Ultraviolet acoustooptic device and optical imaging device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0058] In order to examine laser damage and optical damage caused by ultraviolet light, various kinds of single crystal materials were evaluated with respect to their light resistance using a laser having a light source of third harmonics of a YAG laser. The result is shown in Table 1. The crystal materials evaluated herein were a TeO2 crystal that had been used conventionally, and LN, MgO:LN, Li2B4O7, (GdY)1Ca4O(BO3)3, and CsLiB6O10 that were used for the acoustooptic device of the present invention.

TABLE 1Absolute ValuePresence orof Laser DamageRelative ValueAbsence ofThresholdof Laser DamageOpticalMaterial(kW / mm2)ThresholdDamageTeO2291AbsentLN873PresentMgO:LN57-872-3AbsentLi2B4O7At least 120At least 4Absent(GdY)1Ga4O(BO3)3At least 120At least 4AbsentCsLiB6O10At least 120At least 4Absent

[0059] From the result, it is understood that among these materials, the TeO2 crystal has the lowest relative value of the laser damage threshold and therefore is the most susceptible to the lase...

example 2

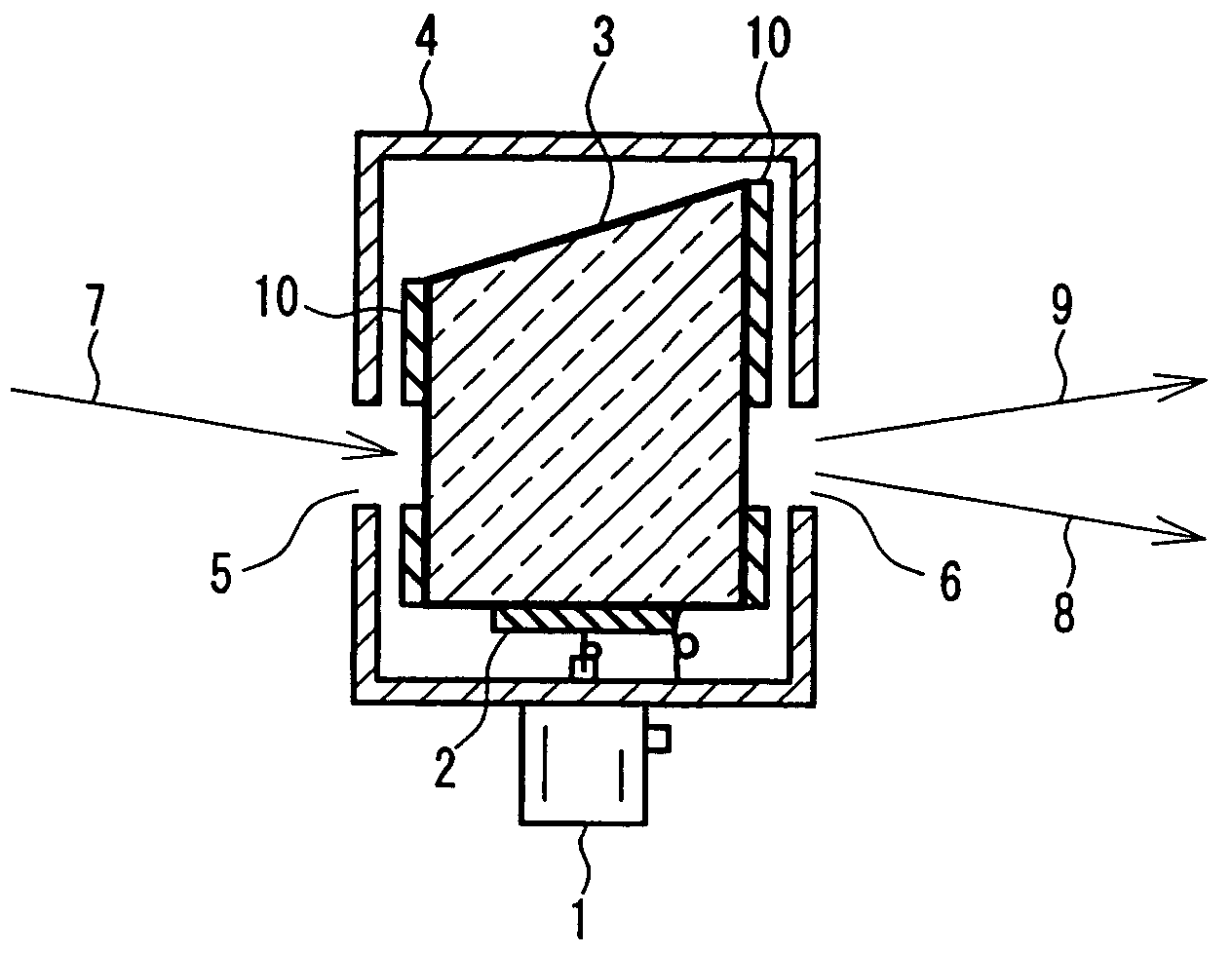

[0066] Acoustooptic devices like the one shown in FIG. 1 were produced and their acoustooptic performance was evaluated as in Example 1 using a GaN-based LED that emitted light having a wavelength in the range of 360 nm to 380 nm. The LED used herein had a maximum output of about 2 mW.

[0067] In this case, the diffraction efficiency was about 4% to 15% as shown in Table 3, with the input power of an RF signal being 2 W. The reason why the diffraction efficiency decreased as compared to that in Example 1 conceivably is that the wavelength of the incident light was slightly longer and the monochromaticity of the light source was poorer. When using the incident light having power in this range, no optical damage was found even in the case of using a common LN single crystal.

TABLE 3DiffractionMaterialEfficiency (%)LN15MgO:LN15Li2B4O74(GdY)1Ga4O(BO3)35CsLiB6O104

example 3

[0068] Acoustooptic devices like the one shown in FIG. 1 were produced and their acoustooptic performance was evaluated with respect to fourth harmonics of a YAG laser having a wavelength of 266 nm. In this case, it was not possible to use LN and MgO:LN for the acoustooptic devices since they do not transmit ultraviolet light having a wavelength of 266 nm. The diffraction efficiency of the acoustooptic devices produced using the Li2B4O7 crystal, the (GdY)1Ca4O(BO3)3 crystal, and the CsLiB6O10 crystal was 6% to 8% as shown in Table 4. In addition, deteriorations in transmittance and beam pattern were not found even after these acoustooptic devices were irradiated with ultraviolet light having a wavelength of 266 nm for 10 hours continuously.

TABLE 4DiffractionMaterialEfficiency (%)LN—MgO:LN—Li2B4O76(GdY)1Ga4O(BO3)38CsLiB6O107

[0069] With respect to the (GdY)1Ca4O(BO3)3 crystal, in the case of using light having a wavelength of 266 nm, higher light transmittance was obtained when YCa4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com