Composition of cationic asphalt emulsifier, preparation method and application thereof

An asphalt emulsifier and cation technology, applied in chemical instruments and methods, chemical/physical processes, building components, etc., can solve the problems of coarse emulsion particles, insignificant improvement of asphalt high-temperature performance, poor storage stability, etc., and achieve good temperature resistance Change ability and anti-fatigue ability, improve the strength of the seal layer and its anti-deformation ability, excellent effect of low temperature cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Preparation of cationic emulsifier: combine 35 g of octadecylamine, 10 g of stearyl-1,3-propylene diamine and 10 g of C 17 H 35 -CO-NH-C 2 H 4 -NH 2 , and 10 g of octadecylamine polyoxyethylene ether (AC1802) were put into 35 g of isopropanol in sequence, and stirred at 80° C. for 1 h to make them evenly mixed to obtain a cationic emulsifier.

[0016] Preparation of modified asphalt: heat Liaohe 90# base asphalt to 160℃, add 3.5% SBS, keep stirring for 60min, then grind with colloid mill for 30-90min to make SBS modified asphalt. The SBS modified asphalt was kept at 165-170°C for later use.

[0017] Preparation of soap solution: Weigh 5g of the cationic emulsifier, add 492g of hot water, and add 3g of hydrochloric acid with a concentration of 36%. At this time, the pH value of the solution is 2.0, which is soap solution. Keep the soap temperature at 55-60°C.

[0018] Turn on the colloid mill, add 500 g of SBS modified asphalt with a temperature of 165°C and the ab...

Embodiment 2

[0020] Preparation of cationic emulsifier: 15g octadecylamine, 25g tallow-1,3-propylenediamine and 20gC 17 H 35 -CO-NH-(C 2 H 4 NH) 4 H, and 15 g of octadecylamine polyoxyethylene ether (AC1810) were put into 25 g of isopropanol in sequence, and stirred at 90° C. for 1 h to obtain a cationic emulsifier.

[0021] Preparation of soap solution: Weigh 6g of the cationic emulsifier, add 341g of hot water, and add 3g of hydrochloric acid with a concentration of 36%. At this time, the pH value of the solution is 2.0, which is soap solution. Keep the soap temperature at 55-60°C.

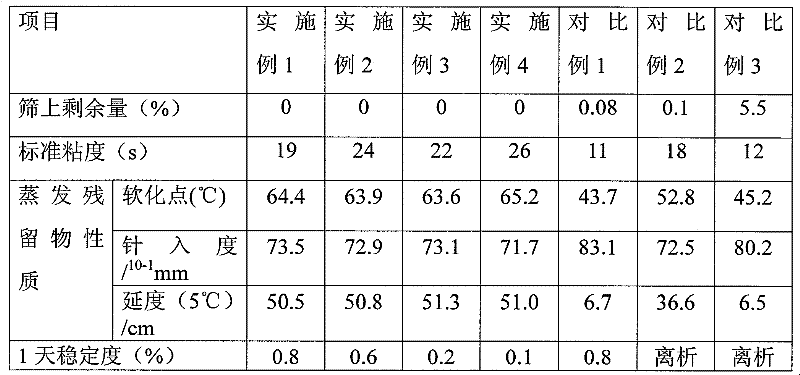

[0022] Turn on the colloid mill, add 650 g of SBS modified asphalt with a temperature of 165°C prepared in Example 1 and the above soap liquid into the colloid mill at the same time for shearing to obtain emulsified SBS modified asphalt. This emulsified asphalt is a high-viscosity and high-concentration emulsified modified asphalt, which is suitable for ultra-thin wear layers of expressways. Its perfor...

Embodiment 3

[0024] Preparation of cationic emulsifier: 15g hydrogenated tallow primary amine, 10g oleyl-1,3-propylene diamine and 30g C 17 H 33 -CO-NH-(C 2 H 4 -NH) 4 H, and 10 g of octadecylamine polyoxyethylene ether (AC1820) were put into 35 g of isopropanol in sequence, and stirred at 80° C. for 1 h to obtain a cationic emulsifier.

[0025] Preparation of soap solution: Weigh 8g of the cationic emulsifier, add it to 358g of hot water, and add 4g of hydrochloric acid with a concentration of 36%. At this time, the pH value of the solution is 2.0, which is soap solution. Keep the soap temperature at 55-60°C.

[0026] The colloid mill was turned on, and 630 g of SBS modified asphalt with a temperature of 165° C. prepared in Example 1 and the above soap solution were simultaneously added to the colloid mill for shearing to obtain emulsified SBS modified asphalt. This emulsified asphalt is a high-viscosity emulsified modified asphalt, suitable for use as a modified sticky oil for highw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com