss at 60 minutes (in ml) over a range of permeabilities. The lower curve (full lozenges) was obtained with brine saturated cores and an aqueous solution at 3 wt % potassium chloride and 3 wt % N-erucyl-N,N-bis(2-hydroxyethyl)-N-methyl ammonium chloride. The open lozenge corresponds to a test made with the 3 wt % fluid on an oil saturated core. A strong increase in leak-off is observed where the core permeability is grater than 5 mD.

[0046] When lower concentrations of surfactant are used (1 wt %, open and full circles), leak-off greater than 20 ml are observed for formation permeabilities of about 2 mD. At about 10 md permeability, a leak-off of more than 100 ml per hour is achieved with the 1 wt % surfactant solution.

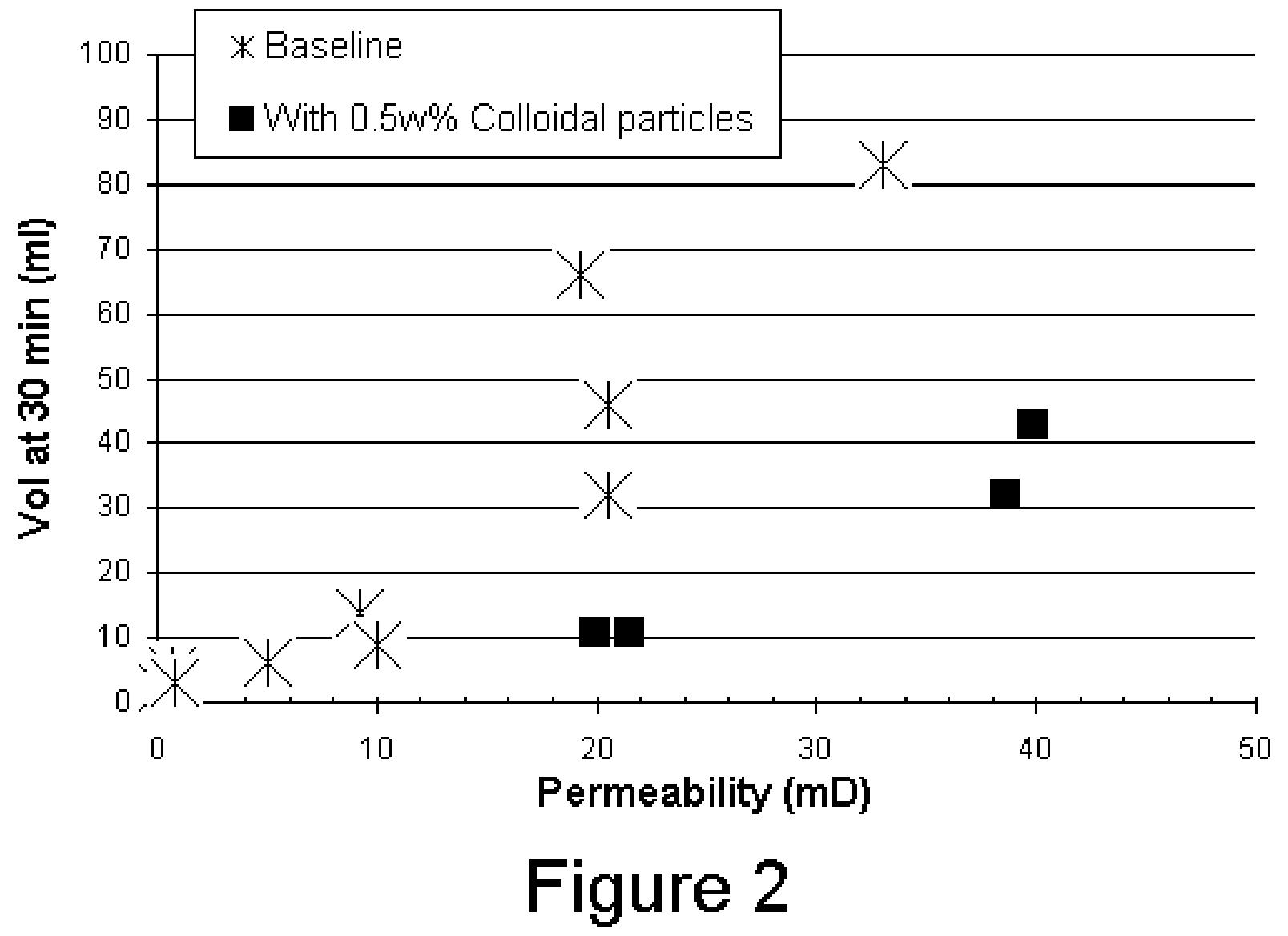

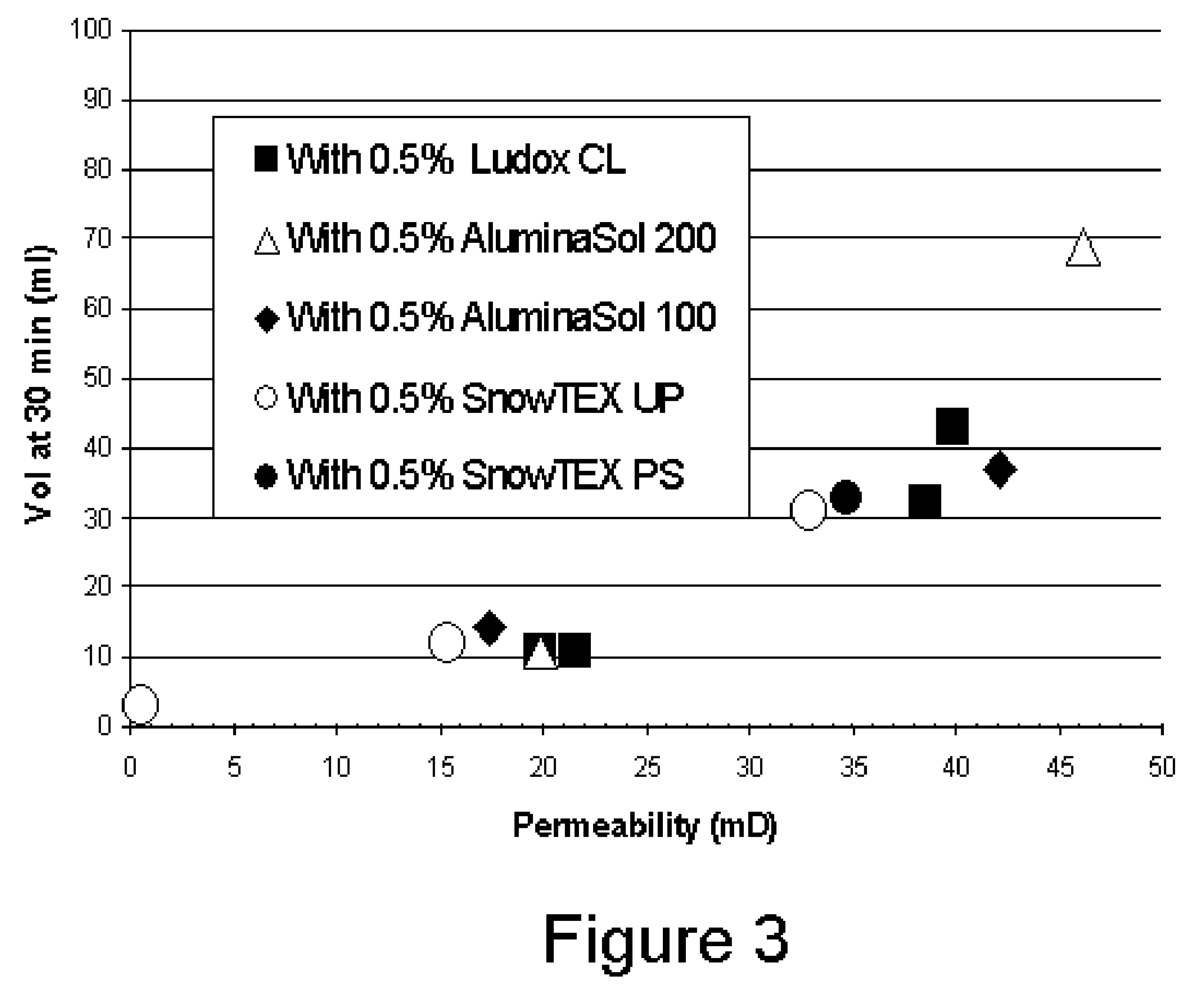

[0047] Similar results are obtained with an aqueous solution containing a betaine surfactant that contains an erucic acid amide group (including a C21H41 alkene tail group) as shown FIG. 2 where the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com