Wrapping member for a glass substrate for FPD and a method of transferring a glass substrate for FPD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

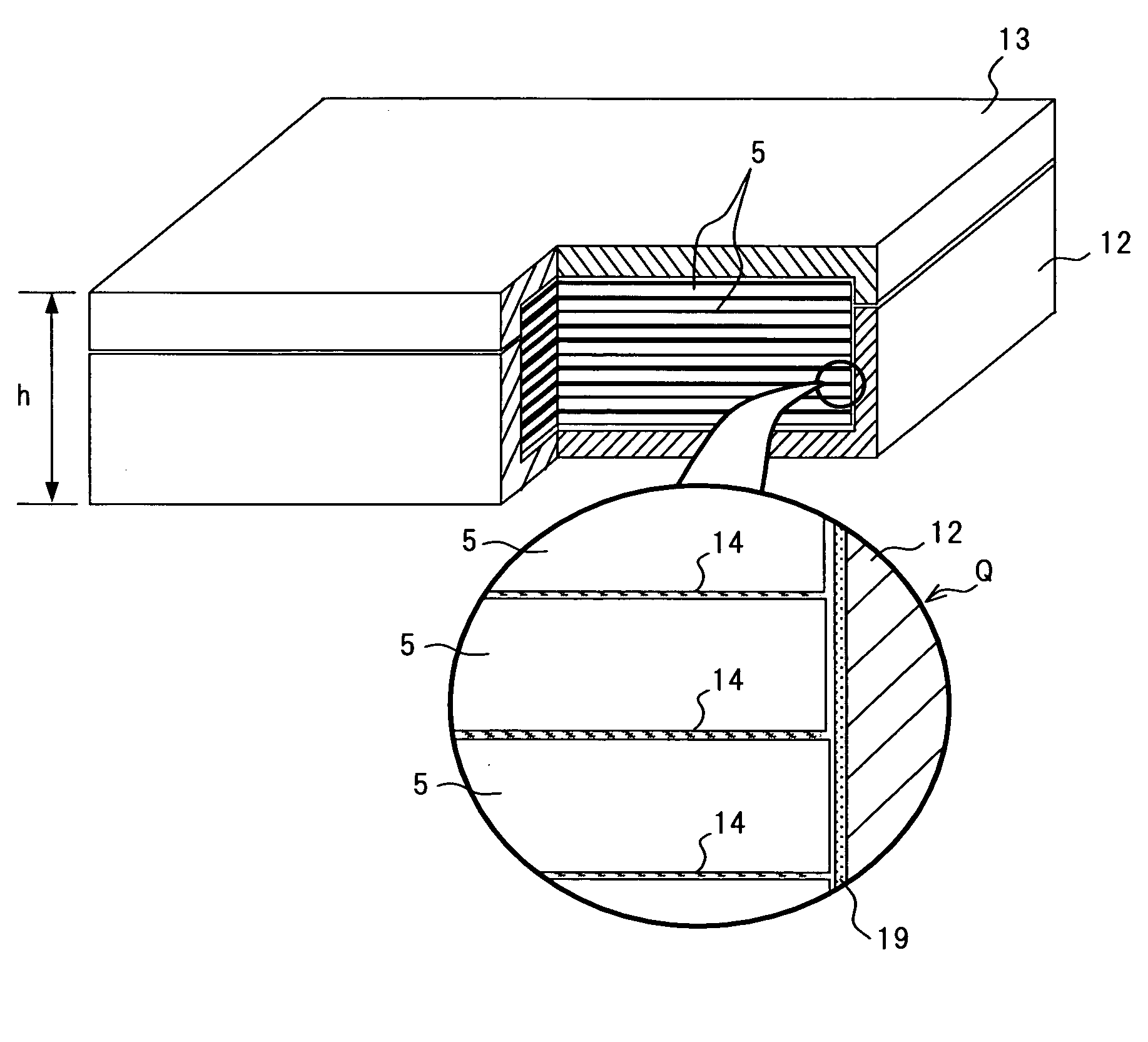

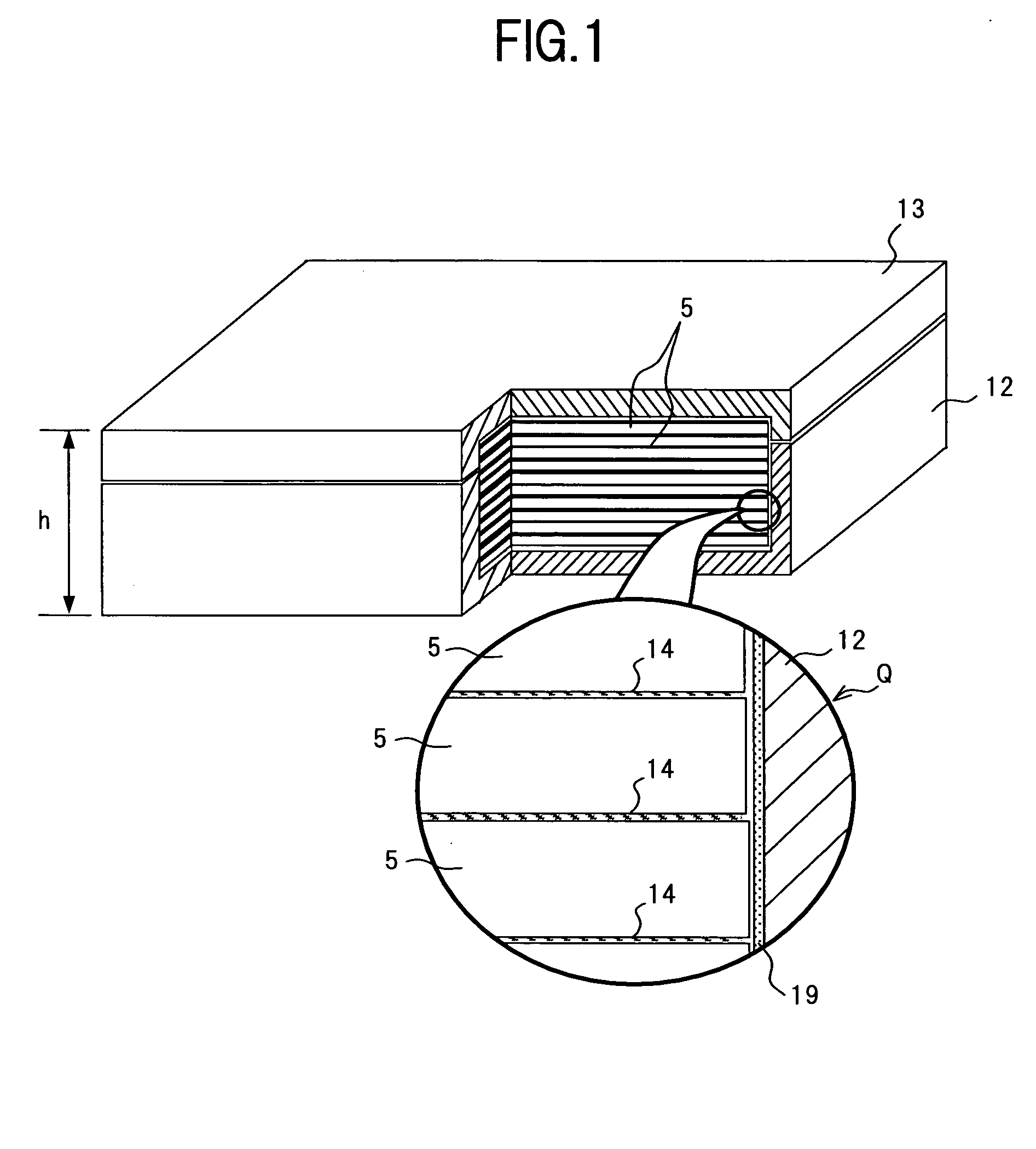

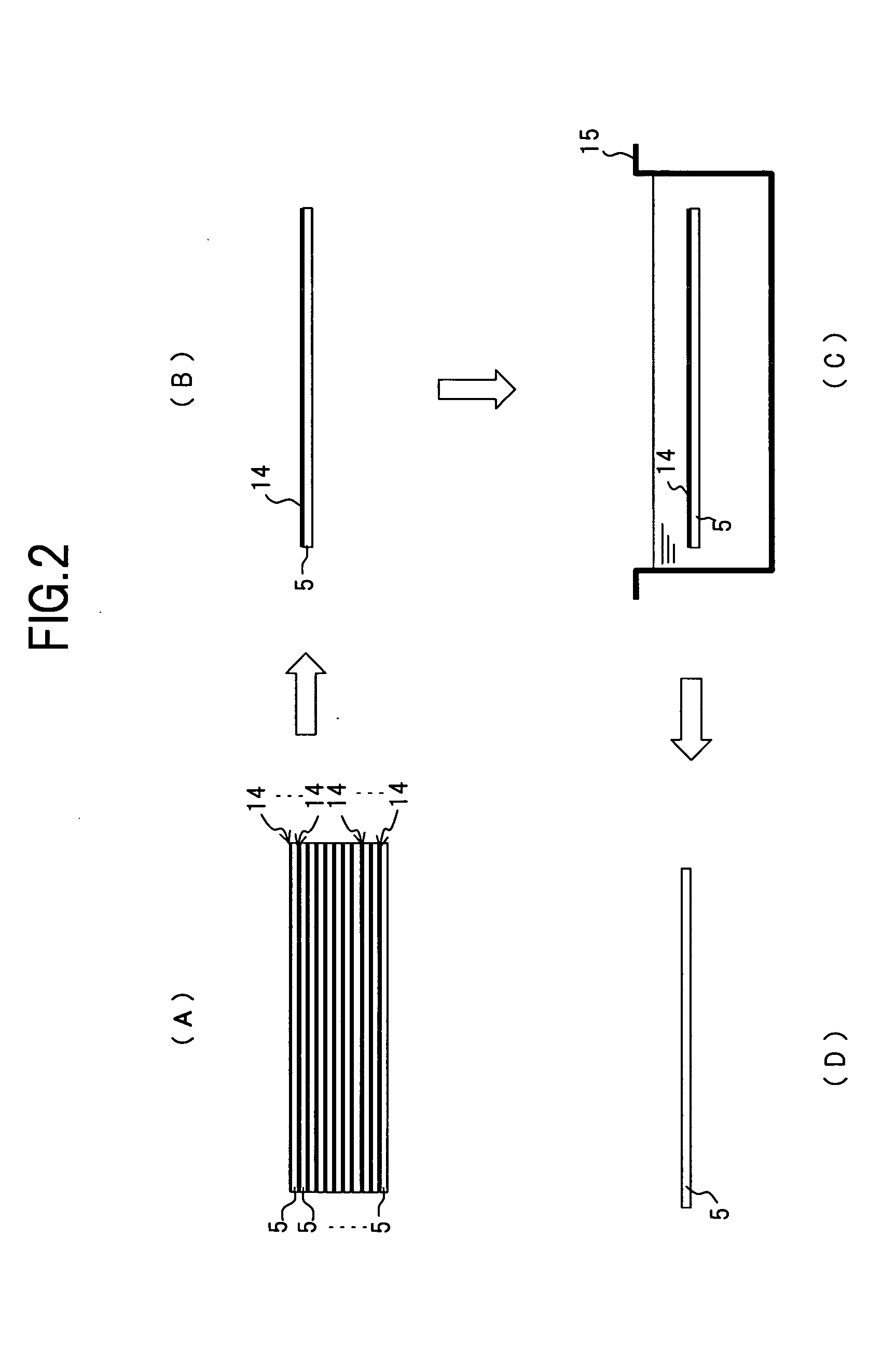

[0028] Referring to FIG. 1, which illustrates a transfer box 12 with a lid 13 covering an open end of the box 12, a plurality of glass substrates 5 for FPDs are stored and packed in the transfer box 12 covered by the lid 13, by the employment of a wrapping member according to the present invention. The wrapping members 14 are respectively provided as a thin film for protecting the surfaces of each the glass substrates 5 for FPD, and as shown in a partially enlarged view “Q” of FIG. 1, one wrapping member 14 is interposed between the respective upper and lower glass substrates 5 superposed one another. Owing to this interposition of the wrapping members 14, without using of the transfer box 1 of the prior art as shown in FIG. 6, a plurality of glass substrates 5 for FPD may be stored in the interior of the transfer box 12 and the lid 13 as shown in FIG. 1, and can be transferred. Since the transfer box 12 and the lid 13 may have a capacity thereof sufficient for storing a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com